Triode cooling fin assembling clamp and equipment

A technology for assembling equipment and assembling fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

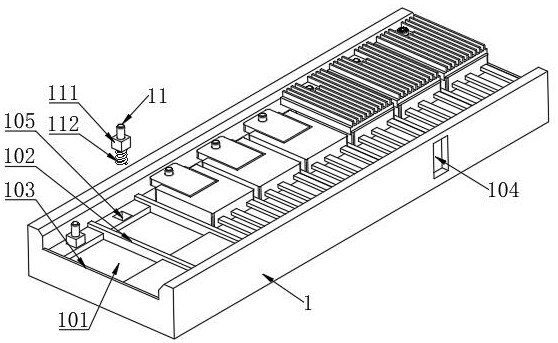

[0038] like figure 1 As shown, a triode heat sink assembly fixture includes: a mounting plate 1 in a rectangular parallelepiped structure.

[0039]Specifically, a plurality of accommodating grooves 101 are arrayed on the top surface of the mounting plate 1 along the length direction for positioning the package body of the triode, so as to realize the rough positioning of the triode. A spacer plate 102 is provided between adjacent accommodating grooves 101 for spacing the triodes in the adjacent accommodating grooves 101, so as to facilitate subsequent assembly of the heat sink. There are end partitions 103 between both end surfaces of the mounting plate 1 in the length direction and the most adjacent accommodating grooves 101, and the thickness of the end partitions 103 is equal to half of the thickness of the partition plates 102, so that the plurality of mounting plates 1 along the length direction When connecting end to end, the distance between the two adjacent accommodat...

Embodiment 2

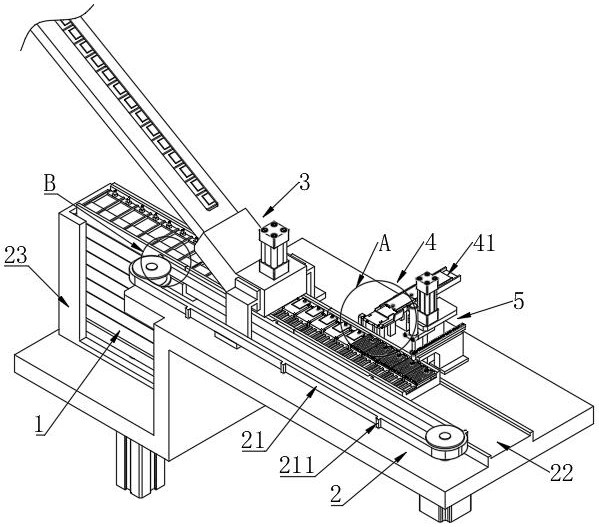

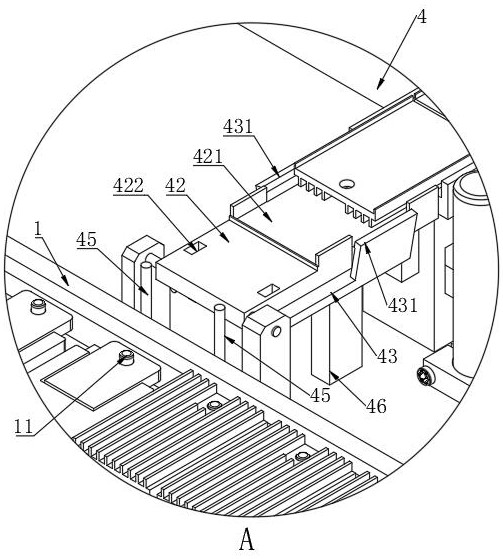

[0044] like figure 2 , Figure 5 and Figure 8 As shown, a triode heat sink assembly equipment includes: a transmission mechanism 2, a feeding mechanism 3, a feeding mechanism 4, a locking mechanism 5, and the triode heat sink assembly fixture of the above-mentioned embodiment 1.

[0045] Specifically, as figure 2 As shown, the feeding mechanism 3, the feeding mechanism 4 and the locking mechanism 5 are arranged in sequence along the conveying direction of the transmission mechanism 2, and the distance between the feeding mechanism 3, the feeding mechanism 4 and the locking mechanism 5 is equal to the distance between the mounting plate 1 n times the distance between the adjacent positioning pins 11, n is an integer.

[0046] Specifically, the feeding mechanism 3 is used to place the triode into the accommodating tank 101 . like figure 2 , Figure 12 As shown, the feeding mechanism 3 includes a feeding tube 31, and the front end of the feeding tube 31 is used to conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com