Embroidery machine head and embroidery machine

An embroidery machine and machine head technology, applied in the field of embroidery machines, can solve the problems of increasing the difficulty of assembling the machine head, increasing the production cost of the machine head, inconvenient maintenance and replacement, etc., to achieve rich functional uses, meet market demands, and reduce assembly. time consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

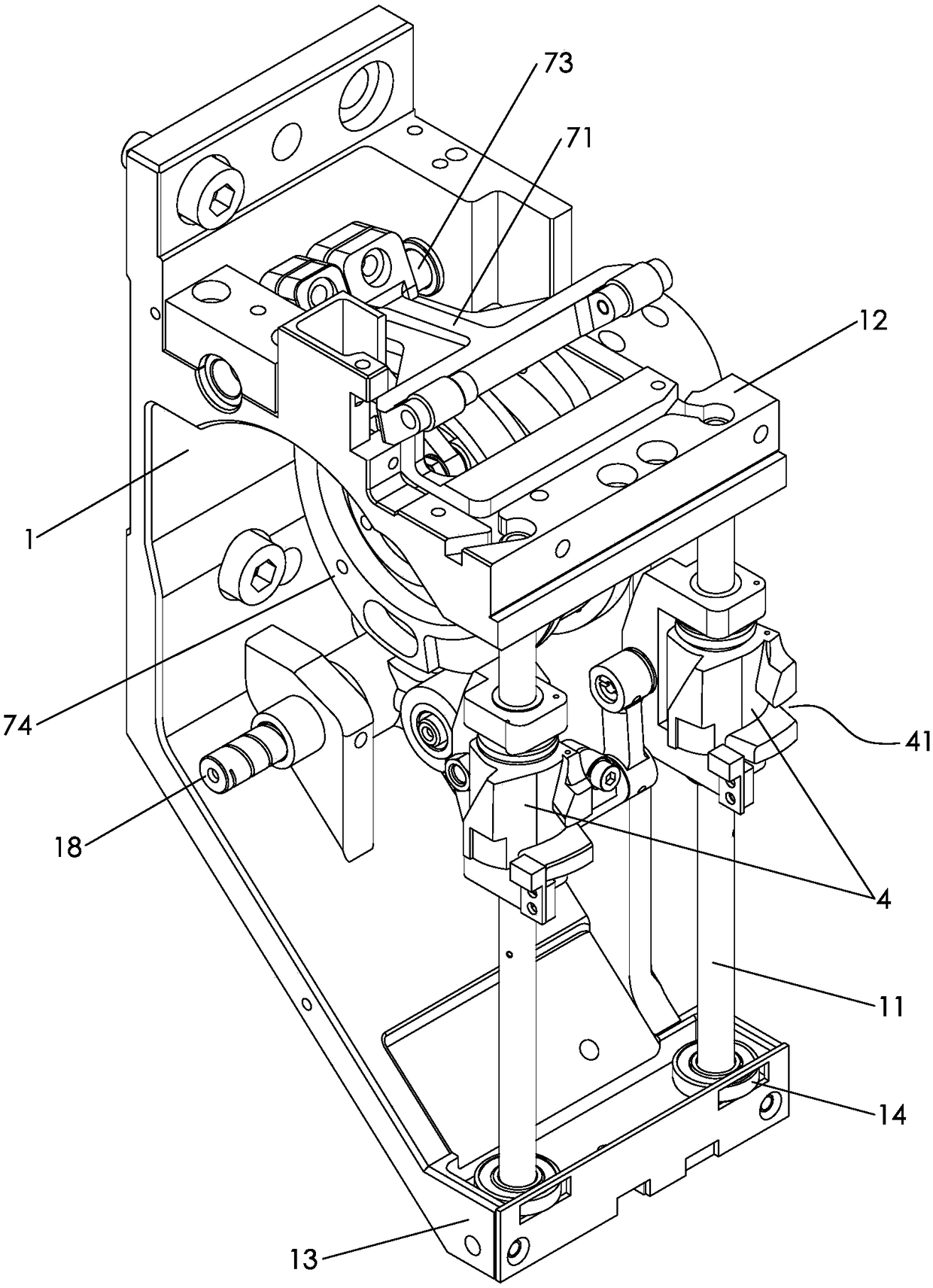

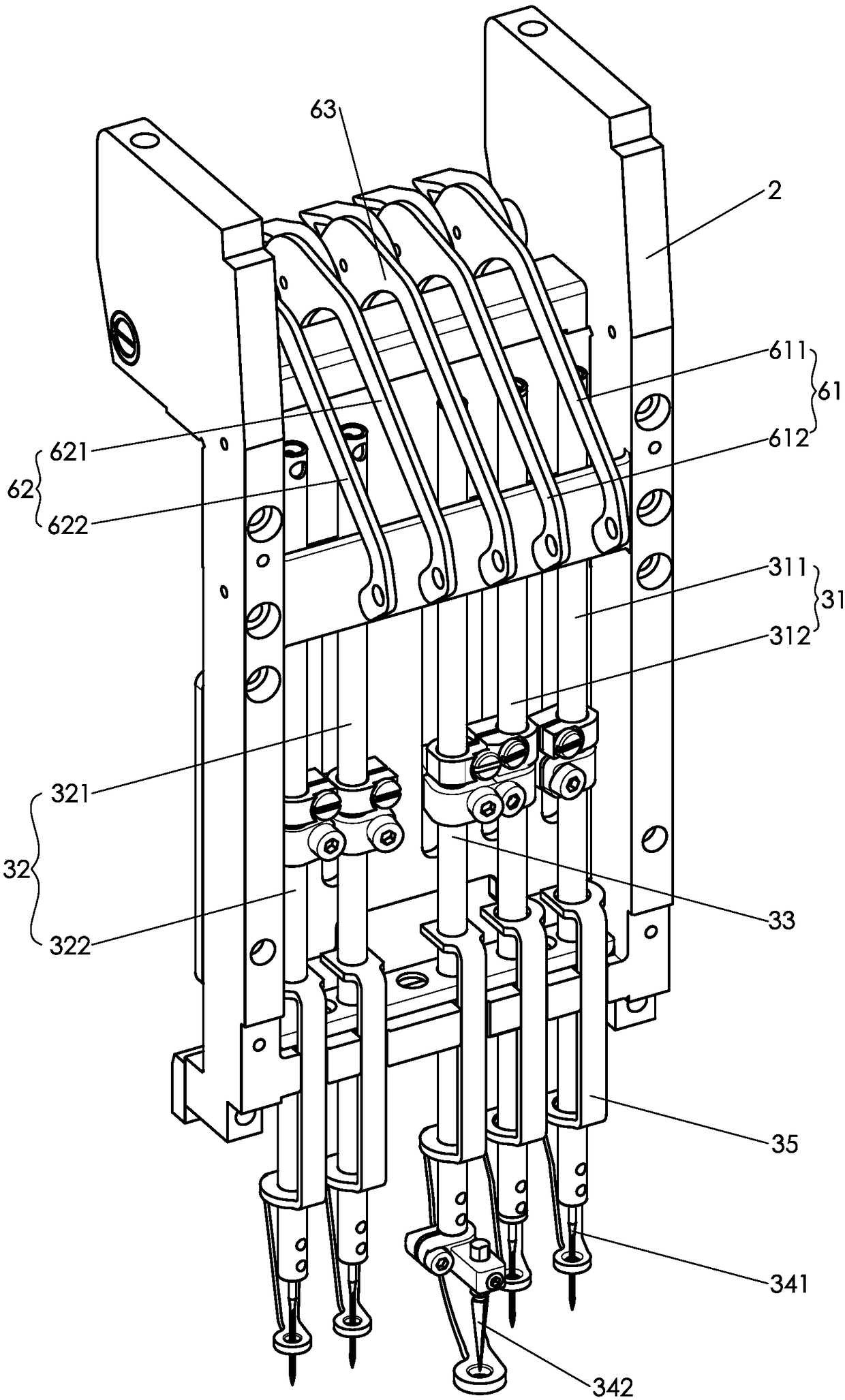

[0037] like figure 1 , figure 2 As shown, the embroidery machine head provided by Embodiment 1 of the present invention includes a casing 1 and a needle bar frame 2 arranged on the casing, and the needle bar frame can move back and forth laterally relative to the casing. The needle bar frame is provided with first needle bar 31, second needle bar 32 and carved hole needle bar 33, is provided with two needle bar drivers 4 on the casing, when one needle bar driver drives the carved hole needle bar, the other The needle bar driver is staggered with the first needle bar and the second needle bar in the moving direction of the needle bar frame and is in no-load.

[0038] The embroidery needle bar and the engraving needle bar are set on the machine head at the same time. When the fabric needs to be engraved at the head, the needle bar driver can drive the engraving needle bar to move back and forth. There is no need to shut down the machine head to replace the needles. On the pre...

Embodiment 2

[0067] The difference between Embodiment 2 of the present invention and Embodiment 1 above is that the machine needles at the bottom ends of needle bar I311 and needle bar III321 are replaced with engraved needles, and thread take-up lever I611 and thread take-up lever III621 are not threaded.

[0068] The machine head can realize the function of engraving holes on the flat head. At this time, the protrusions on the needle bar I and the needle bar III are respectively inserted into the grooves 41 on the two needle bar drivers 4, and the two thread take-up rollers 72 are respectively located on the pick-up In the open slot 25 of wire rod I and thread take-up rod III rear end. When the transmission shaft 15 rotates, the first cam and the transmission mechanism drive the needle bar I and the needle bar III to move up and down to realize the flat-headed double-needle carving hole. The thread roller drives the thread take-up lever Ⅰ and thread take-up lever Ⅲ to swing up and down f...

