Patents

Literature

42results about How to "Improve assembly positioning accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

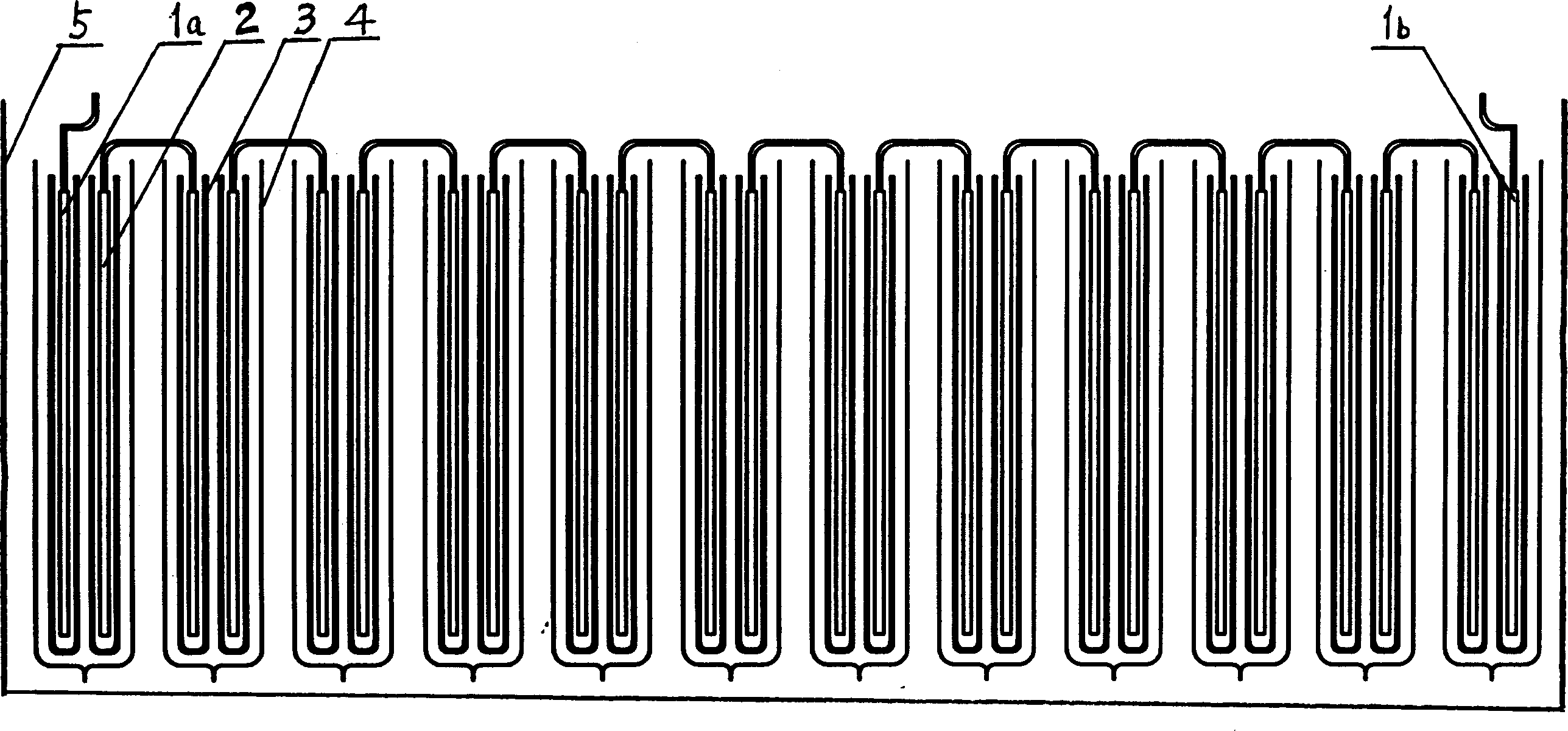

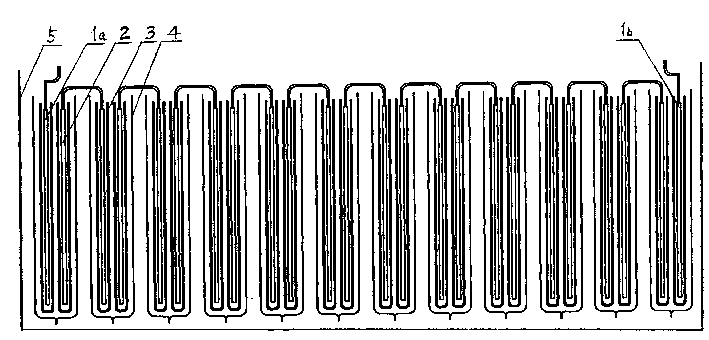

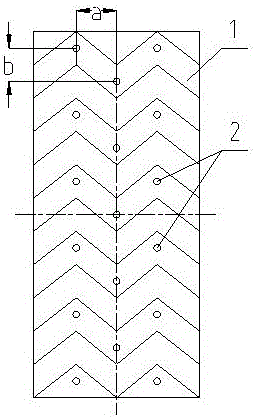

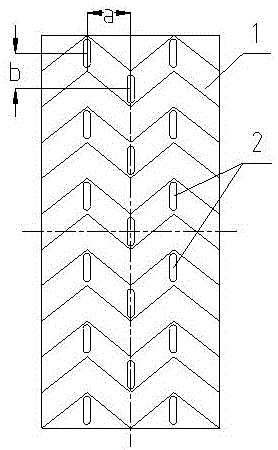

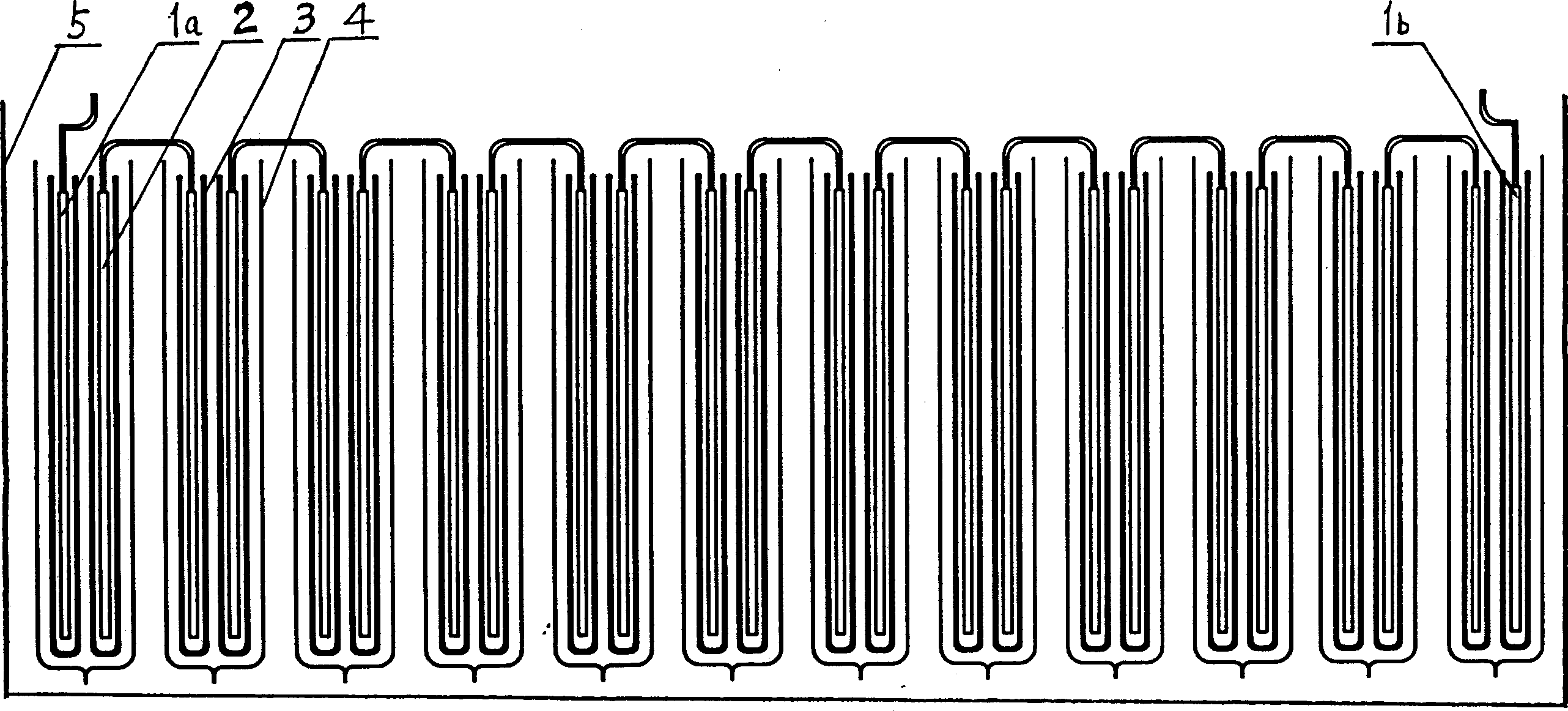

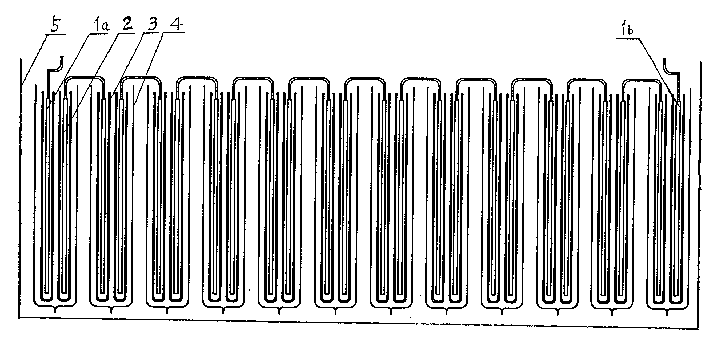

Pole Plate folding type lead-acid accumulator and its preparing method

InactiveCN1458708AReduce volumeReduce weightFinal product manufactureLead-acid accumulators constructionElectrical polarityEngineering

This invention discloses a folded polar plate lead acid battery and its making method, among which the lead wire connecting two plates is folded into u-shape and monopolar and bipolar plates are arranged in the box in sequence according to the matched polarities, a V-shaped diaphragm wraps both sides of each plate, insulation bag sleeve two adjacent polar plates and the diaphragm warapping the polar plates, realizing internal serials connection by lead wires. The lead acid battery has the advantages of small volume, light weight and good power characteristic.

Owner:SHIJI QIANWANG BATTERY TECH CO LTD BEIJING

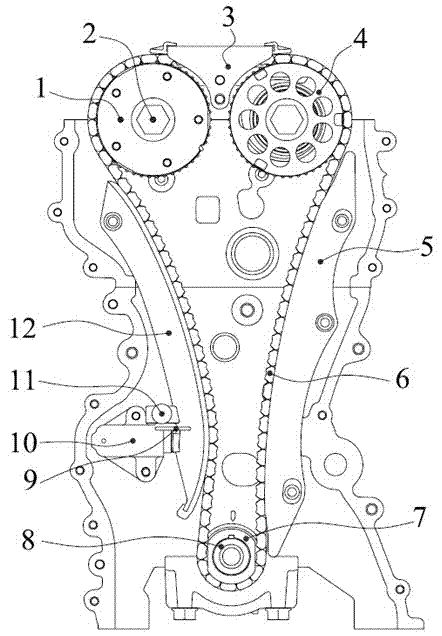

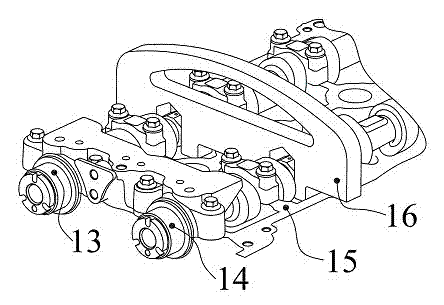

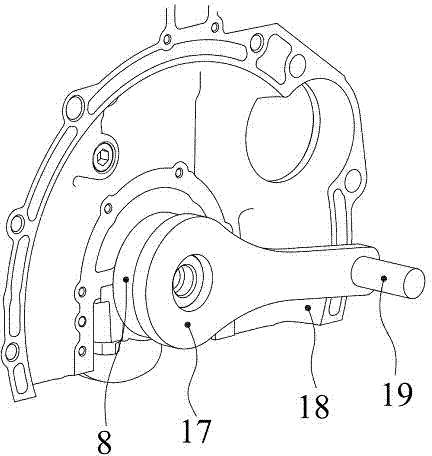

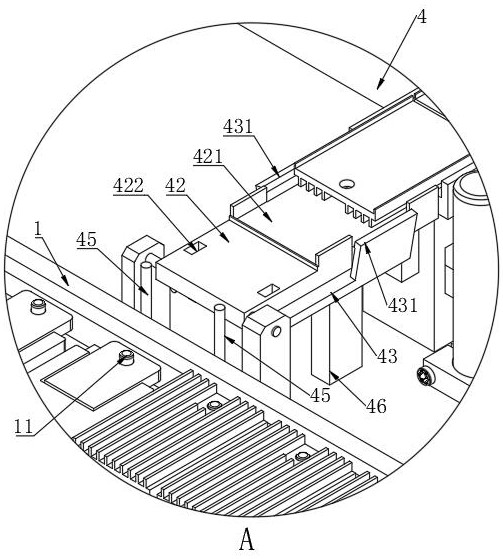

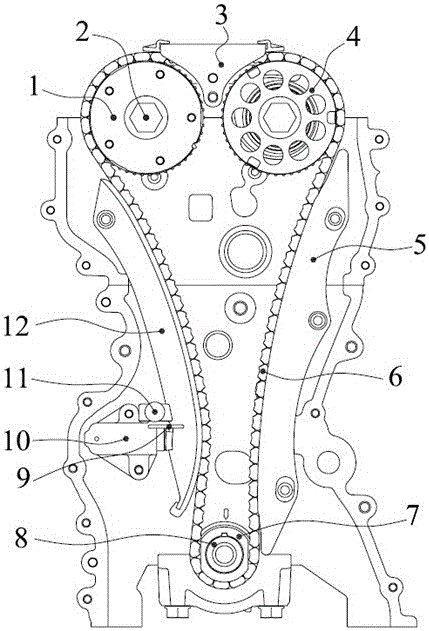

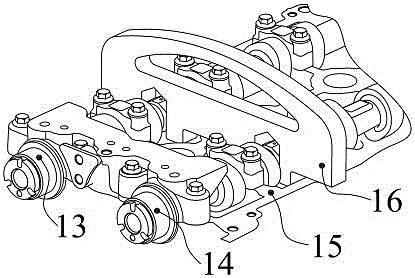

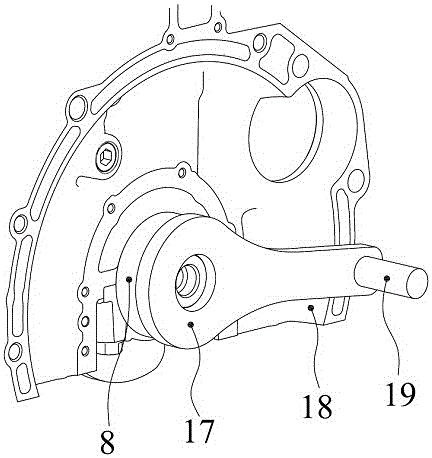

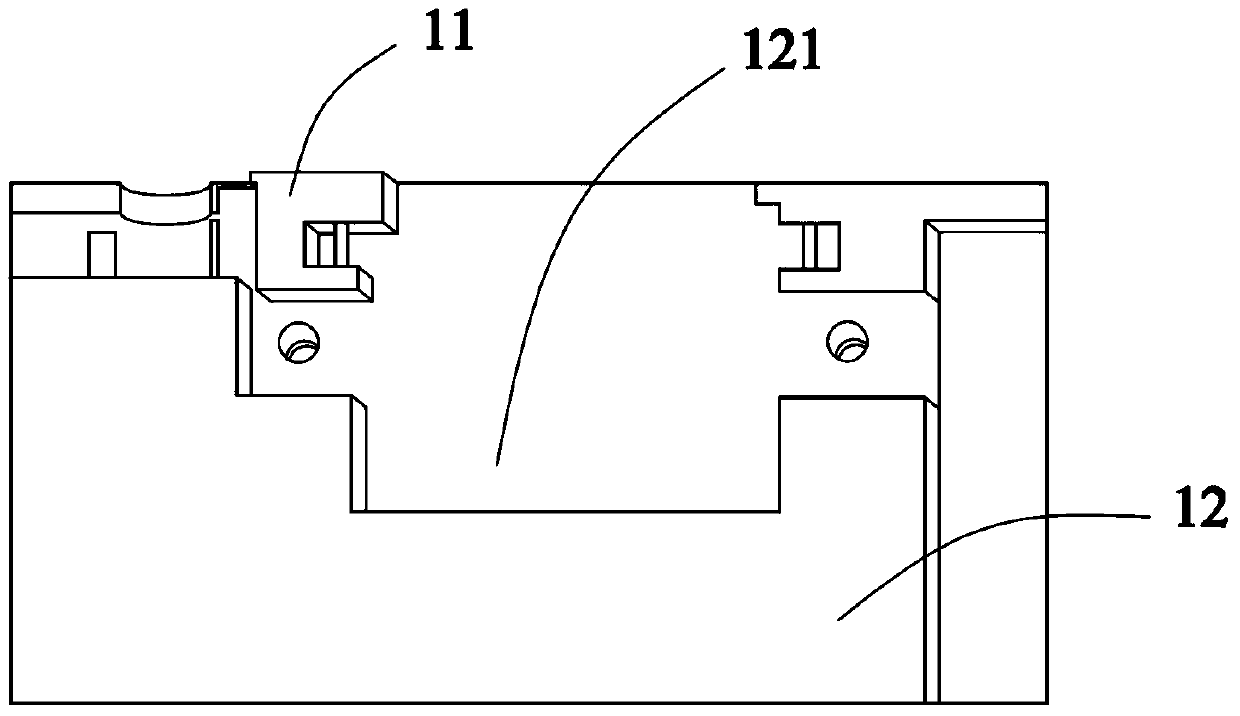

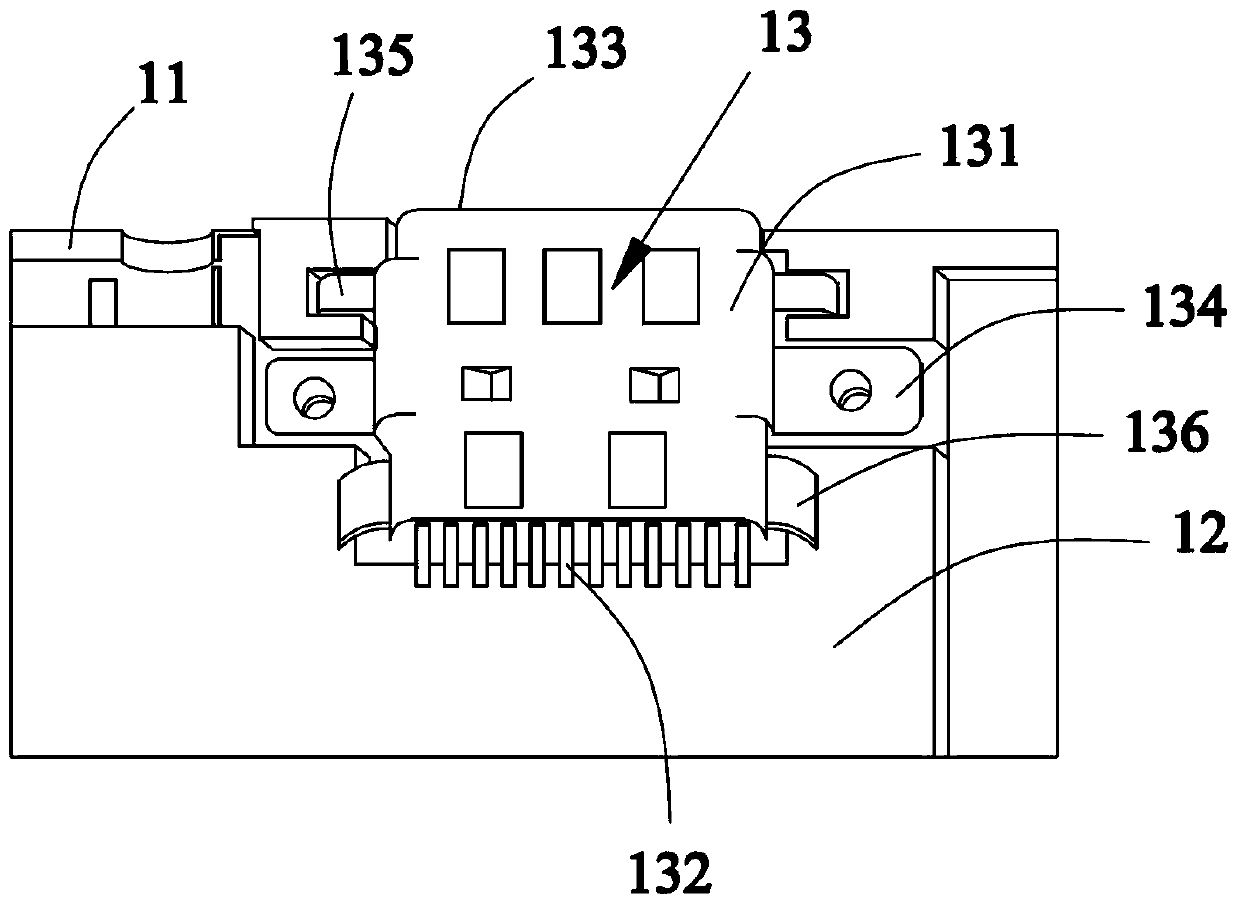

Engine timing chain system assembly tool and an assembly method

ActiveCN104493787AImprove assembly positioning accuracyReduced phase deviationMetal-working hand toolsChain systemCam

The invention discloses an engine timing chain system assembly tool and an assembly method. The assembly tool comprises a crank timing tool, a cam shaft timing tool and a tensioner tool. Through the adoption of the assembly tool provided by the invention, the assembly positioning accuracy can be effectively improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

