Patents

Literature

42results about How to "Simple clamping method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

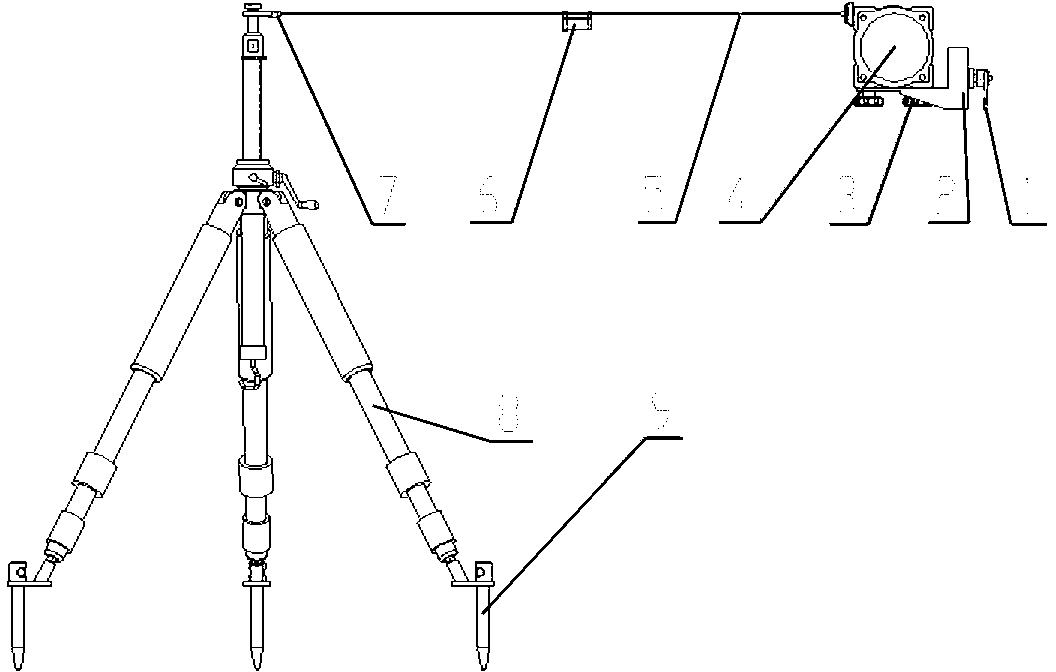

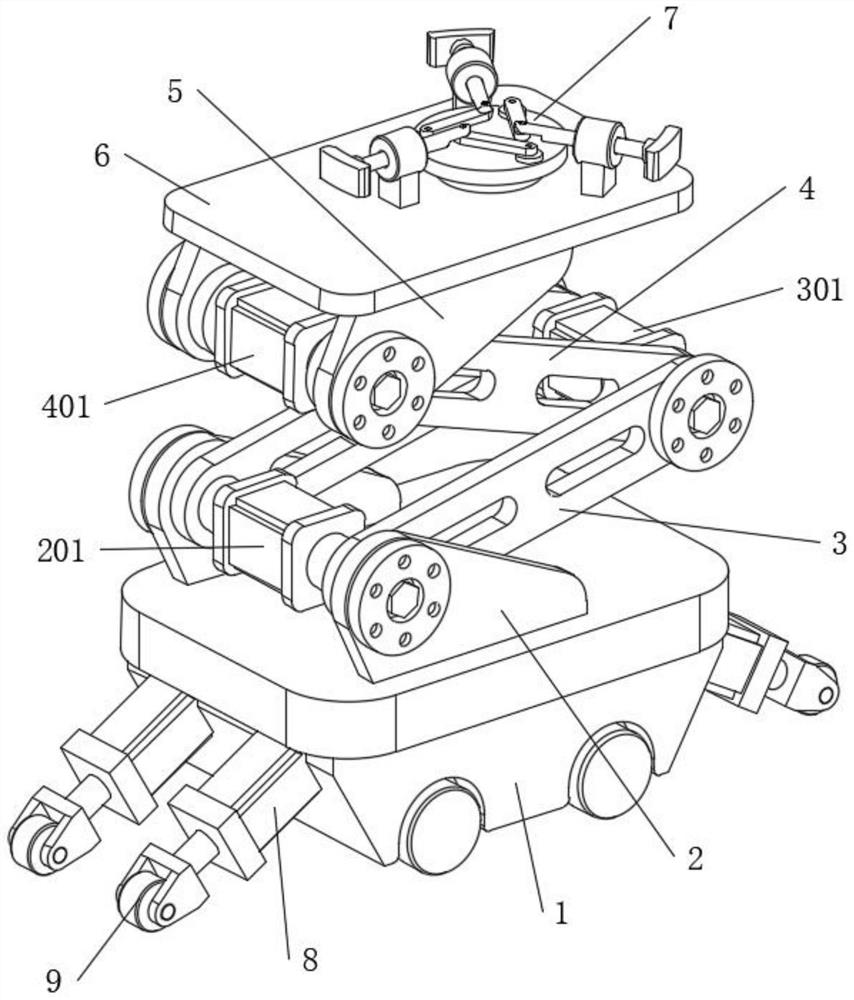

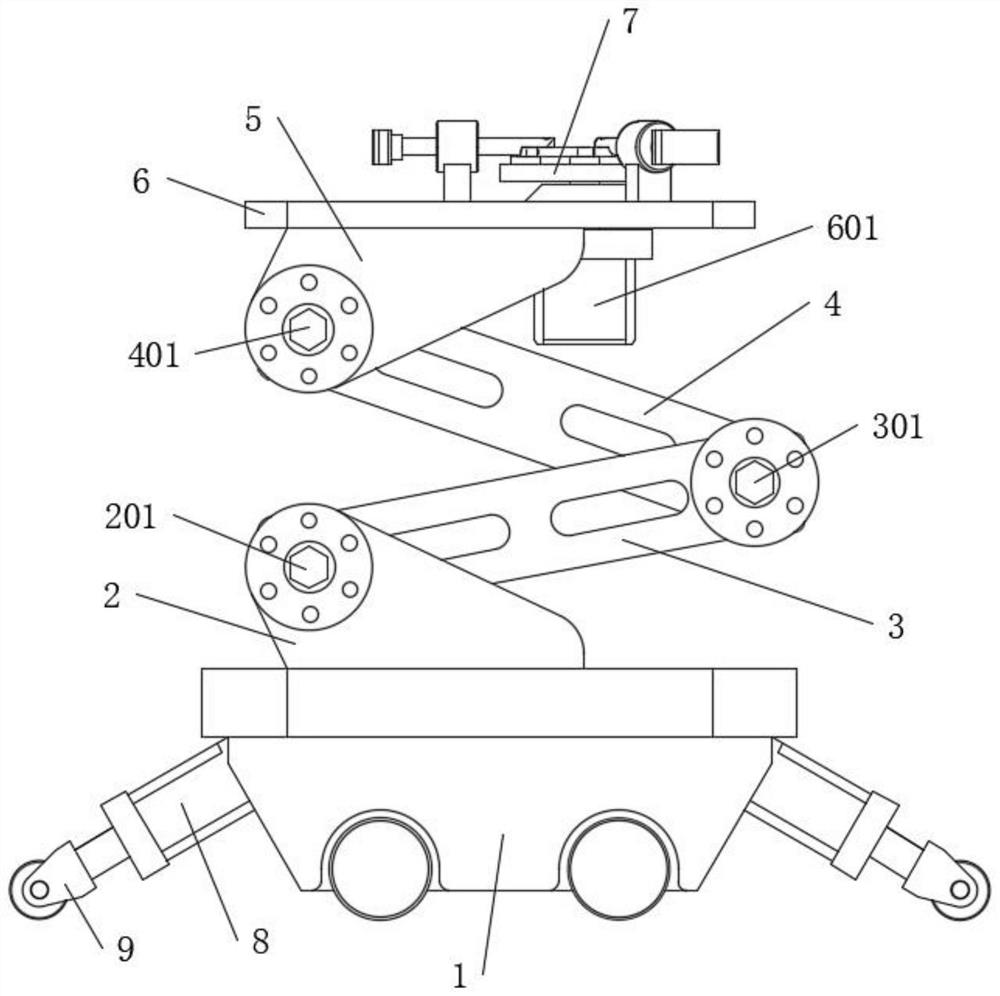

Cable-stayed bridge cable robot

ActiveCN103696365AReduce the frequency of on and offExtend working lifeBridge structural detailsVehicle frameElectromagnetic clutch

