A self-adjusting distance corrugated paper cutting machine

A corrugated paper and self-adjusting technology, which is applied in metal processing and other directions, can solve problems such as complicated operation process, shortened service life, and easy warping of corrugated paper, so as to avoid wrong cutting route, realize self-adjusting control, and improve product qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

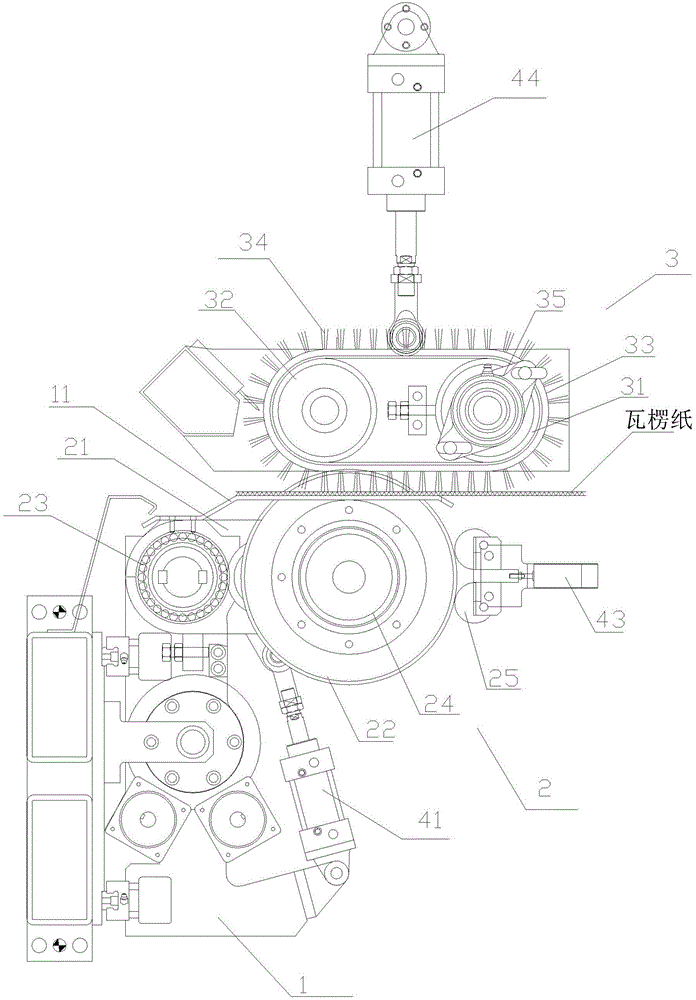

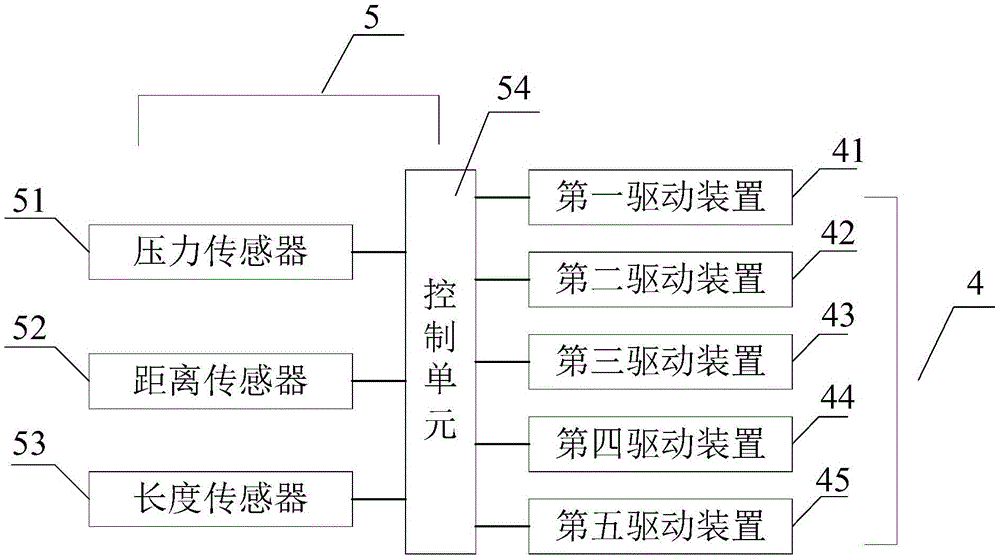

[0028] refer to figure 1 , figure 2 , image 3 , a self-adjusting distance corrugated paper cutting machine proposed by the present invention includes a base 1 , a blade mechanism 2 , a brush seat 3 , a drive mechanism 4 and a control module 5 .

[0029] A knife clamping plate 11 is arranged on the top of the base 1 , and a knife clamping slit is arranged on the knife clamping plate 11 .

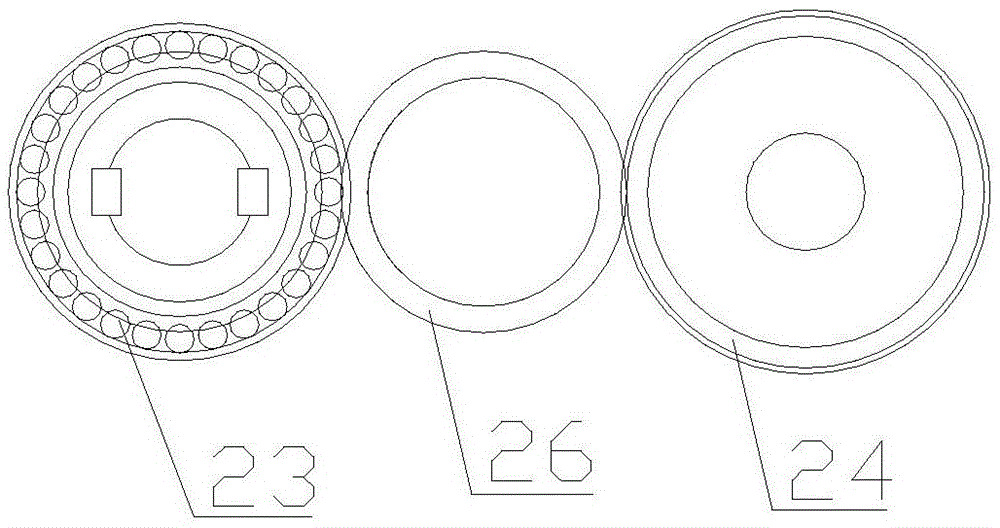

[0030] The blade mechanism 2 includes a knife rest 21 , a blade 22 , a driving wheel 23 , a driven wheel 24 , a grinding wheel 25 and a transmission wheel 26 .

[0031] Knife rest 21 is installed on the base 1 rotatably vertically, and blade 22 is rotatably installed on the knife rest 21 by driven wheel 24 and corresponds to the position of clamping knife seam, and driving wheel 23 is rotatably installed on the base 1, and driving wheel 23 connects driven wheel 24 and drives it to rotate so as to realize blade 22 autorotation. In this embodiment, the driving wheel 23 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com