Backlight module and optoelectronic device

A technology for a backlight module and a light-emitting device, which is applied to lighting devices, fixed lighting devices, components of lighting devices, etc., can solve problems such as difficult rework procedures, simplify assembly and rework procedures, reduce light source damage, and improve assembly positioning. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

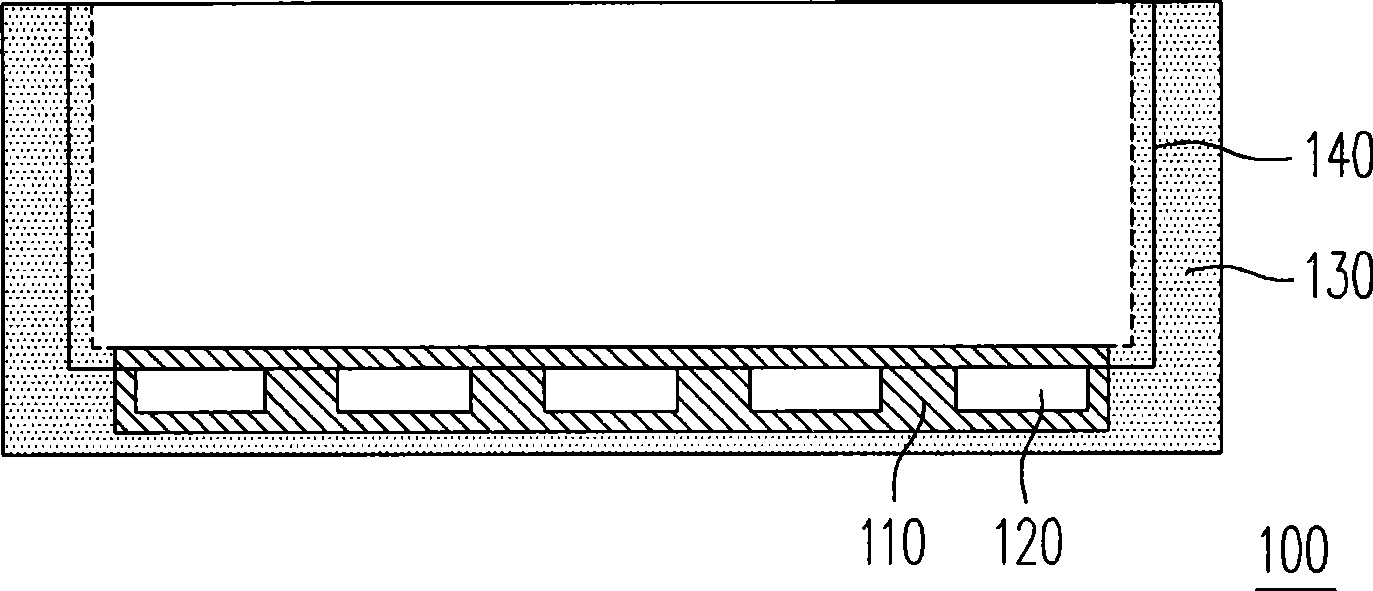

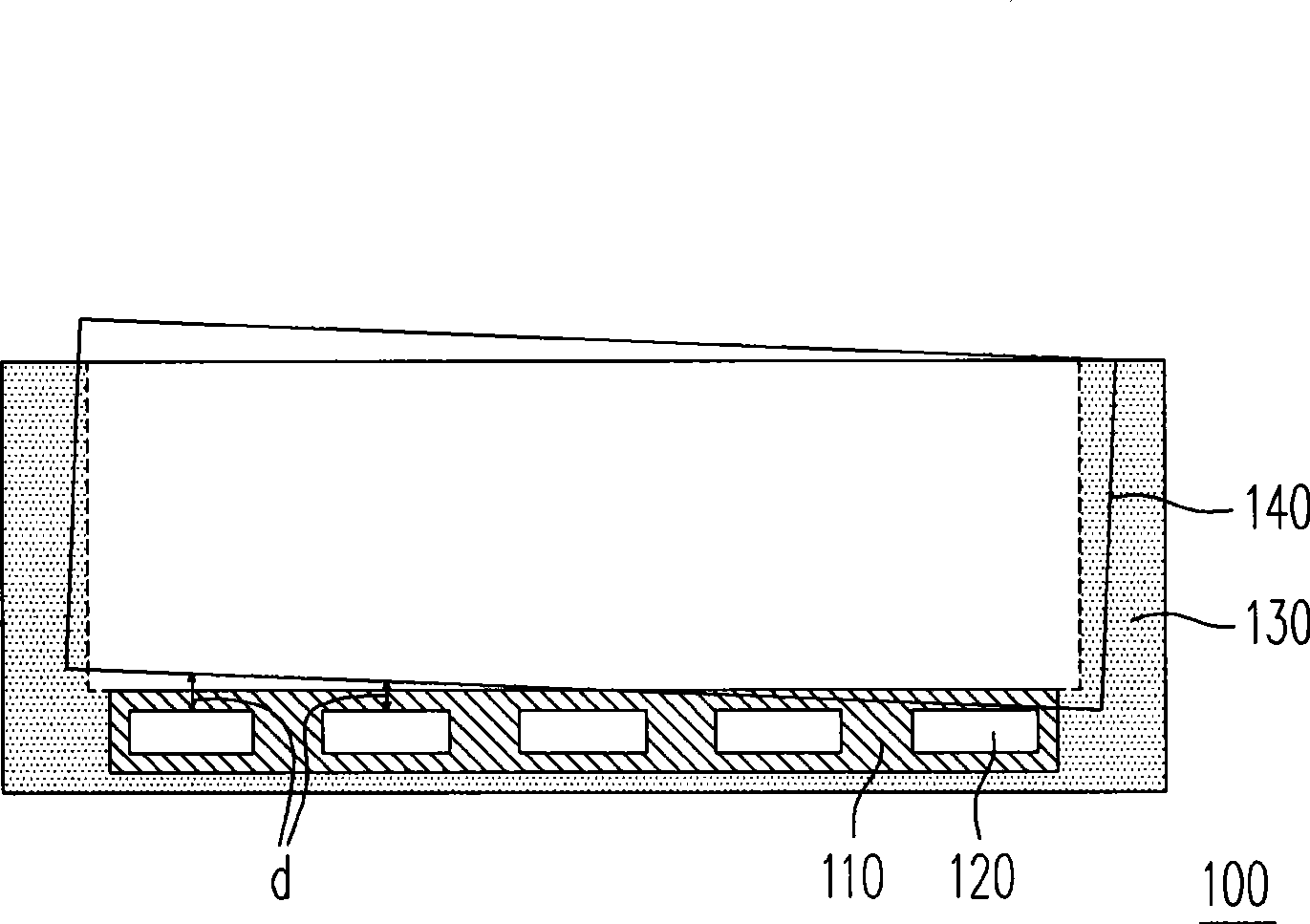