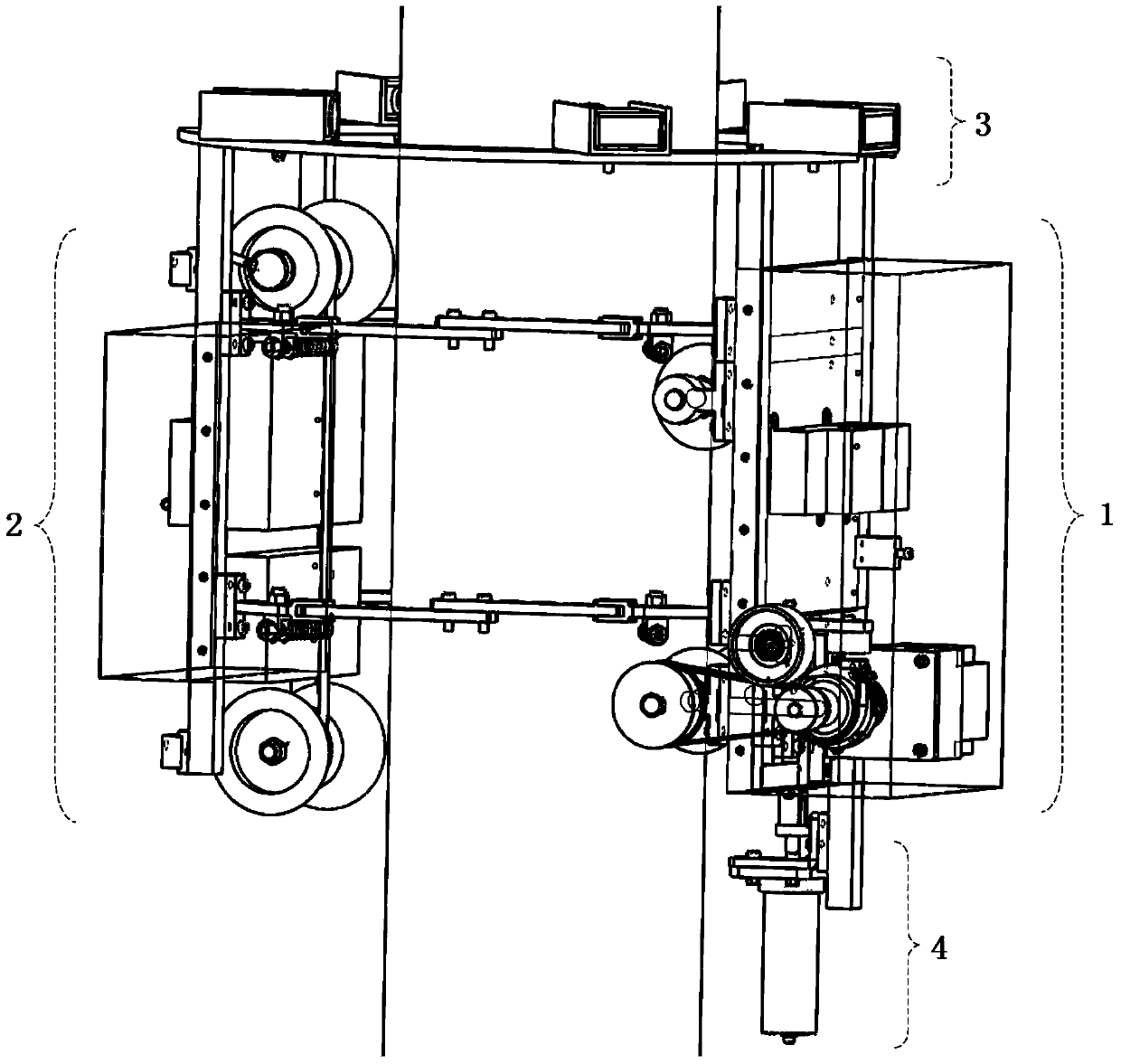

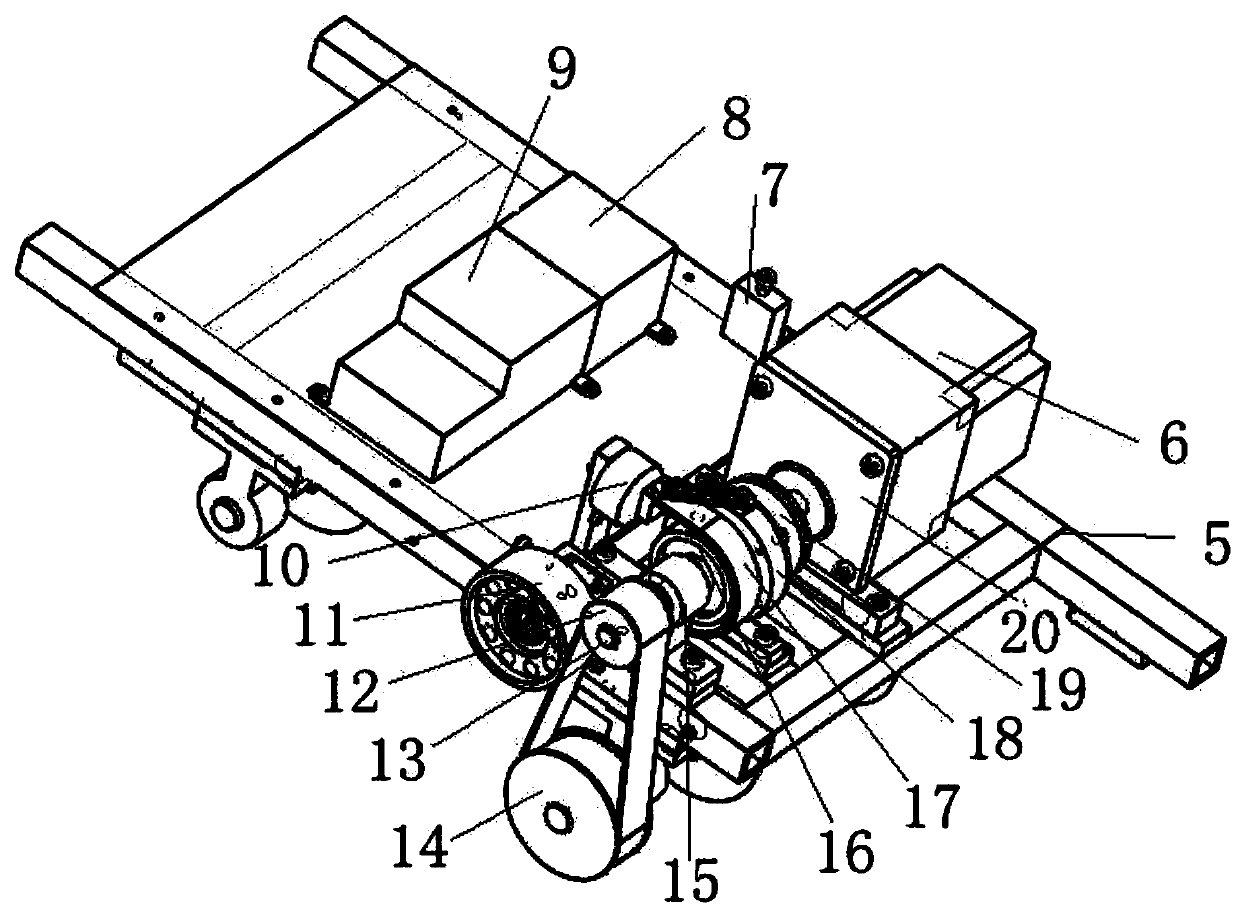

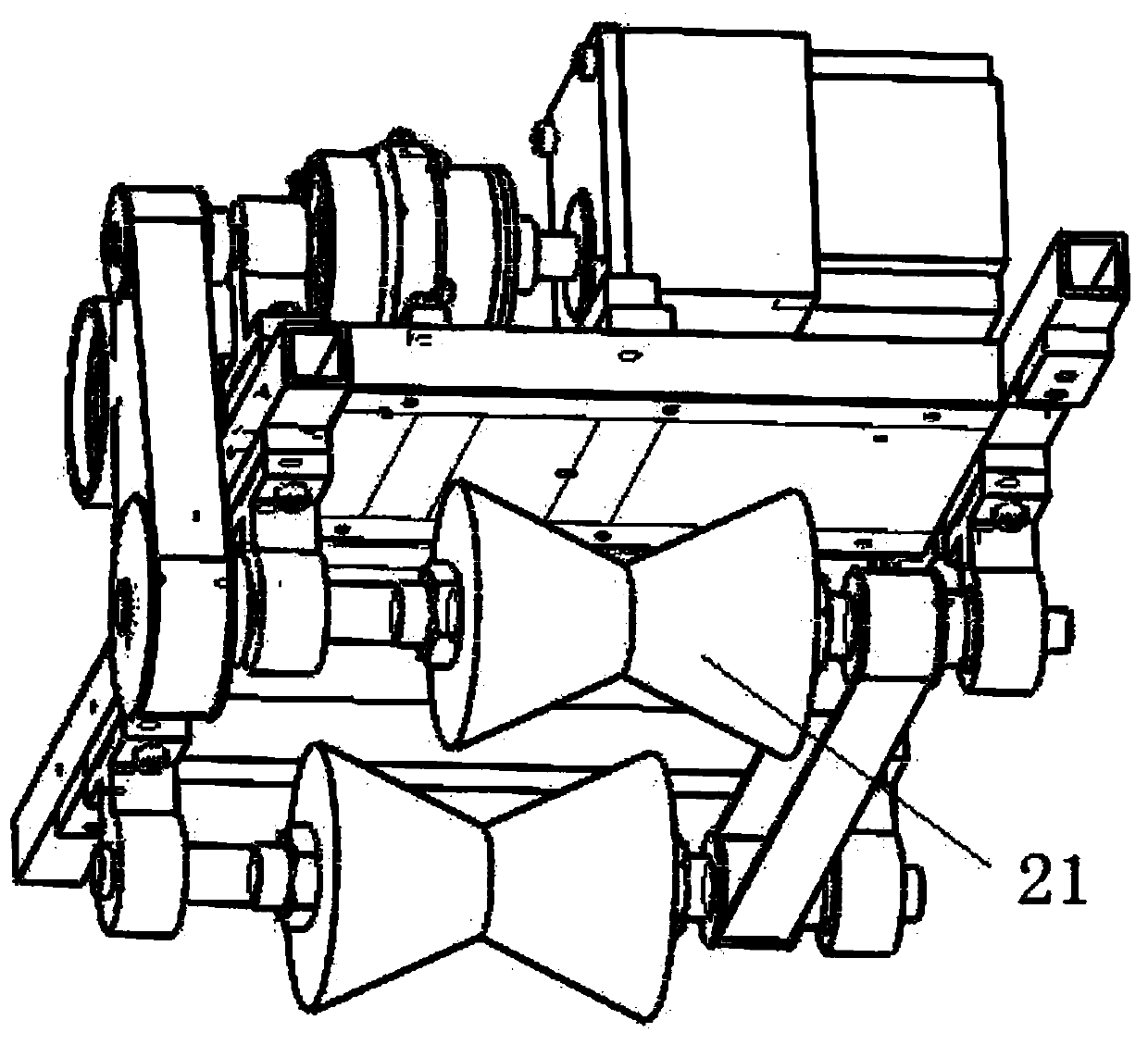

