Full-process suspension pneumatic balancer control system

A technology of pneumatic balance and control system, which is applied in the directions of portable lifting device, hoisting device, spring mechanism, etc., can solve the problems such as the inability to realize the full suspension effect of the object, the limitation of the hoisting range of the pneumatic balancer, and the inability to realize hoisting and moving, etc. Achieve the effect of shortening work cycle time, reducing labor intensity and improving hoisting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

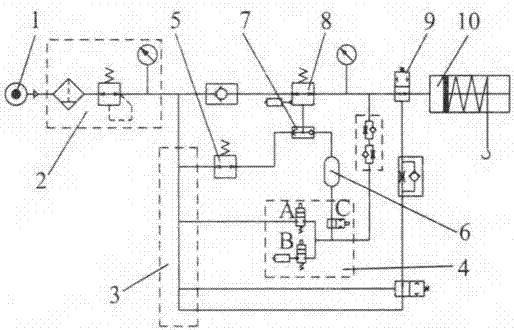

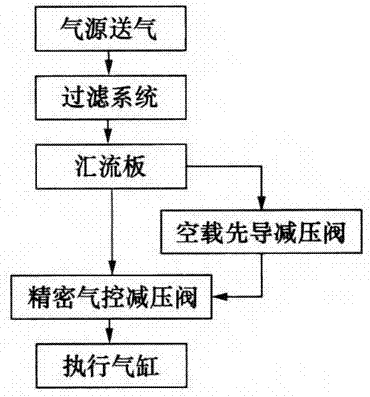

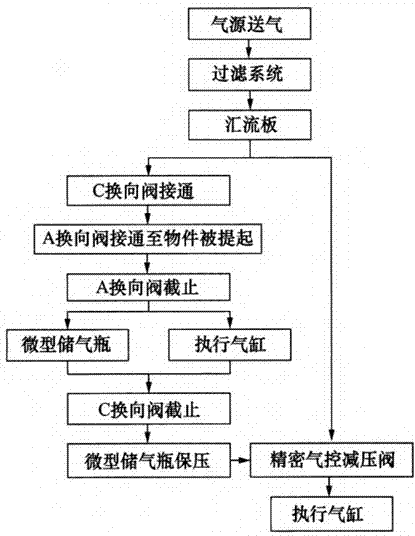

[0016] like figure 1 , Pneumatic balancer control system In the case of normal air supply from the air source, the reversing valve 9 is in the on state, and the gas pressure inside the execution cylinder is determined by the precision air control pressure reducing valve 8. When hoisting without load, the gas passes through the gas source 1, the filter system 2, the manifold 3, the no-load pilot pressure reducing valve 5, the shuttle valve 7 in sequence, and then reaches the control end of the air-controlled pressure reducing valve. The control pressure value of the precision air-operated pressure reducing valve is determined by the output value of the no-load pilot pressure reducing valve, so that the gas pressure in the execution cylinder is controlled through the precision air-operated pressure reducing valve. At this time, the operator can drag the crane up and down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com