Self-mounting three-cylinder combined multistage variable amplitude device

A self-installation, oil cylinder technology, applied in cranes and other directions, can solve the problems of low transfer efficiency of large-tonnage cranes, inability to realize one-time installation of the jib, affecting the stability and safety of the jib, etc., to improve the transfer efficiency, Simple structure and easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

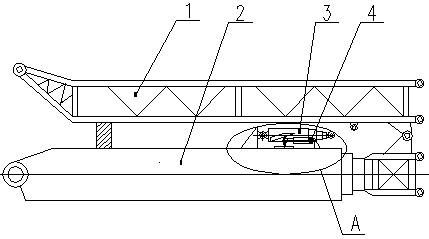

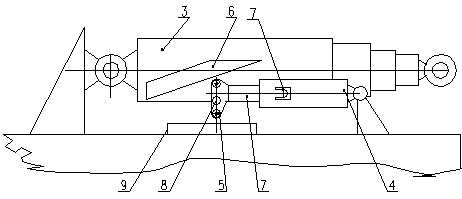

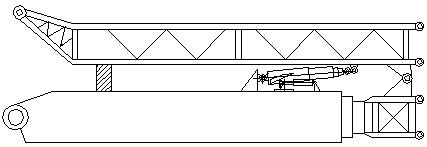

[0026] combine Figure 1 to Figure 4 As shown, a self-installing three-cylinder combined multi-stage luffing device includes a boom 2 and a jib 1 hinged on the boom 2 .

[0027] The luffing main cylinder 3 is a multi-stage cylinder, the bottom end of the luffing main cylinder 3 is hinged with the boom 2, the piston rod end of the luffing main cylinder 3 is provided with a pin hole, and the auxiliary arm 1 is fixed with a pin hole matching the pin hole seat. The pin hole on the piston rod end of the luffing master oil cylinder 3 is detachably hinged with the pin hole seat on the auxiliary arm 1 through a pin shaft. Symmetrically arranged wedge-shaped guide rails 6 and roller slots 7 are fixed on both sides of the luffing master oil cylinder 3 .

[0028] There are two auxiliary displacement oil cylinders 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com