Fabricated simple jig frame used for assembly of steel structure and using method thereof

A steel structure, prefabricated technology, applied in building construction, building material processing, construction, etc., can solve the problems of non-repetitive use, difficult to control precision, low production efficiency, etc., to improve assembly positioning accuracy, overall structure Simple, reduced usage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further illustrated below by specific examples.

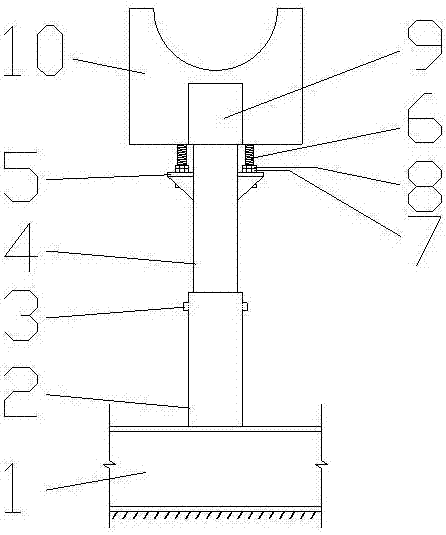

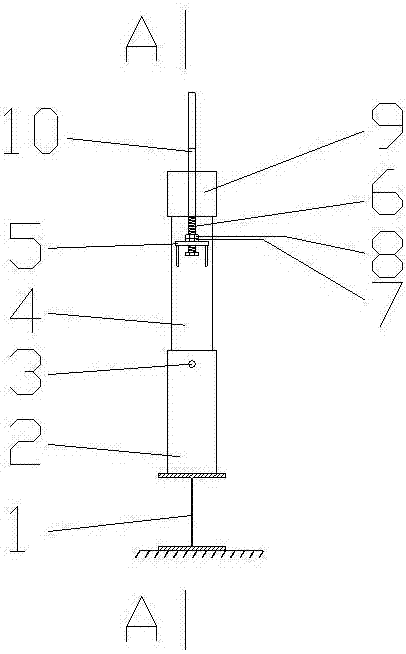

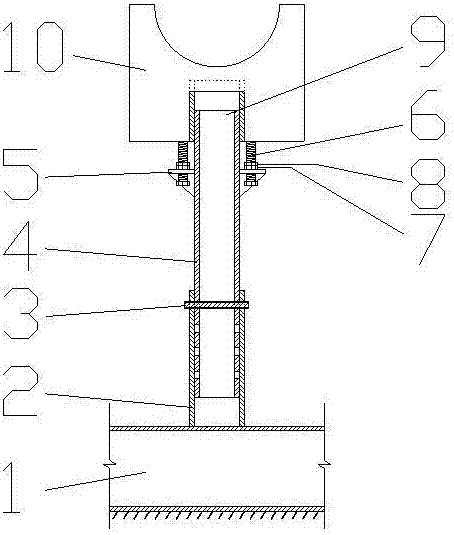

[0026] As shown in Figure 1, a tire frame for steel structure assembly is composed of a base part, a support part and a bracket part. The base part includes a horizontal bottom plate 1 and a bottom round tube 2, and the bottom round tube 2 is welded vertically on the horizontal bottom plate 1; the support part includes a support round tube 4, nuts 7, 8 and a screw 6, nuts 7, 8 and a screw 6 Located on both sides of the support tube 4 and on the same level, it is fixed to the support tube 4 by welding on the corbel 5 on the side of the support tube 4 , the screw 6 is connected to it by screwing in the nut 7 , and passed through the upper part of the nut 7 . The second nut 8 is fastened; the bracket part includes a supporting plate 10 and a top round pipe 9 , and the supporting plate 10 is vertically welded on the middle and upper part of the top round pipe 9 .

[0027] Such as image 3 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com