Steel guide rail structure used within wide temperature range and at high precision

A high-precision, wide-temperature technology, used in linear motion bearings, rotating parts that resist centrifugal force, bearings, etc., can solve problems such as failure to meet the accuracy requirements of steel guides, errors, affecting the connection between steel guides and non-steel bases, etc. , to achieve the effect of ensuring accuracy requirements and ensuring force requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described below in conjunction with accompanying drawing.

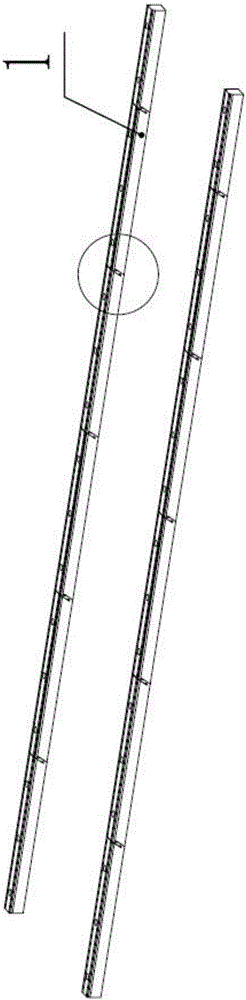

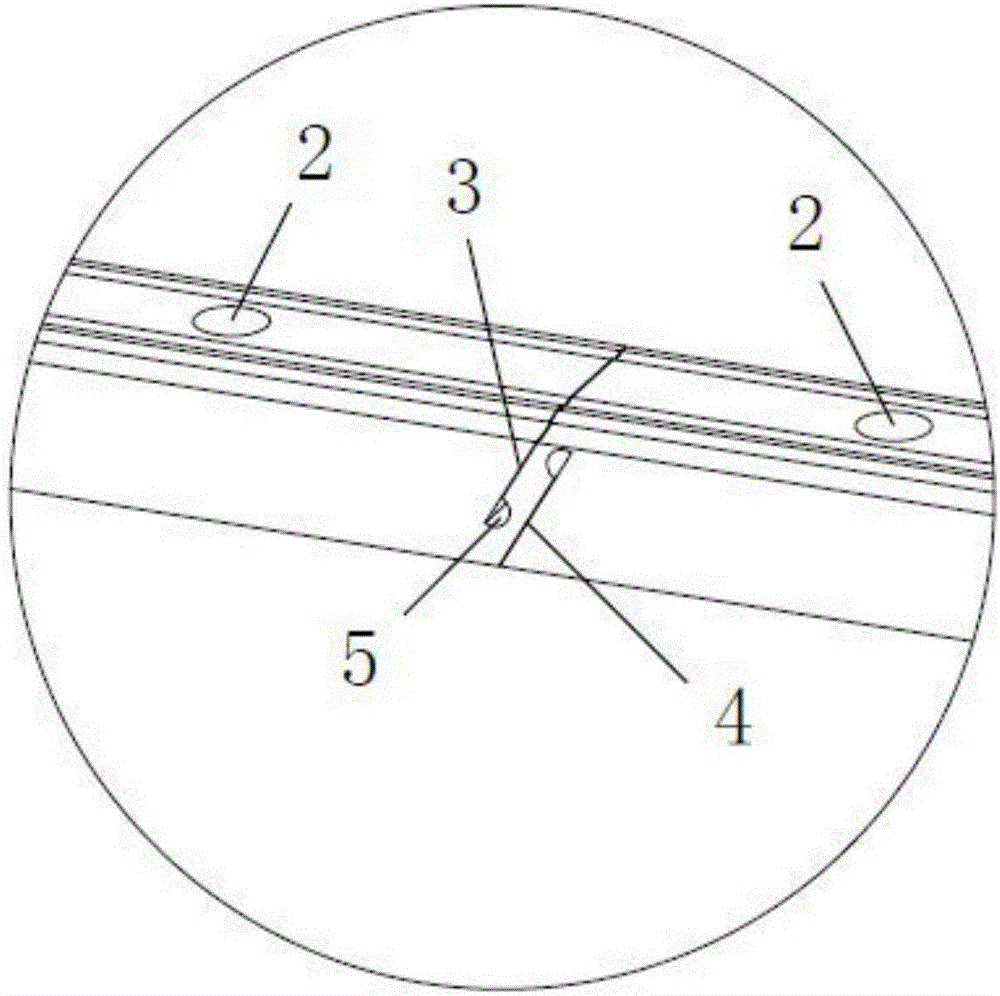

[0016] as attached Figure 1-2 As shown, the steel guide rail structure under a wide temperature range and high precision use state according to the present invention includes a non-steel base and a steel guide rail 1 arranged on the non-steel base; the steel guide rail 1 is provided with multiple screw fixing holes 2 evenly spaced; multiple sets of expansion joint structures are arranged on the steel guide rail 1, and three screw fixing holes 2 are spaced between adjacent expansion joint structures to ensure the service strength of the steel guide rail 1; The group expansion joint structures all include upper expansion joints 3 and lower expansion joints 4 parallel to each other, the upper expansion joints 3 extend downward from the upper surface of the steel guide rail 1, and the lower expansion joints 4 extend upward from the lower surface of the steel guide rail 1; Both the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com