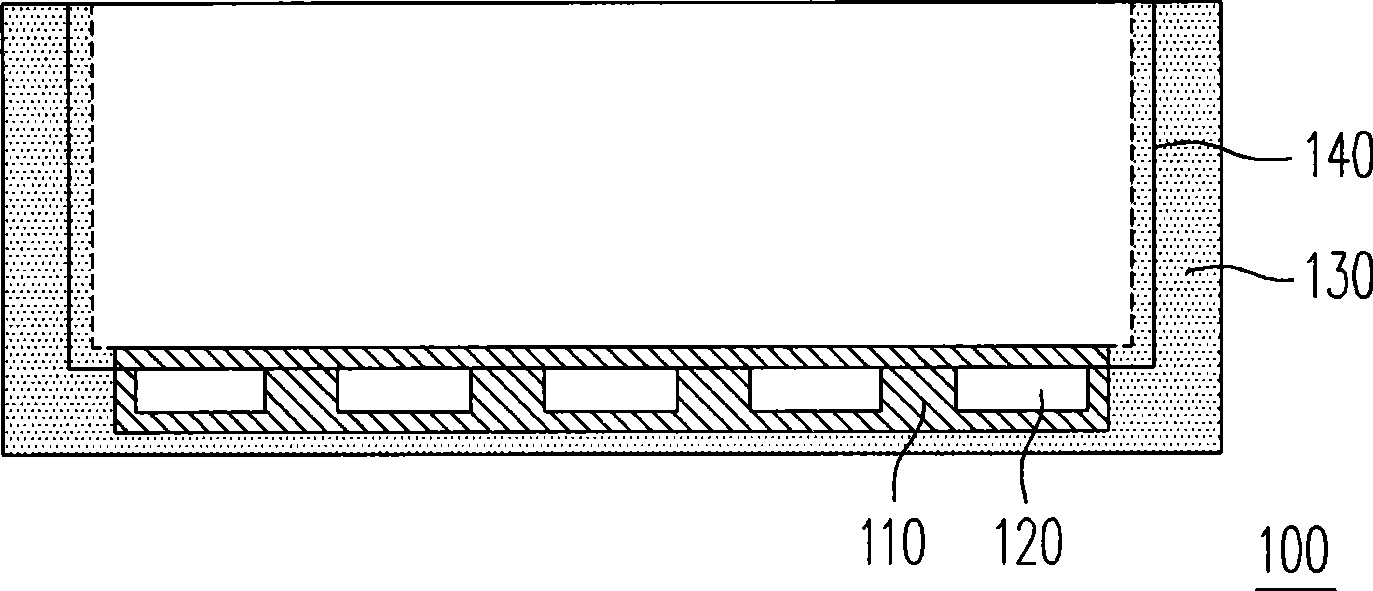

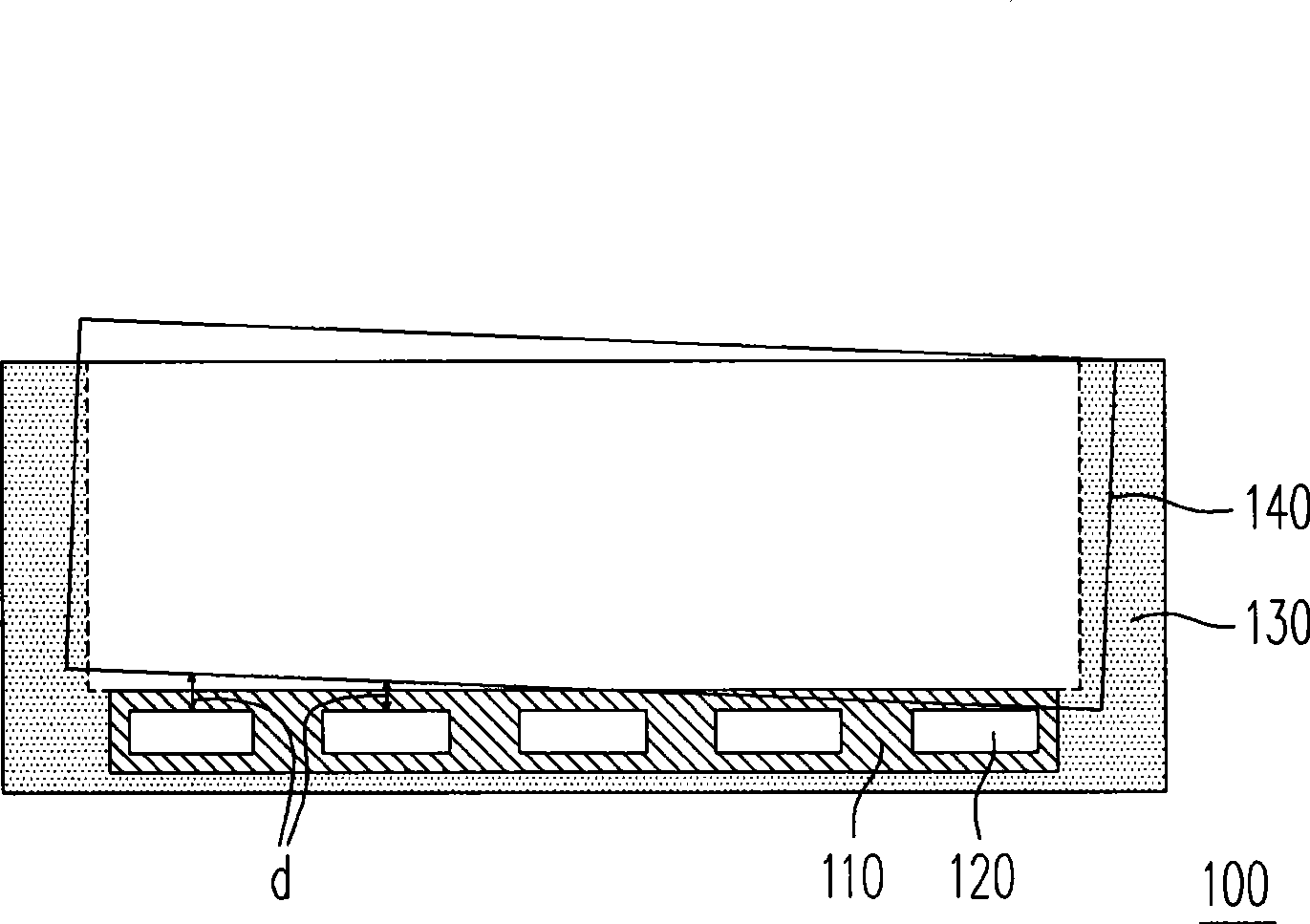

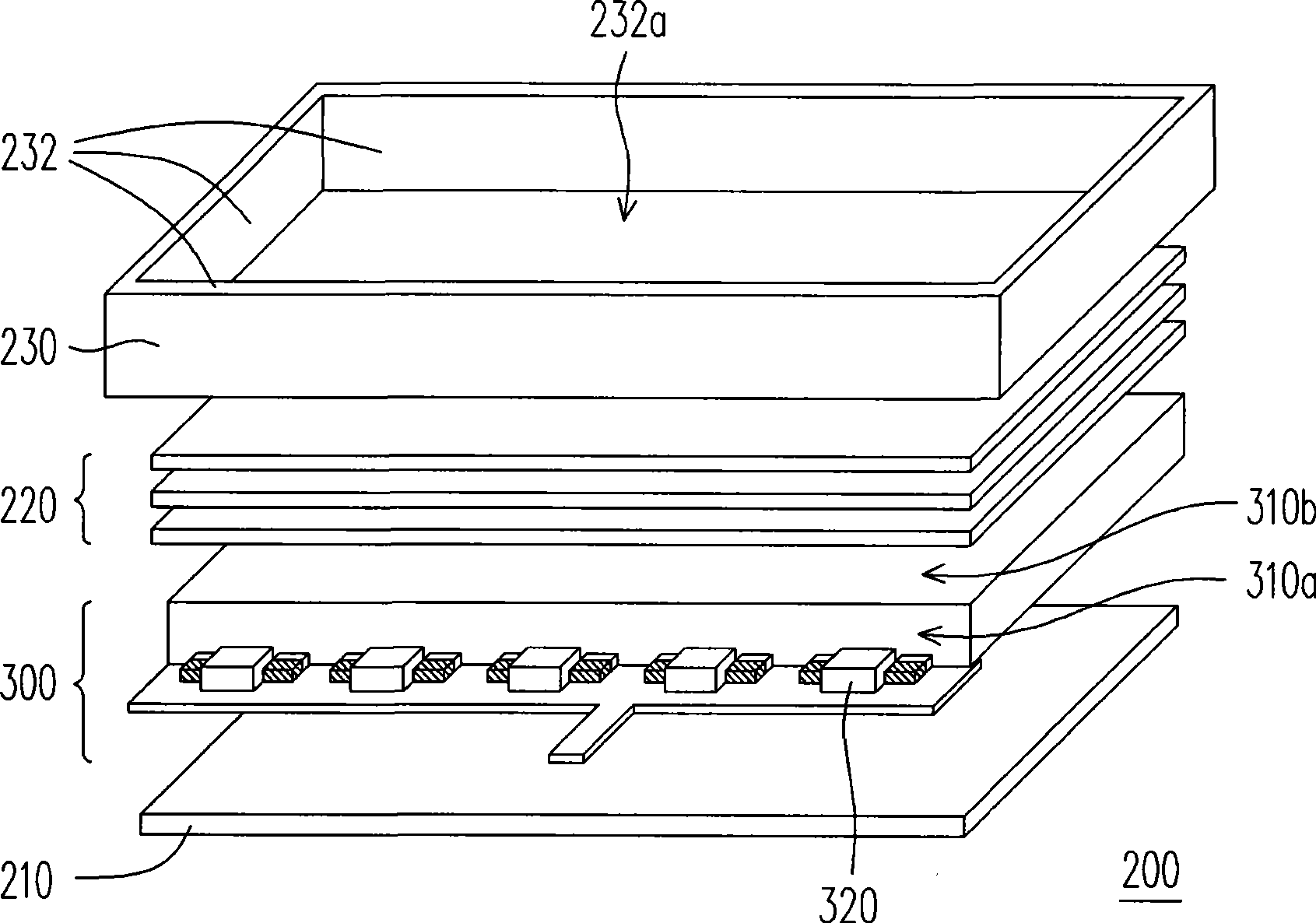

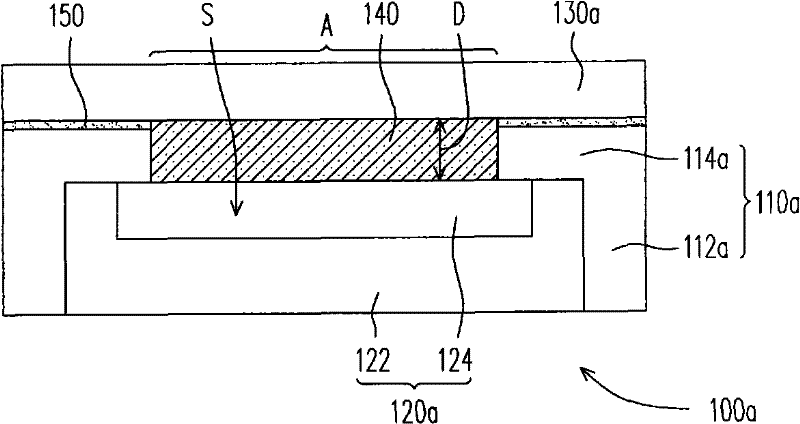

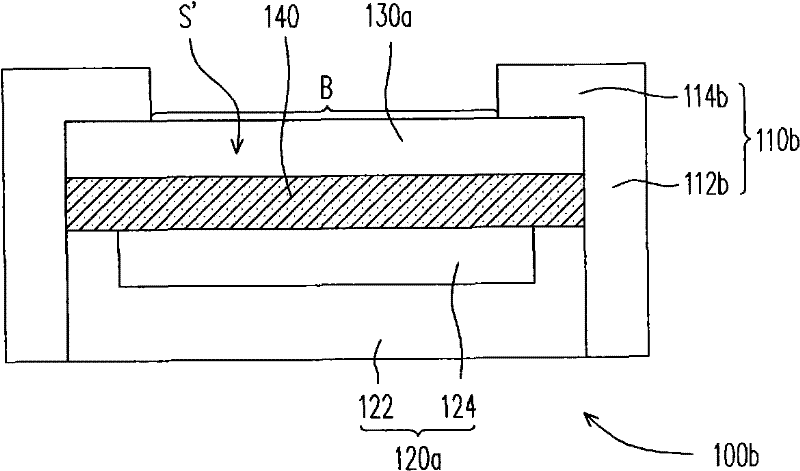

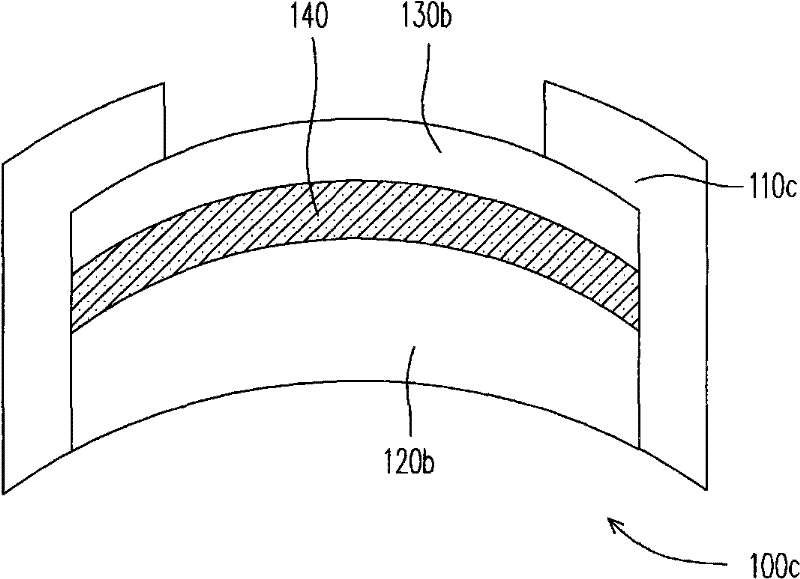

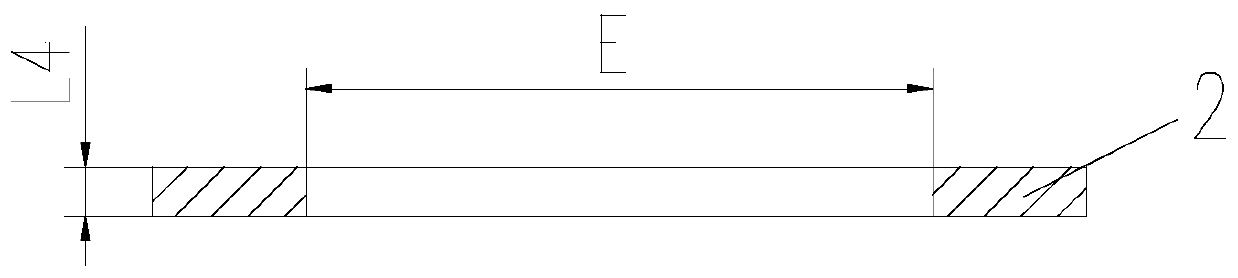

Backlight module and optoelectronic device

ActiveCN101509625AImprove assembly positioning accuracyReduce light source damageMechanical apparatusPoint-like light sourceOpto electronicEngineering

The invention relates to a backlight module and a photoelectric device, the backlight module comprises an optical plate and at least one light emitting element. The optical plate comprises a light-incoming face and a light-exiting face. The light emitting element is arranged on a circuit board and faces toward the light-incoming face, wherein, the light emitting element is magnetically absorbed on the optical plate by making use of at least one magnetic absorption member that is arranged on at least one or both of the optical plate and the circuit board. On account of using the magnetic absorption member for the assembly, the assembly positioning precision of the backlight module can be improved and the risk that the light emitting element is damaged can be reduced.

