An engine timing chain system assembly tool and assembly method

A technology of assembly tooling and assembly method, which is applied in the field of engine timing chain system assembly tooling and assembly, and can solve the problems of increased phase deviation between crankshaft sprocket and camshaft sprocket, unavoidable elongation of timing chain, camshaft and camshaft Increased sprocket phase deviation and other issues, to achieve the effect of reduced phase deviation, reduced timing mark design, and short assembly hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

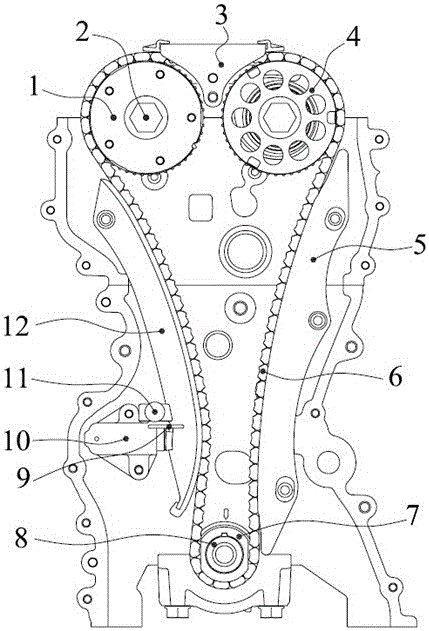

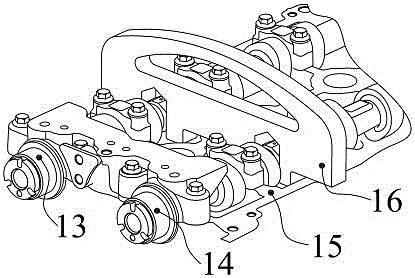

[0051] Such as figure 1 The shown engine timing chain system assembly tooling includes crankshaft timing tooling 17 , camshaft timing tooling 16 and tensioner tooling 11 .

[0052] The front journal of the crankshaft is processed with a keyway, which is assembled and positioned with the crankshaft timing sprocket through a semicircular key. Two pin holes are machined on the rear end surface of the crankshaft for the positioning of the crankshaft timing tool.

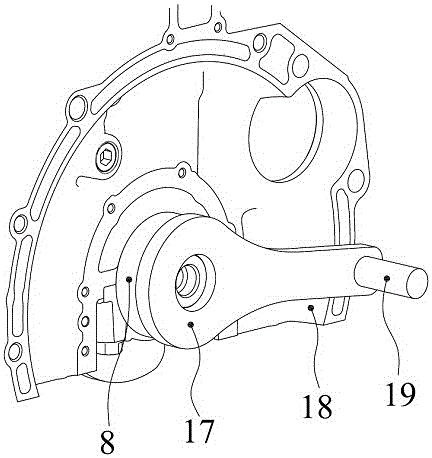

[0053] see image 3 , Figure 4 , the crankshaft timing tooling 17 includes a flange body 171, a connecting arm 172 and a latch 19, two locating pins 173 are arranged on the inner end surface of the flange body, and the two locating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com