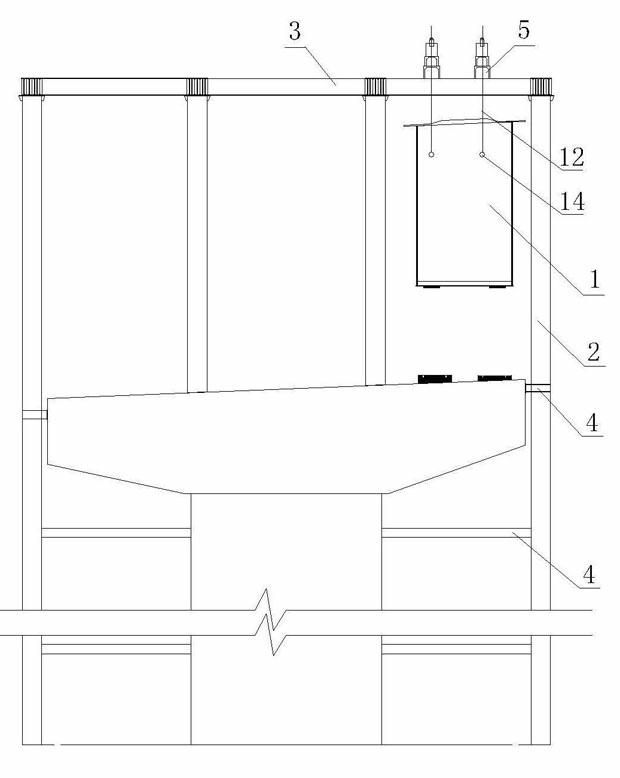

Continuous beam falling system and continuous beam falling method

A technology of falling beams and connecting sleeves, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

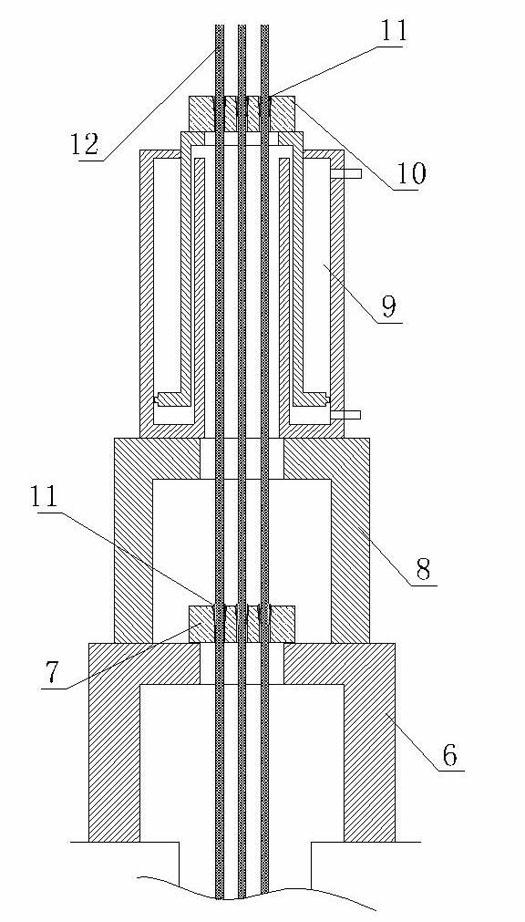

Embodiment 1

[0033] During use, use the continuous beam drop system of this embodiment to complete the drop beam operation through the following steps:

[0034] The first step is to knock the first set of clips one by one between the anchor hole of the lower tool and the steel strand to clamp the steel strand;

[0035] The second step is to control the continuous jack to rise through the hydraulic system;

[0036] The third step is to knock the second set of clips one by one between the anchor hole of the upper tool and the steel strand to clamp the steel strand;

[0037] The fourth step is to use the pliers to pick out the clips of the lower tool anchor one by one;

[0038] The fifth step is to control the drop of the continuous jack through the hydraulic system, and the upper tool anchor with the drop of the jack drives the steel strand and the hoisted beam down;

[0039] Repeat the above steps until the hoisted beam is dropped to the desired place.

[0040] Embodiment two

Embodiment 2

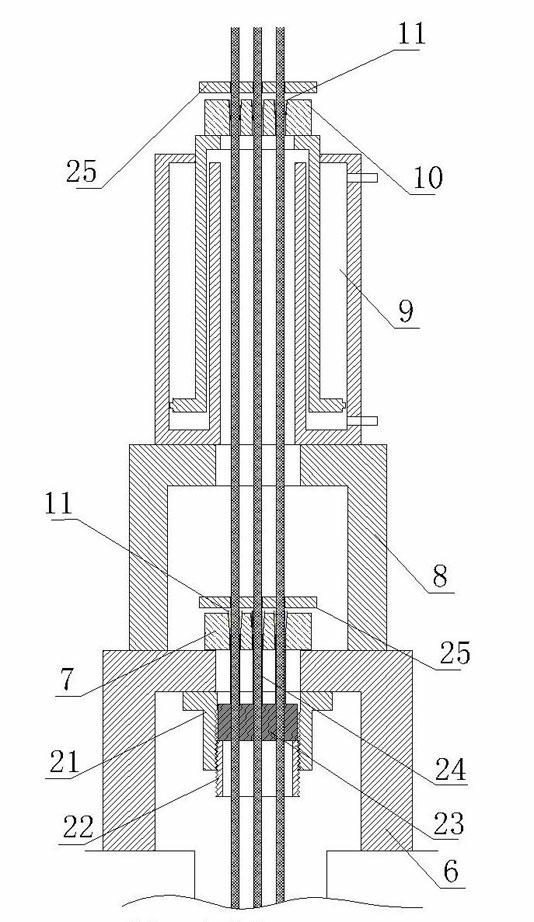

[0042] Embodiment Three

Embodiment 3

[0044] When in use, use the continuous beam drop system of this embodiment to complete the drop beam operation through the following steps:

[0045] The first step is to screw down the movable sleeve of the anchor retractor, and make the first group of clips clamp the steel strand by hitting the reset plate at the top of the anchor of the lower tool;

[0046] The second step is to control the continuous jack to rise through the hydraulic system;

[0047] The third step is to make the second set of clips clamp the steel strand by knocking the reset plate at the top of the upper tool anchor;

[0048] The fourth step is to screw up the movable sleeve of the anchor retractor to drive the push plate to move, and the push tube on the push plate pushes out the first set of clips to complete the anchor removal of the tool;

[0049] The fifth step is to control the drop of the continuous jack through the hydraulic system, so that the upper tool anchor drives the steel strand and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com