Owner:AU OPTRONICS CORP

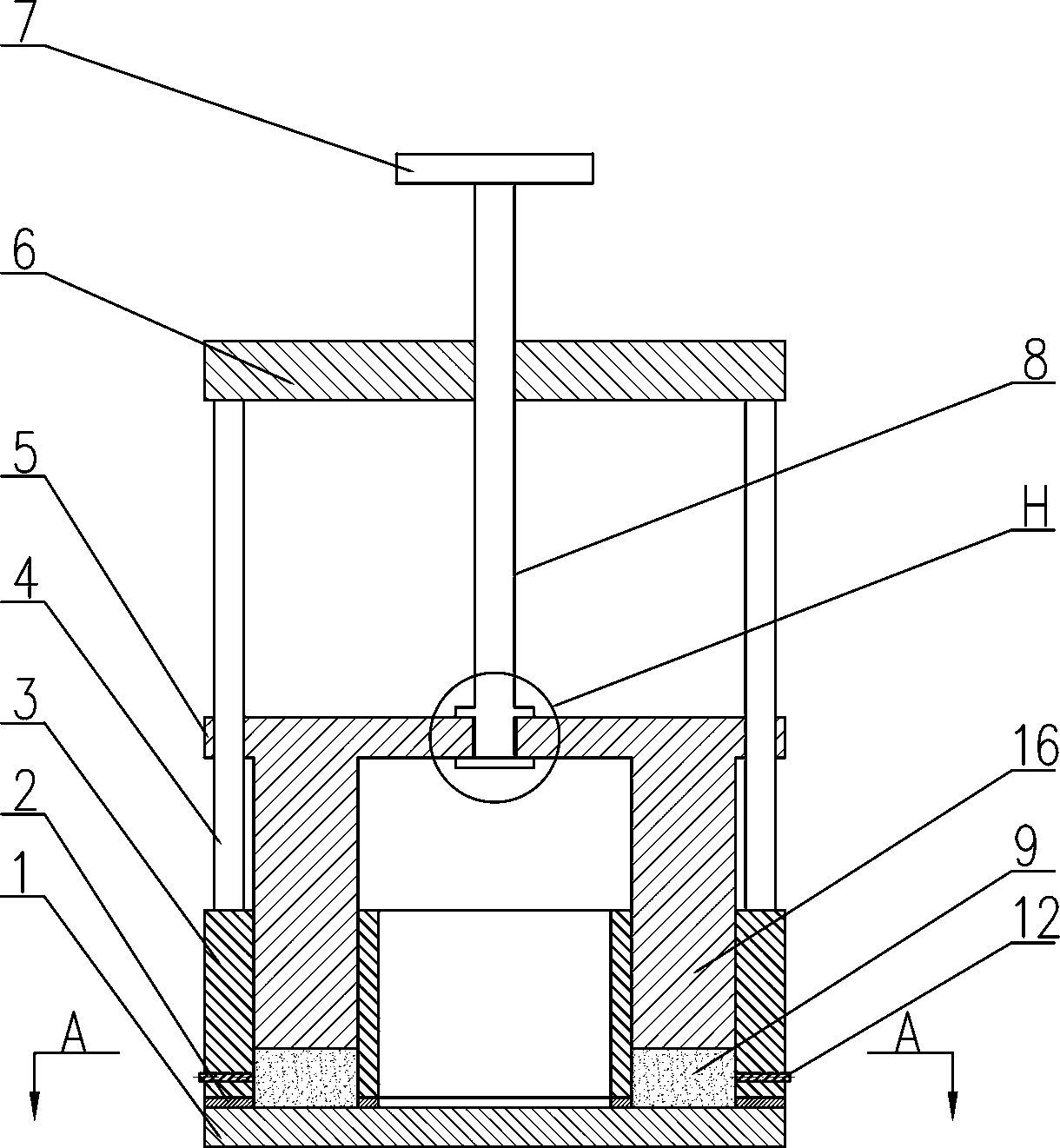

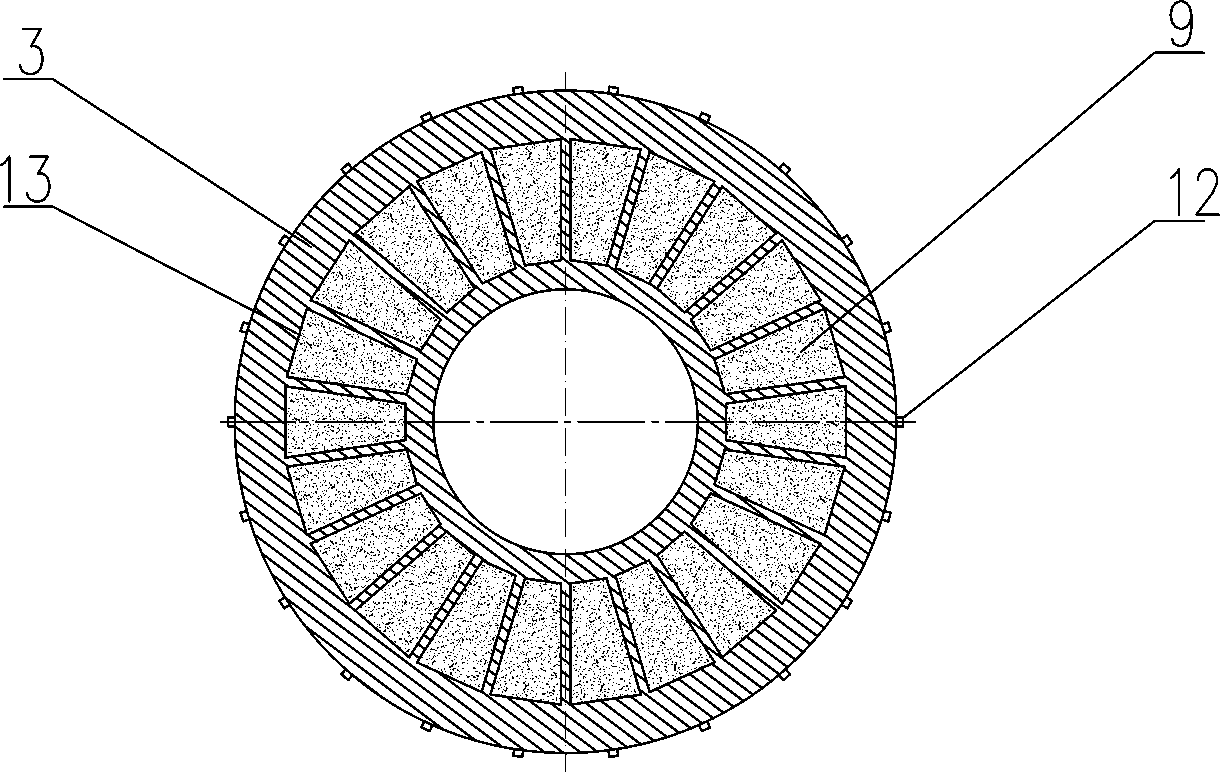

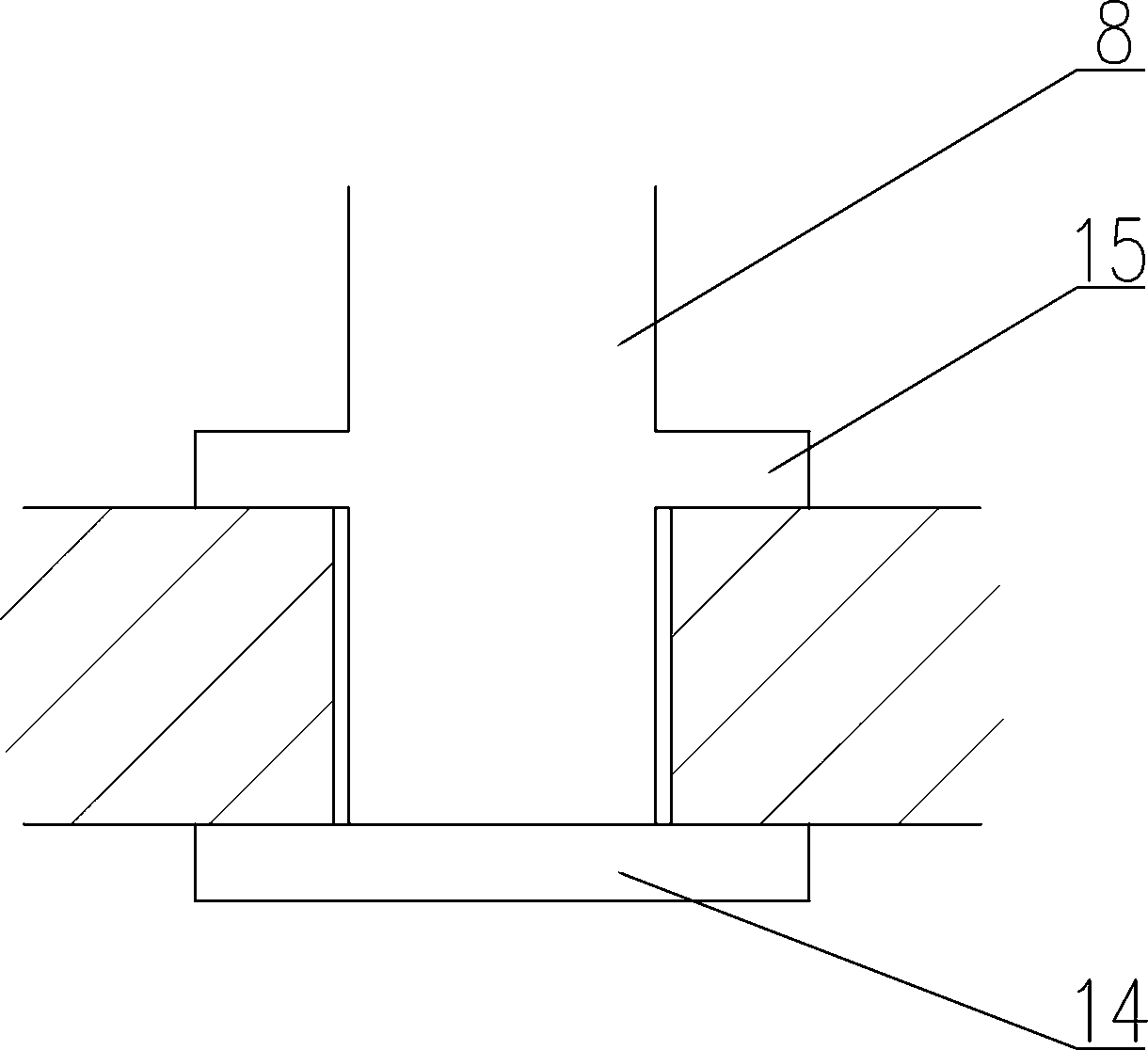

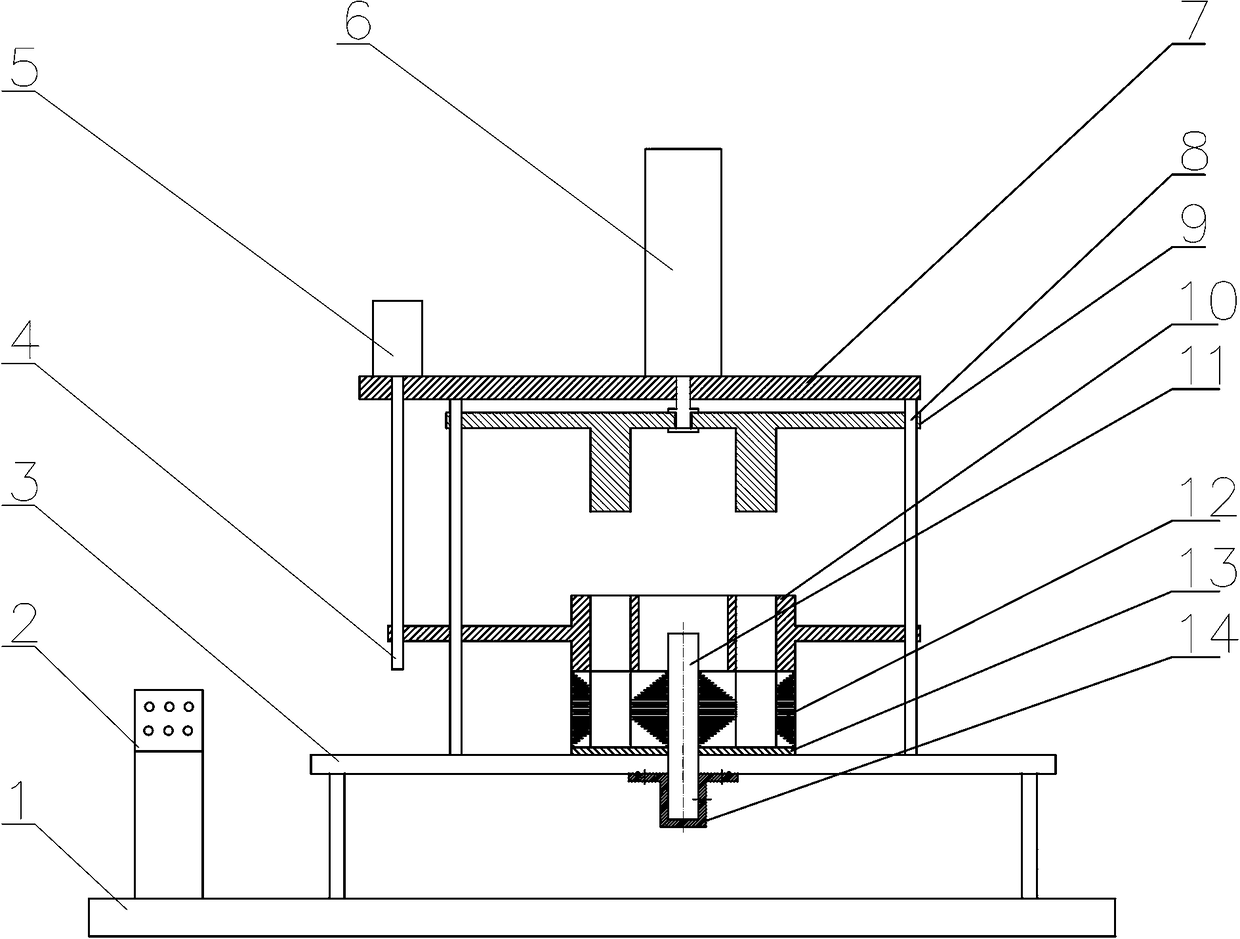

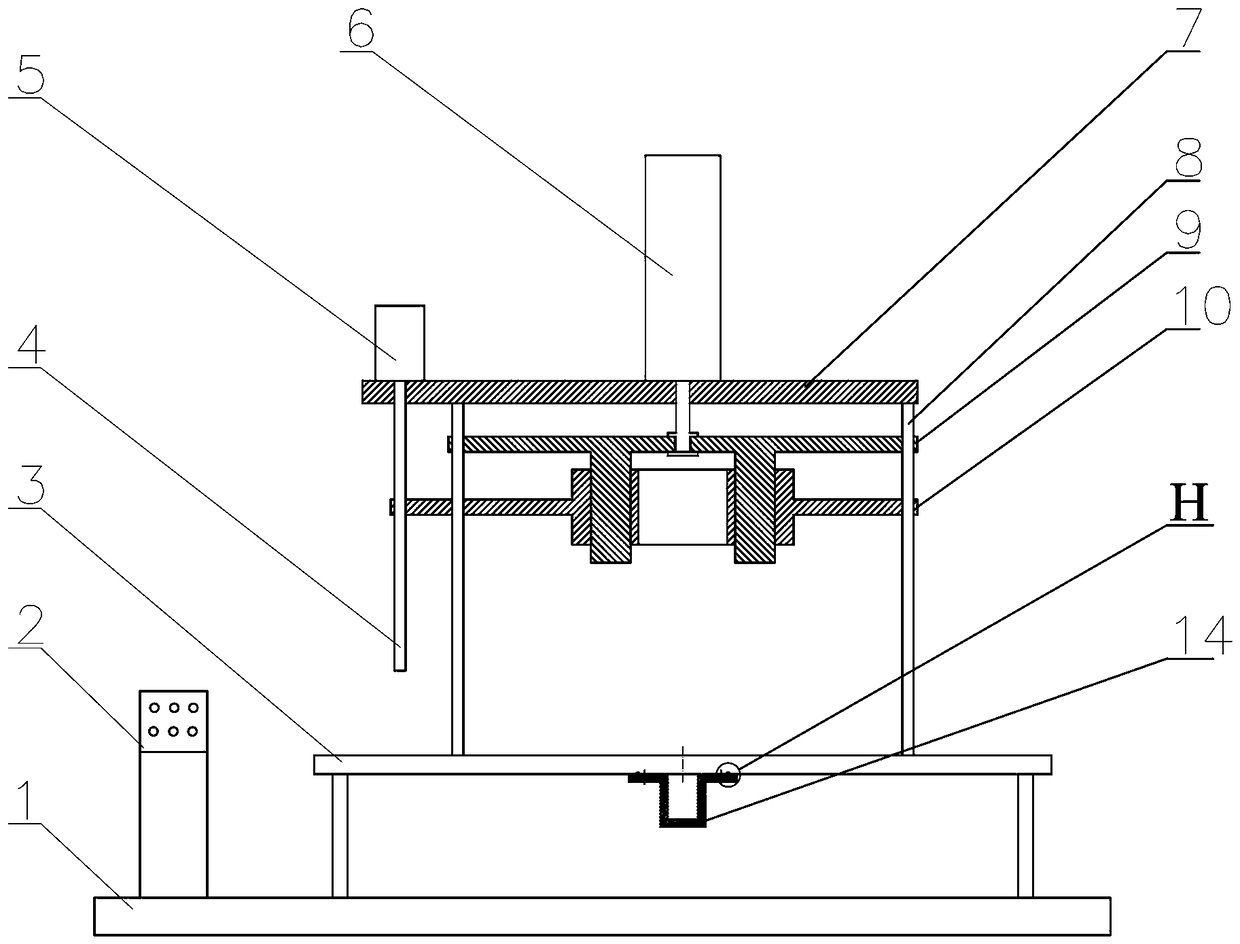

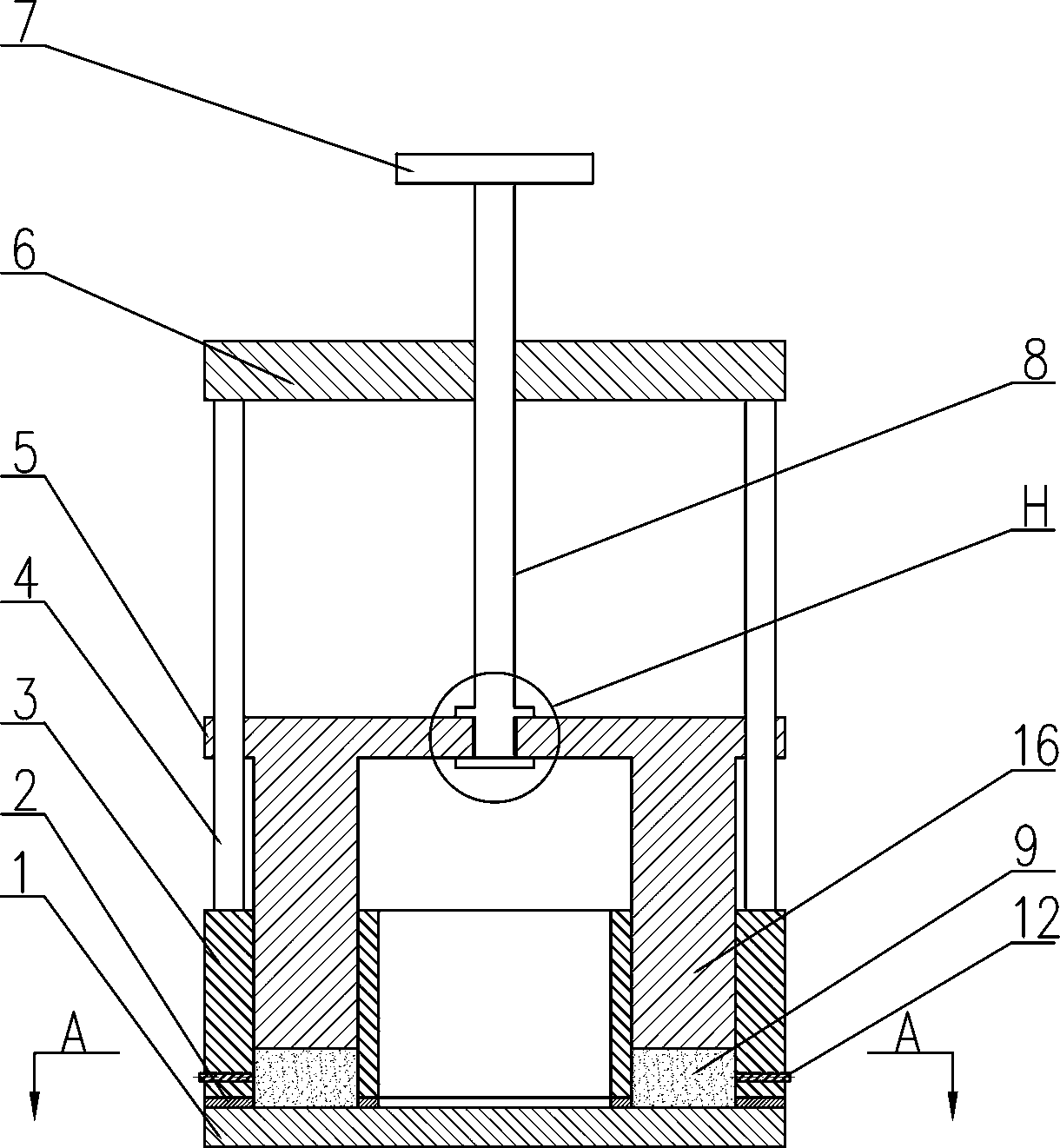

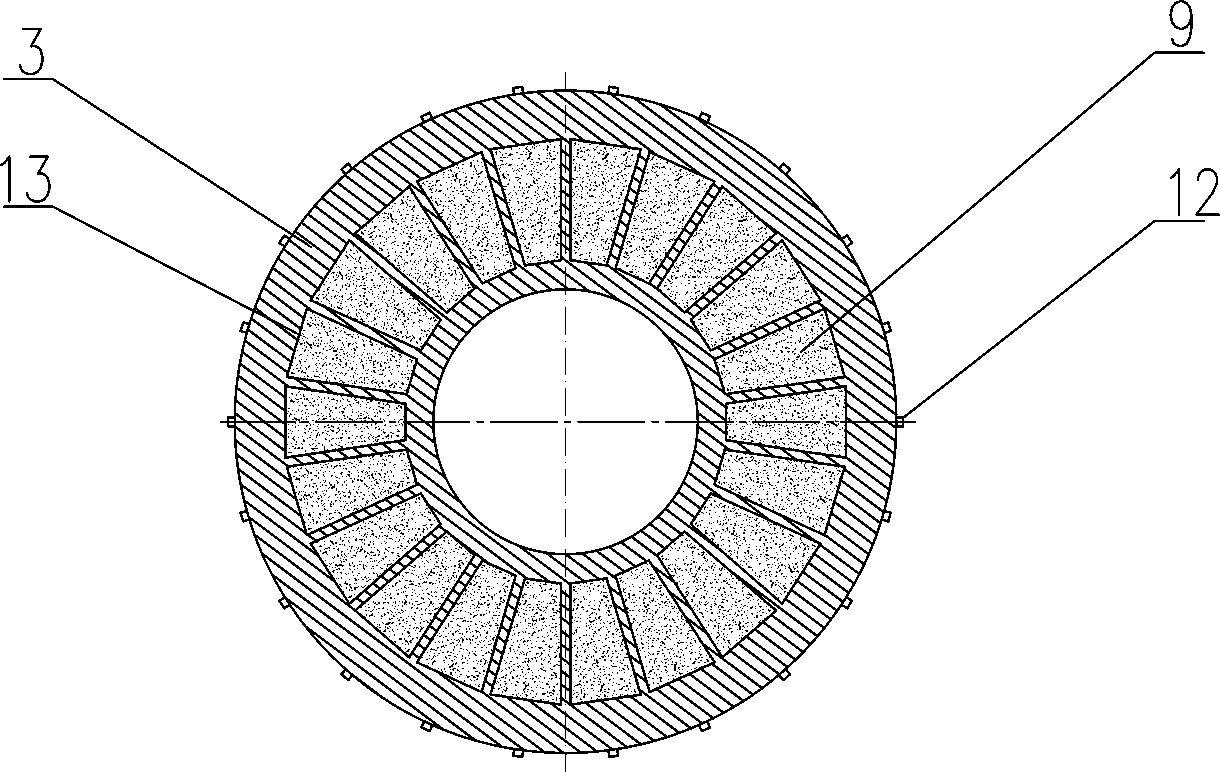

Device and method for assembling permanent magnets of axial magnetic flux permanent magnet motors

ActiveCN107612245AImprove assembly positioning accuracyHigh degree of mechanizationManufacturing stator/rotor bodiesPermanent magnet motorMagnetic flux

The invention relates to a device and a method for assembling permanent magnets of axial magnetic flux permanent magnet motors. The device comprises a fixing portion and a feeding portion. A guide gasket of the fixing portion is positioned at the upper end of a positioning bottom plate, a guide groove is formed in the upper end of the guide gasket, a plurality of vertical connecting holes are formed in the upper end of the guide groove, the lower ends of linear guide rails are positioned in the connecting holes and are connected with the guide groove, a permanent magnet groove is formed in theguide groove in the vertical direction, positioning jackscrews are further arranged on the side surfaces of the permanent magnet groove, and a guide rail fixing plate is connected with the upper endsof the linear guide rails; a propulsion guide block of the feeding portion is slidably fittingly connected with the linear guide rails, a feeding lead screw is connected with the upper end of the propulsion guide block, external threads are arranged on the surface of the feeding lead screw, the feeding lead screw penetrates the guide rail fixing plate to be matched with the guide rail fixing plate in a threaded manner, and a hand wheel is arranged at the upper end of the feeding lead screw. The device and the method have the advantage that the problem of high difficulty in assembling permanent magnets of axial magnetic flux permanent magnet motors at present can be solved by the aid of the device and the method.

Owner:SHENYANG POLYTECHNIC UNIV

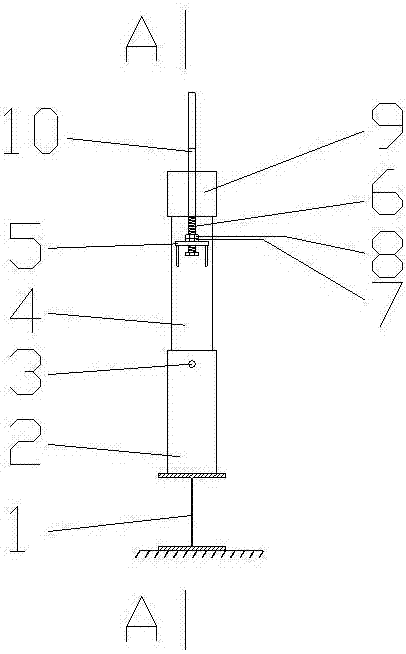

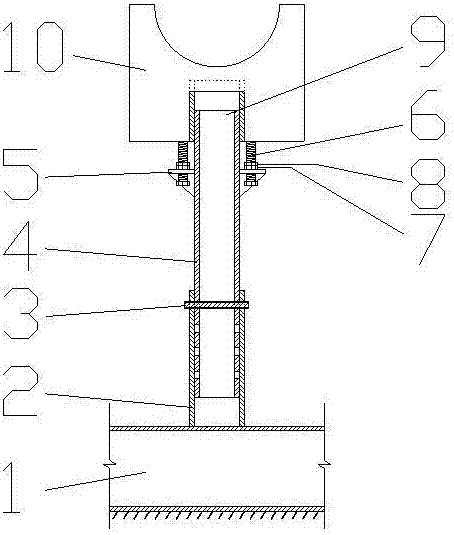

Fabricated simple jig frame used for assembly of steel structure and using method thereof

InactiveCN107327146AAchieve precision controlLarge adjustment rangeBuilding material handlingEngineeringScrew cap

The invention particularly relates to a jig frame used for assembly of a steel structure. The jig frame comprises a base part, a support part and a bracket part and is characterized in that the base part comprises a horizontal bottom plate and a bottom circular pipe, wherein the bottom circular pipe is vertically welded to the horizontal bottom plate; the supporting part comprises a supporting circular pipe, screw caps and screws, the screw caps and the screws are located on the two sides of the supporting circular pipe and fixed to the supporting circular pipe by being welded to brackets on the side faces of the supporting circular pipe on the same horizontal plane; the screws are connected with the supporting circular pipe through screwing-in nuts and fastened through second nuts on the nuts; the bracket part comprises a supporting plate and a top circular pipe, and the supporting plate is vertically welded to the middle-upper part of the top circular pipe; the heights of the base part and the supporting part are adjusted through a plug pin positioning method, and fine adjustment of the heights of the supporting part and the bracket part is achieved through bolt adjustment; and the shape of the supporting plate can be changed according to the shape of an assembly member. The jig frame is used for assembly of the steel structure, assembly precision can be improved, assembly efficiency is improved, and the assembly jig frame can be used repeatedly.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

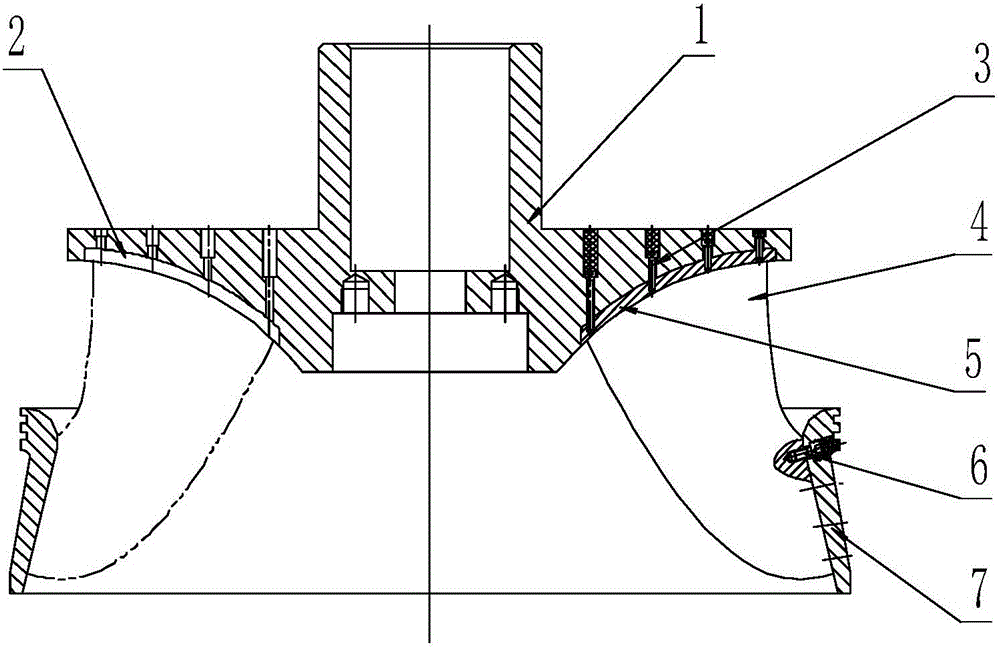

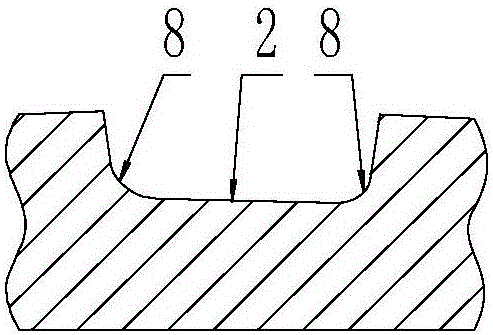

Trapezoid groove mosaic structure for blades and upper canopy of water turbine model runner

InactiveCN105927451AReduce the difficulty of positioningGuaranteed assembly accuracyHydro energy generationReaction enginesWater turbineAerospace engineering

The invention provides a trapezoid groove mosaic structure for blades and an upper canopy of a water turbine model runner. An original rectangular groove assembling type structure adopted in the upper canopy and the blades of the water turbine model runner is changed into the trapezoid groove mosaic structure, the other structures are not changed, the blades and the upper canopy are tightly held and combined through screws, and therefore trapezoid grooves can make tight contact with side faces of trapezoid protruding blocks. The trapezoid groove mosaic structure is simple, convenient to operate, safe and reliable, machining problems are solved, the assembling difficulty is lowered, the problem that matching gaps exist between rectangular protruding blocks of the blades and rectangular grooves of the upper canopy is thoroughly solved, and the phenomenon that because the gaps exist in the flow passing surface of the upper canopy after assembling, the flow passing surface of the upper canopy is not smooth is eliminated.