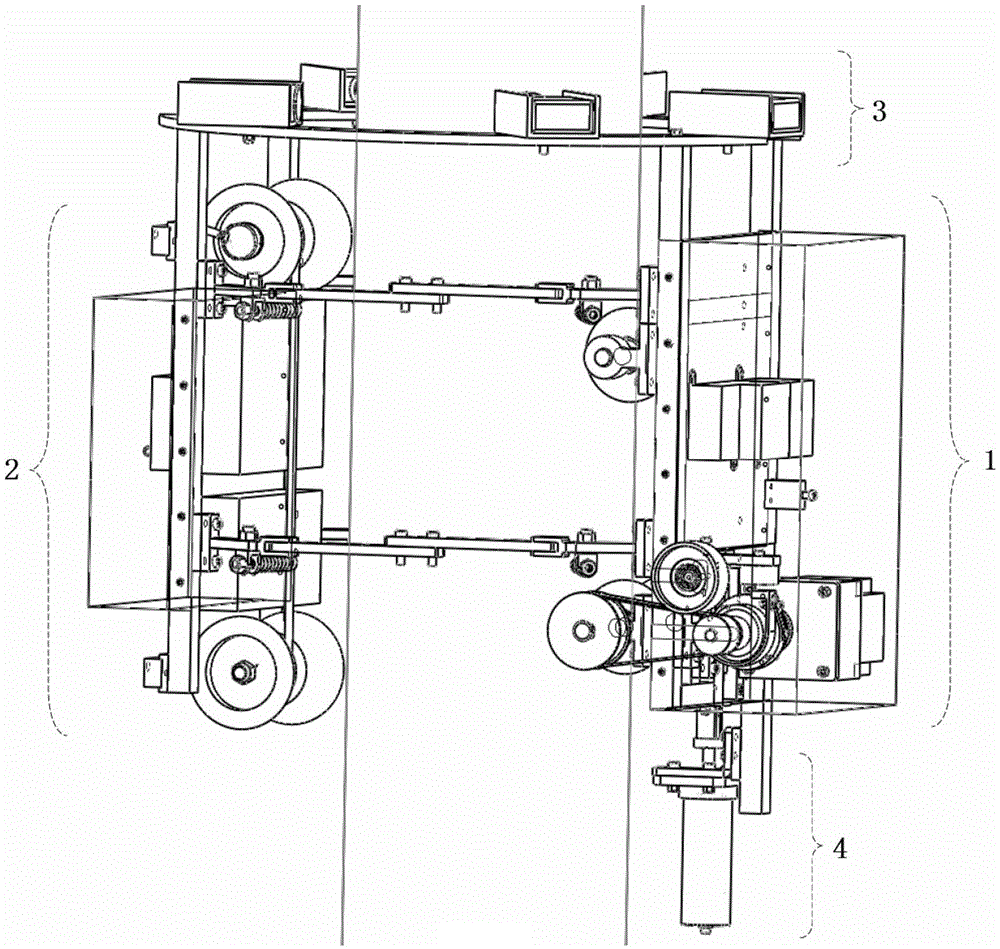

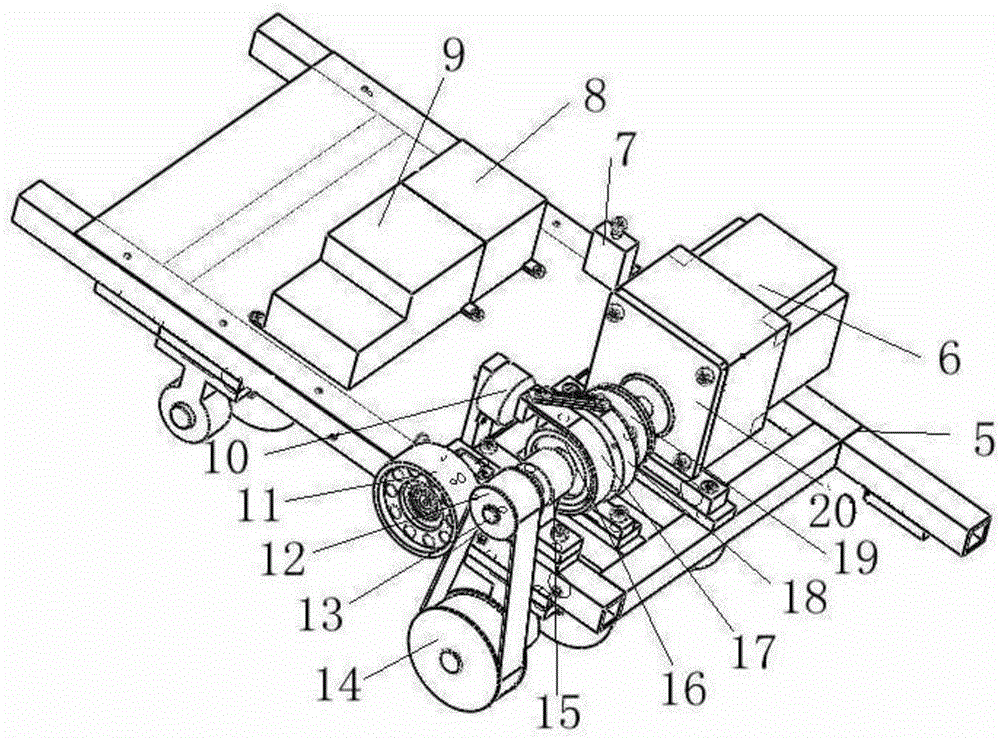

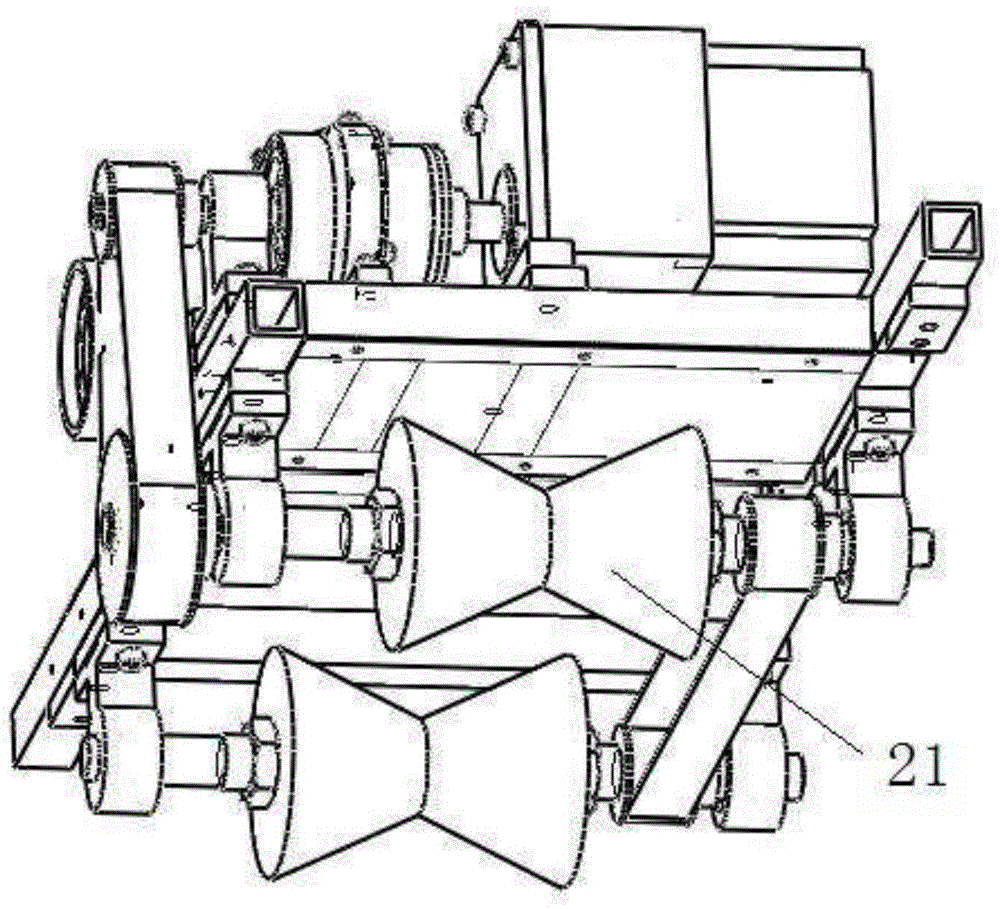

