Hard disk magnetic head load method capable of compensating friction force

A magnetic head loading and friction technology, applied in the field of control, can solve problems such as non-linear friction, unstable hard disk head speed, and deterioration of control quality, and achieve good control quality, safe head loading process, and accurate models Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

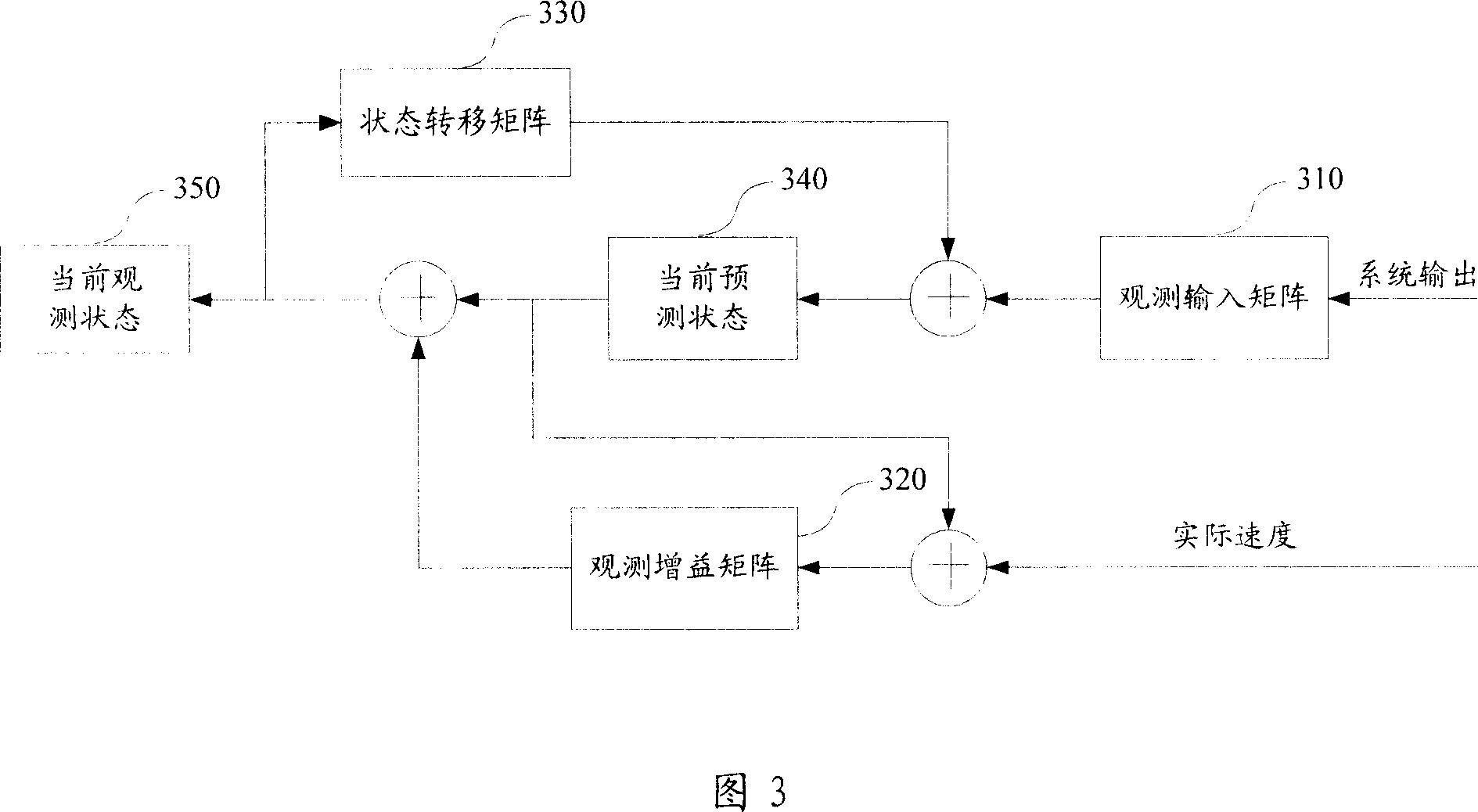

[0047] The core of the present invention is to provide a hard disk magnetic head loading method that compensates for friction. When the hard disk magnetic head receives the loading command, the system sets the target loading speed of the magnetic head and the parameter value at the current moment, and the system passes through the state according to the parameter value at the current moment. The space equation obtains the parameter value at the next moment until the hard disk head is loaded on the platter.