Owner:HARBIN ELECTRIC MASCH CO LTD

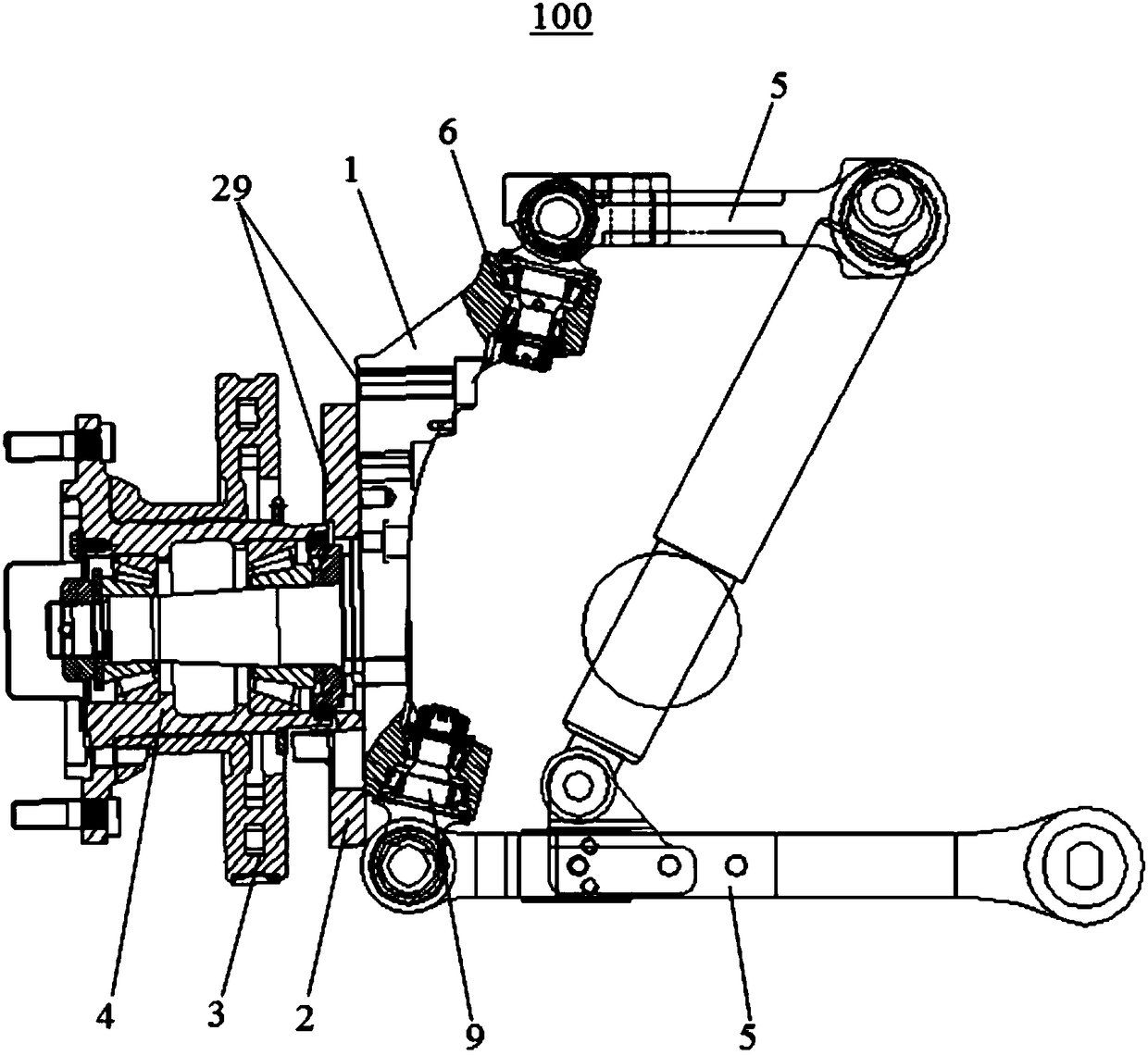

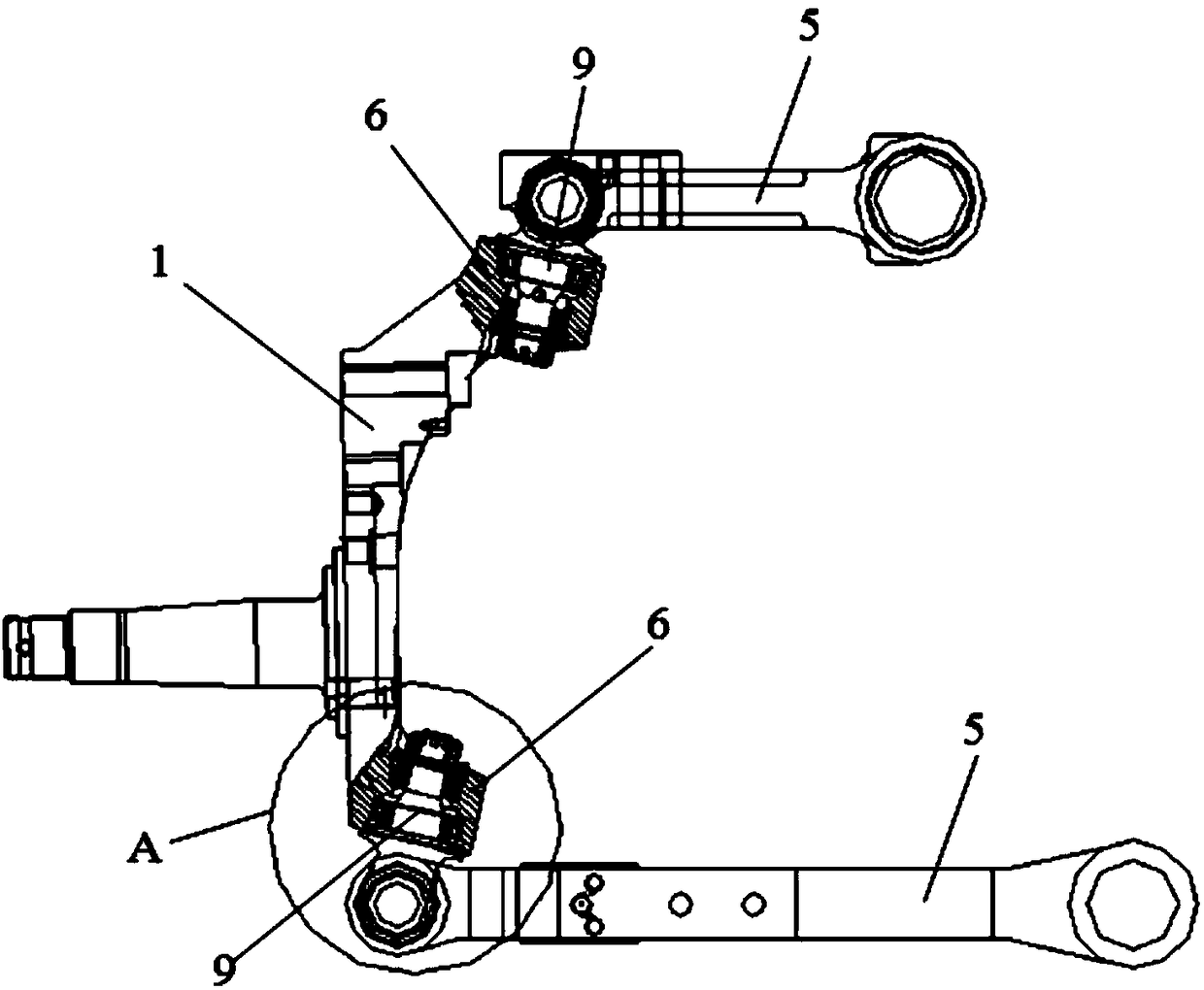

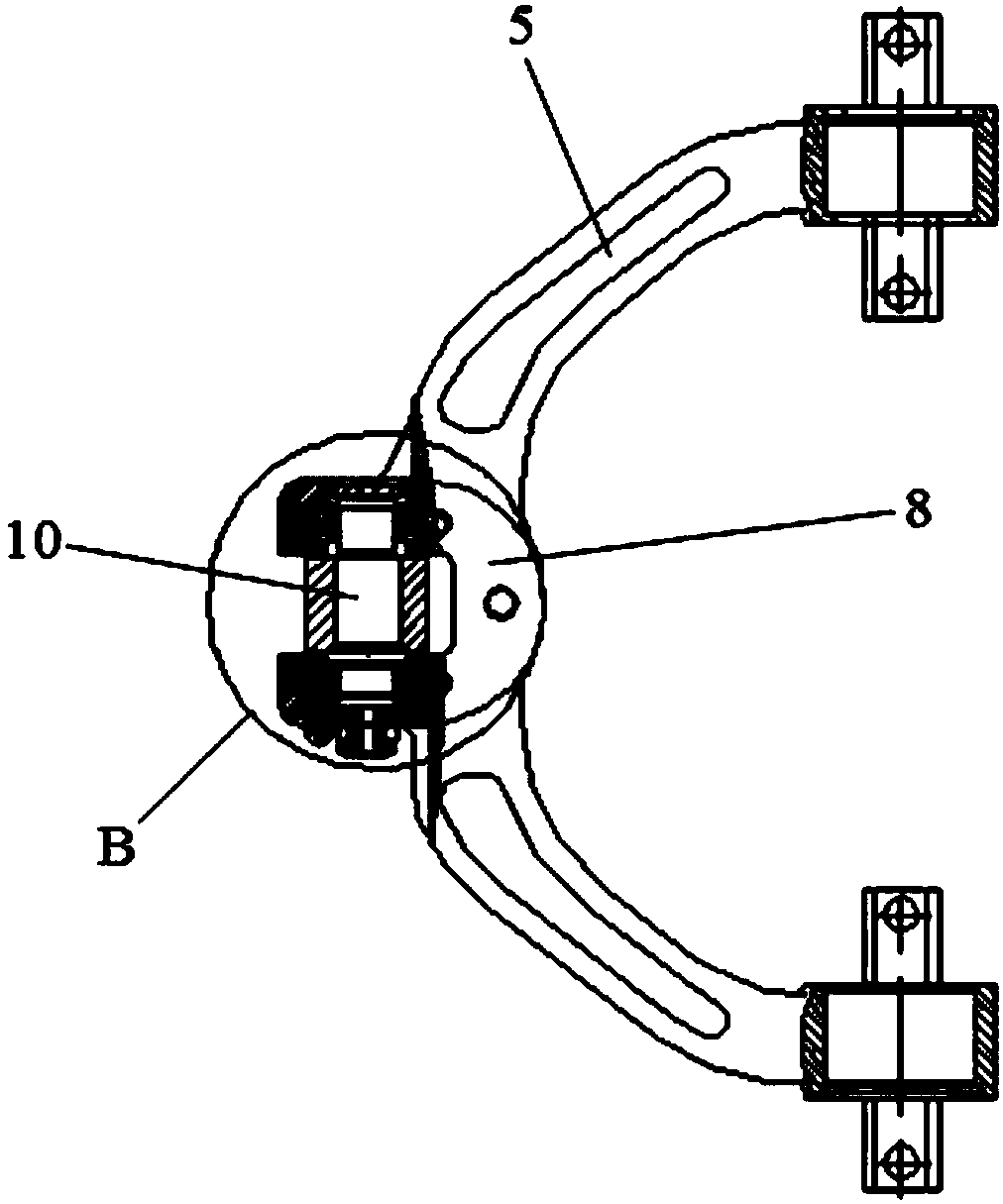

High comfort performance independent suspension for new energy bus

PendingCN108407889AReduce offset distanceRaise the inclinationSteering linkagesPivoted suspension armsNew energyControl arm

The invention discloses a high comfort performance independent suspension for a new energy bus. The high comfort performance independent suspension for the new energy bus comprises a steering knuckleassembly, a mounting plate, a brake disc, a hub assembly and a control arm, wherein the mounting plate, the brake disc and the hub assembly are fixed on the end surface of the steering knuckle assembly; the control arm is connected with the steering knuckle assembly; connecting lug blocks are arranged at the upper and lower ends of the steering knuckle assembly; the control arm is connected with the connecting lug block through a short pin rotating piece in a rotating manner; a step-shaped mounting hole is formed in the connecting lug block; a U-shaped fork is arranged at the end part of the control arm; coaxial mounting holes are formed in the two sides of the U-shaped fork; the short pin rotating piece comprises a short pin connecting piece and a T-shaped knuckle, wherein one end of theshort pin connecting piece is connected with the mounting hole through a bearing, and the two ends of the T-shaped knuckle are erected in the coaxial mounting holes through bearings; and the other endof the short pin connecting piece is fixedly connected with the T-shaped knuckle. According to the high comfort performance independent suspension for the new energy bus, the kingpin offset distanceis reduced, the kingpin inclination angle is increased, and the stability and comfort of the braking of the complete bus are improved.

Owner:方盛车桥(苏州)有限公司

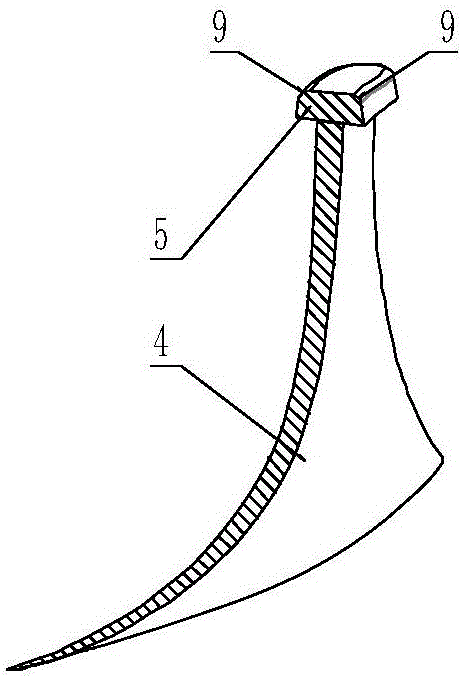

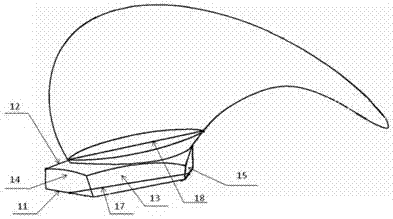

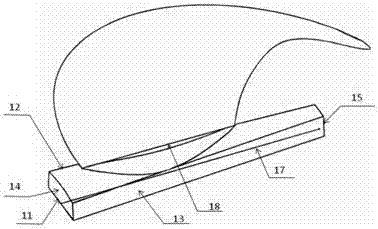

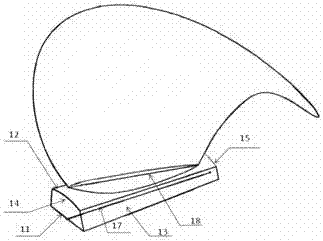

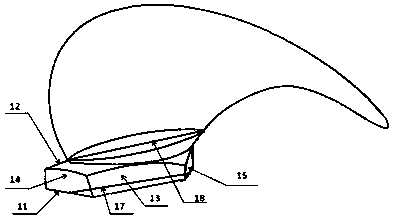

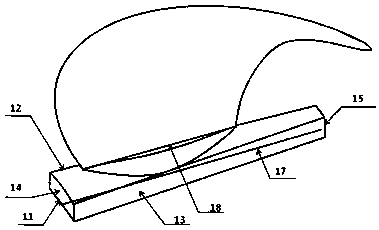

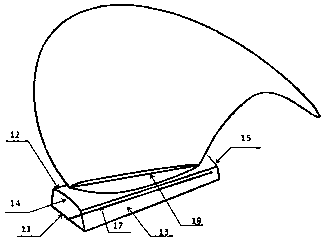

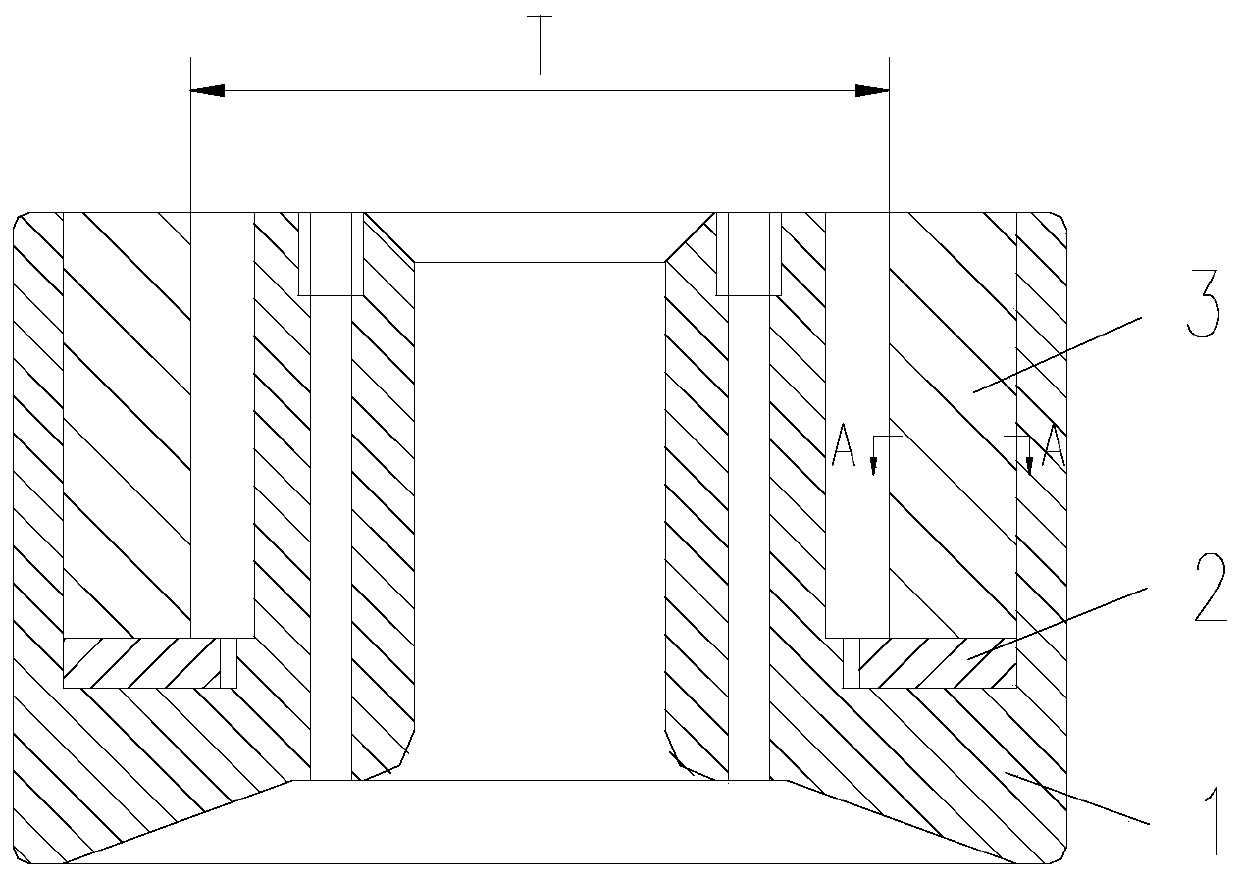

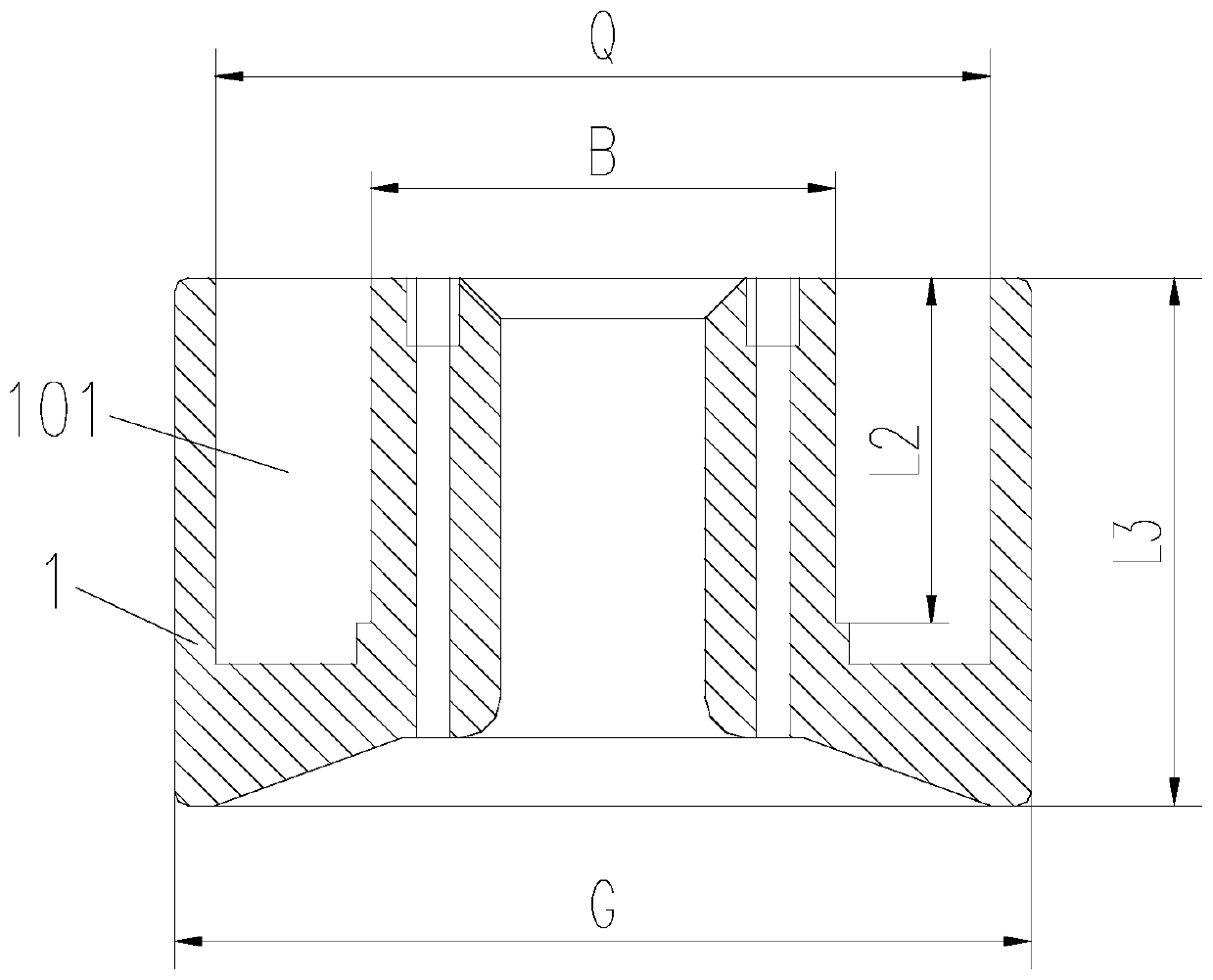

Propeller with combined continuous fiber reinforced composite blades for ship

The invention belongs to the technical field of propellers and relates to a propeller with combined continuous fiber reinforced composite blades, in particular to a propeller with combined continuous fiber reinforced composite blades for a ship. The propeller with the combined continuous fiber reinforced composite blades for the ship is characterized in that the assembly surfaces of dovetail grooves in a propeller hub and blade roots are planes, and thus the assembly positioning precision of the dovetail grooves and the blade roots is high; the blades are inserted from large ends of the dovetail grooves in the propeller hub, then an end cap is fixed to the propeller hub to exert fastening force so as to mount the blades in position, thus mounting is convenient, and the composite blades are not damaged; the space between the dovetail grooves and the blades is filled with resin adhesive, the end cap and the propeller hub are fixed, the blades are not loosened, dropped or damaged under a working condition after testing, and thus the propeller has high reliability; and the structure, performance and manufacturing features of the composite blades are fully taken into account in the aspect of designing of the dovetail grooves in the propeller hub, and thus the blades are suitable for various immersion propellers and water surface propellers.

Owner:AVIC BASIC TECH RES INST

Air cylinder cover water draining sleeve water feeding hole sand core tenon and mounting technique thereof

ActiveCN104209468AAvoid deformationImprove assembly positioning accuracyFoundry mouldsFoundry coresEngineeringProcess design

The invention discloses an air cylinder cover water draining sleeve water feeding hole sand core tenon and a mounting technique of the tenon. The tenon is characterized in that a water draining sleeve sand core is arranged on a chassis core, convex tenons of the water draining sleeve sand core are inserted in concave tenon pits of the chassis core, non-following tenons are arranged on the contact portions of the convex tenons and the concave tenon pits, the non-following tenons are made in cooperation with concave holes of the concave tenon pits, when the non-following tenons of the convex tenons are arranged in the concave tenon pits, first clearances, second clearances, third clearances, slope distances and the non-following tenons are formed in the clearances between the non-following tenons and the pit walls, the length of the non-following tenons is more than 1 / 2 of that of the convex tenons, the convex tenons and the non-following tenons are round, and the concave convex pits are round. The technique has the advantages that casting burrs are reduced, core assembling mistake prevention can be achieved, the assembling and positioning precision of the sand core can be improved, and the technique is suitable for the process design of various air cylinder cover water draining sleeve water feeding hole sand core tenons.

Owner:GUANGXI YUCHAI MASCH CO LTD

Mobile terminal with metal bracket

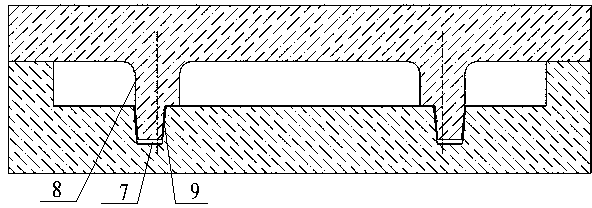

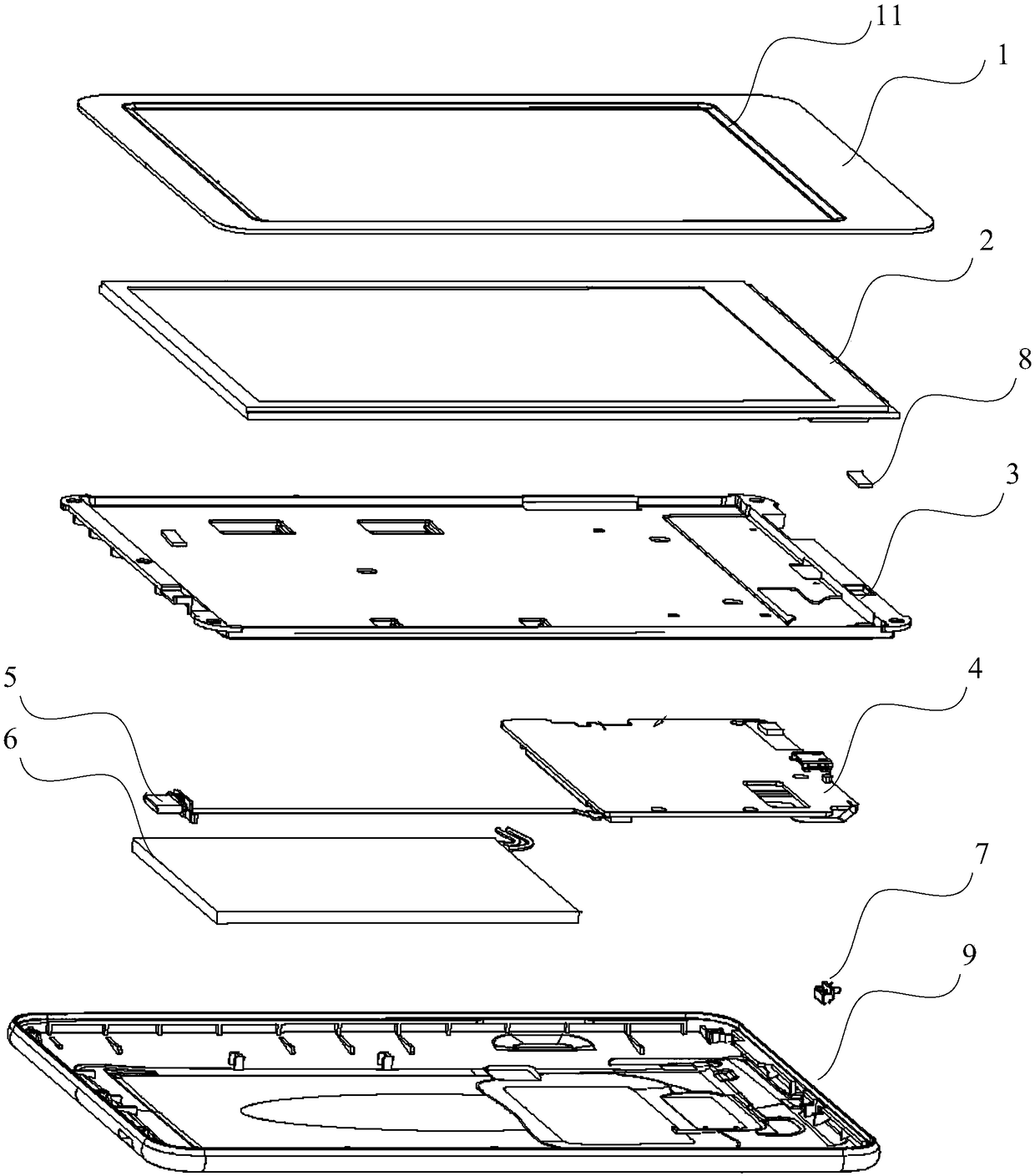

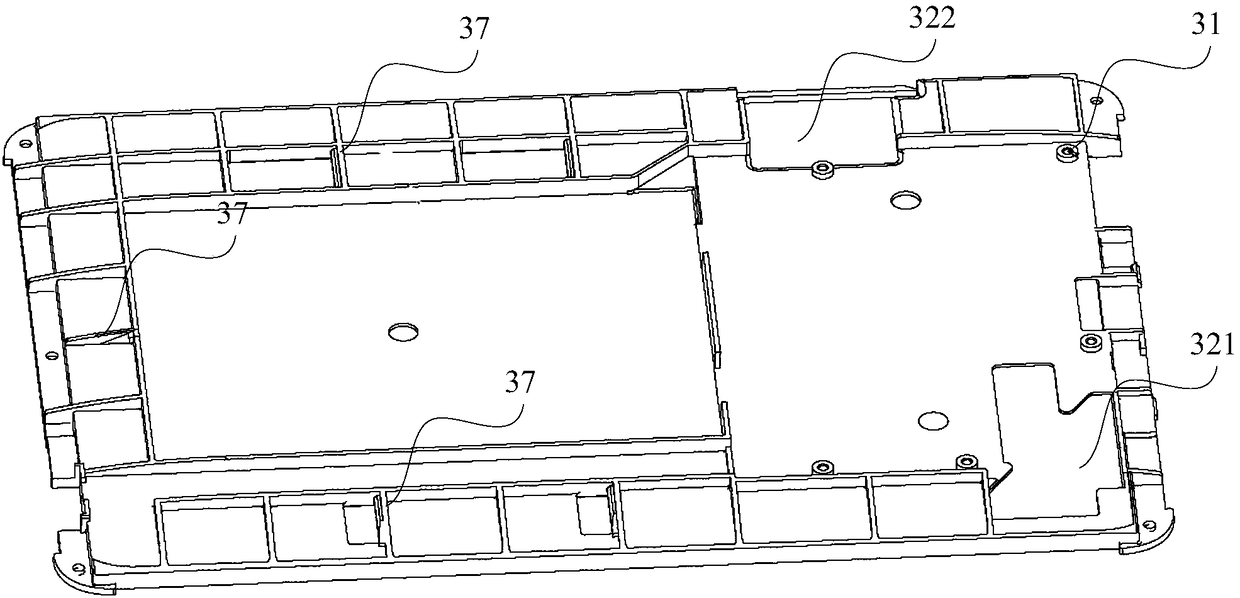

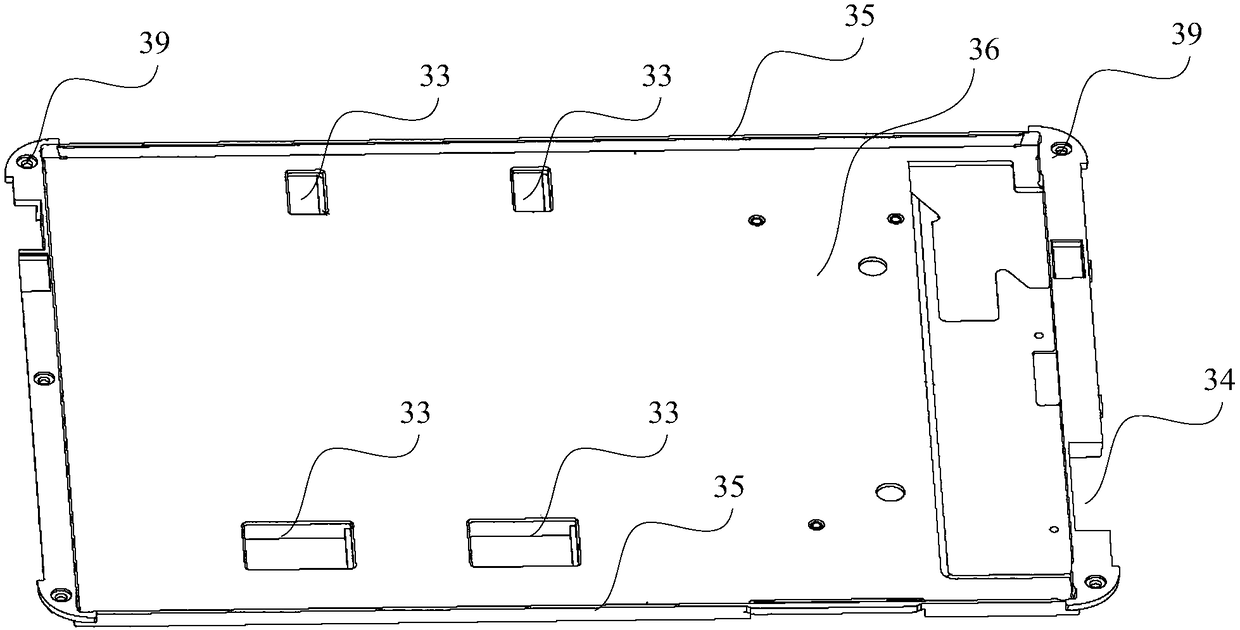

PendingCN109391715AHigh strengthImprove assembly positioning accuracyTelephone set constructionsPlastic materialsComputer terminal

