Composite rotary cross arm

A cross-arm and composite insulator technology, applied in the field of cross-arm, can solve the problems of wind deflection, easy corrosion, pollution flashover of transmission lines, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

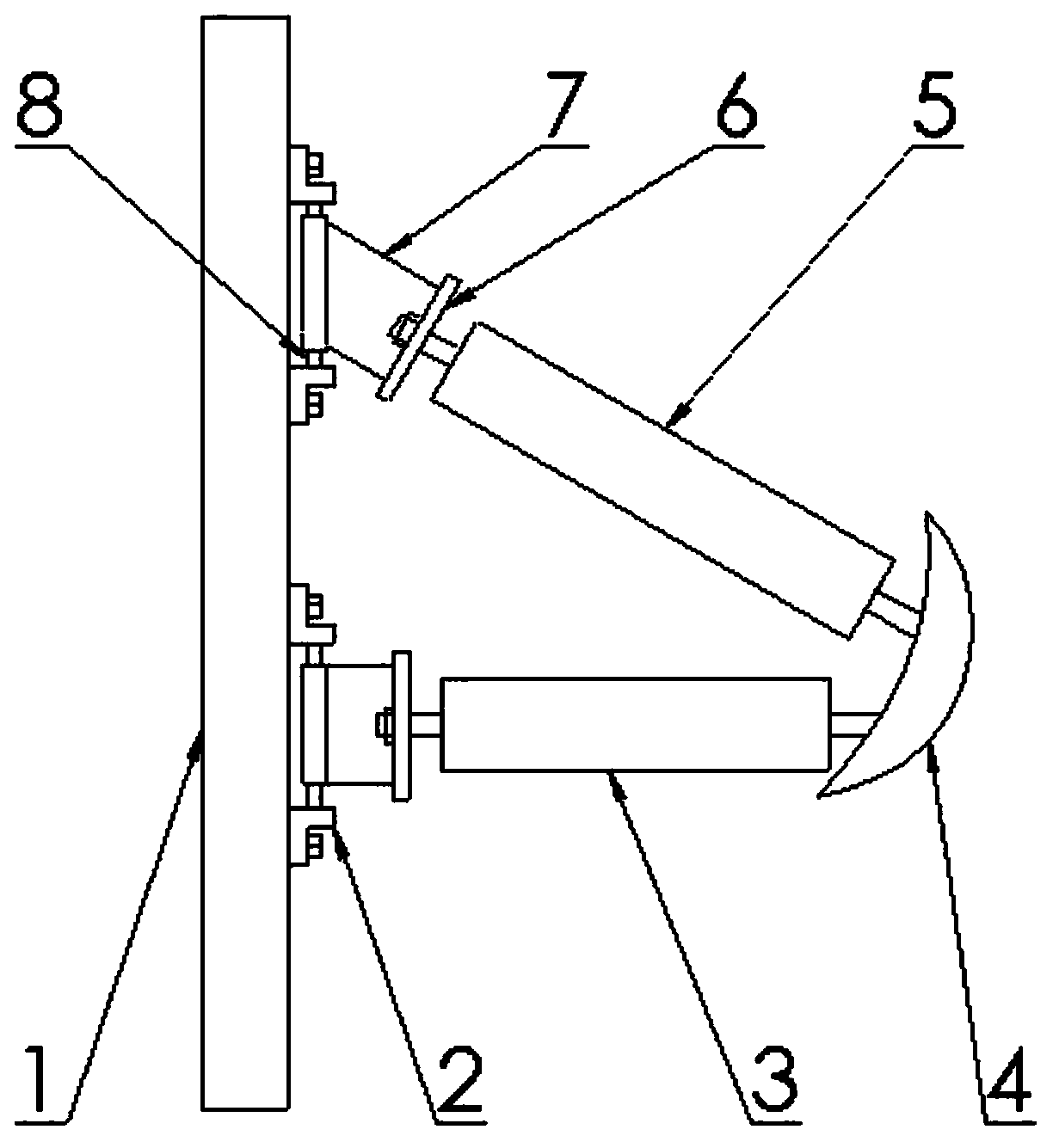

[0030] Such as figure 1 A preferred embodiment of the composite rotating cross arm of the present invention is shown, which mainly includes post insulators 3 and composite insulators 5 . The post insulator 3 and the composite insulator 5 are respectively arranged on the tower body 1 through hinge parts, the post insulator 3 is horizontally hinged on the tower body 1, and is vertically arranged with the tower body 1, the composite insulator 5 is obliquely hinged with the tower body 1, and the composite insulator 5 The ends merge with the ends of the post insulators 3 and are connected by hanging wire clamps 4 . When the composite rotating cross-arm is installed on a 110kV voltage level high-voltage line, the length of the post insulator 3 is greater than 1 meter, so as to meet the lightning overvoltage, the design of the minimum gap between the live part and the tower frame, and the 110kV voltage level high-voltage line is 1 meter lightning overvoltage clearance. When the com...

