Temperature bending deformation measurement of surface piezoelectric composite material

A piezoelectric composite material and curved surface technology, applied in measurement devices, analytical materials, thermal analysis of materials, etc., can solve the problem of affecting the frequency consistency of the transducer array primitives, reducing the water pressure resistance of the transducer, and reducing the beam of the transducer. Open angle change and other problems, to achieve the effect of solving the quantitative test problem of temperature deformation and improving environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

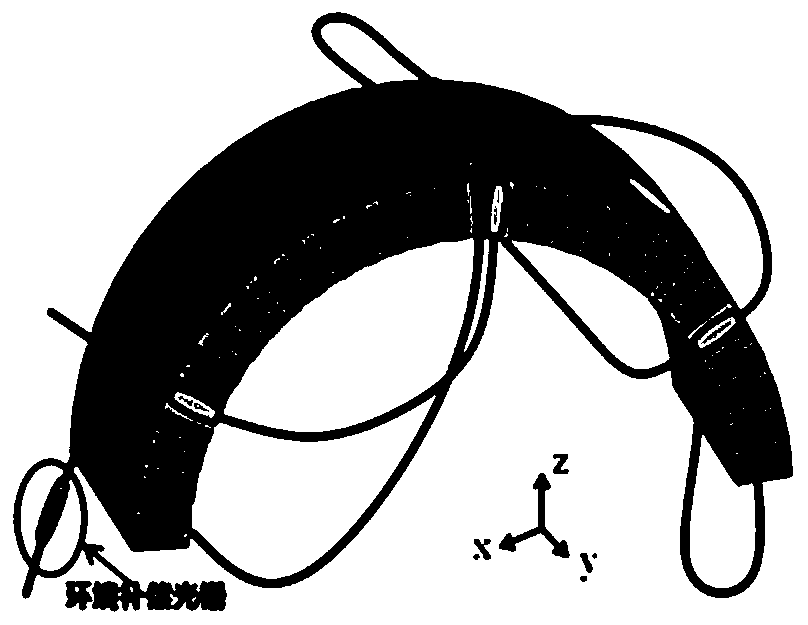

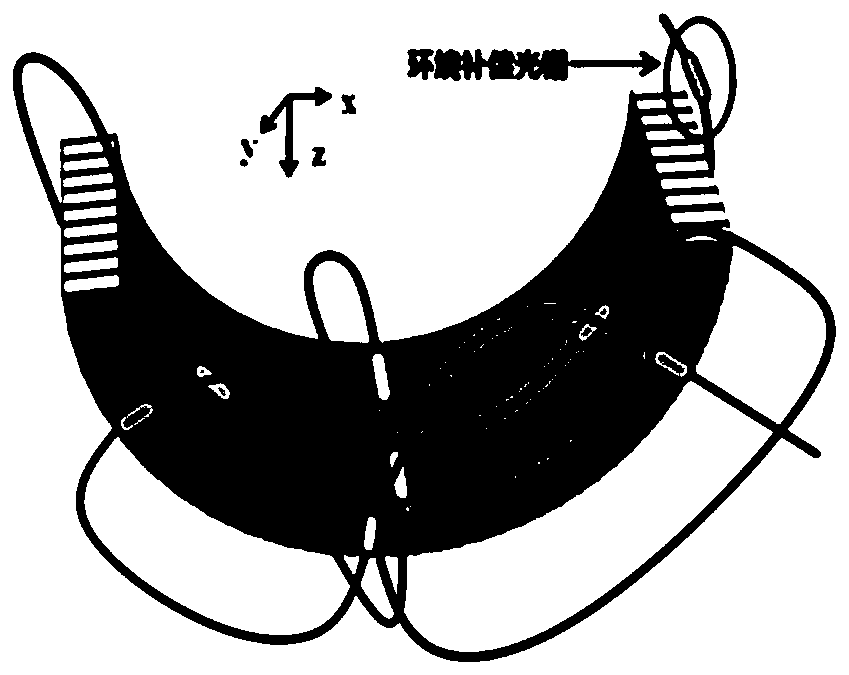

[0052]In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

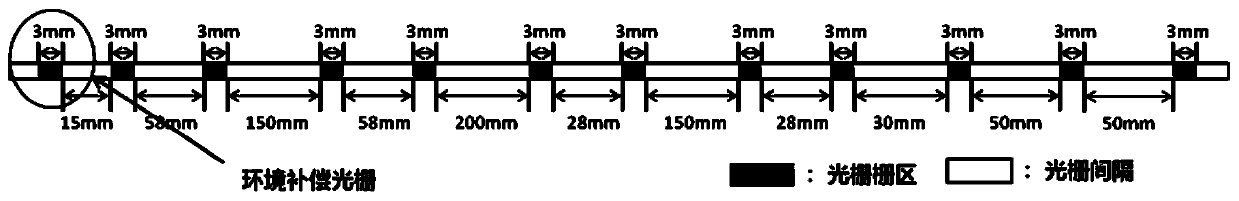

[0053] A fiber grating is a diffraction grating formed by periodically modulating the refractive index of the fiber core in the axial direction, and is a passive filter device. Because grating fiber has the advantages of small size and full compatibility with optical fiber, and its resonant wavelength is sensitive to changes in the external environment such as temperature and strain, it has been widely used in the field of sensing. The relationship between the wavelength change of the fiber grating reflected light and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com