Grooved filter rod forming machine realizing synchronization of paper tape and filament bundle

A filter rod forming machine and groove technology, which is used in e-liquid filter, application, tobacco and other directions, can solve the problems of poor synchronization performance, affecting production operations, and high manufacturing costs, and achieves reduced phase deviation, high forming speed, and low manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

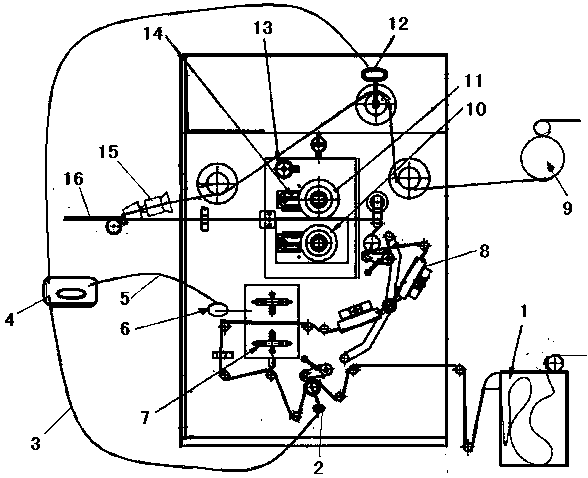

[0034] like figure 1 The shown grooved filter rod forming machine with synchronous paper tape and tow is used to manufacture grooved filter rods, with tow conveying mechanism, paper tape groove embossing and conveying device, filter rod forming machine, electrical synchronous control system , the paper tape groove embossing and conveying device pulls the paper tape into the groove embossing device, so that the paper tape is extruded to form concave-convex grooves and conveyed out, and enters the filter rod forming machine together with the tow to wrap the tow to form grooves Filter rod; the electrical synchronous control system can sense the speed of tow transmission and paper groove embossing and transmission speed. The tow transmission is driven by servo motor B, and the paper groove embossing and conveying device is driven by servo motor A. The machine respectively provides signals to control the operation of the two servo motors, so that the speed of the tow and the paper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com