Lifting device for logistics supply chain

A logistics supply chain, hoisting device technology, applied in transportation and packaging, load hoisting components, etc., can solve problems such as shaking, direct hoisting, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

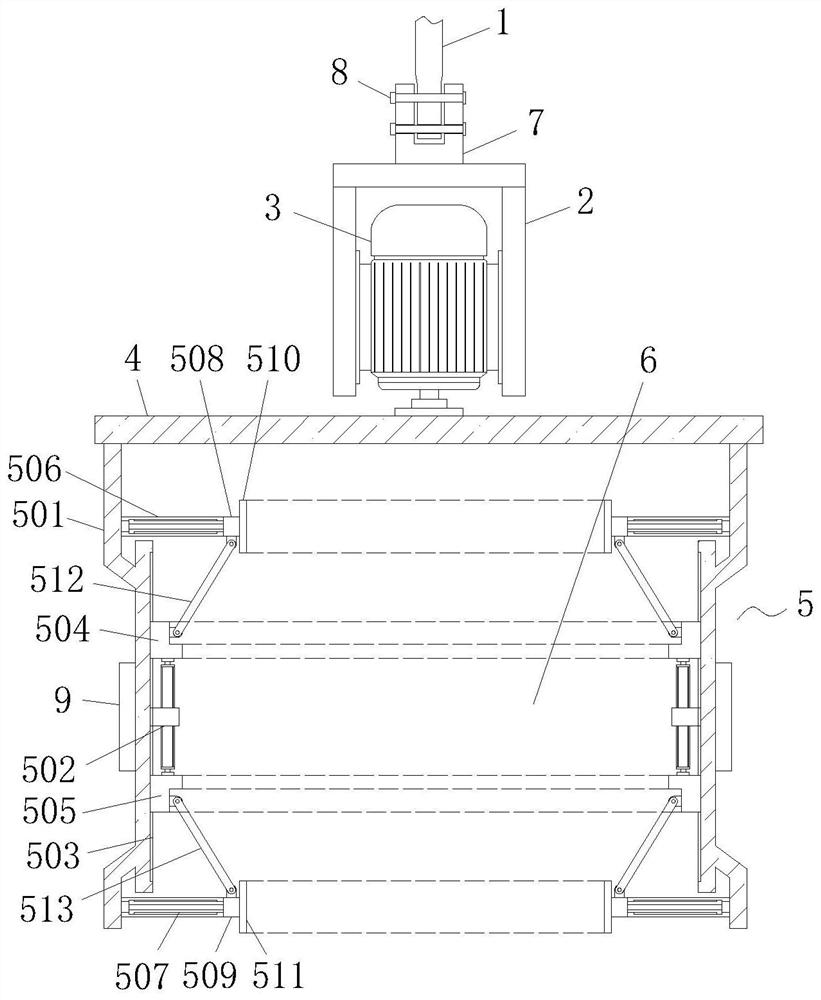

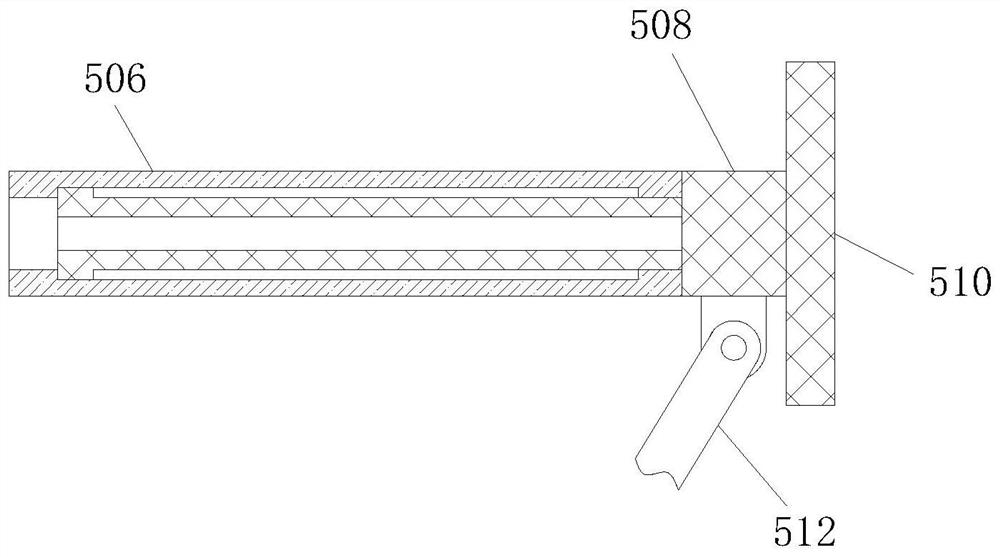

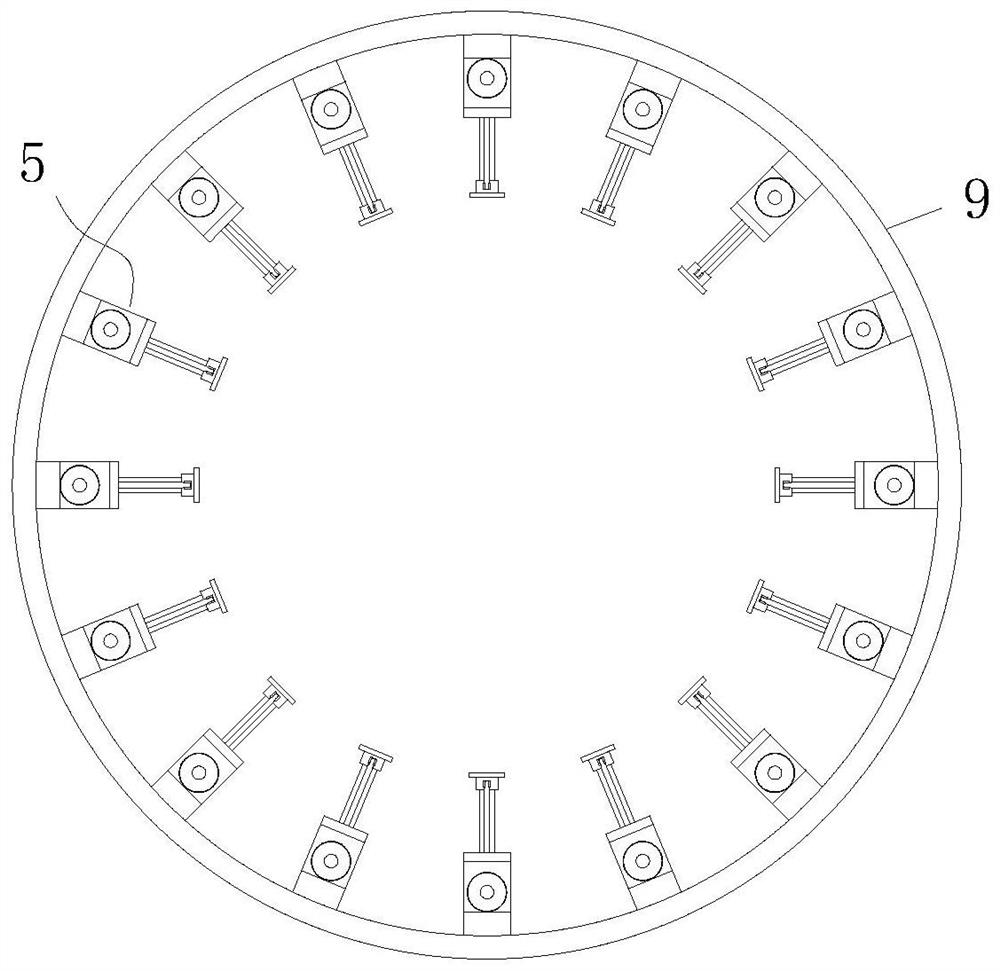

[0031] see Figure 1-5 , the present invention provides the following technical solutions: a hoisting device for a logistics supply chain, including a lifting rod 1, a connecting frame 2, a motor 3, an assembly plate 4, and several hoisting and clamping units arranged in a circular array along the bottom edge of the assembly plate 4 5. The connecting frame 2 is connected to the bottom of the lifting rod 1, the lifting rod 1 is connected to the transfer mechanism of the logistics supply chain, the motor 3 is fixedly installed on the connecting frame 2, the assembly plate 4 is horizontally connected to the bottom of the output shaft of the motor 3, several hoisting A hoisting and clamping cavity 6 is formed between the clamping units 5. The hoisting and clamping unit 5 includes a longitudinal connecting plate 501 and a double-headed cylinder 502 installed in the middle of the inner side wall of the longitudinal connecting plate 501. A slide is arranged radially on the longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com