Embodiment 3

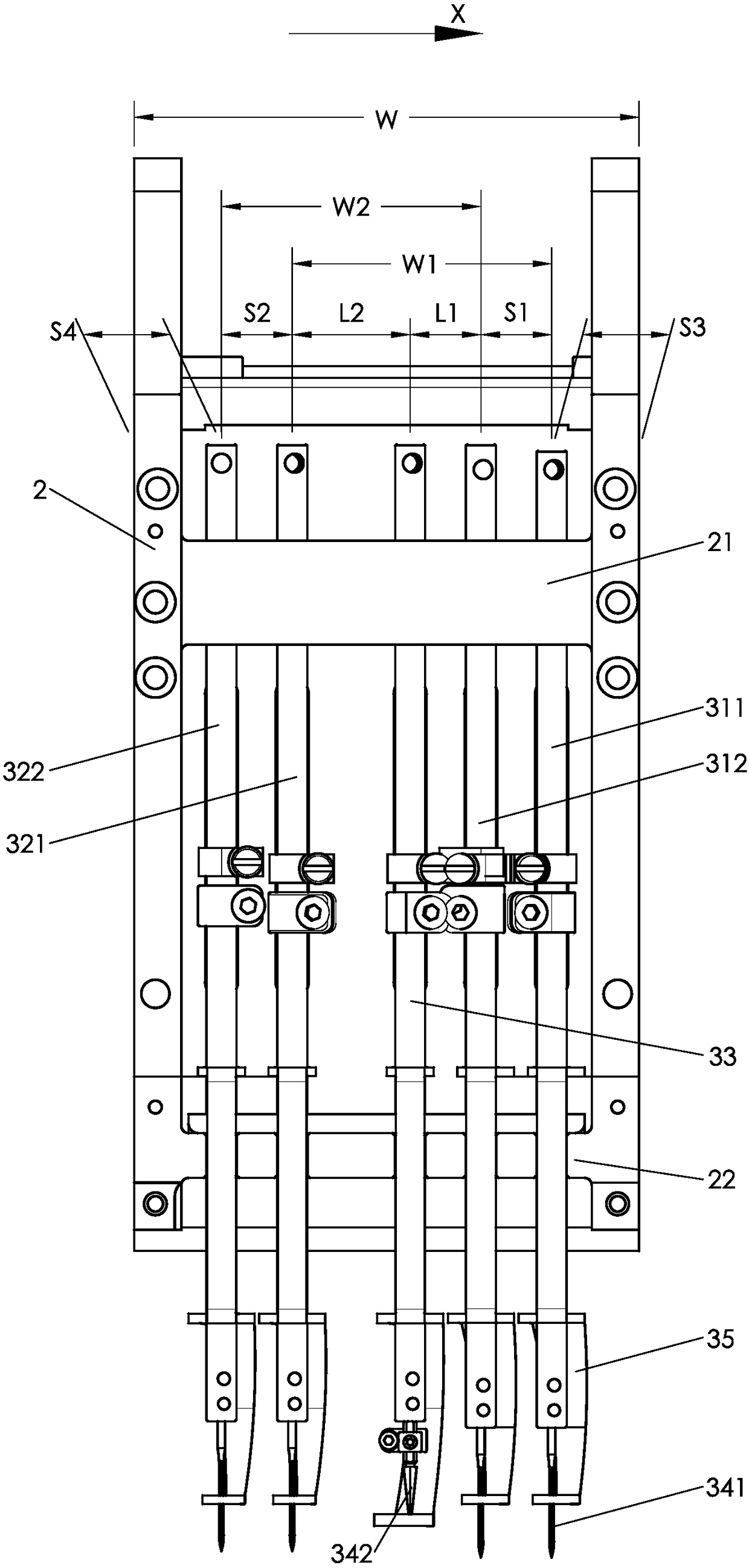

[0076] like Figure 11 As shown, the difference between the third embodiment of the present invention and the above-mentioned first embodiment is that the needle bar frame 2 moves left and right relative to the casing 1, and the direction shown by X' in the figure is the forward direction of the needle bar frame relative to the casing , the opposite direction of X' is the direction in which the needle bar frame moves back and resets relative to the casing.

[0077] At this time, needle bar I 311, needle bar II 312, carved hole needle bar 33, needle bar III 321 and needle bar IV 322 are arranged on the needle bar frame 2 from right to left along the needle bar frame 2, that is, needle bar I, needle bar II , carved hole needle bar, needle bar III and needle bar IV are sequentially arranged on the needle bar frame from back to front along the moving direction X' when the needle bar frame advances. The center distance between the needle bar III and the needle bar IV is S2, the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com