The embodiment of the invention, which relates to the technical field of the structural design of a mobile terminal, discloses a mobile terminal with a metal bracket. The mobile terminal comprises a front shell having an inner frame, a display screen module having a display frame connected with the inner frame in a matching manner, a rear shell, and a metal bracket. The rear shell is made of a plastic material based on injection moulding and includes a support member and a connecting member that are formed by injection moulding. The metal bracket arranged between the display screen module andthe rear shell includes a sinking portion, a rigid connecting portion and a fitting portion; and the metal bracket that fixes and the supports the display screen module by the sinking portion is in rigid connection with the rear shell by the rigid connecting portion and is in fitting connection with the front shell by the fitting portion. Therefore, the structural strength of the mobile terminal is improved.

Owner:SHENZHEN ZHANGYUE TECH CO LTD +1

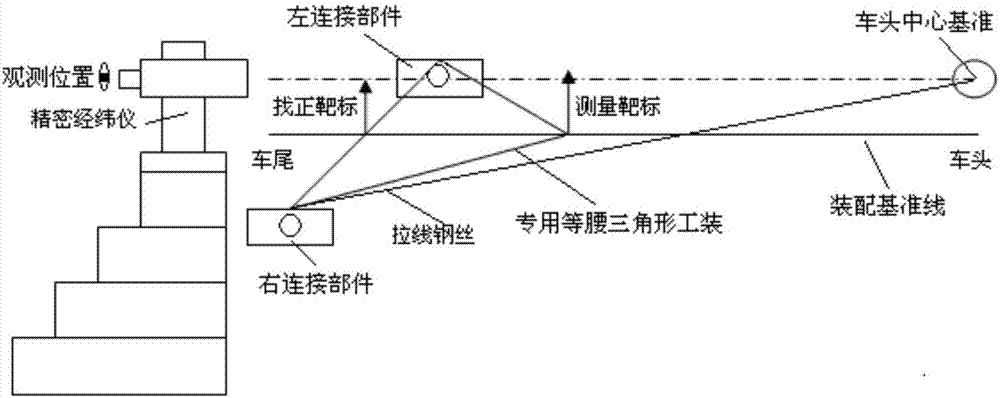

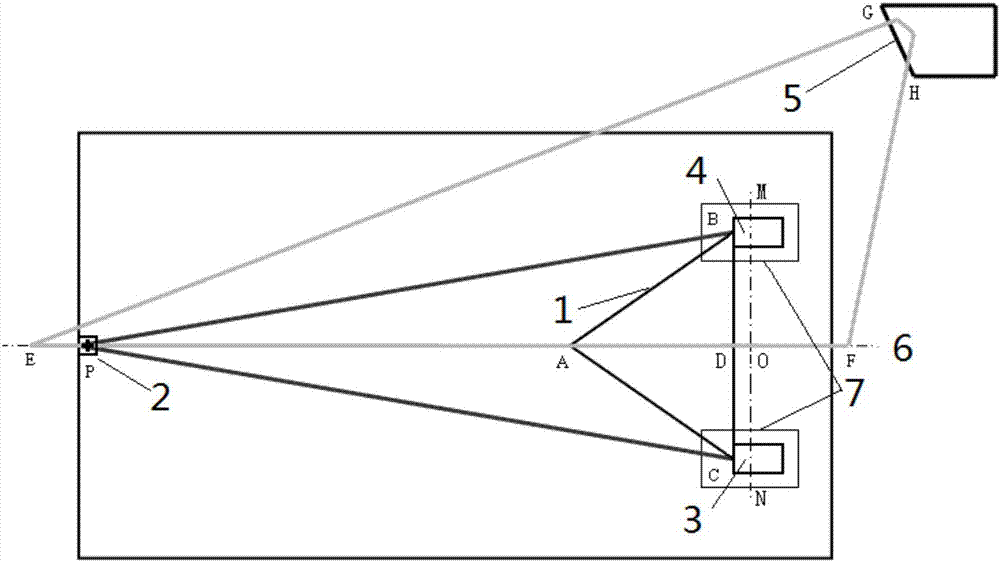

Laser positioning measuring system and method

ActiveCN107272009AHigh precisionStrong anti-interference abilityElectromagnetic wave reradiationLaser rangingEngineering

The invention discloses a laser positioning measuring system used to build a vehicle assembly baseline. The system comprises an isosceles triangle tooling fixed at a predetermined position of a tail of a vehicle body, and a left connecting part and a right connecting part of a vehicle are located at both sides of the bottom of the isosceles triangle tooling. The system also comprises a first laser range finding positioning device and a second laser range finding positioning device mounted on both sides of the bottom of the isosceles triangle tooling and symmetrical to each other, and a laser marking device. The invention also discloses a laser positioning measuring method.

Owner:BEIJING XINLI MACHINERY

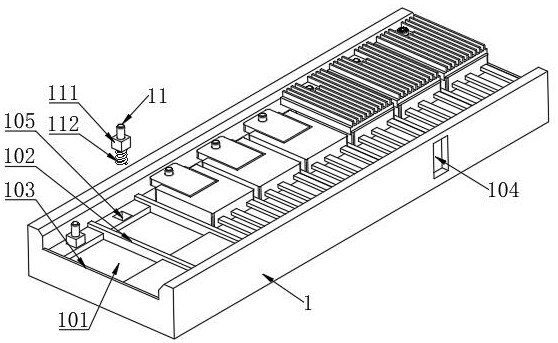

Triode cooling fin assembling clamp and equipment

ActiveCN114851117AImprove assembly positioning accuracyImprove assembly efficiencyFinal product manufactureWork holdersHeat sinkSemiconductor

A triode radiating fin assembling clamp and equipment belong to the technical field of equipment for manufacturing semiconductors, the assembling clamp comprises a mounting plate, and the top surface of the mounting plate is provided with a plurality of accommodating grooves. A positioning pin is arranged at one end of each containing groove and movably arranged in the direction perpendicular to the top face of the mounting plate. Triode cooling fin assembling equipment comprises a conveying mechanism, a feeding mechanism, a feeding mechanism, a locking mechanism and an assembling clamp. The feeding mechanism is used for placing triodes in the containing groove, the feeding mechanism is used for assembling cooling fins to the triodes located in the containing groove, and the locking mechanism is used for assembling the triodes and the cooling fins and locking the connecting screws. The conveying mechanism is used for conveying the mounting plates and simultaneously drives the at least two mounting plates to move. The assembling clamp can improve the assembling and positioning precision of the cooling fins and the triodes, and assembling equipment is simple in structure and high in automation degree.

Owner:四川晁禾微电子有限公司

Combined continuous fiber reinforced composite blade propeller for ships

The invention belongs to the technical field of propellers and relates to a propeller with combined continuous fiber reinforced composite blades, in particular to a propeller with combined continuous fiber reinforced composite blades for a ship. The propeller with the combined continuous fiber reinforced composite blades for the ship is characterized in that the assembly surfaces of dovetail grooves in a propeller hub and blade roots are planes, and thus the assembly positioning precision of the dovetail grooves and the blade roots is high; the blades are inserted from large ends of the dovetail grooves in the propeller hub, then an end cap is fixed to the propeller hub to exert fastening force so as to mount the blades in position, thus mounting is convenient, and the composite blades are not damaged; the space between the dovetail grooves and the blades is filled with resin adhesive, the end cap and the propeller hub are fixed, the blades are not loosened, dropped or damaged under a working condition after testing, and thus the propeller has high reliability; and the structure, performance and manufacturing features of the composite blades are fully taken into account in the aspect of designing of the dovetail grooves in the propeller hub, and thus the blades are suitable for various immersion propellers and water surface propellers.

Owner:AVIC BASIC TECH RES INST

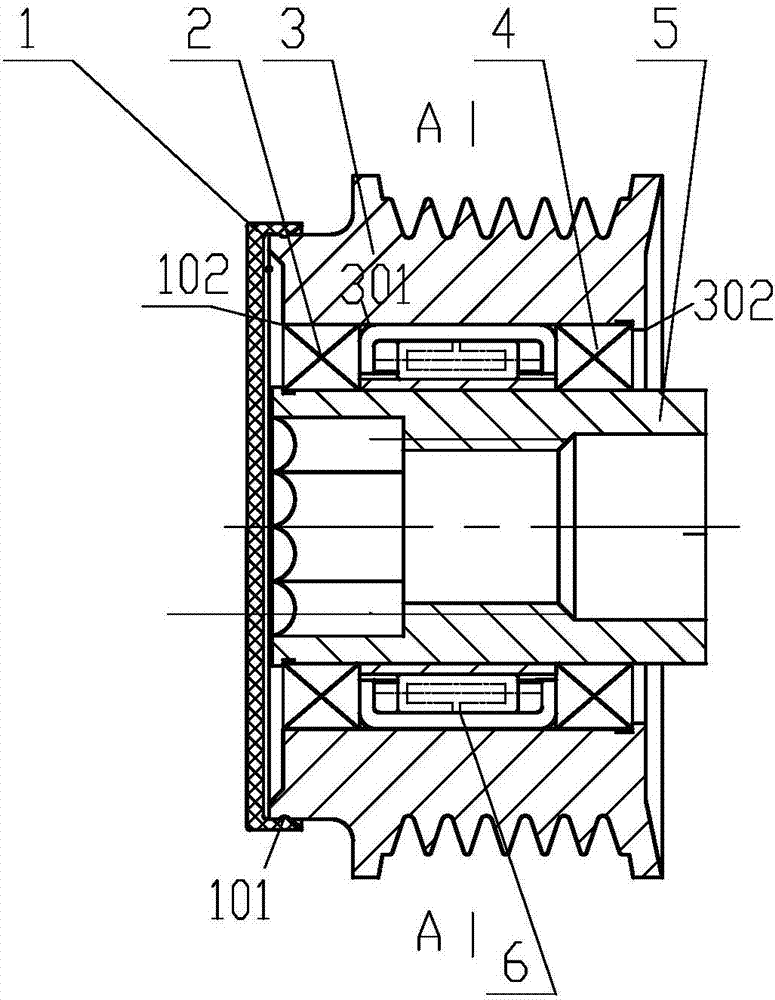

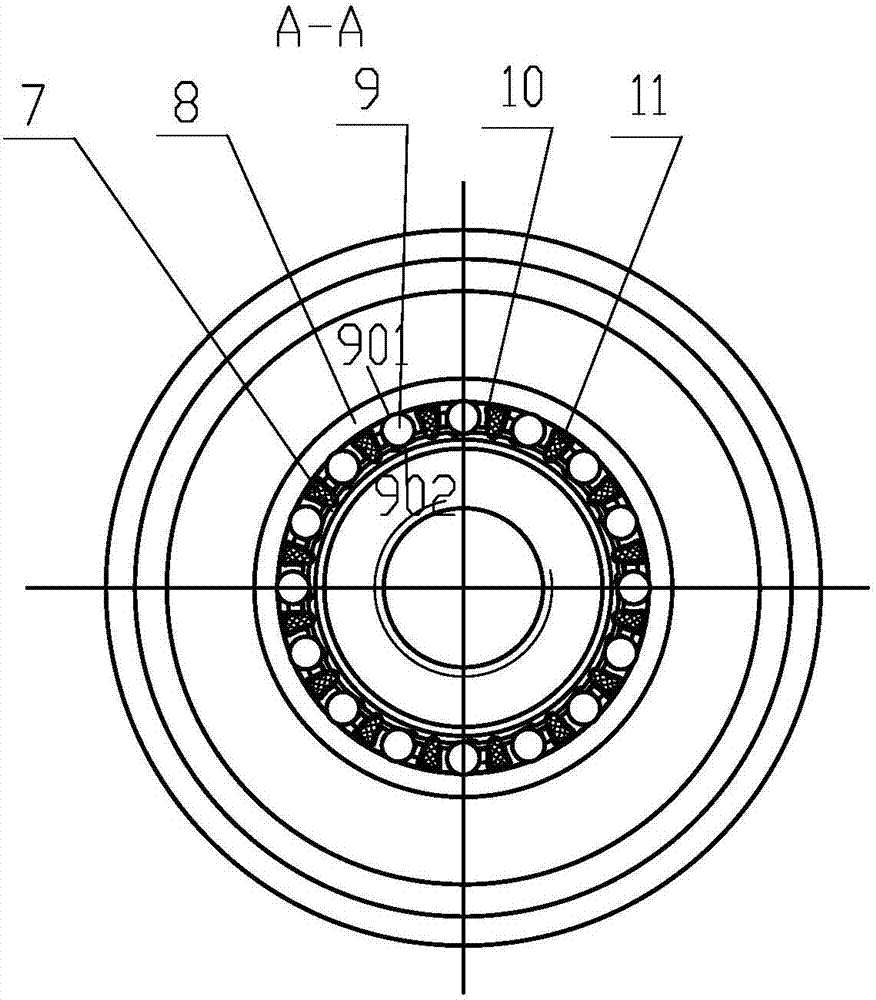

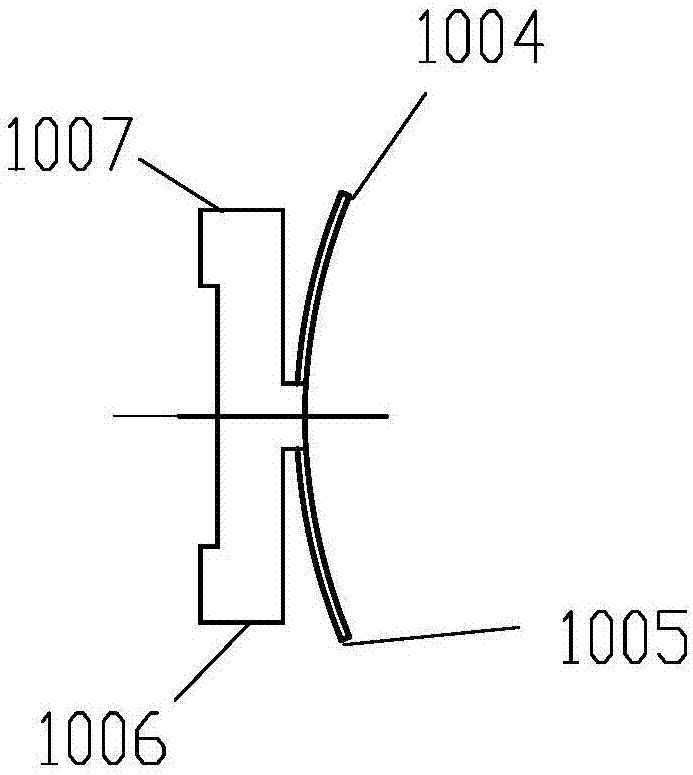

Roller friction type one-way belt wheel

PendingCN106884965ALarge deformationAvoid breakingPortable liftingGearing elementsClassical mechanicsEngineering

The invention relates to a one-way belt wheel, in particular to a roller friction type one-way belt wheel for an automobile generator. The roller friction type one-way belt wheel comprises a belt wheel body and a sleeve, wherein the belt wheel body is arranged on the outer ring of the sleeve in a sleeving mode, the belt wheel body and the sleeve are coaxially arranged, and a first positioning bearing and a second positioning bearing are sequentially arranged in the inner hole of the belt wheel body in the axial direction. The roller friction type one-way belt wheel is characterized in that a one-way clutch assembly is arranged between the first positioning bearing and the second positioning bearing and comprises an inner ring, an outer ring, rollers, supporting springs and retainers, wherein the inner ring is tightly arranged on the outer circle of the sleeve in a sleeving mode, a plurality of grooves are uniformly formed in the surface of the inner ring, every two adjacent grooves are connected through an arc-shaped groove, each groove is provided with an arc-shaped working face, and the circle center corresponding to each arc-shaped working face is deviated from the center of the inner ring. According to the belt wheel, the problems of friction heating and fracturing of the supporting springs can be avoided, the noise can be effectively reduced, and the service life of the one-way belt wheel can be prolonged.

