Dissimilar metal connection structure and manufacturing method of transition lead for titanium coil rolling

A technology for connecting structures and dissimilar metals, which is applied in the field of metallurgy, can solve the problems of unequal thickness of connection parts and damage to related equipment, and achieve the effects of avoiding falling off, improving production efficiency and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

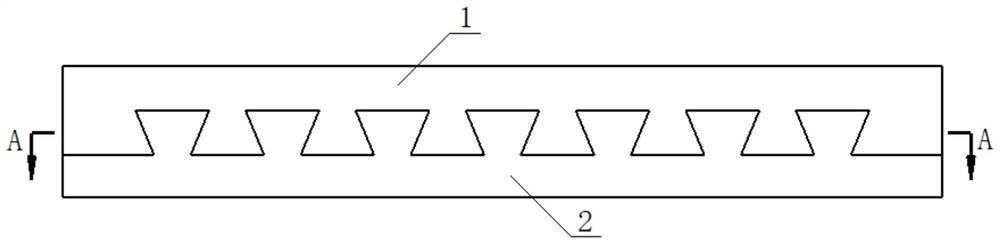

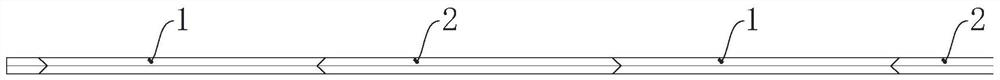

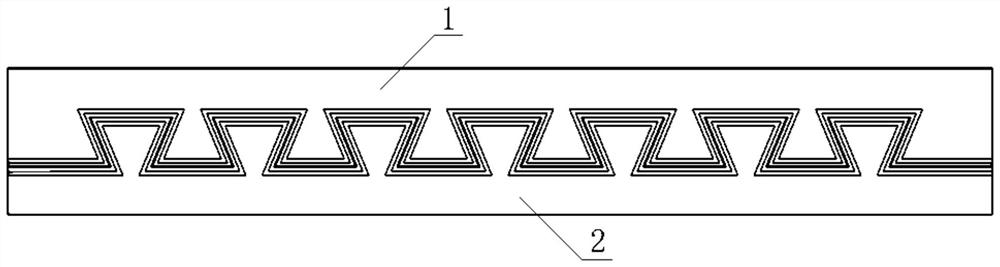

[0044] First, prepare two industrial pure titanium plates with a width of 1200mm and a length of 100mm, both of which are half the thickness of the titanium coil, and prepare two stainless steel plates with the same thickness and width at the same time. 9 trapezoidal notches, of which the upper bottom of the trapezoidal notch is 100mm, the lower bottom is 50mm, and the notch depth is 60mm. Do the same, that is, make the same notch. Secondly, along the edge of the inverted trapezoid between the notch and the notch of the titanium plate and the stainless steel plate, the groove is processed by grinding, and the groove angle is 45°. Thirdly, the inverted trapezoid of the titanium plate is pressed into the gap of the stainless steel plate along the groove by a press. Connecting piece, stack two layers of connecting piece together, so that the upper and lower connecting pieces are symmetrical with their bonding surfaces as symmetrical planes; again, laser welding method is used, a...

Embodiment 2

[0048] First, prepare two industrial pure titanium plates with a width of 1050mm and a length of 100mm, both of which are half the thickness of the titanium coil; prepare two stainless steel plates with the same thickness and width;

[0049] At one end of the titanium plate, 11 T-shaped notches are cut by laser. The long side of the T-shaped notches is 60mm, the short side is 30mm, the depth of the notches is 20+20mm, the spacing between adjacent trapezoidal notches is equal to 90mm, and the gap between adjacent trapezoidal notches is equal to 90mm. The shape of the part is an upside-down T-shape; do the same for the stainless steel plate, i.e. make the same notch. Secondly, along the edge of the inverted trapezoid between the notch and the gap of the titanium plate and the stainless steel plate, the groove is processed by grinding, and the groove angle is 60° and 30°; the inverted trapezoid of the stainless steel plate is moved along the groove by a press. Press into the gap ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com