Embodiment 2

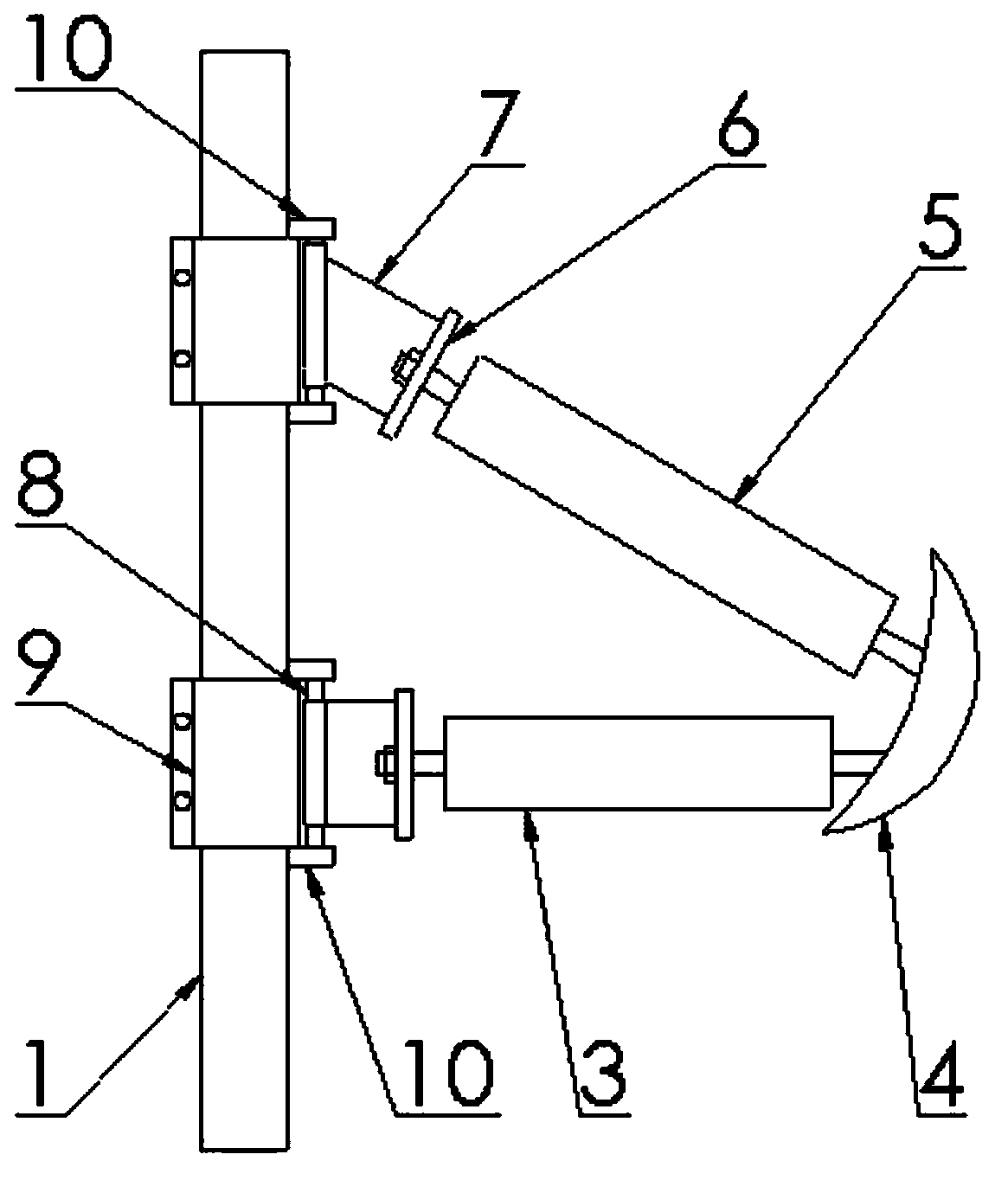

[0033] Such as figure 2As shown, the composite rotating cross arm in this embodiment is installed on the steel pole tower, and the post insulator 3 and the composite insulator 5 are hinged on the same busbar of the tower body 1 . The difference from Embodiment 1 is that: the hinge parts between the post insulator 3 and the composite insulator 5 and the tower body 1 include an annular hoop 9 mounted on the tower body 1 and fastened by bolts, and the hoop 9 is opposite to the side where the bolts are arranged. Two mounting ears 10 facing up and down are provided, and a hinge shaft 8 is provided between the two mounting ears 10 , and stiffeners are also provided between the mounting ears 10 . A hinge 7 is installed on the hinge shaft 8, and the setting form of the hinge 7 is the same as that of Embodiment 1. The other end of the hinge 7 is provided with a hanging plate 6 perpendicular to the hinge 7 for connecting the post insulator and the composite insulator. The hanging plat...

Embodiment 3

[0035] Different from Embodiment 2, the composite rotating cross arm described in this embodiment is installed on a square iron tower with an angle steel structure, and the post insulator 3 and the composite insulator 5 are connected in the vertical plane where the midline of one side of the square iron tower is located, and the post insulator 3 and composite insulator 5 and the hinge parts of the square iron tower adopt the same design as that of embodiment 1. The difference from Embodiment 1 is that in order to reduce the insulation length, this embodiment extends part of the post insulator 3 into the interior of the square iron tower, so that the hinged ends of the post insulator 3 and the composite insulator 5 are on the same plumb line . Specifically, the composite insulator 5 is hinged to the center line of one side of the square iron tower. A connecting frame is welded or bolted inside the square iron tower. The connecting frame is located directly below or slightly be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com