Quick coupling for connecting box-beam steel structure module

A technology of structural module and box girder, applied in the direction of building structure, construction, etc., can solve the problems of large size, large number of bolts, time-consuming and labor-intensive, etc., and achieve the effect of improving connection rigidity, simple structure, and simple force bearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiments (drawings):

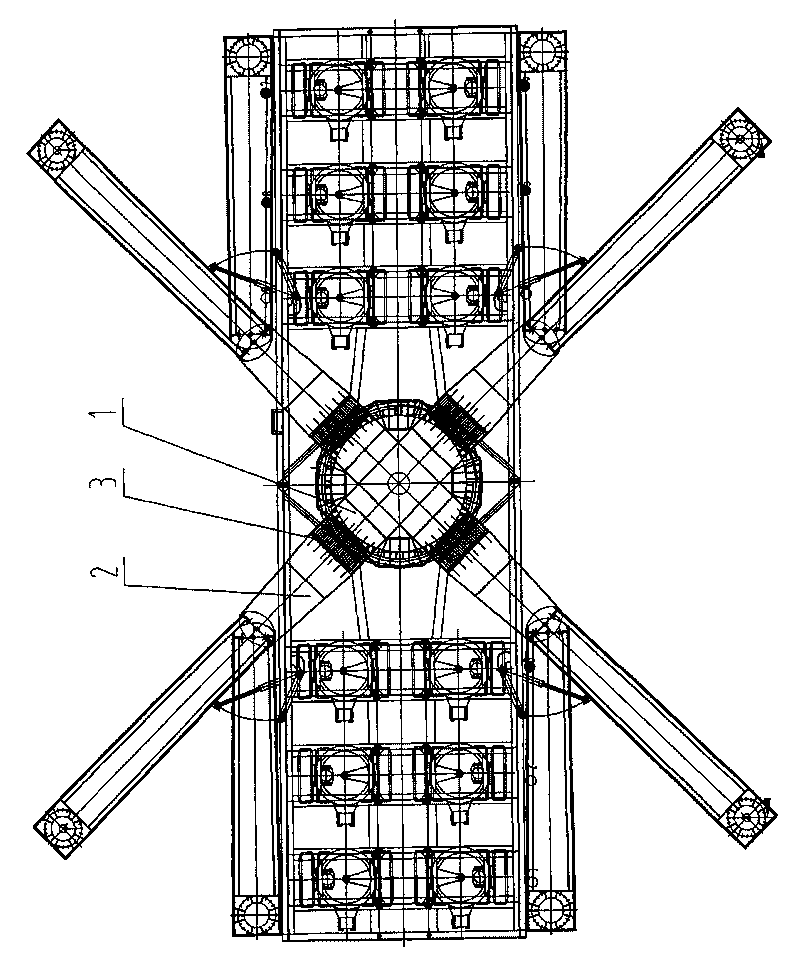

[0021] figure 1 Shown is the general diagram of the wind power crane bottom car using the quick coupling of the box girder steel structure module of the present invention, where 1 is one of the bottom car structural modules, 2 is the second bottom car structural module, and 3 is the module 1 and Quick connector for connection between module 2.

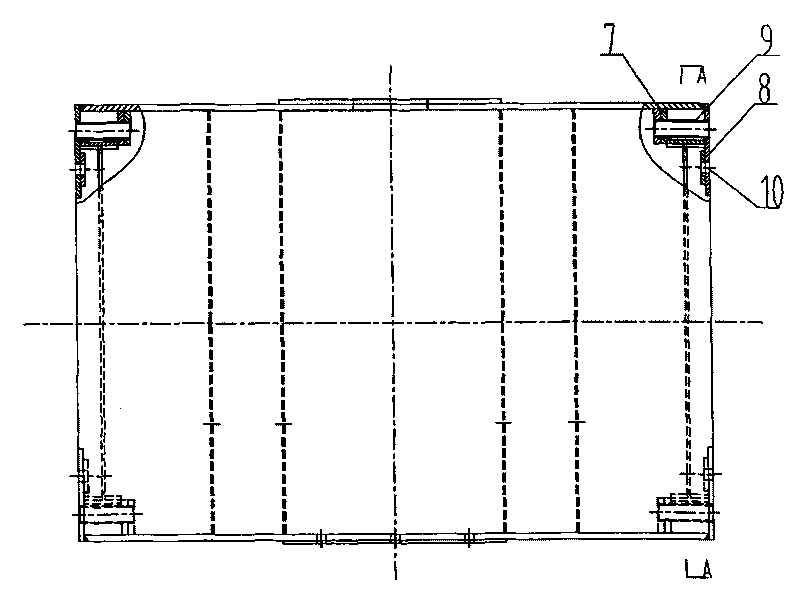

[0022] figure 2 , diagram 2-1 , Figure 2-2 Shown is the structure diagram of the upper and lower closed flange connection boxes 12 and 13 of the box girder steel structure module 1 with quick connectors 3 at both ends. They are all composed of vertical plates 4, horizontal plates 5, and box girder cover plates. 6. Box girder web 11, front flange plate 7, rear flange plate 8, fastener double-ended stud hole tube 9 (made by seamless steel pipe inserted into the plate hole and welded), welded to each other to form a closed Style f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com