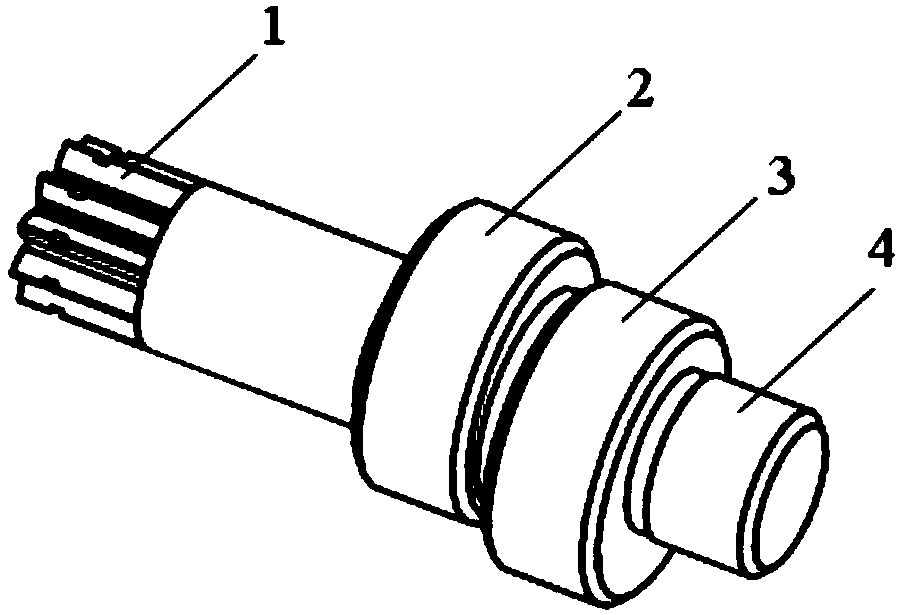

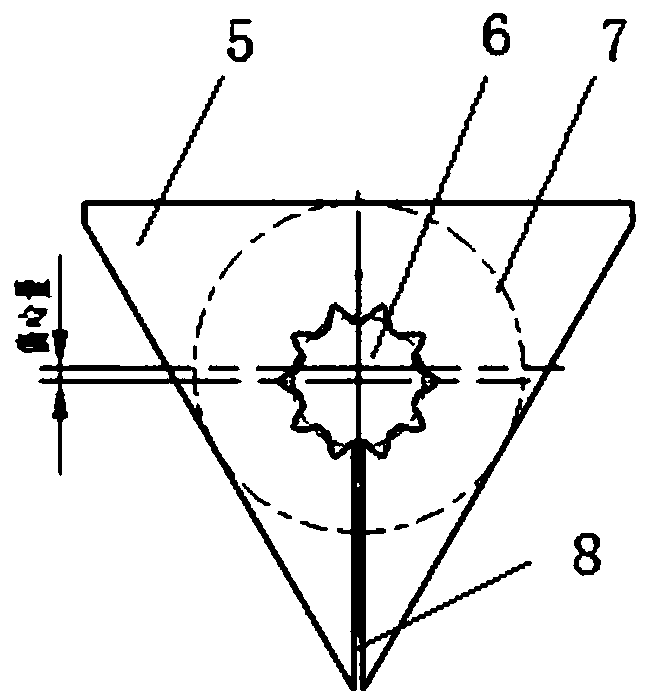

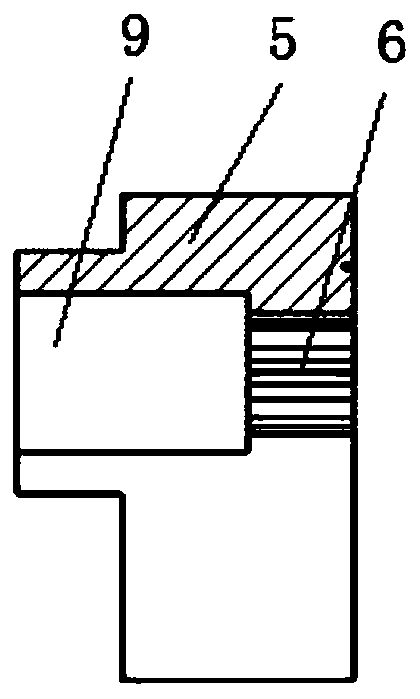

