Pole Plate folding type lead-acid accumulator and its preparing method

A lead-acid battery and foldable technology, applied in the direction of lead-acid battery, lead-acid battery construction, final product manufacturing, etc., can solve the problems of complex production process, heavy battery weight, large volume, etc., and achieve small volume and large discharge current. , the effect of uniform current distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

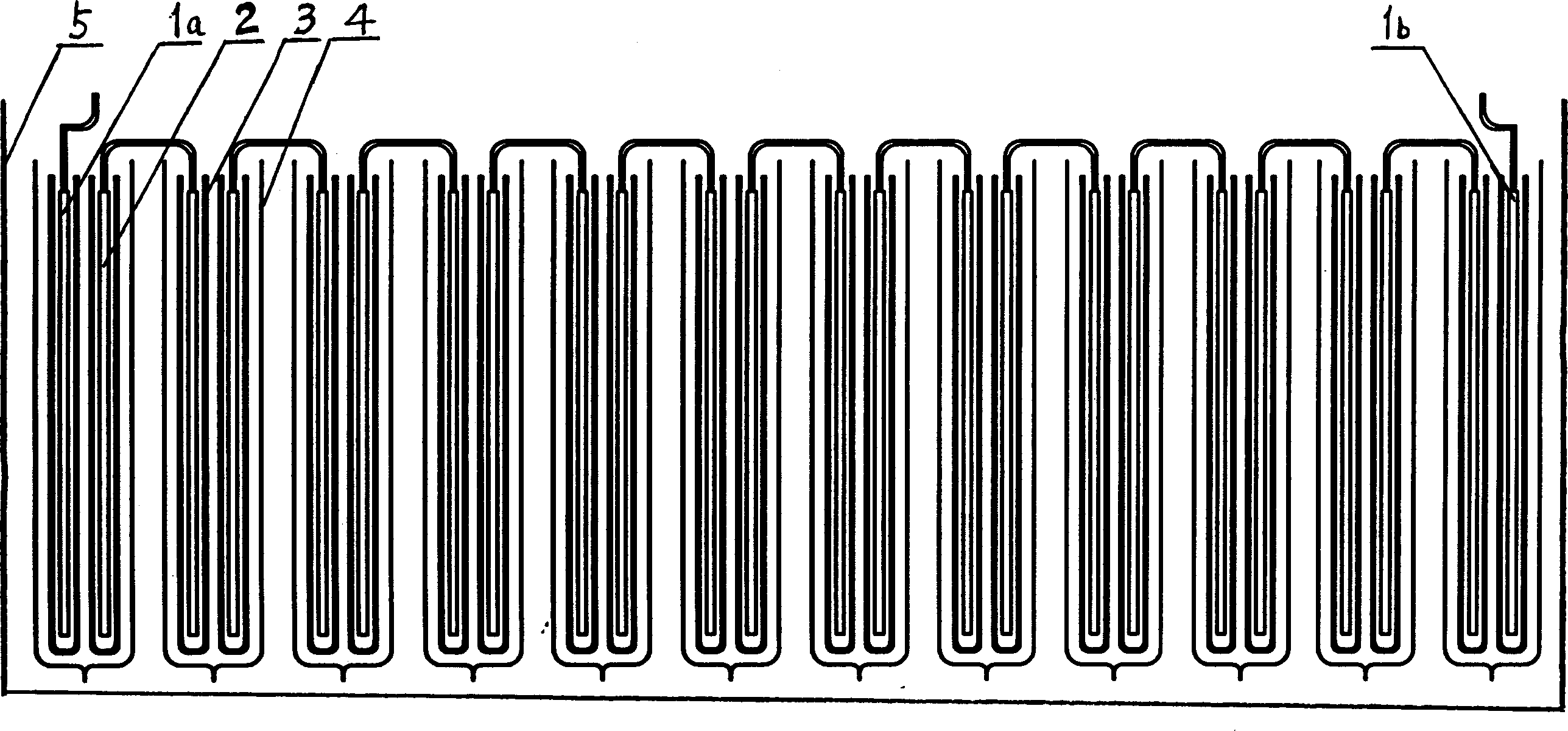

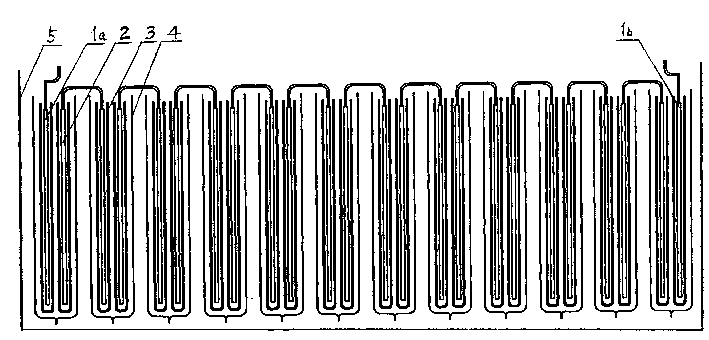

[0028] as attached figure 1 As shown, the bipolar plate 2 is folded in half at the lead wire, and a total of 11 pieces are folded; the U-shaped bipolar plate 2 is vertically placed inside the unipolar plate 1a, and the opposite polarity side is adjacent to the unipolar plate, and the bipolar plates are placed in sequence. A total of 11 bipolar plates 2 are stacked to ensure that the polarities are staggered, and a unipolar plate 1b with opposite polarity is placed outside the last bipolar plate; the separator is cut into a separator 3 that is 2.1 times the area of the side surface of the unipolar plate 1 , cutting a total of 24 pieces, and then folding them into a V shape to surround the aforementioned 24 polar plates respectively; cutting the insulating plastic film into 24 film sheets slightly larger than the area of the side surface of the unipolar plate 1, and pasting these films on the unipolar plate 1 respectively. The outer surface of the outer side of the polar pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com