[0048]In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

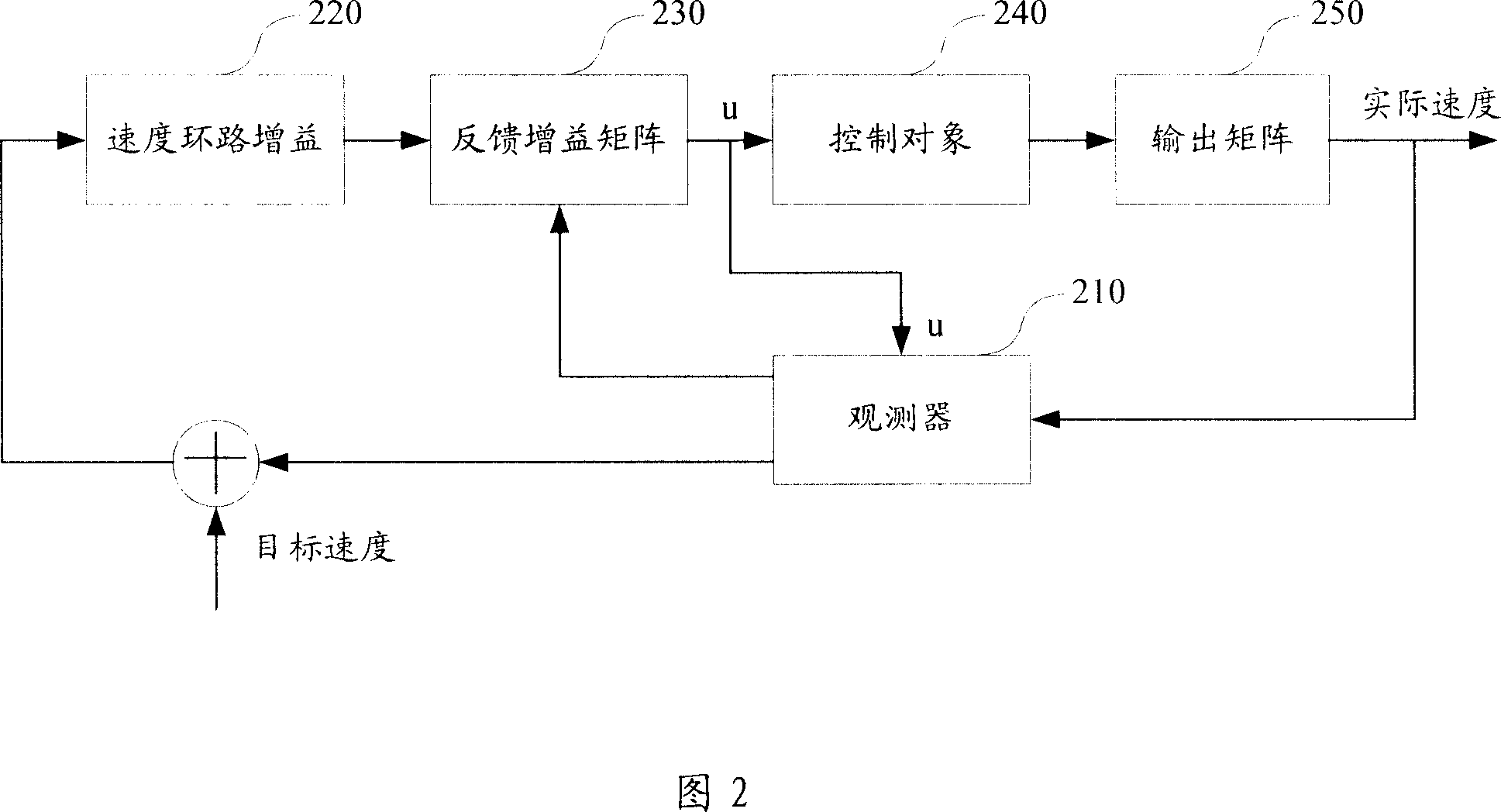

[0049] The control process principle of hard disk magnetic head loading among the present invention is as shown in Figure 2:

[0050] First design the state space equation during the loading process of the hard disk head, and define the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com