Hoisting clamp and hoisting method for wheel of circular cooler

A hoisting method and the technology of an annular cooler, which are applied in the directions of transportation and packaging, loading hoisting components, and processing discharged materials, etc., can solve the problems of the hoisting method is not stable enough, the installation is difficult, and it is not easy for the wheels to align with the wheel axles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

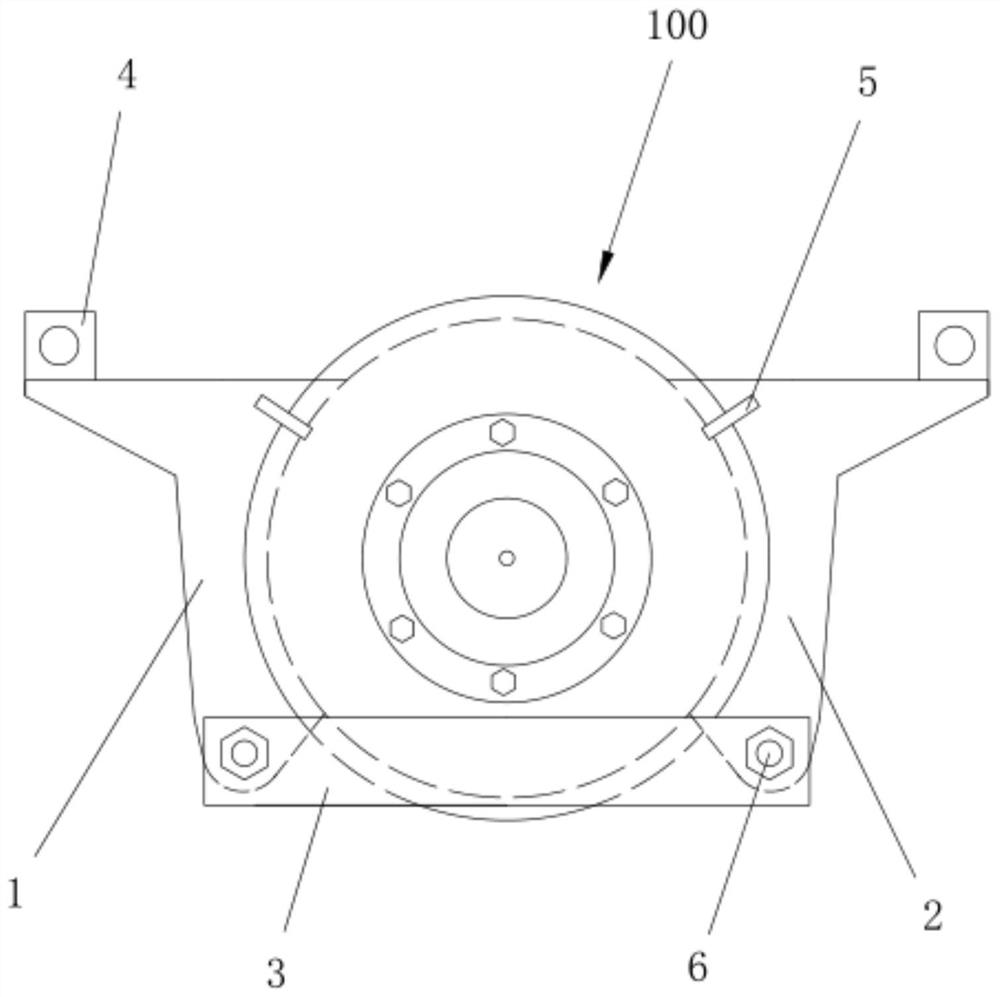

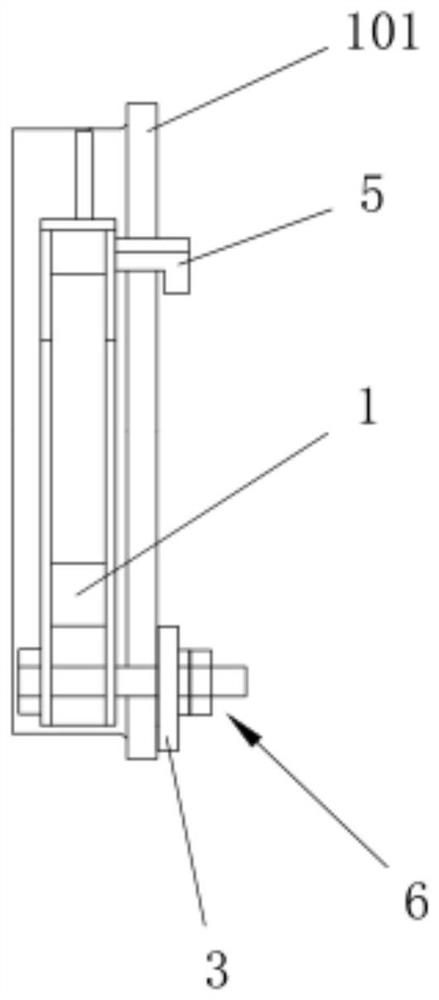

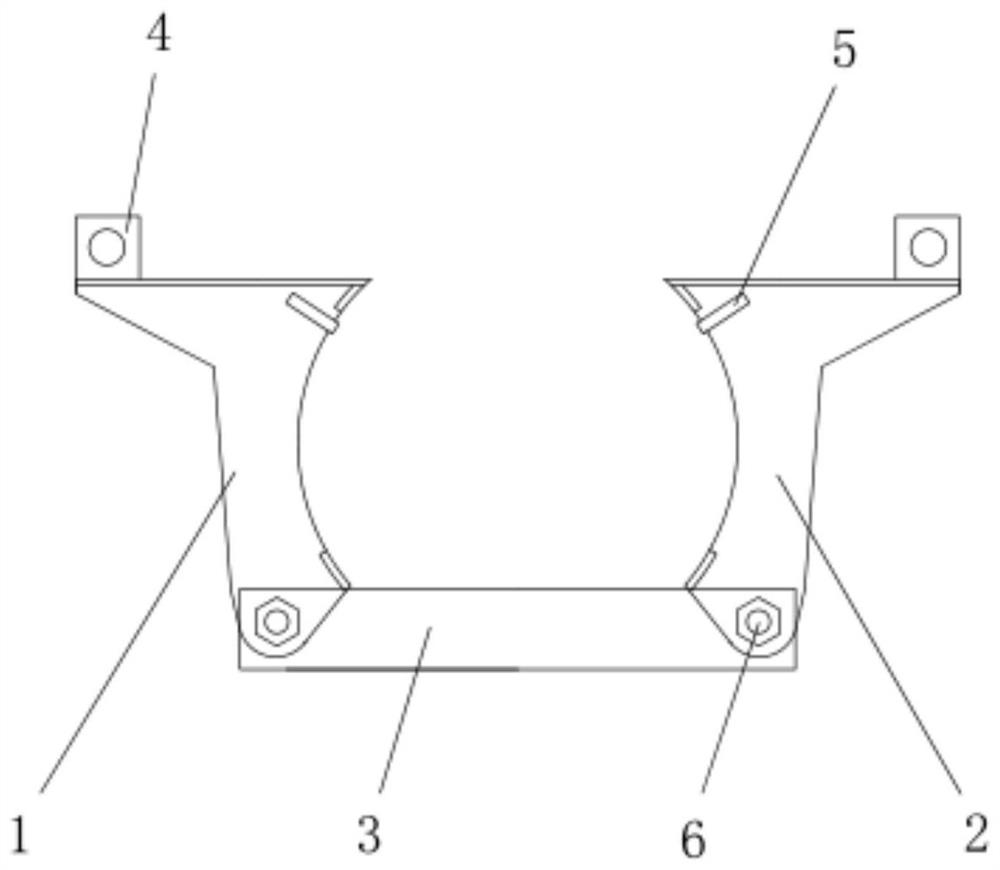

[0037] This embodiment provides a hoisting fixture for the wheel of the annular cooler, which is used for hoisting and dismounting the wheel of the annular cooler, such as figure 1 As shown, the hoisting fixture of the ring-cooled locomotive wheel includes a first splint 1, a second splint 2 and a connecting plate 3, the first splint 1 and the second splint 2 are symmetrical and spaced apart, and the first splint 1 and the second splint 2 Respectively hinged to the two ends of the connecting plate 3, so that the first splint 1 and the second splint 2 can rotate, the opposite sides of the first splint 1 and the second splint 2 are arc-shaped surfaces, and the arc of the arc-shaped surface is the same as The arc of the wheel 100 is the same, and the first splint 1 and the second splint 2 rotate toward each other so that the arc-shaped surfaces of the first splint 1 and the second splint 2 can abut against the wheel 100 of the ring cooler; The lifting fixture of the locomotive wh...

Embodiment 2

[0045] This embodiment provides a hoisting method for a wheel of an annular cooler. The hoisting method uses the hoisting fixture of the wheel of an annular cooler in Embodiment 1 to hoist the wheel 100 of an annular cooler. The hoisting method includes the following steps:

[0046] S1. Rotate the first splint 1 and the second splint 2 in a direction away from each other to open the first splint 1 and the second splint 2, and place the wheel 100 between the first splint 1 and the second splint 2. At the same time, The rim 101 of the wheel 100 is clamped between the connecting plate 3 and the first splint 1 and the second splint 2;

[0047] S2. Turn the first splint 1 and the second splint 2 towards the direction of approaching each other, so that the arc-shaped surfaces of the first splint 1 and the second splint 2 abut against the wheel 100, and at the same time, make the two sets of stoppers 5 engage connected to the wheel rim 101, so that the lifting fixture clamps the whee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com