Owner:无锡市神力齿轮冷挤有限公司

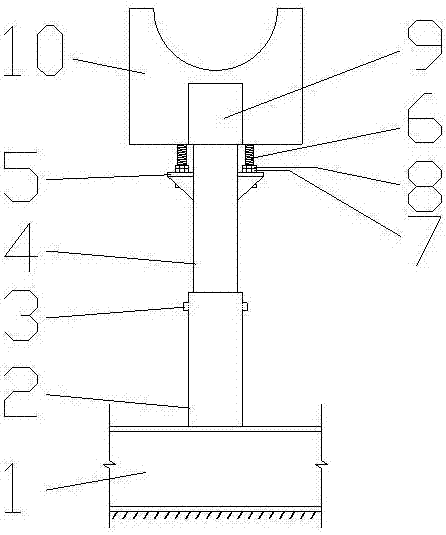

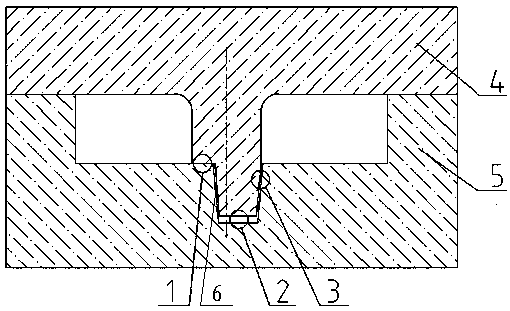

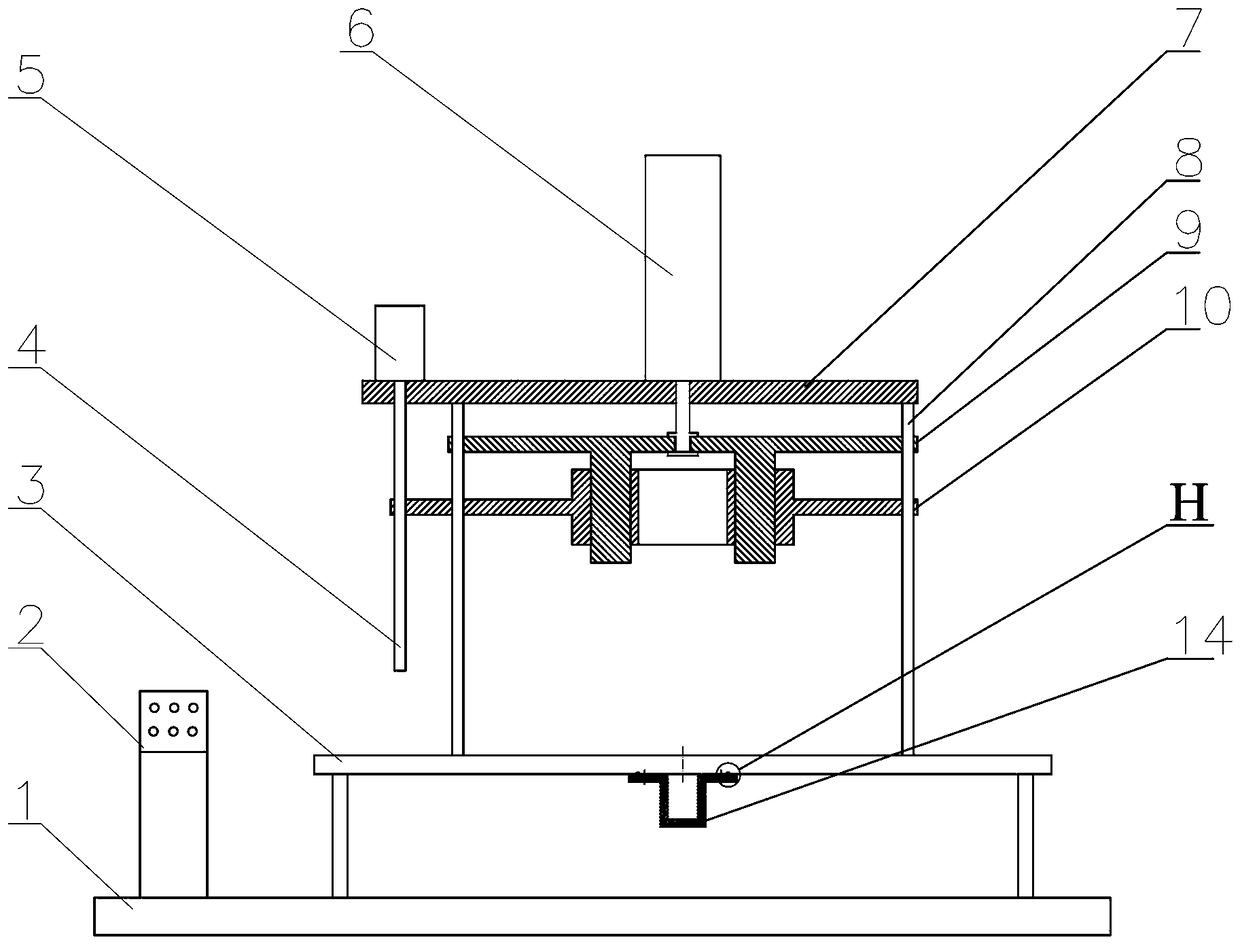

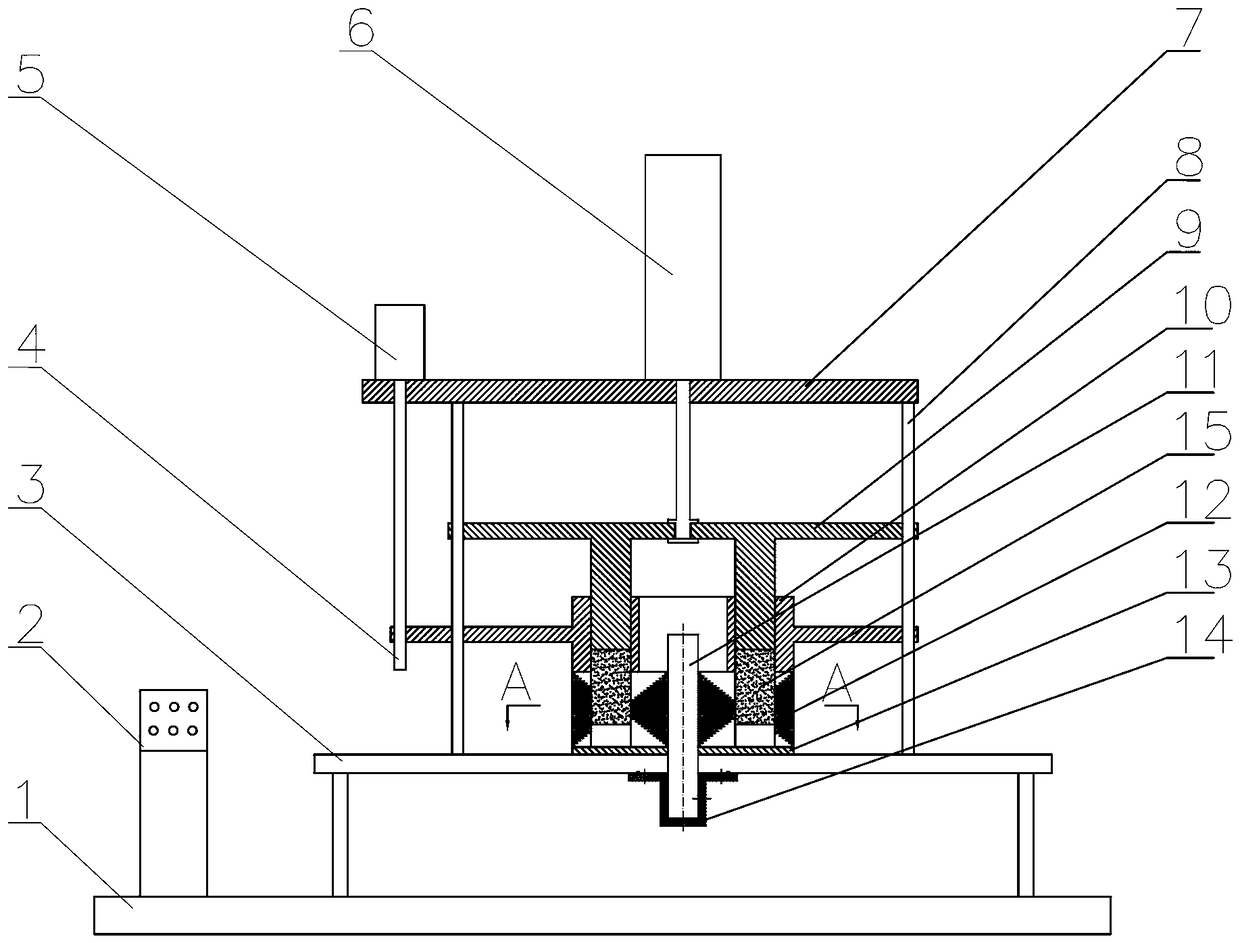

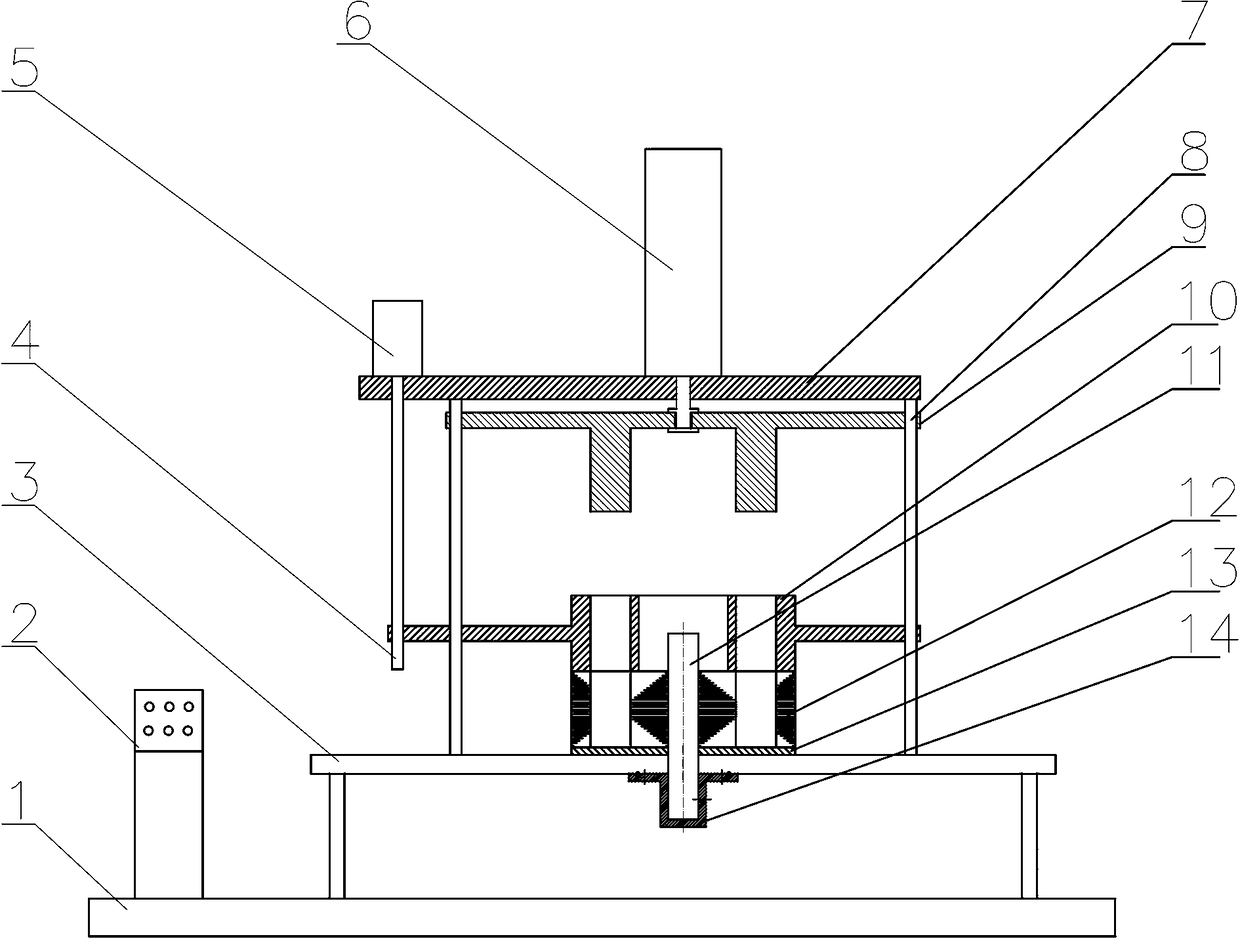

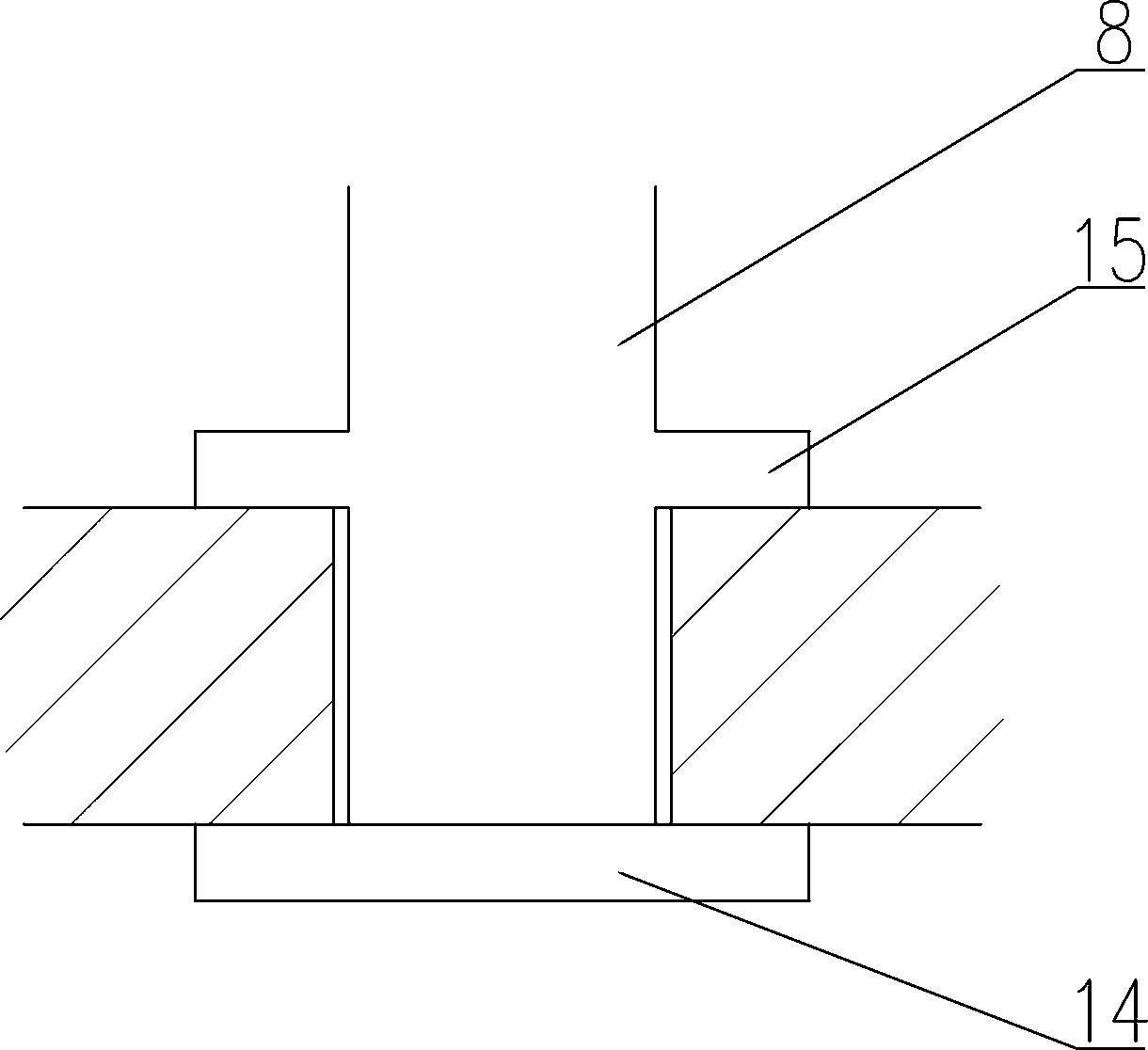

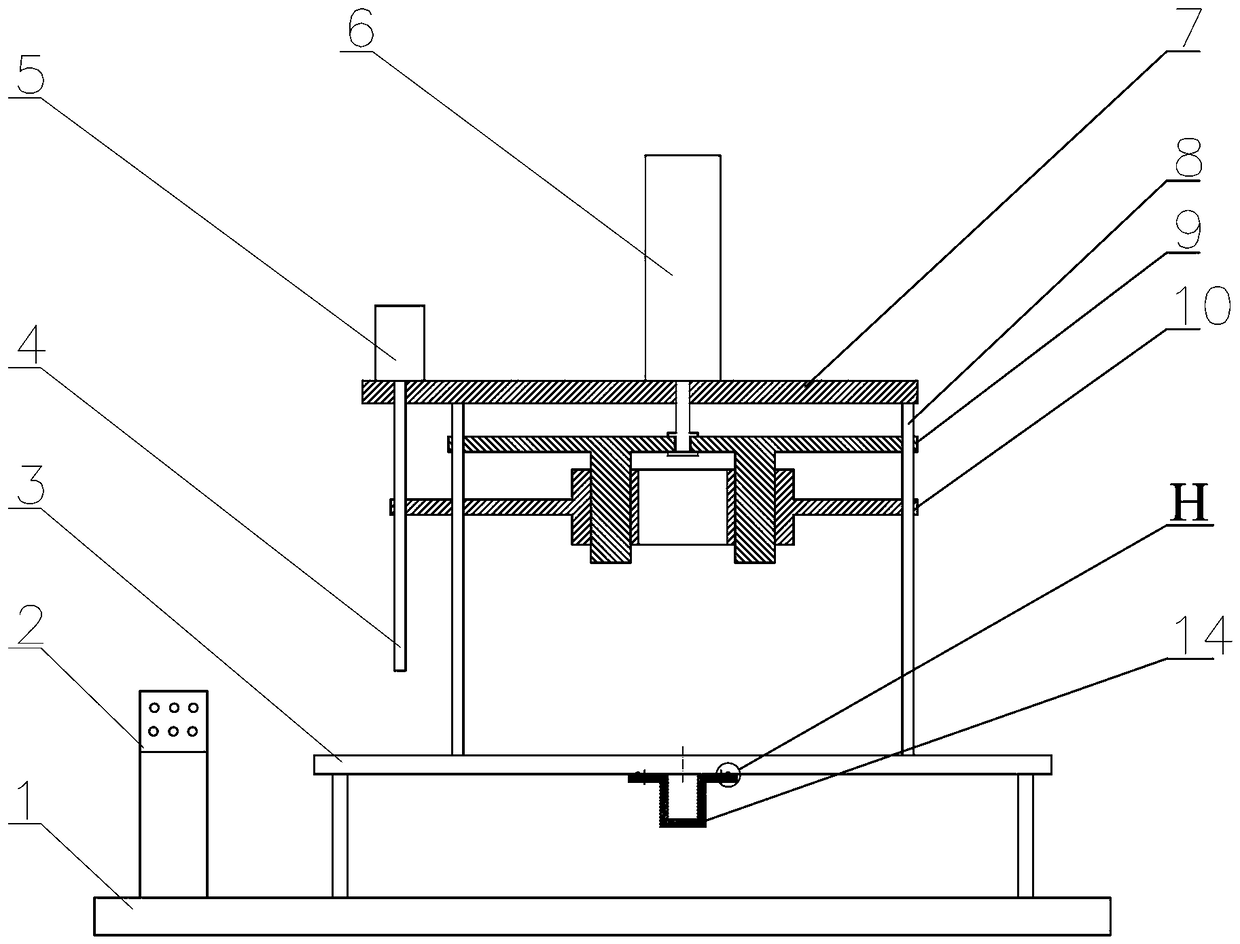

Assembly device and assembly method for permanent magnet of internal V-shaped permanent magnet motor

InactiveCN108258859ASimple structureEasy to install and maintainManufacturing stator/rotor bodiesArchitectural engineeringPermanent magnet motor

The invention relates to an assembly device and assembly method for a permanent magnet of an internal V-shaped permanent magnet motor. The assembly device comprises a fixing portion and a feeding portion; the fixing portion comprises a bottom plate, a workbench, a linear guide rail and a fixing end plate, the workbench is perpendicularly fixed to the upper end of the horizontal bottom plate, the lower end of the linear guide rail is connected with the workbench, and the upper end of the linear guide rail is connected with the fixing end plate; the feeding portion comprises a motor, a screw rod, a permanent magnet guide groove, a pneumatic device and a permanent magnet pushing guide block. The motor is fixed to the upper end of the fixing end plate, the screw rod is arranged at the lower end of the motor and connected with the permanent magnet guide groove, the motor and the screw rod rotate to drive the permanent magnet guide groove to slide up and down along the linear guide rail, thepneumatic device is fixed to the upper end of the fixing end plate and connected with the permanent magnet pushing guide block through a push rod, and the permanent magnet pushing guide block can bedriven to slide up and down along the linear guide rail. The problem of high difficulty in assembly of the permanent magnet of the internal V-shaped permanent magnet motor is solved.

Owner:SHENYANG POLYTECHNIC UNIV

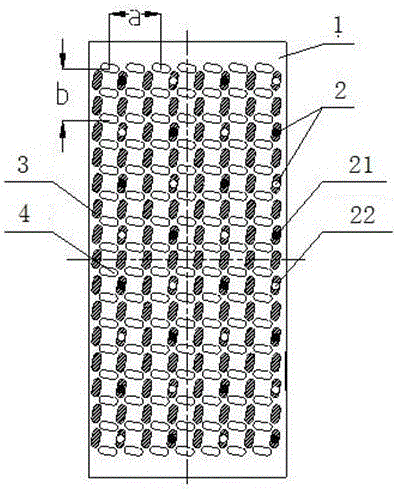

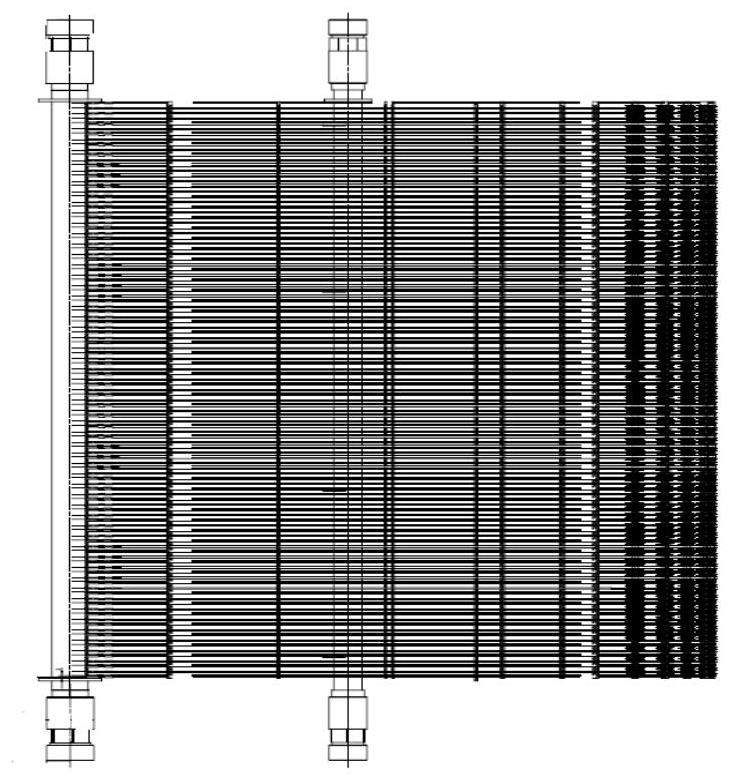

Heat exchanger plate set positioning device

InactiveCN106017190AImprove assembly positioning accuracyOvercome plate deformation and misalignmentWelding/cutting auxillary devicesAuxillary welding devicesDislocationEngineering

The invention discloses a heat exchanger plate set positioning device. The device is provided with multiple rows of projected or recessed ripples in each plate heat exchange area; and after plates are assembled, the projected ripples of one plate are buckled with the recessed ripples of the adjacent plates to limit the moving dislocation of the adjacent plates so as to realize a positioning function of a heat exchanger plate set. The positioning device improves the plate assembly precision, effectively prevents the leakage problem of the plate set caused by dislocation between the adjacent plates under high-temperature or high-pressure and alternating load operation environment, and has the advantages of improvement of the pressure bearing capacity of the plate set and prolonging of the service life of the plate set.

Owner:GANSU LANPEC TECH +2

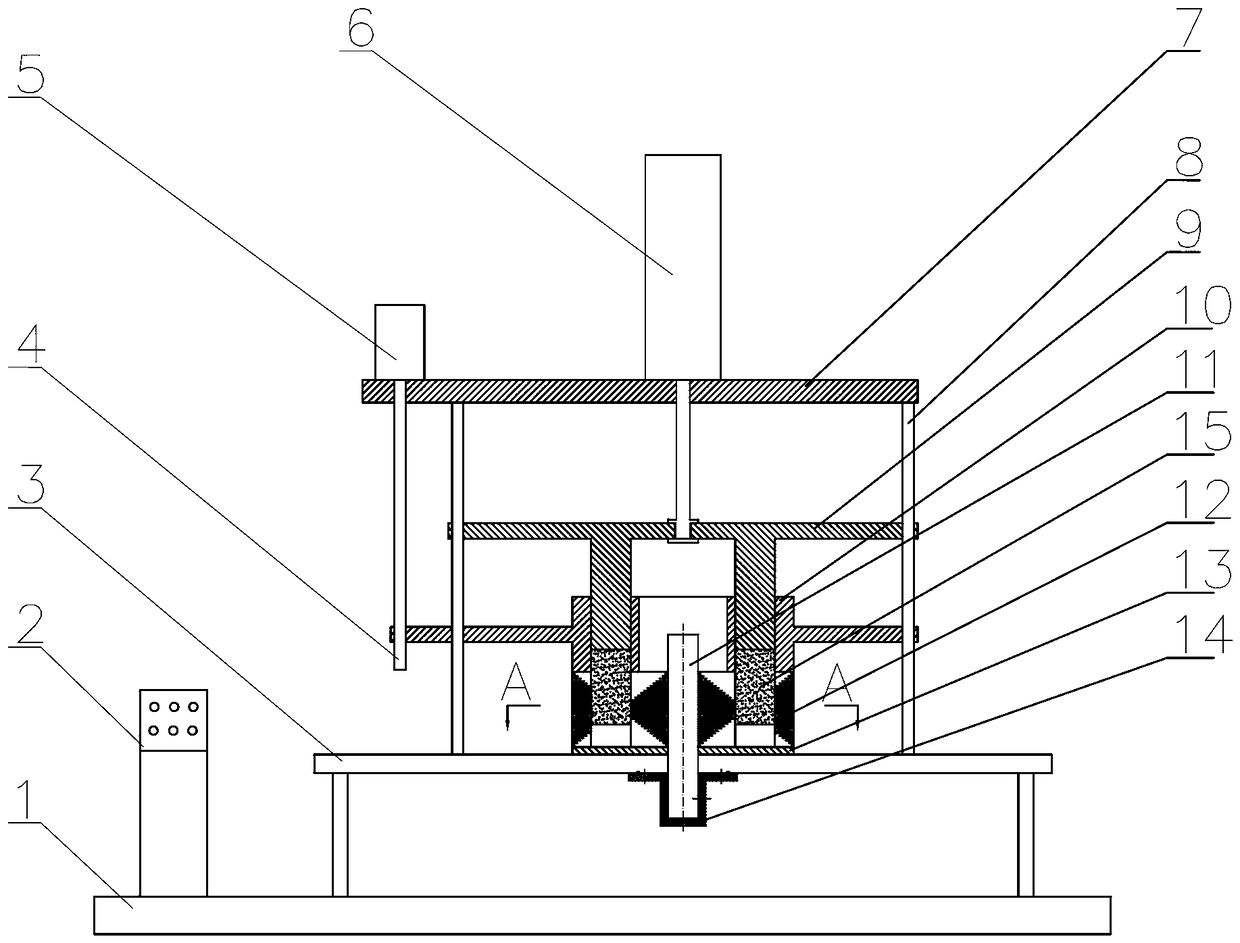

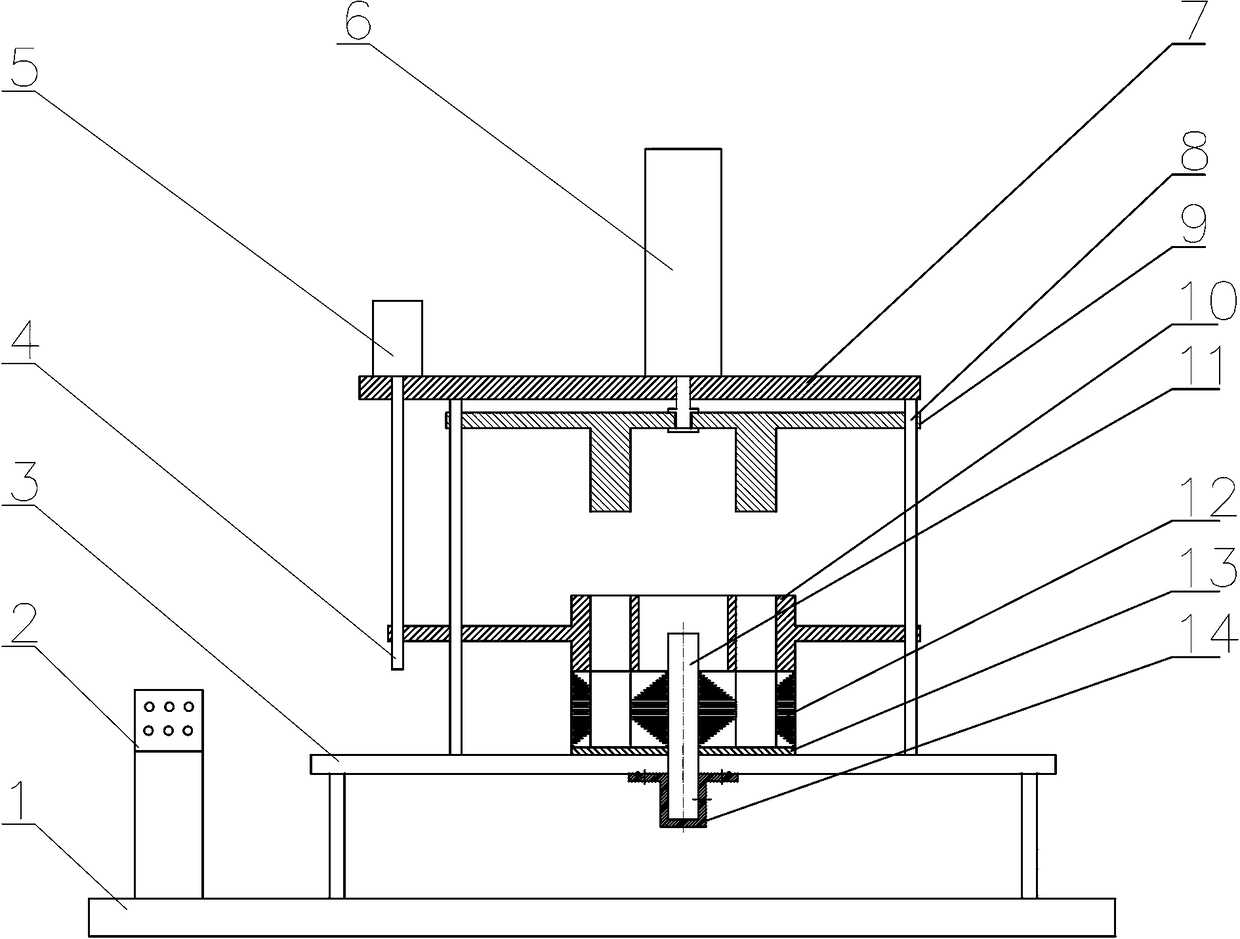

Built-in V I-type permanent magnet motor permanent magnet assembling device and assembling method

InactiveCN108199544ASimple structureEasy to install and maintainMagnetic circuit rotating partsManufacturing stator/rotor bodiesArchitectural engineeringPermanent magnet motor

The invention relates to a built-in V I-type permanent magnet motor permanent magnet assembling device and an assembling method. The device comprises a fixing part and a feeding part, wherein the fixing part comprises a bottom plate, a working table, a linear guide rail, and a fixing end plate; the working platform is vertically fixed at the upper end of the horizontal bottom plate; the lower endof the linear guide rail is connected with the working table; the upper end of the linear guide rail is connected with the fixing end plate; the feeding part comprises a motor, a screw rod, permanentmagnet guide grooves, a pneumatic device and a permanent magnet push guide block; the motor is fixed at the upper end of the fixing end plate; the lower end of the motor is provided with the screw rod; the screw rod is connected with the permanent magnet guide grooves; the motor and the screw rod rotate to drive the permanent magnet guide grooves to vertically slide along the linear guide rail; the pneumatic device is fixed at the upper end of the fixing end plate; and the pneumatic device is connected with the permanent magnet push guide block through a push rod and can drive the permanent magnet push guide block to vertically slide along the linear guide rail. The problem of large assembling difficulty of the built-in V I-type permanent magnet motor permanent magnet can be solved.