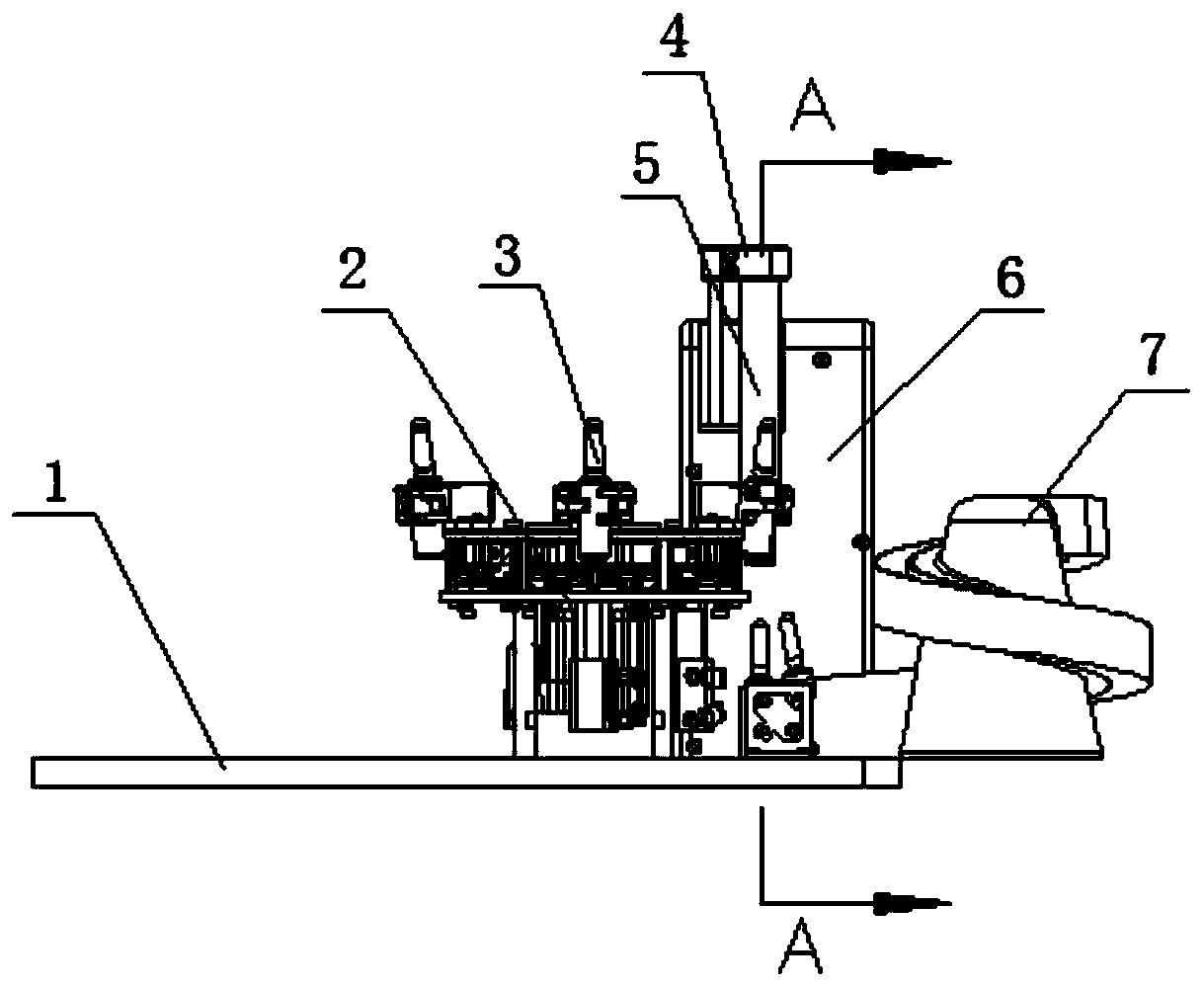

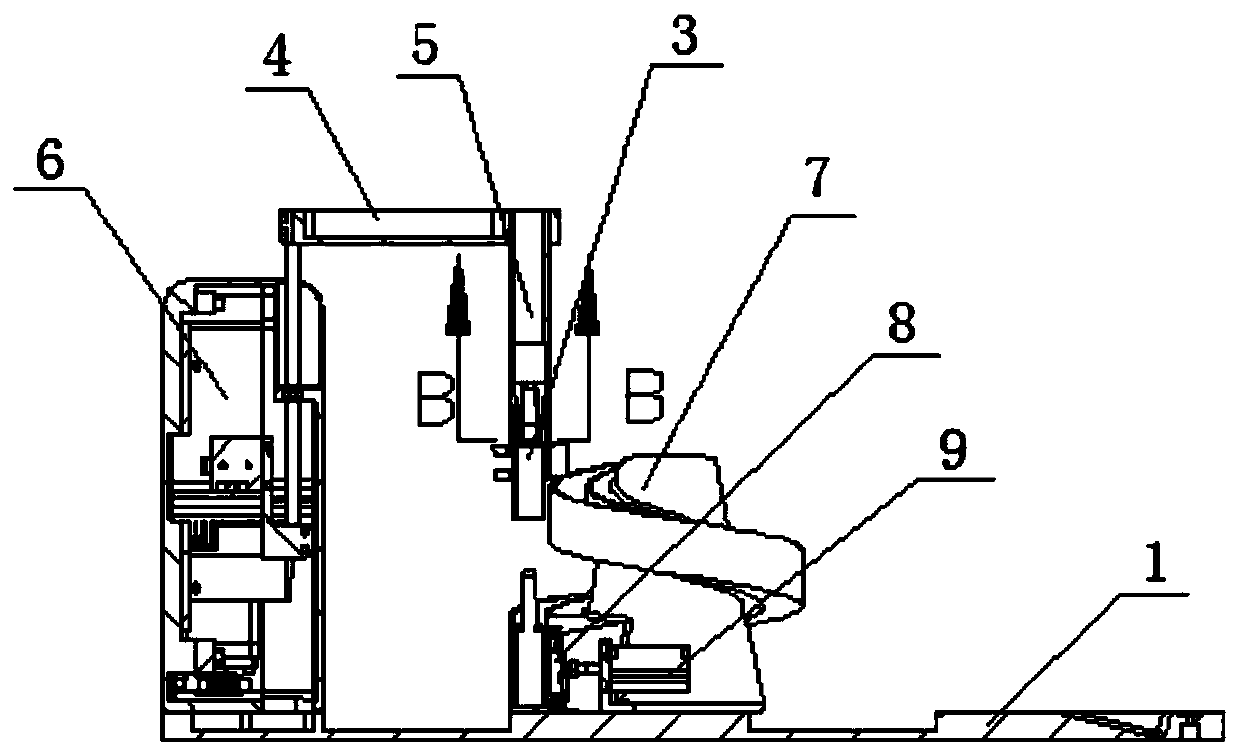

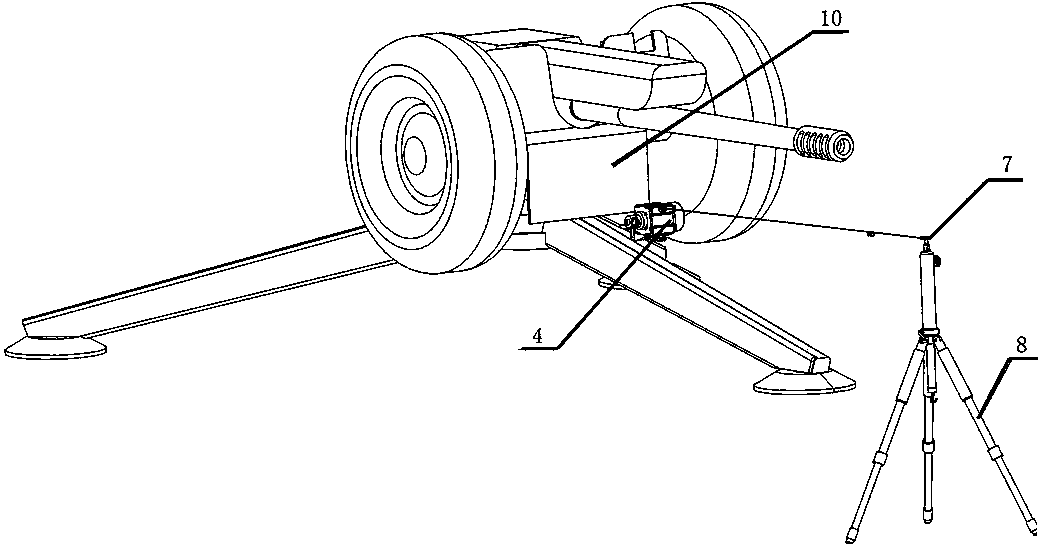

