Stern boarding platform structure for ship

A platform structure and marine technology, which is applied to ship accessories, ships, cargo handling equipment, etc., can solve the problems of long time and many working procedures, and achieve the effect of fast boarding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

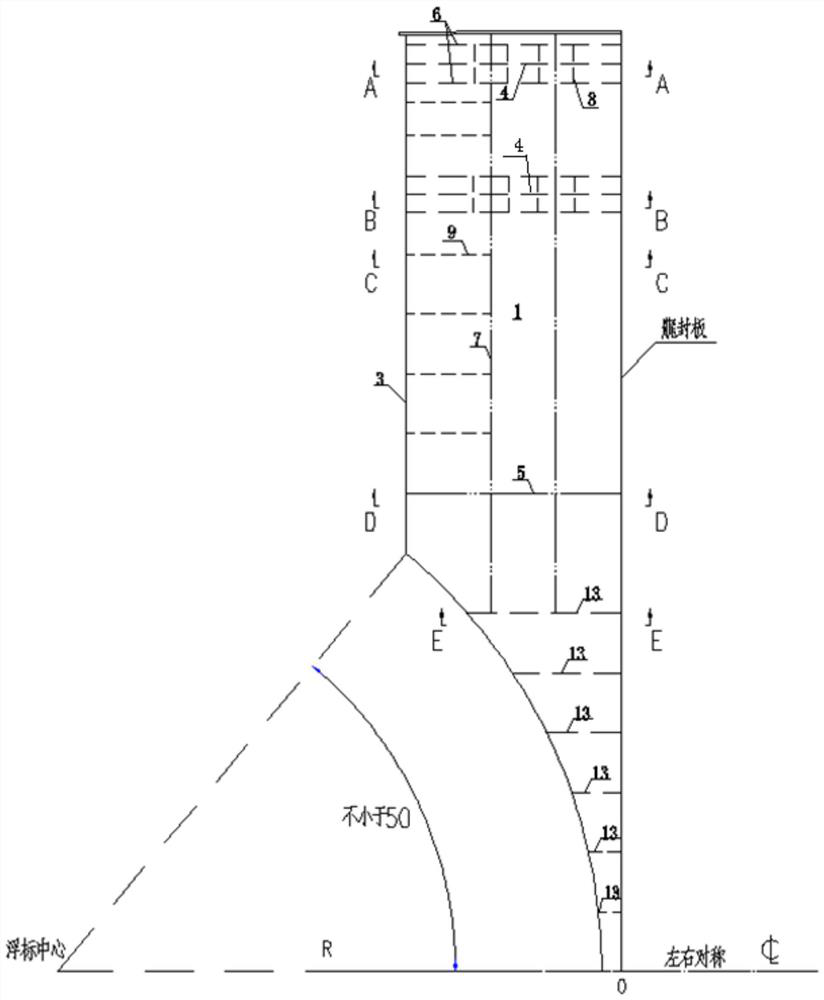

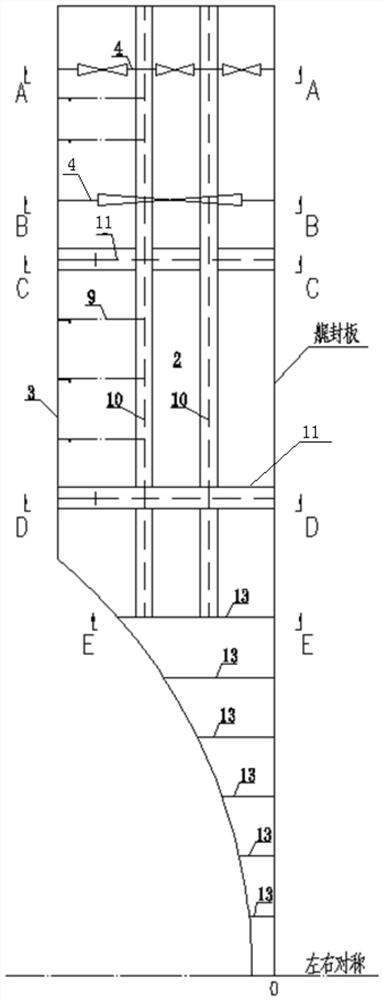

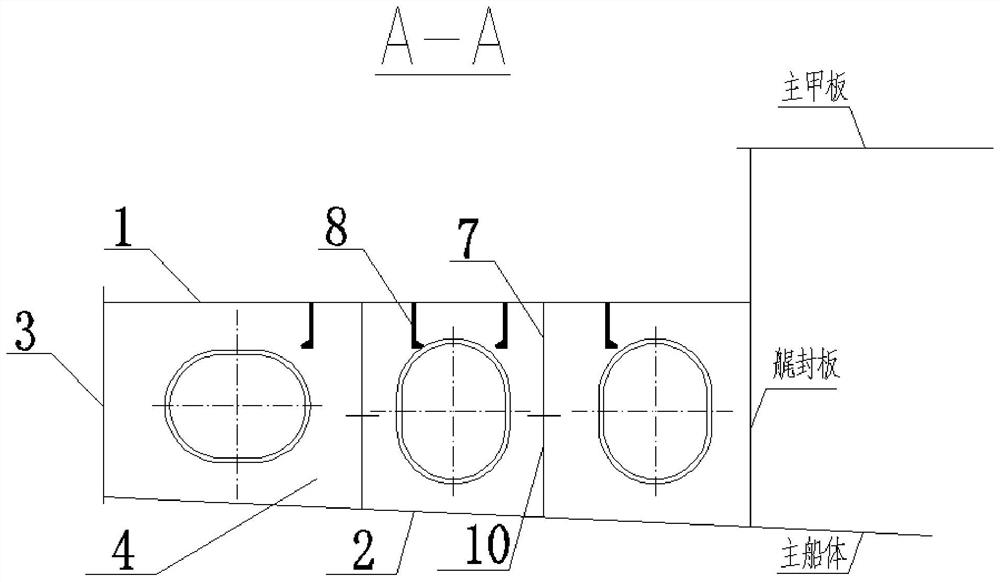

[0027] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0028] Such as Figure 1-7 As shown, the marine stern landing platform structure provided by the embodiment of the present invention, the stern landing platform structure is arranged on the outside of the ship stern seal plate, and its bottom is along the line shape of the bottom of the main hull, and its width extends to the side. The water flow field in the stern region has adverse effects. The top is a platform, and the height is set according to the freeboard of the buoy. The height above the waterline of the buoy is required to be consistent with the freeboard of the buoy, so as to ensure that the boarding platform is flush with the surface of the buoy when the ship approaches the buoy. The width is equal to the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com