Owner:SHENYANG POLYTECHNIC UNIV

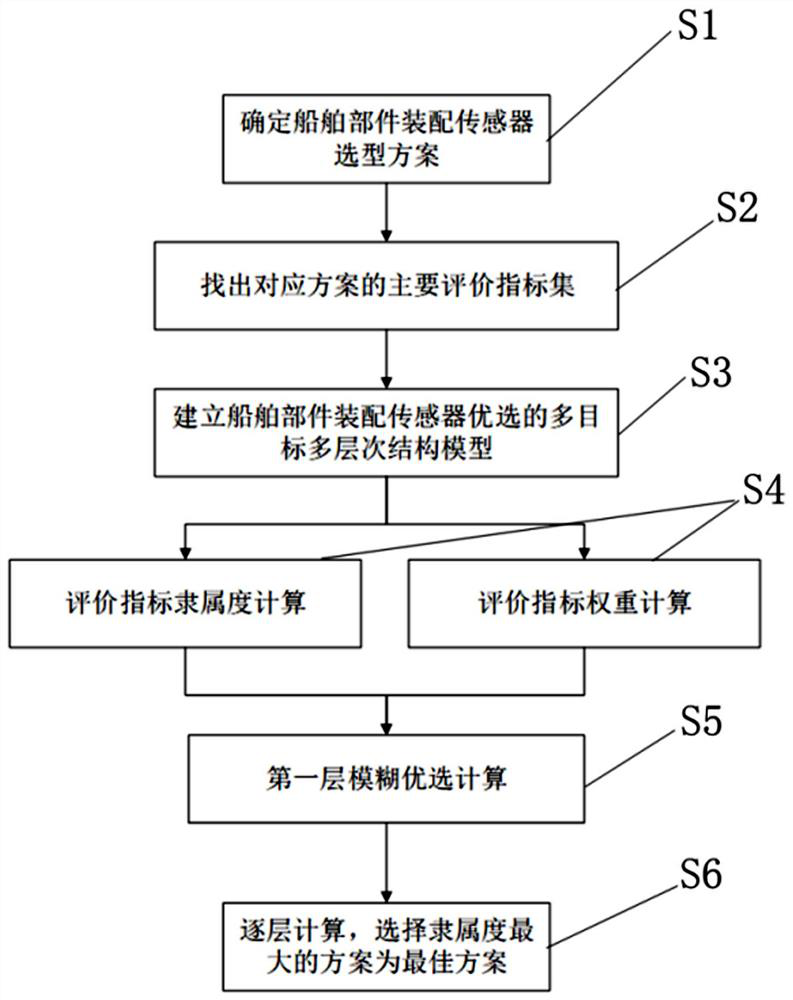

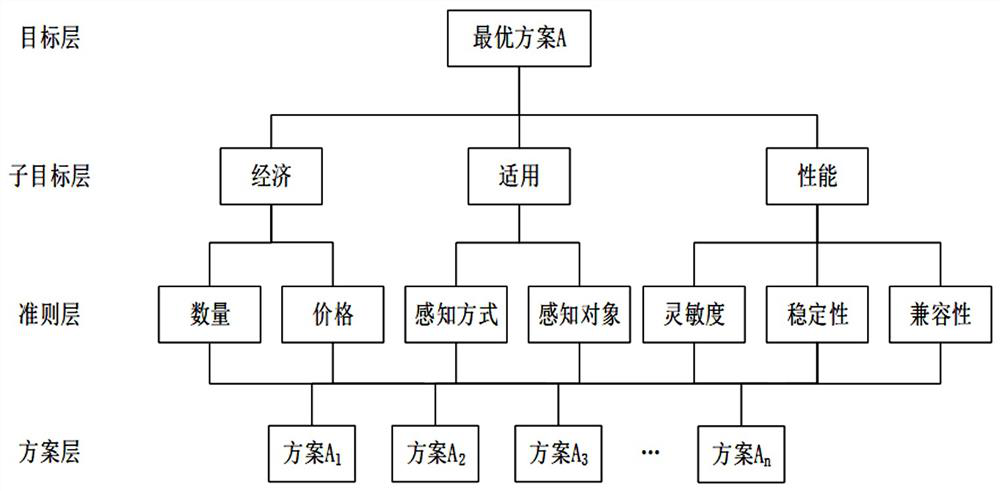

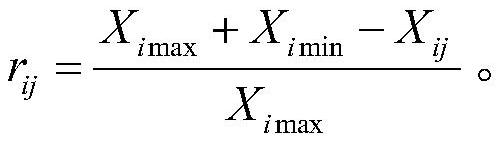

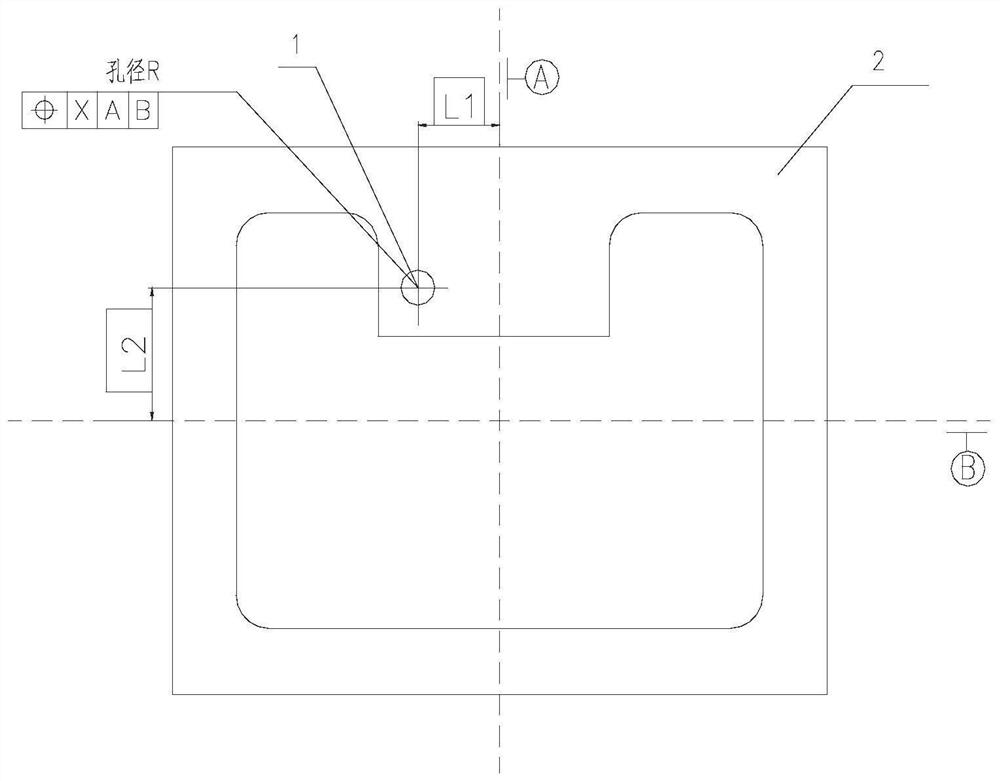

Sensor fuzzy optimization method for accurate positioning of ship component assembly

PendingCN113742843AChoose accuratelyImprove assembly positioning accuracyGeometric CADDesign optimisation/simulationControl engineeringAssembly cells

The invention provides a sensor fuzzy optimization method for accurate positioning of ship component assembly. The method comprises the following steps: determining a ship component assembly unit sensor type selection scheme; finding out an evaluation index set of a corresponding scheme; classifying and layering all evaluation indexes, and establishing a multi-target multi-layer structure model of the ship component assembly sensor; determining the membership degrees of all indexes in the model and the weight of each layer, and calculating the membership degrees and the weights of evaluation indexes; using the target layer as a first layer of the structure, enabling the membership degree corresponding to each index in the first layer to form a first layer fuzzy optimization membership degree matrix, calculating the fuzzy optimization membership degree of the first layer, giving an index weight set of the first layer, and obtaining the fuzzy optimization membership degree of the layer; and descending layer by layer from the first layer, performing fuzzy operation on each layer until the bottommost layer obtains the membership degrees of all the schemes, and selecting the scheme with the maximum membership degree as the optimal scheme according to the maximum membership degree principle.

Owner:SHANGHAI SHIPBUILDING TECH RES INST

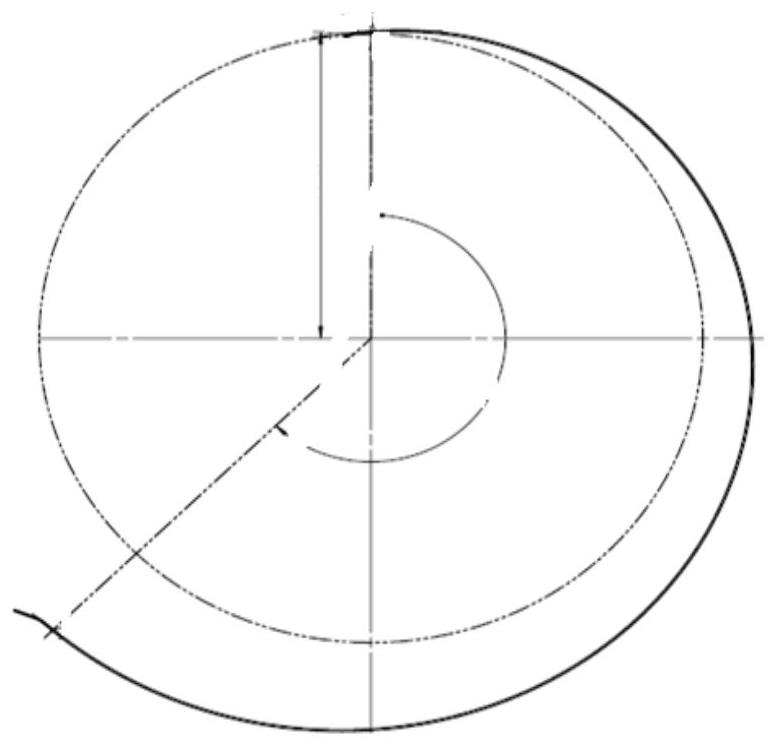

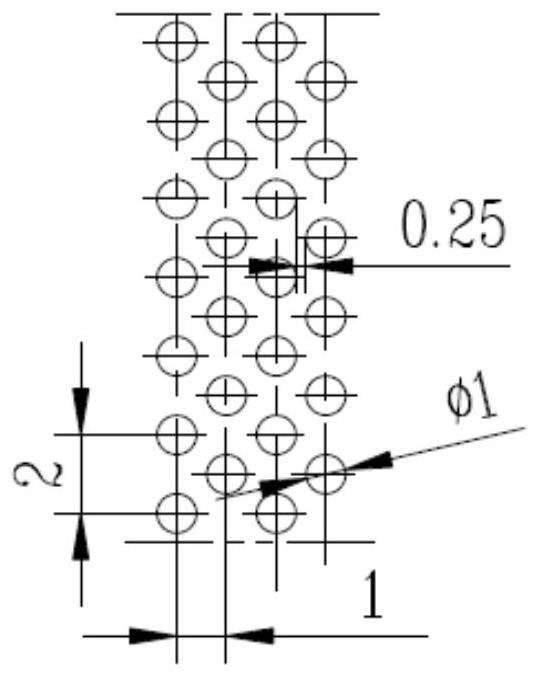

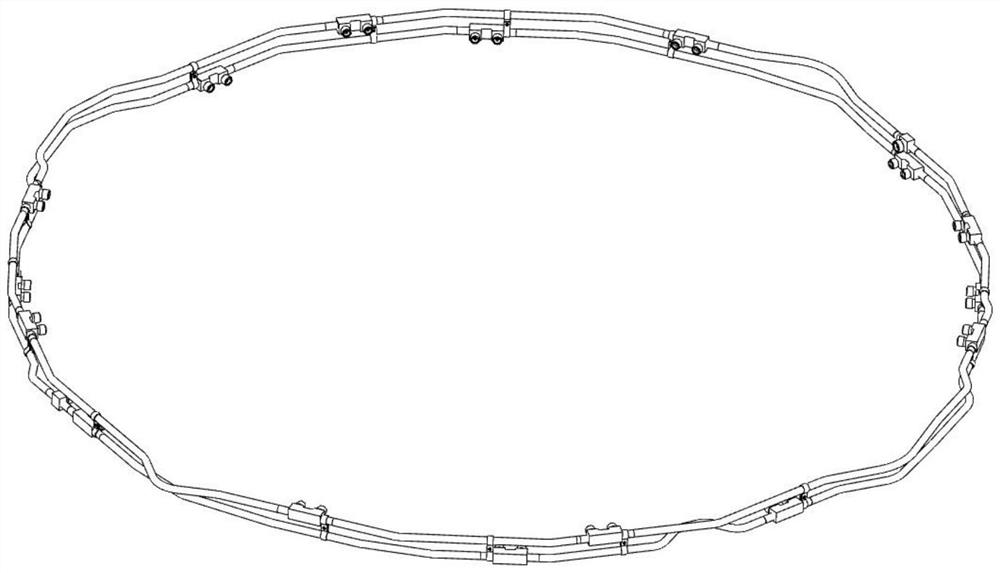

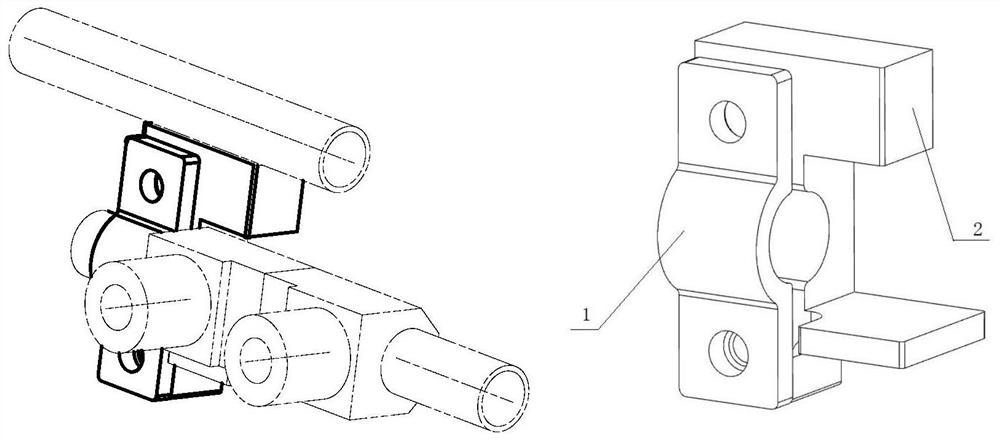

Microcapillary membrane assembling, positioning and welding tool based on C-shaped positioning wire

ActiveCN114473117AMeet the design requirementsPrecise positioningMetal working apparatusTubular articlesEngineeringMechanical engineering

The invention discloses a microcapillary membrane assembling, positioning and welding tool based on C-shaped positioning wires. The microcapillary membrane assembling, positioning and welding tool comprises an upper positioning mechanism, an upper positioning disc, a stand column, a lower positioning disc and a lower positioning mechanism. The upper positioning disc is supported on the lower positioning disc through three or more stand columns, and the three or more stand columns are evenly arranged in the circumferential direction of the disc body. An upper positioning mechanism and a lower positioning mechanism are installed on the upper positioning disc and the lower positioning disc respectively and used for being jointly connected with a plurality of C-shaped positioning wires and achieving tensioning of each C-shaped positioning wire. Wherein the C-shaped positioning wire is used for assembling, positioning and welding a microcapillary membrane, and the C-shaped positioning wire is formed by uniformly pressing a plurality of C-shaped grooves in the single side of a positioning wire blank along the axial direction through a C-shaped positioning wire forming tool.

Owner:BEIJING POWER MACHINERY INST

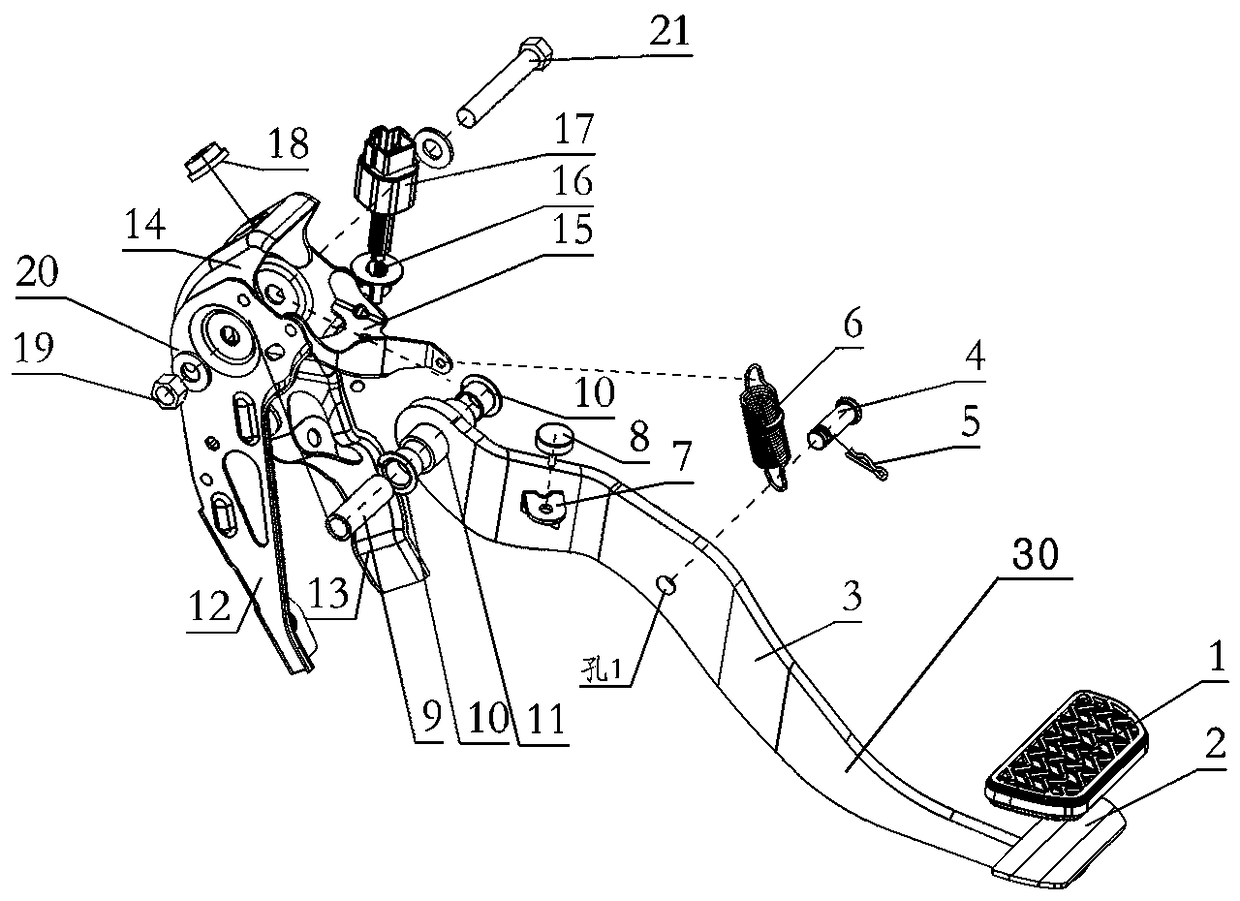

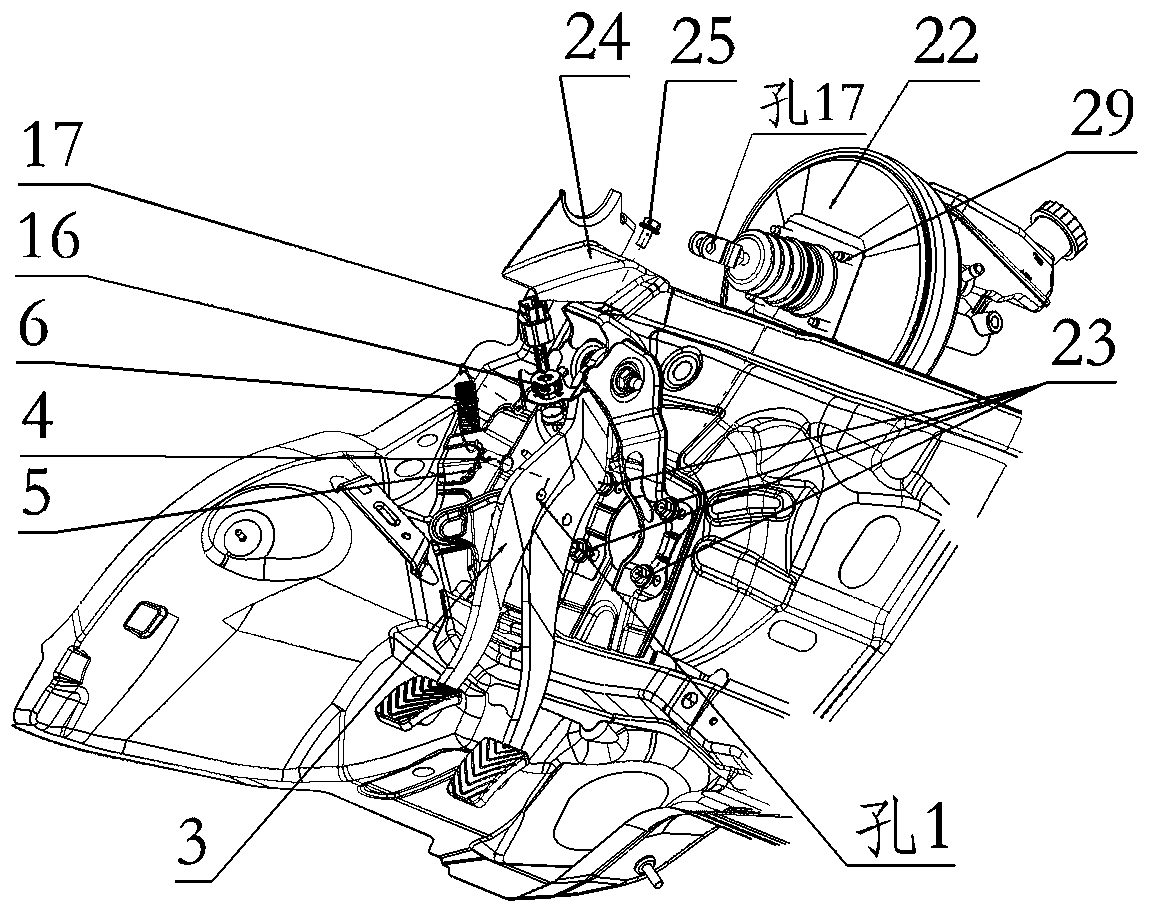

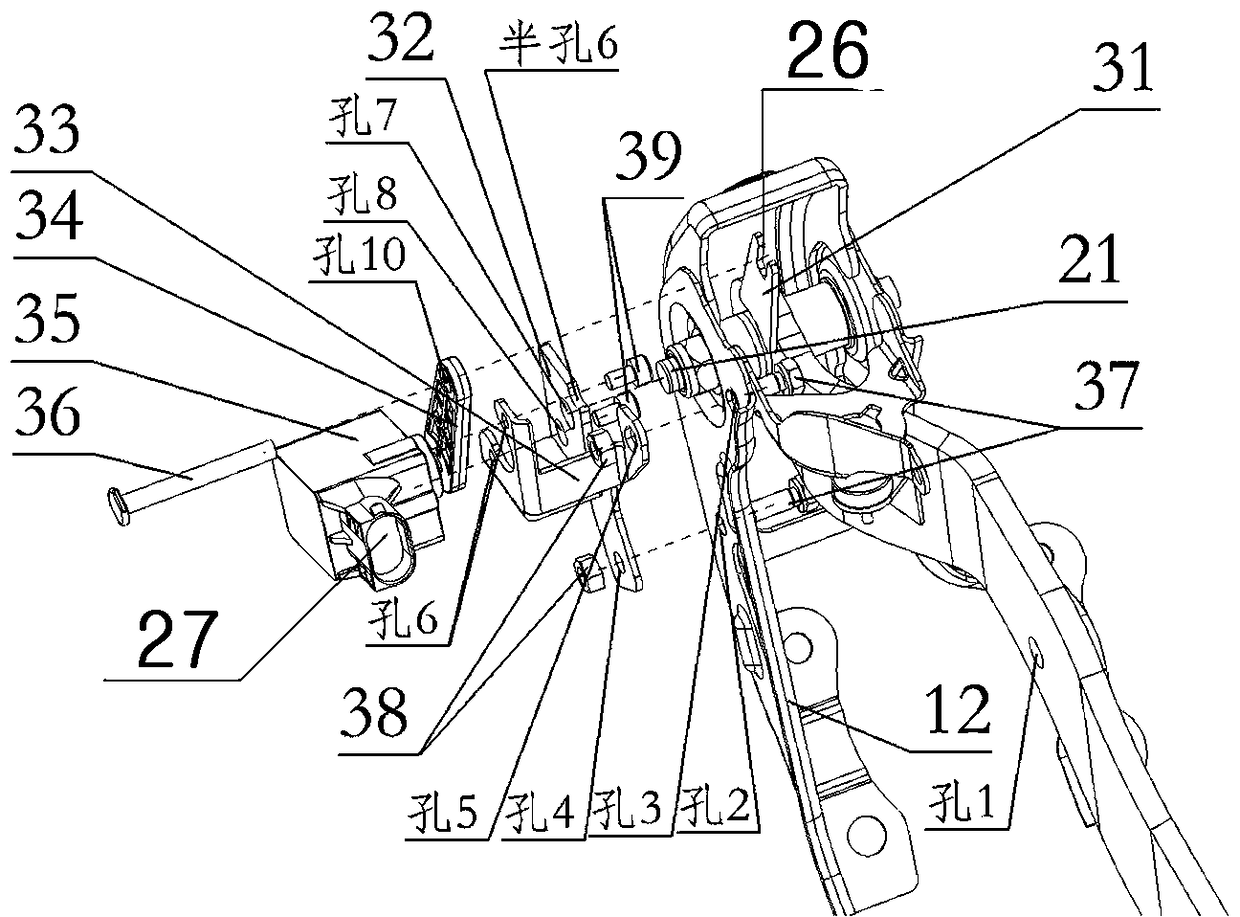

Brake pedal assembly with steering angle sensor

PendingCN108944847AImprove assembly positioning accuracyAvoid damageFoot actuated initiationsBrake safety systemsRocker armSensor holder

The invention relates to a brake pedal assembly with a steering angle sensor. The left side of a brake pedal body is connected with the steering angle sensor through two sensor supports. The steeringangle sensor comprises a rocker arm, a pipe shaft, an electrical pull port, a rotary shaft, a double-screw bolt, a threaded hole and multiple round holes. The pipe shaft is pressed in a hole of the rocker arm and matched with a shifting fork open slot welded to a pedal arm, the front end of the double-screw bolt penetrates through a hole of the sensor support II to be matched with the threaded hole of the steering angle sensor, the steering angle sensor, the sensor support I and the sensor support II are fixed together, and the electrical pull port outputs a brake pedal steering angle signal.The pedal steering angle sensor is additionally arranged so as to provide a pedal steering angle signal, the assembling accuracy of the steering angle sensor is effectively improved, the structure issimple, design is reasonable, and installation is convenient.