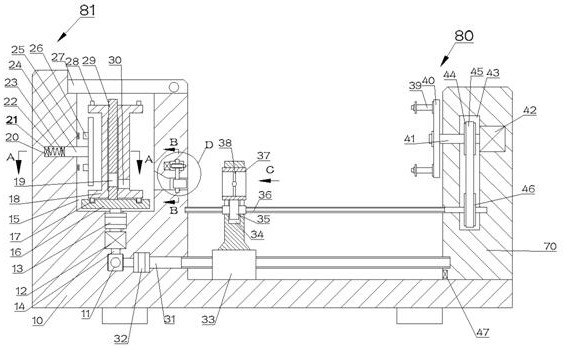

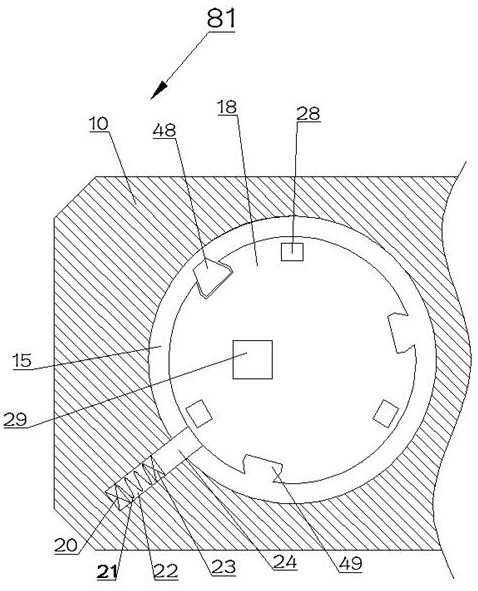

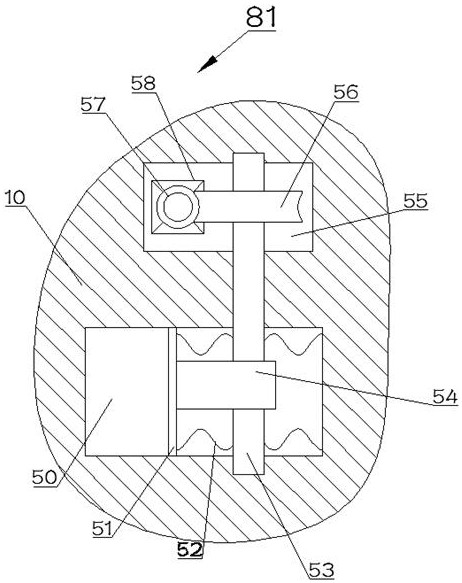

