A prefabricated building superimposed lotus root beam-column joint structure and its construction method

A lotus root beam-column and prefabricated technology, which is applied to the superimposed lotus root beam-column joint structure of prefabricated buildings and its construction field, can solve the problems of poor force characteristics of beam-column joints, high construction cost, low hoisting speed and accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

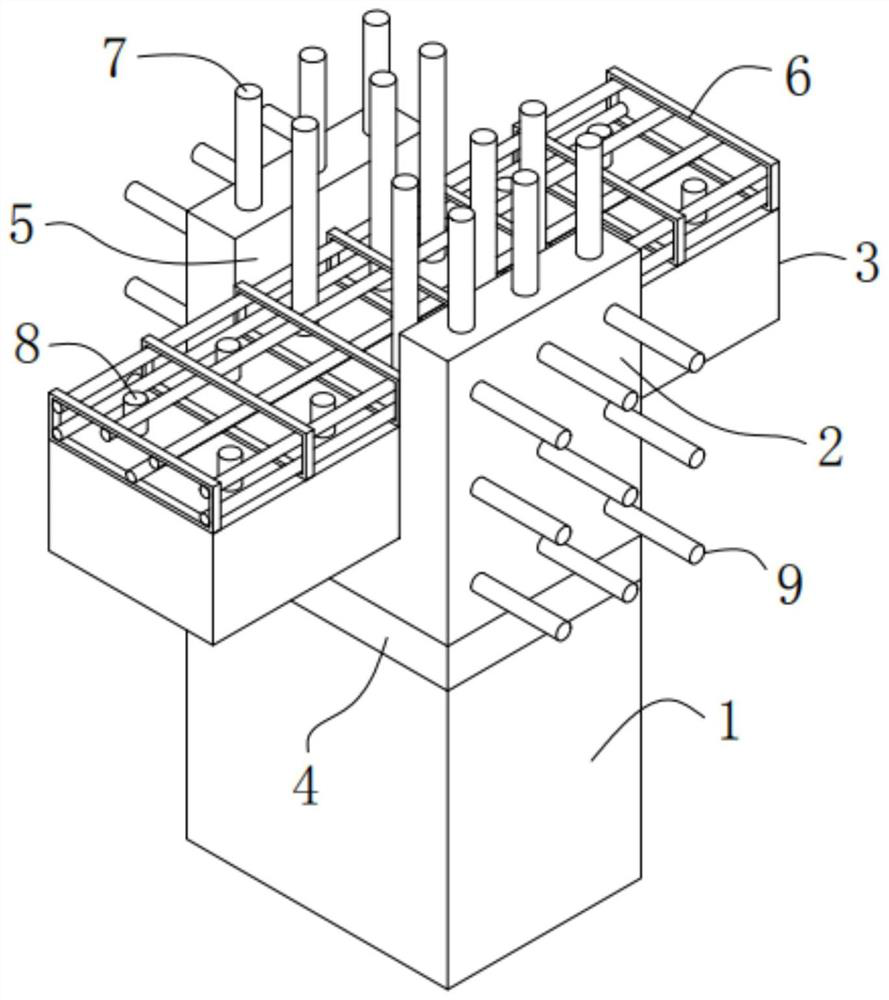

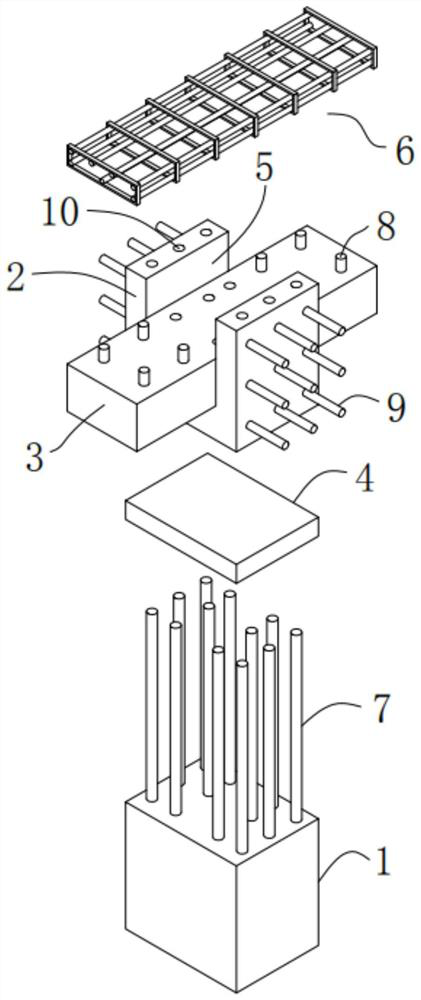

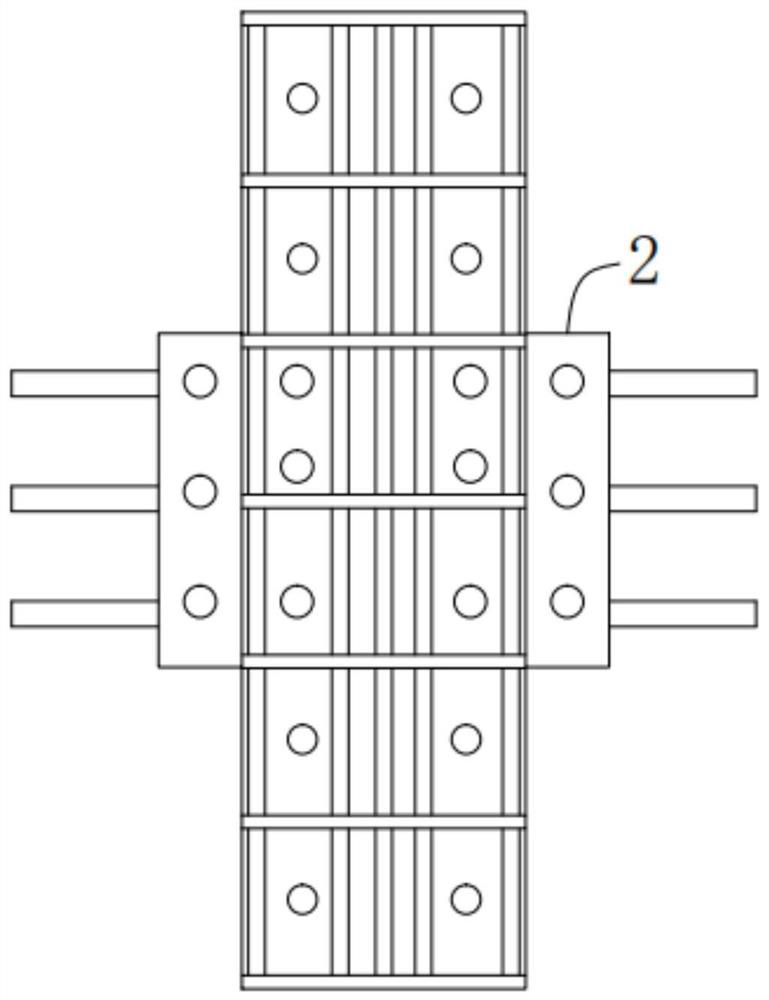

[0041] A prefabricated building superimposed lotus root beam-column joint structure, such as Figure 1-2 As shown, it includes prefabricated column 1, prefabricated column vertically extending steel bar 7, superimposed lotus root beam column head 2, lotus root beam protruding superimposed beam 3, lotus root beam reserved superimposed groove 5, and superimposed lotus root beam side protruding Steel bar 9, exposed steel bar 8 on the upper part of the superimposed lotus root beam, and flat hidden beam steel mesh 6;

[0042] Such as Figure 1-5 As shown, the vertically extending steel bars 7 of the prefabricated columns are poured vertically inside the prefabricated columns 1, and the upper ends of the vertically extending steel bars 7 of the prefabricated columns extend above the top of the prefabricated columns 1, so The superimposed lotus root beam column head 2 is set on the outside of the vertically extending steel bar 7 of the prefabricated column, and the bottom of the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com