A Part Surface Design Method for Improving Visual Recognition of Automatic Assembly

A visual recognition and automatic assembly technology, which is applied in the field of part surface design, can solve the problems that the quality of the picked up image does not fully meet the definition requirements and the difficulty of machining, so as to improve the ability of automatic deviation correction, reduce the difficulty of processing, and reduce the cost of development Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] A part surface design method for improving automatic assembly visual recognition, comprising the following steps:

[0036] (1) When designing a part, a reference feature is arranged in the center of the part plane. The position accuracy of the reference feature in the part plane is the highest. The reference feature can be a positioning hole, a positioning pin or a reference edge. The reference feature is used as the benchmark reference feature during part design, and it is ensured that the reference feature has little wear and tear due to clamping or daily transportation, which will affect the line quality of the image during automatic assembly visual recognition; in addition, the reference feature should be as close as possible The center of the part surface, while ensuring that the reference feature will not be blocked after the part surface is assembled.

[0037] (2) Add a sharp color contrast to the surface treatment of the visual recognition area of the part. Go...

no. 1 example

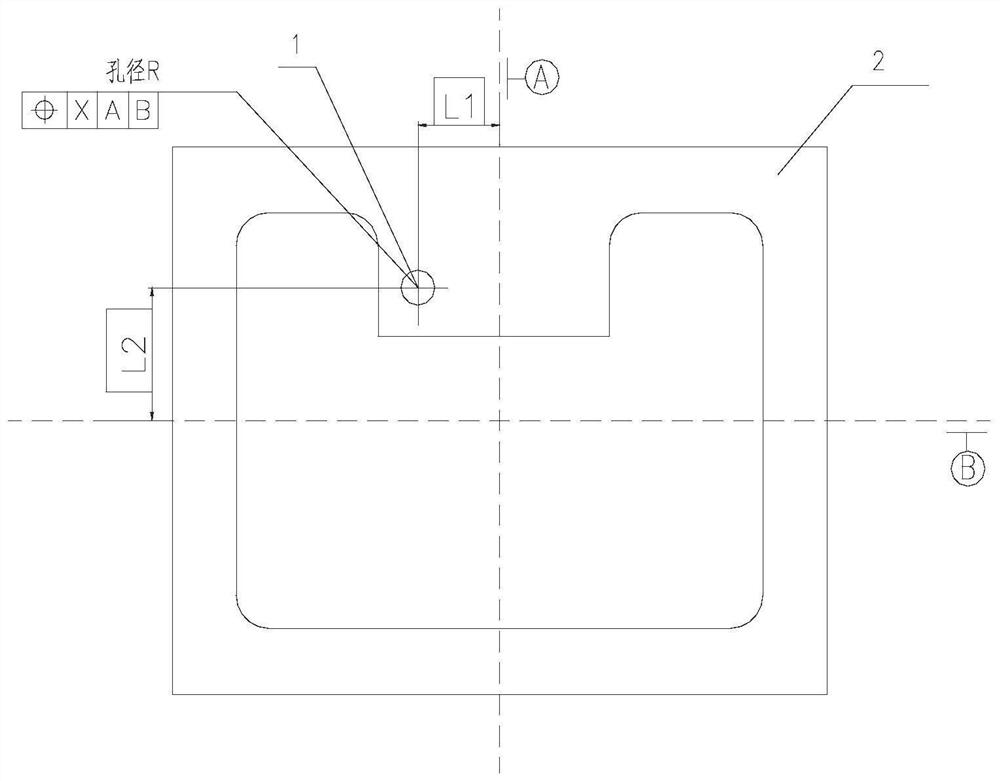

[0040] Such as figure 2 As shown, the assembly part 2 is provided with a high-precision positioning pin hole 1. Since the centerline of the whole part is used as the processing and marking reference of the part, it cannot directly reflect the visual area of the reference, and the positioning pin hole 1 is marked with dimensions L1, L2 and The position tolerance X is based on the center line, and it is the hole with the highest precision based on the marked datum, and this hole is not easy to be damaged by bumps, so it is selected as a reference feature and a visual identification item.

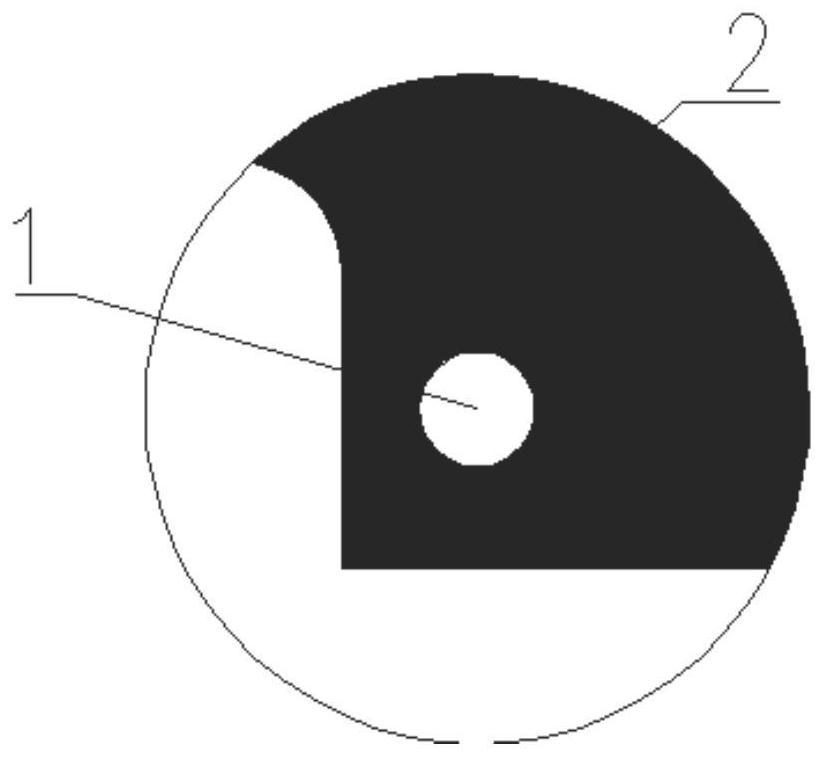

[0041] When the surface treatment of the assembly part 2 is carried out, since the whole part is made of aluminum, the surface needs to be treated with black anodization to meet the emissivity requirements, while the inner surface of the pin hole 1 can be protected, and only the natural color conductive oxidation is done, such as image 3 As shown, the natural color is the conductive oxidat...

no. 2 example

[0043] Such as Figure 4 As shown, the reference reference line 3 for part processing is arranged on the assembly part 2. Since the assembly part 2 considers other installation fits, the edges within the range of the reference reference line 3 are used as the processing X and Y references, that is, the dimensions H1, H2, Both W1 and W2 are marked with X and Y axes. Since these two sides have the highest machining accuracy, they can be regarded as visual identification items.

[0044]The assembly part 2 is a metal aluminum part, which needs to be gold-plated in order to meet the weldability. The method of the present invention is applied to the part plating treatment to adopt a local treatment method. The welding area needs gold-plating treatment, and other areas need to be conductively oxidized in natural color, such as Figure 5 As shown, 4 is the conductive oxidation area of the natural color, which does not require welding, and 5 is the gold-plated area, which needs to me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com