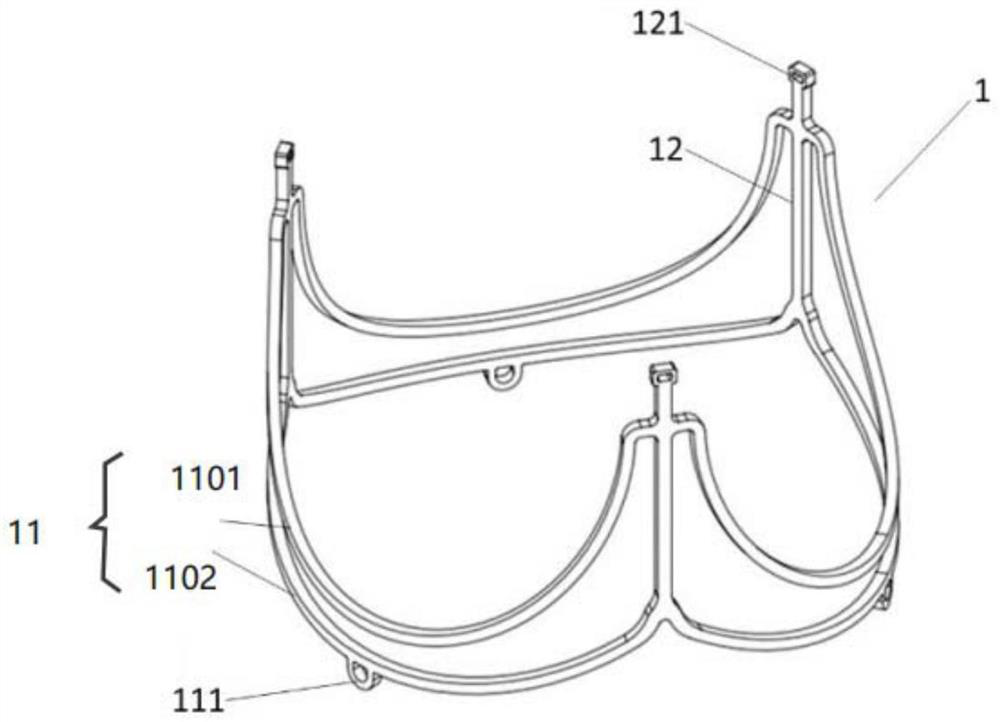

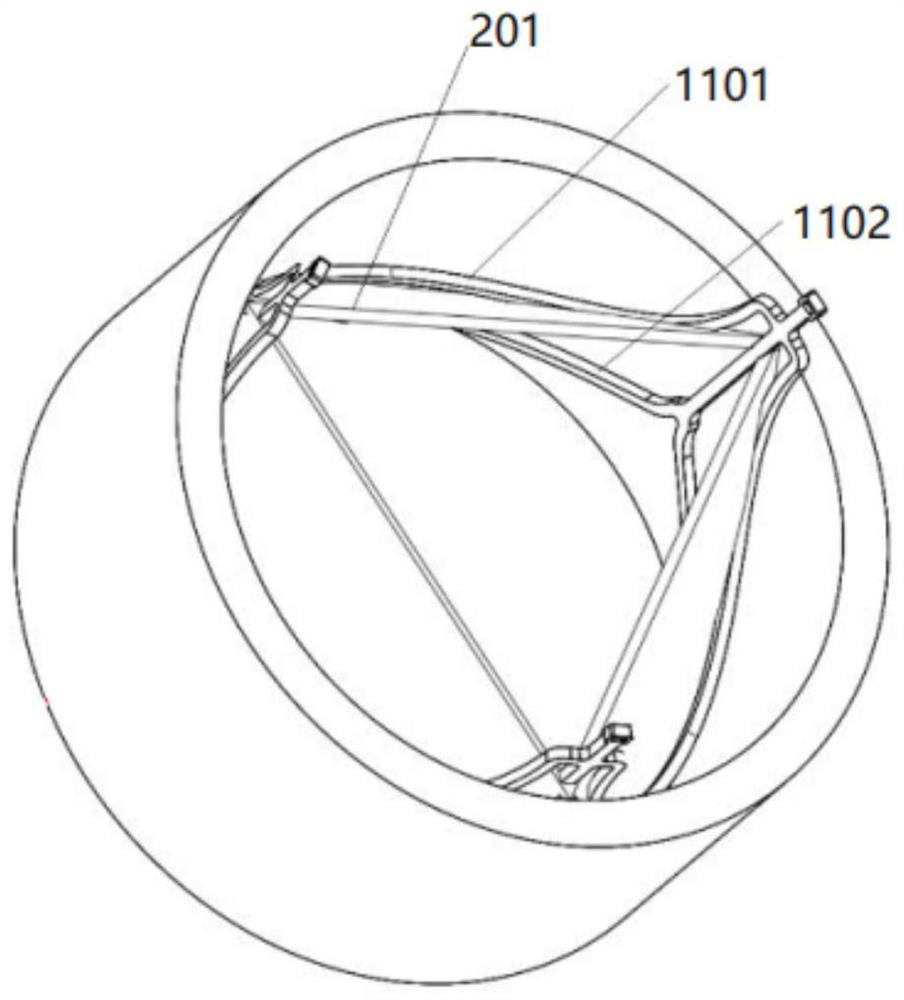

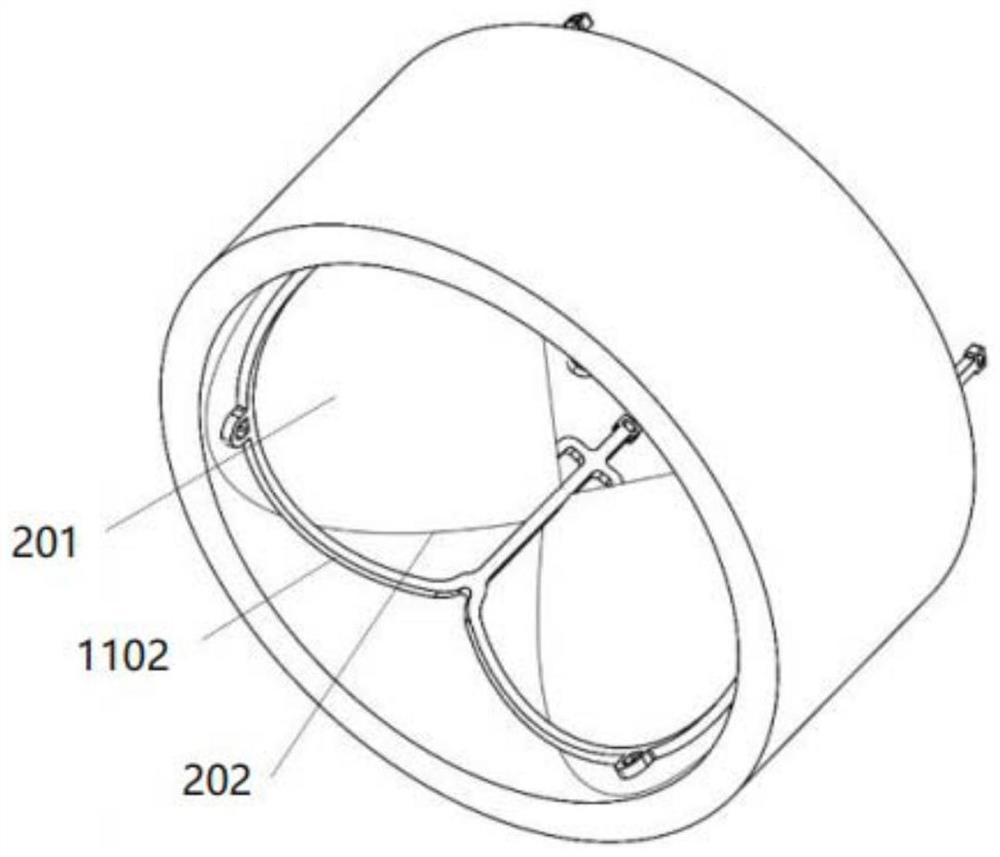