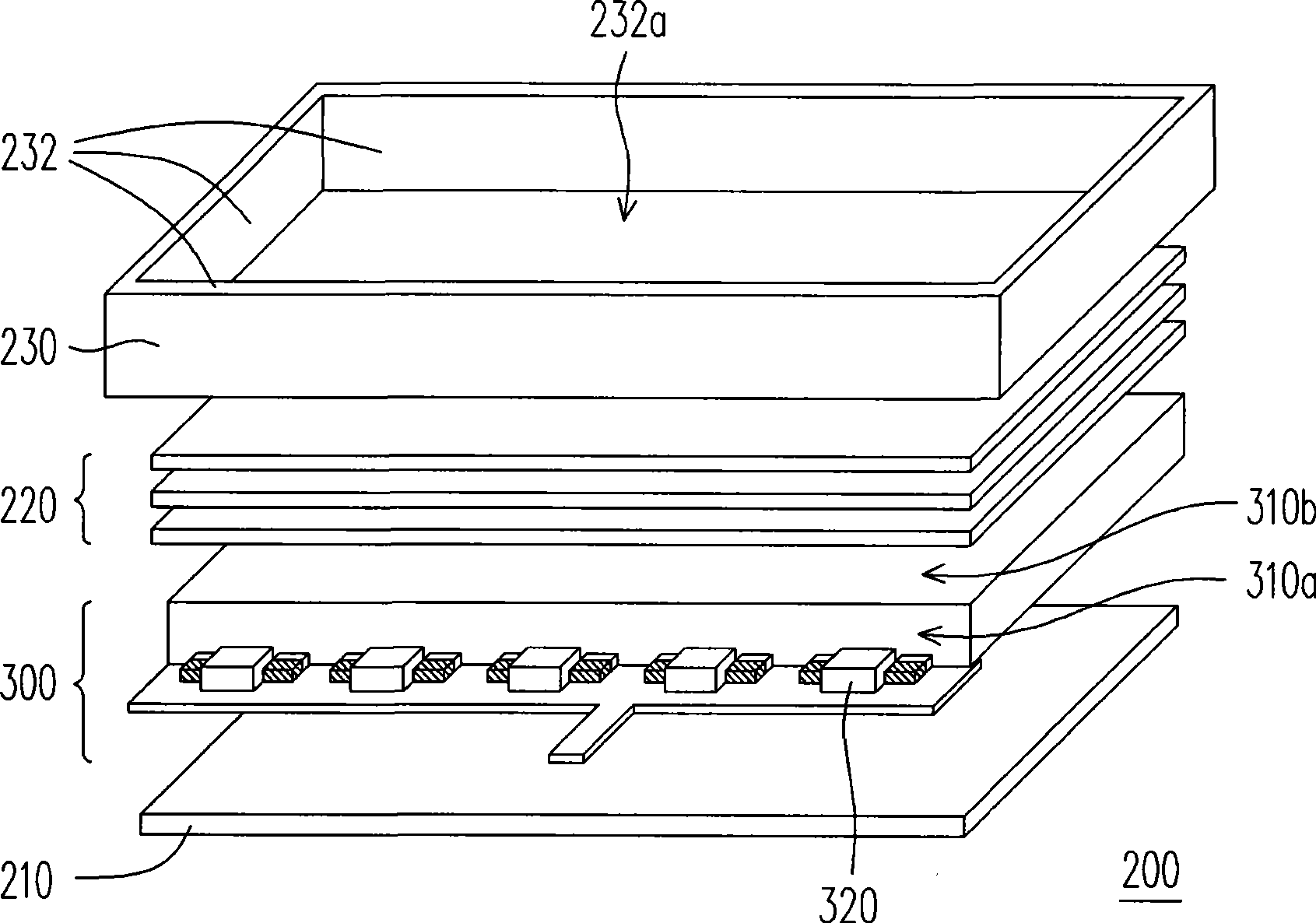

[0053] figure 2 It is an exploded schematic diagram of the backlight module 200 of the preferred embodiment of the present invention. Figure 3A for figure 2 A schematic diagram of the local components of the backlight module. Figure 3B for Figure 3A side view diagram. In this embodiment, the backlight module 200 is a side-facing backlight module, and Figure 3A and Figure 3B for figure 2 The schematic diagram of the light guide plate and the circuit board in the light emitting device 300 before assembly.

[0054] Please refer to figure 2 , Figure 3A and Figure 3B The backlight module 200 includes a light emitting device 300 , preferably, the backlight module 200 further includes a reflector 210 , an optical sheet group 220 and a frame 230 . The reflection plate 210 is disposed under the light emitting device 300 . The optical sheet group 220 is disposed above the light emitting device 300 . The accommodating side 232 of the frame 230 defines an accommodat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com