Foundation bolt structure and construction method thereof

A technology of anchor bolts and bolts, which is applied in basic structure engineering, construction, etc., can solve problems such as the difficulty in fixing concrete and anchor bolt steel bars, misalignment of anchor bolts and equipment bolt holes, and high construction accuracy requirements for anchor bolts. Achieve the effects of reducing rework, bolts and cylinders are simple and practical, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The anchor bolt structure and construction method provided by the present invention will be further described below in conjunction with the accompanying drawings.

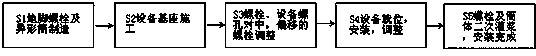

[0040] like figure 1 As shown, the construction flow diagram of the anchor bolt structure provided by the present invention includes five parts.

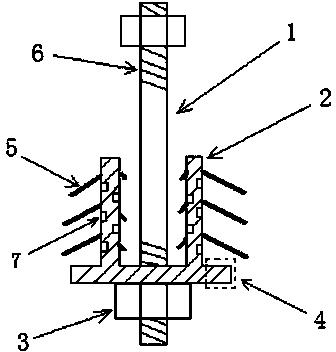

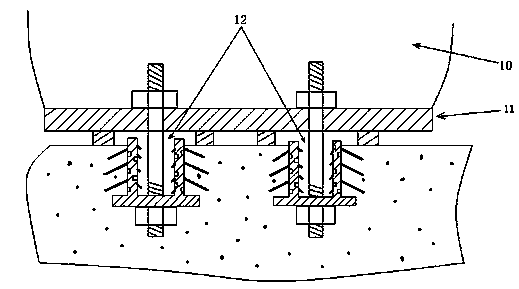

[0041] like figure 2 As shown, the schematic diagram of the anchor bolt structure provided in this embodiment includes a screw rod 1, a special-shaped cylinder body 2 and a bolt 3, wherein the special-shaped cylinder body 2 is divided into a cylinder body and a cylinder bottom, and there is a through hole in the middle of the cylinder bottom, and the diameter of the through hole is Larger than the diameter of the screw 1, the bottom of the cylinder extends radially outward to form a flange 4; the inner surface of the cylinder is provided with raw tentacles 5 both inwardly and outwardly, and the raw tentacles 5 are all inclined downward; both ends of the screw 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com