Owner:BRILLIANCE AUTO

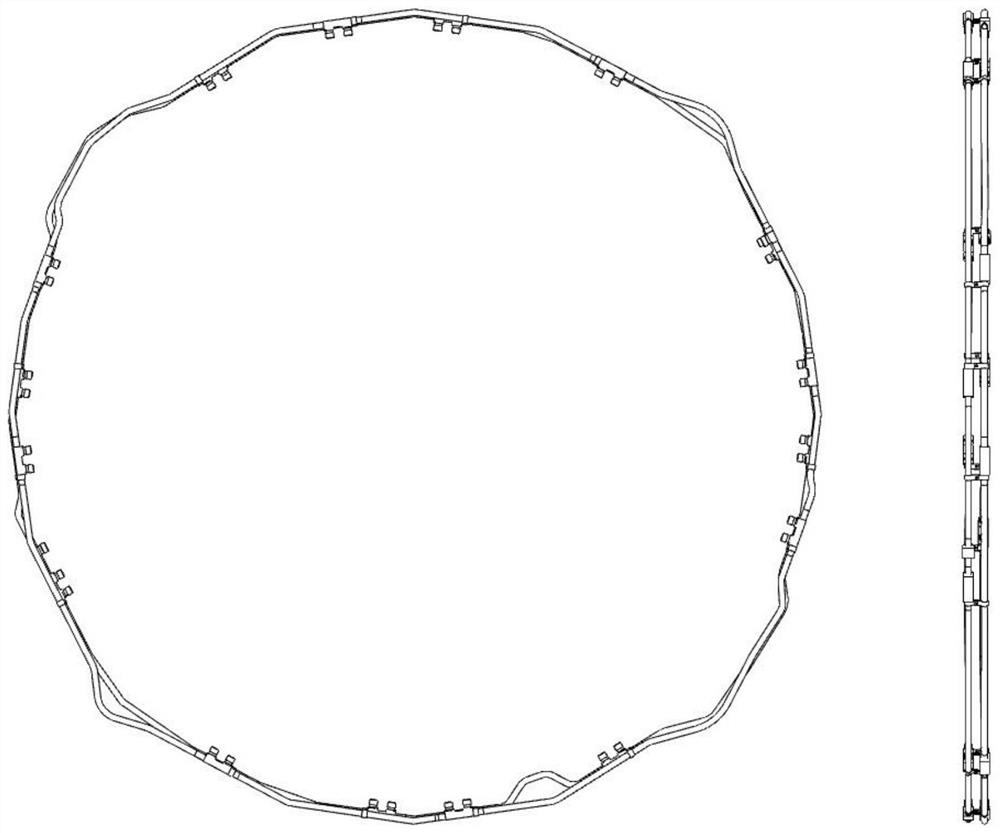

Engine complicated structure ring pipe positioning repairing method

ActiveCN111618520AGuaranteed Space Location RequirementsImprove assembly positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringProduction cycle

The invention provides an engine complicated structure ring pipe positioning repairing method. Mutually buckled positioning clamping blocks are used to fix T-junctions and four-way joints on ring pipes; the buckling positions form a cylindrical through hole which is parallel to the plane where the ring pipes are positioned; when a positioning clamping block fixes a T-junction and a ring pipe, or fixes the four-way joint and the ring pipe, the ring pipe which is connected with one end of the T-junction or the four-way joint penetrates through the through hole, two side faces, perpendicular to the radial direction of the through hole, of the positioning clamping block abut against an axial end of the T-junction or the four-way joint, the side faces, parallel to the plane where the ring pipeis positioned, of the positioning clamping block press against the adjacent ring pipe, or humps are formed in the side faces, parallel to the plane where the ring pipe is positioned, of the positioning clamping block and an L-shaped angle formed by the humps and the positioning clamping block is close attached to the adjacent ring pipe; and titanium pipes are repaired one by one after the T-junctions and the four-way joints on two ring pipes are fixed. The method can lower the positioning and repairing difficulty of a complicated-structure ring pipe module, shorten the production cycle, guarantee the positioning precision, and improve the assembly consistency of an engine.

Owner:XIAN SPACE ENGINE CO LTD

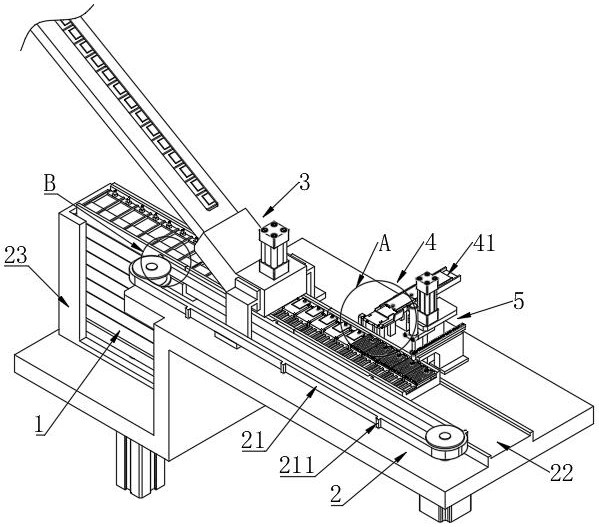

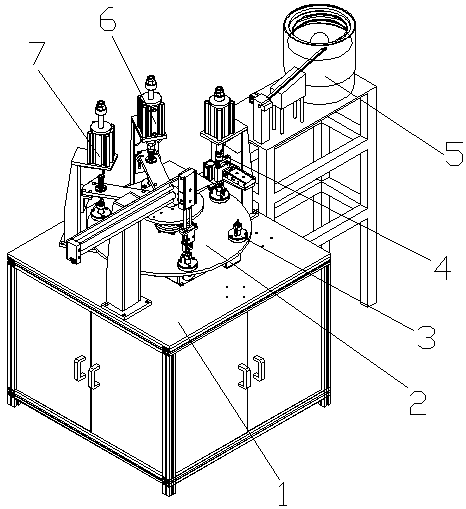

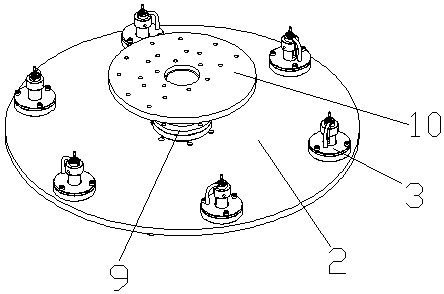

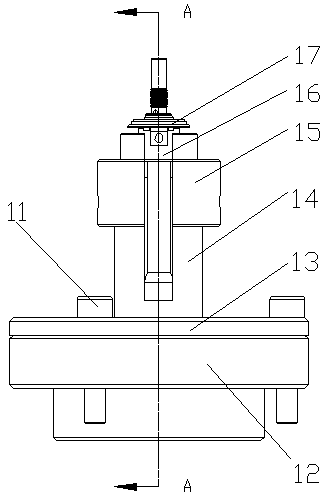

Automatic screw rod valve riveting assembling machine

InactiveCN108672573AImprove assembly positioning accuracyImprove sealingMetal-working feeding devicesPositioning devicesDistribution controlEngineering

The invention relates to valve body assembling equipment, in particular to an automatic screw rod valve riveting assembling machine which comprises a rack, a power distribution control cabinet, as well as a rotary table and a rotary table slicer arranged on the rack and matched with each other, wherein carrier assemblies matched with screw rod valves are arranged on the upper edge of the rotary table at equal intervals; a support shaft fixedly connected with the rack is vertically arranged in the center of the rotary table in a penetrating manner; an upper support disc is fixedly connected with the upper end of the support shaft; a valve tube loading device, a valve tube prepressing device and a valve tube riveting device matched with the carrier assemblies are sequentially arranged on therack in the rotating direction of the rotary table; the valve tube loading device places screw rod valve tubes in the carrier assemblies; the carrier assemblies rotate anticlockwise along with the rotary table and sequentially rotate to the valve tube prepressing device to press the screw rod valve tubes in valve body caps, and the valve tube riveting device carries out riveting on the screw rodvalve tubes and the valve body caps to complete the riveting assembling process of the screw rod valve tubes; and the assembling and positioning precision is high and the sealing effect is excellent.

Owner:DONGGUAN UNIV OF TECH

Touch display device

InactiveCN101859040BEasy to assembleEasy to reworkStatic indicating devicesNon-linear opticsDisplay deviceHuman–computer interaction

The invention relates to a touch display device which comprises a display module, a touch module and an elastic optical film, wherein the touch module is configured above the display module; the elastic optical film has no viscosity and is positioned between the touch module and the display module; and when the touch module is assembled above the display module, the elastic optical film generateselastic deformation to absorb a clearance of a surface between the touch module and the display module.

Owner:华映视讯(吴江)有限公司 +1

An engine timing chain system assembly tool and assembly method

ActiveCN104493787BReduce phase deviationReduced Timing Mark DesignMetal-working hand toolsEngineeringCam

The invention discloses an engine timing chain system assembly tool and an assembly method. The assembly tool comprises a crank timing tool, a cam shaft timing tool and a tensioner tool. Through the adoption of the assembly tool provided by the invention, the assembly positioning accuracy can be effectively improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Pole Plate folding type lead-acid accumulator and its preparing method

InactiveCN1262038CReduce volumeReduce weightFinal product manufactureLead-acid accumulators constructionElectrical polarityLead–acid battery

This invention discloses a folded polar plate lead acid battery and its making method, among which the lead wire connecting two plates is folded into u-shape and monopolar and bipolar plates are arranged in the box in sequence according to the matched polarities, a V-shaped diaphragm wraps both sides of each plate, insulation bag sleeve two adjacent polar plates and the diaphragm warapping the polar plates, realizing internal serials connection by lead wires. The lead acid battery has the advantages of small volume, light weight and good power characteristic.

Owner:SHIJI QIANWANG BATTERY TECH CO LTD BEIJING

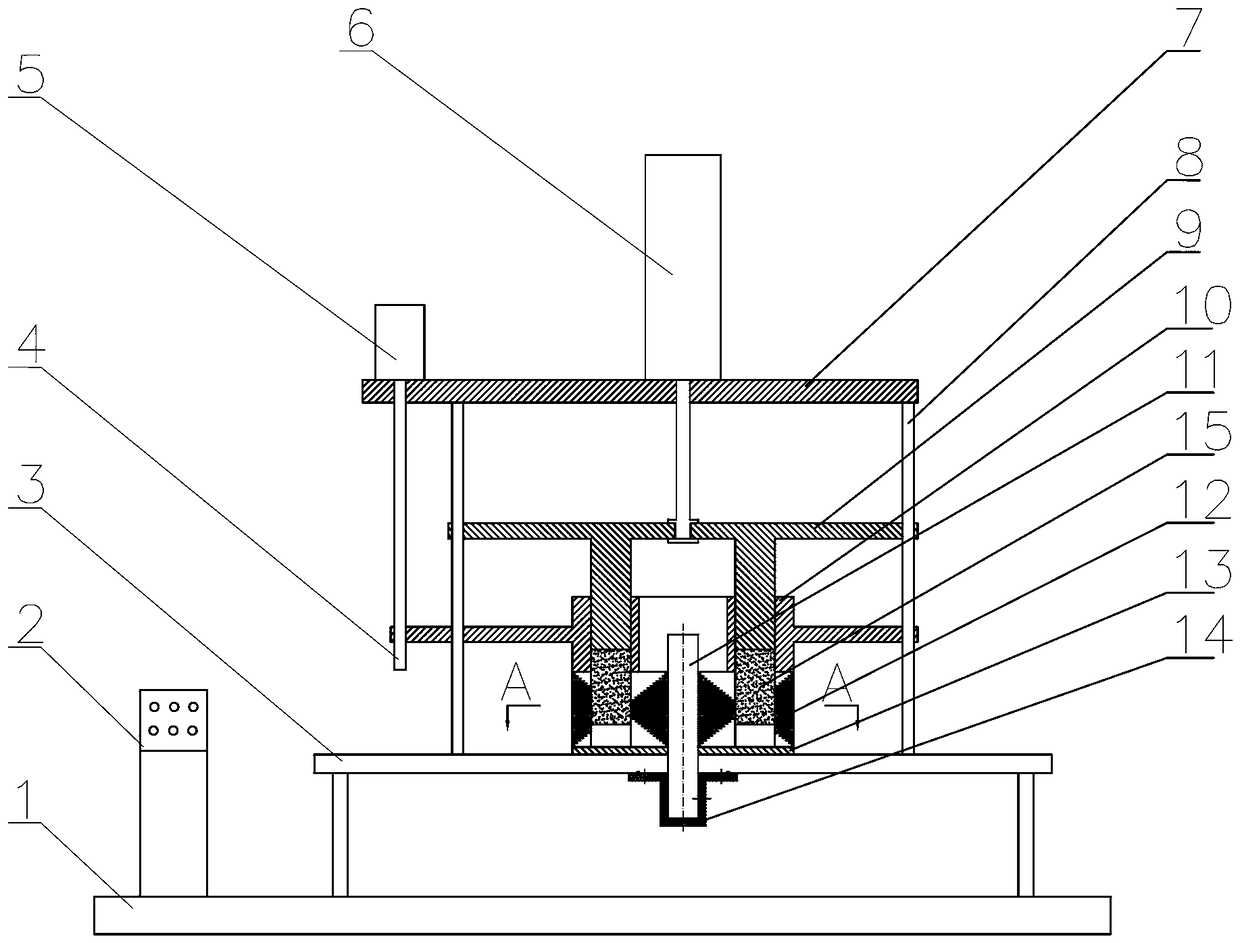

An assembly device and assembly method for permanent magnets of axial flux permanent magnet motors

ActiveCN107612245BImprove assembly positioning accuracyHigh degree of mechanizationManufacturing stator/rotor bodiesEngineeringPermanent magnet motor

The invention relates to an assembly device and an assembly method for permanent magnets of an axial flux permanent magnet motor, comprising a fixed part and a feeding part, the guide pad of the fixed part is located at the upper end of the positioning base plate, and the guide groove is located at the upper end of the guide pad , the upper end of the guide groove is provided with a plurality of vertical connection holes, the lower end of the linear guide rail is located in the connection hole and connected with the guide groove, the vertical direction of the guide groove is provided with a permanent magnet groove, and the side of the permanent magnet groove is also provided with a positioning top The upper end of the linear guide rail is connected with a guide rail fixing plate; the push guide block of the feed part is slidingly connected with the linear guide rail, the upper end of the push guide block is connected with a feed screw, the surface of the feed screw is provided with external threads, and the feed screw Pass through the guide rail fixing plate and thread the guide rail fixing plate, and the upper end of the feed screw is provided with a hand wheel. The invention solves the problem of great difficulty in assembling the permanent magnets of the axial flux permanent magnet motor.

Owner:SHENYANG POLYTECHNIC UNIV

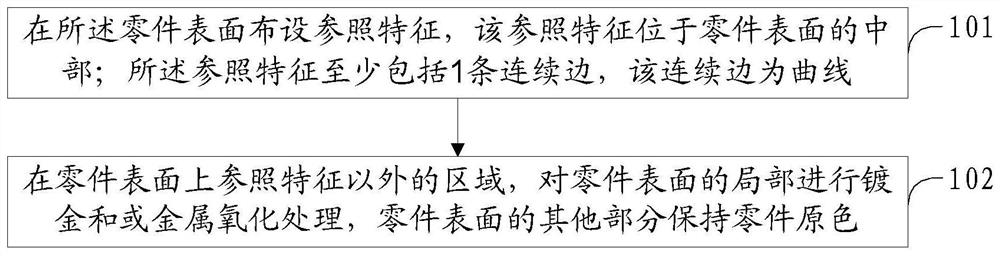

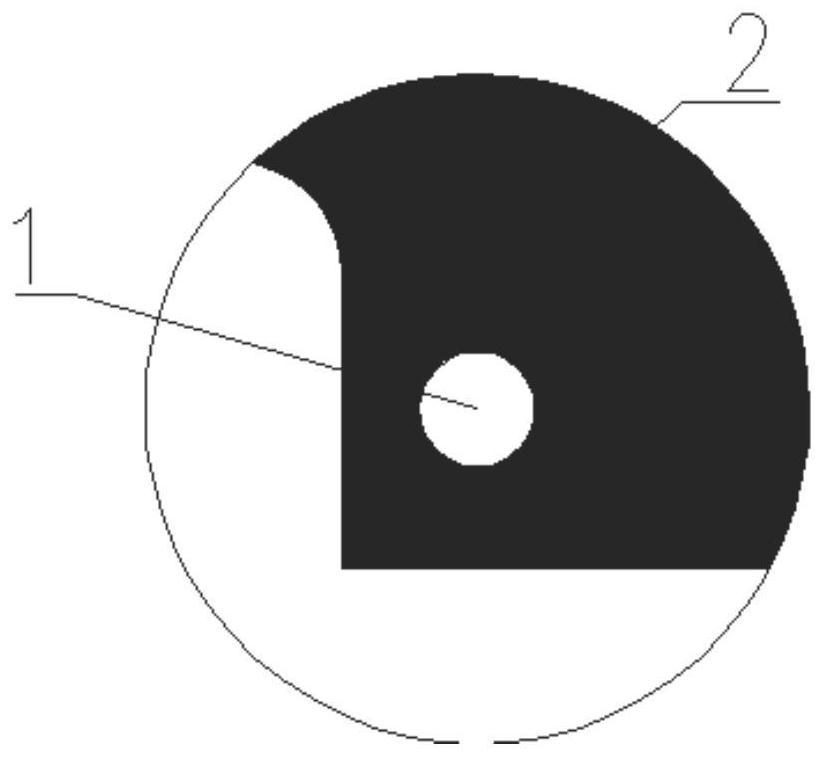

A Part Surface Design Method for Improving Visual Recognition of Automatic Assembly

ActiveCN109590699BGuaranteed accuracyAvoid high-precision Mark featuresMetal working apparatusEngineeringVisual recognition

The invention relates to a part surface design method capable of improving automatic assembling visual identity. The part surface design method comprises the following steps of step I, arranging a reference characteristic on the surface of a part, wherein the reference characteristic is located at the middle part of the surface of the part, the reference characteristic at least comprises one continuous edge, and the continuous edge is a curve; and step II, locally performing gold-plating treatment or metal oxidation treatment on the surface of the part on a region except the reference characteristic on the surface of the part, and enabling the other part of the surface of the part to maintain the primary color of the part. Through the adoption of the method disclosed by the invention, therecognition degree of the visual identity of the part surfaces is high, and the clarity of a visual sense template is higher, so that the automatic deviation correcting capacity of an assembling robotis improved, the surface treatment manner having color differences is easy to realize, and development cost cannot be increased.

Owner:BEIJING RES INST OF TELEMETRY +1

Assembling device and method for permanent magnet of built-in tangential permanent magnet motor

InactiveCN108365713ASimple structureEasy to install and maintainManufacturing stator/rotor bodiesArchitectural engineeringPermanent magnet motor

The invention relates to an assembling device and method for a permanent magnet of a built-in tangential permanent magnet motor. The device comprises a fixing portion and a feeding portion; the fixingportion comprises a base plate, a workbench, a linear guide rail and a fixing end plate; the workbench is perpendicularly fixed to the upper end of the horizontal base plate, the lower end of the linear guide rail is connected with the workbench, and the upper end of the linear guide rail is connected with the fixing end plate; the feeding portion comprises a motor, a screw rod, a permanent magnet guiding groove, a pneumatic device and a permanent magnet pushing guide block, the motor is fixed to the upper end of the fixing end plate, the lower end of the motor is provided with the screw rod,the screw rod is connected with the permanent magnet guiding groove, the motor and the screw rod rotate and can drive the permanent magnet guiding groove to slide up and down along the linear guide rail, the pneumatic device is fixed to the upper end of the fixing end plate, the pneumatic device is connected with the permanent magnet pushing guide block through a push rod, and the permanent magnet pushing guide block can be driven to slide up and down along the linear guide rail. The problem that the permanent magnet of the built-in tangential permanent magnet motor is large in difficulty issolved.

Owner:SHENYANG POLYTECHNIC UNIV

Electronic equipment

ActiveCN105338780BReduce areaIncrease the use of spaceSupport structure mountingStructural engineeringElectronic component

The invention provides an electronic device, which comprises a device shell, a PCB, and a connector, wherein the PCB is located in the device shell; the connector is arranged at the edge of the PCB; the place where the connector is arranged on the PCB is provided with a notch; and the connector partially exceeds the PCB and does not exceed the device shell. According to the electronic device of the invention, through removing wasted leftover on the PCB in the device, the area of the PCB is reduced, the use space of the device shell is increased, strength around the device shell is improved, and the assembly positioning precision of an electronic element on the PCB can be further improved.

Owner:XIAOMI INC

The method of installing magnetic steel in the round hole

ActiveCN108011479BControl the assembly processMeet assembly requirementsManufacturing stator/rotor bodiesMetallurgyReplacement method

The method of installing the magnet in the round hole includes the following installation steps: install the yoke body into the fixture base, install the auxiliary magnet with the auxiliary magnet installation jig and push the auxiliary magnet jig, and install the magnet positioning block into the In the yoke body, put the simulated magnetic steel into the yoke body, replace the first simulated magnetic steel with the first magnetic steel and press it with the pressure plate structure, and replace the one next to the first magnetic steel with the second magnetic steel For the second piece of simulated magnet, push the second piece of magnet close to the first piece of magnet by rotating the pressing device, and press it tightly with the pressure plate structure; install the remaining magnet according to the replacement method of the second piece of magnet above; Fasten the yoke body and the magnetic steel positioning block with the fastening magnetic steel device, then take it out from the fixture base and perform position curing to complete the installation. The invention adopts a special assembly fixture and installs the magnetic steel with a specific process method, can well control the assembly process of the magnetic steel, meets the assembly requirements of the magnetic steel, has high positioning accuracy, simple and practical assembly process, and can be installed in place at one time, reducing Assembly rework rate.

Owner:山东重心电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com