Trapezoid groove mosaic structure for blades and upper canopy of water turbine model runner

A water turbine model and runner blade technology, which is applied in the fields of hydropower, mechanical equipment, machines/engines, etc., can solve the problem of large randomness in the manufacturing quality of model runners, difficult to measure and control the matching size, and uneven flow surface of the upper crown. Smoothness and other problems, to eliminate the phenomenon of gaps but not smooth, solve the problem of matching gaps, and eliminate the effect of non-smooth overcurrent surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

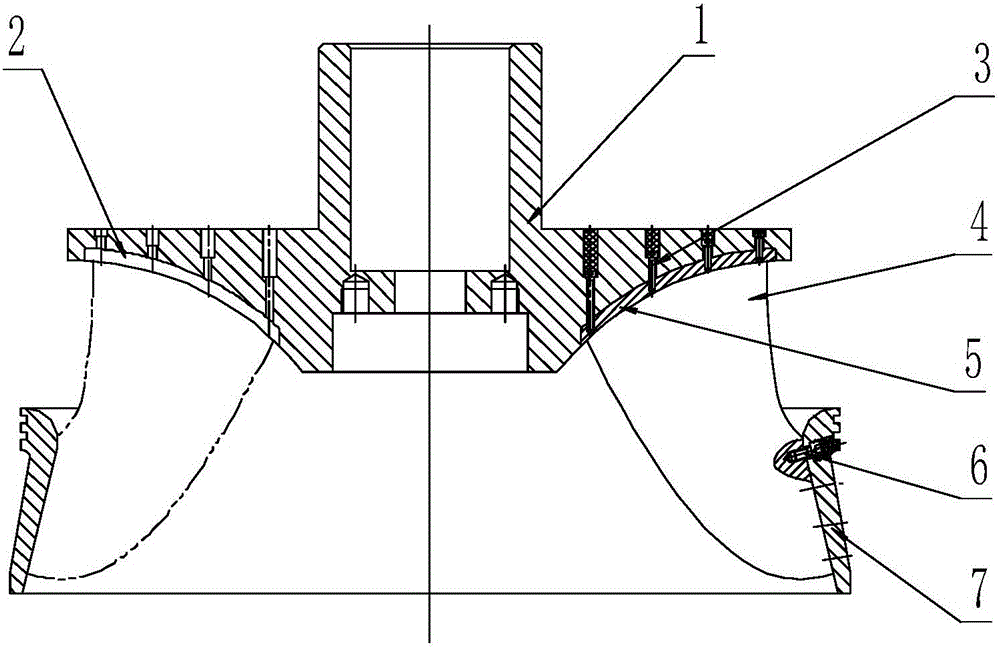

[0015] Such as figure 1 As shown, the present invention is a structure applied in the water turbine model test runner. The blade 4 is installed in the groove 2 of the upper crown 1, and the protrusion 5 on the blade 4 is fixed to the concave groove of the upper crown 1 by the bolt 3. In groove 2, plug the counterbore at 3 bolts with filler, fix the lower ring 7 and blade 4 with screw 6, and plug the counterbore at 6 bolts with filler.

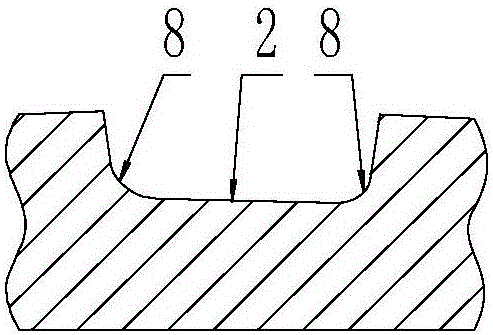

[0016] Such as figure 2 As shown, the groove 2 of the upper crown 1 and the protrusion 5 of the blade 4 cooperate with each other in a trapezoidal cross section.

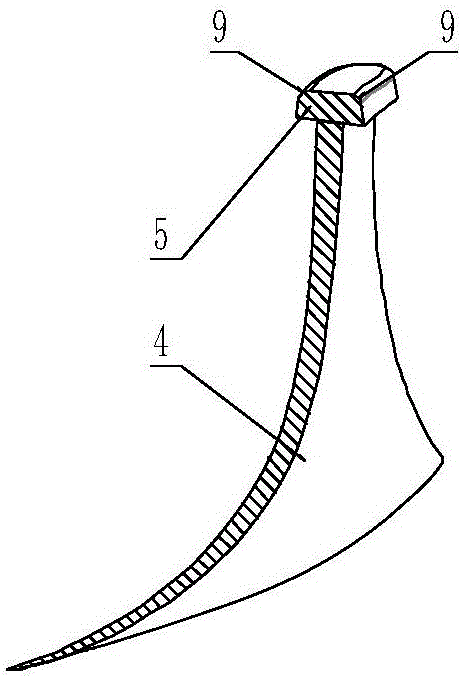

[0017] The bottom edge of the groove 2 of the upper crown 1 is designed as a rounded corner 8, such as image 3 As shown, the upper edge of the protrusion 5 of the blade 4 that cooperates with the groove 2 is designed as a rounded corner 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com