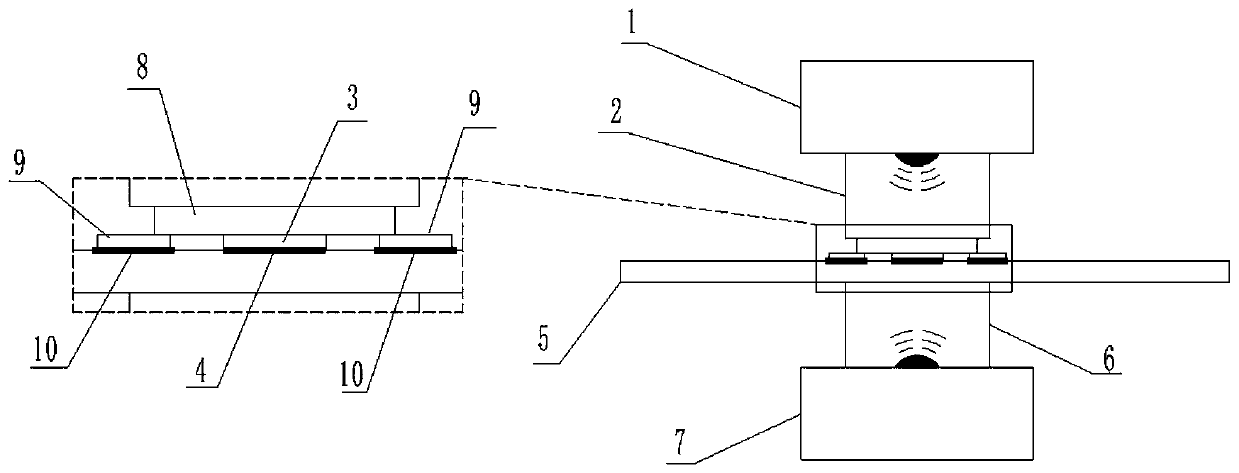

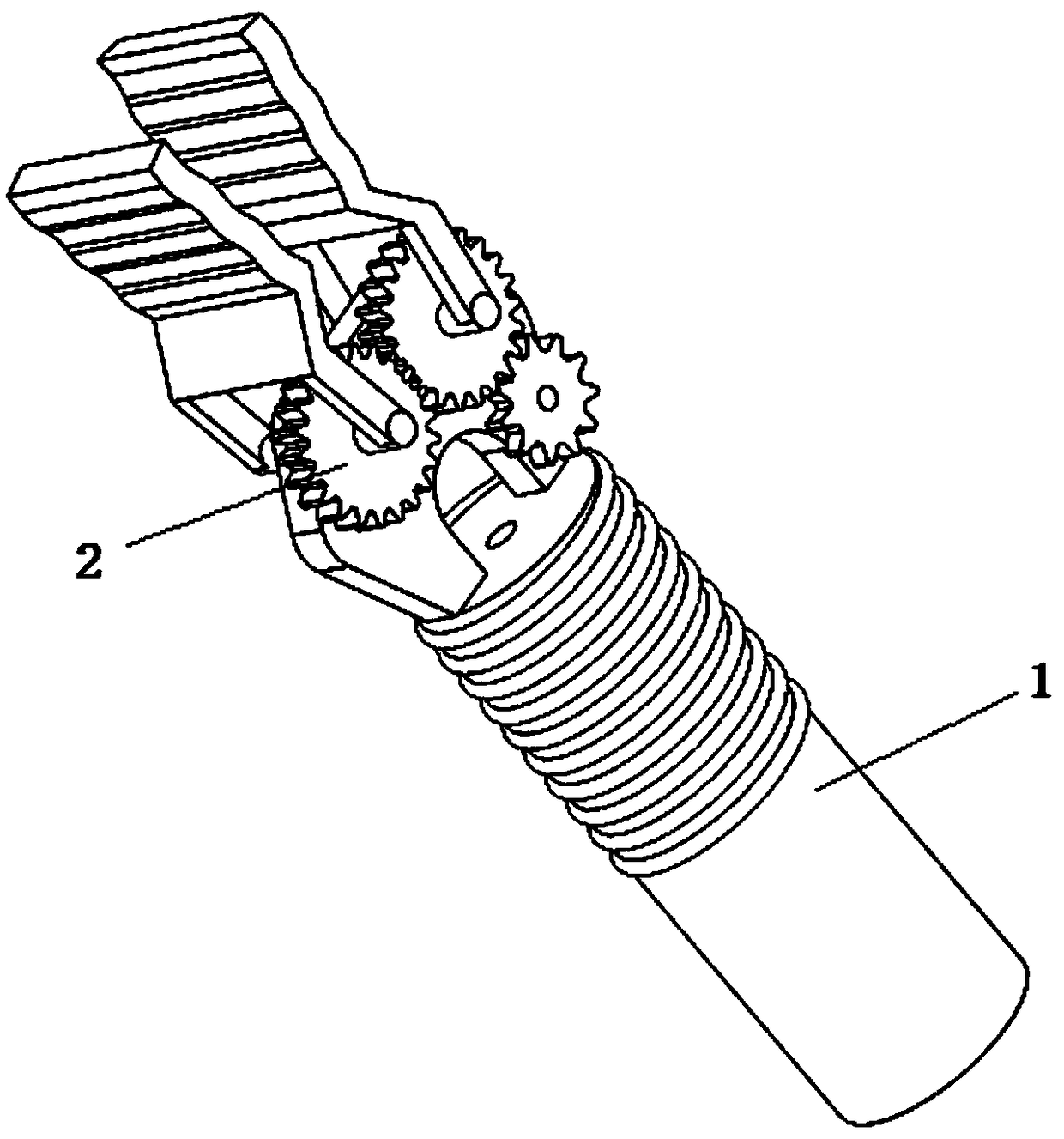

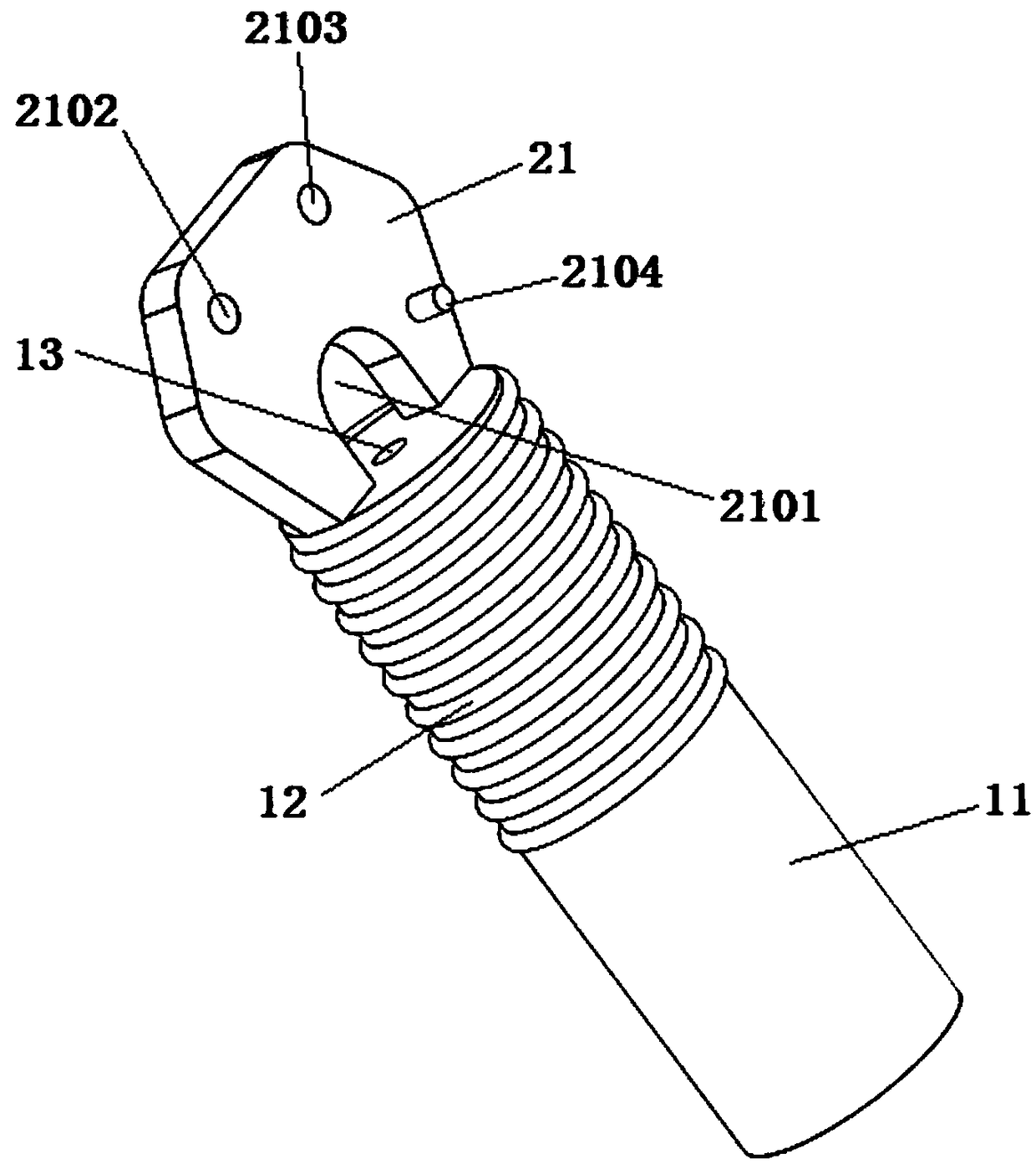

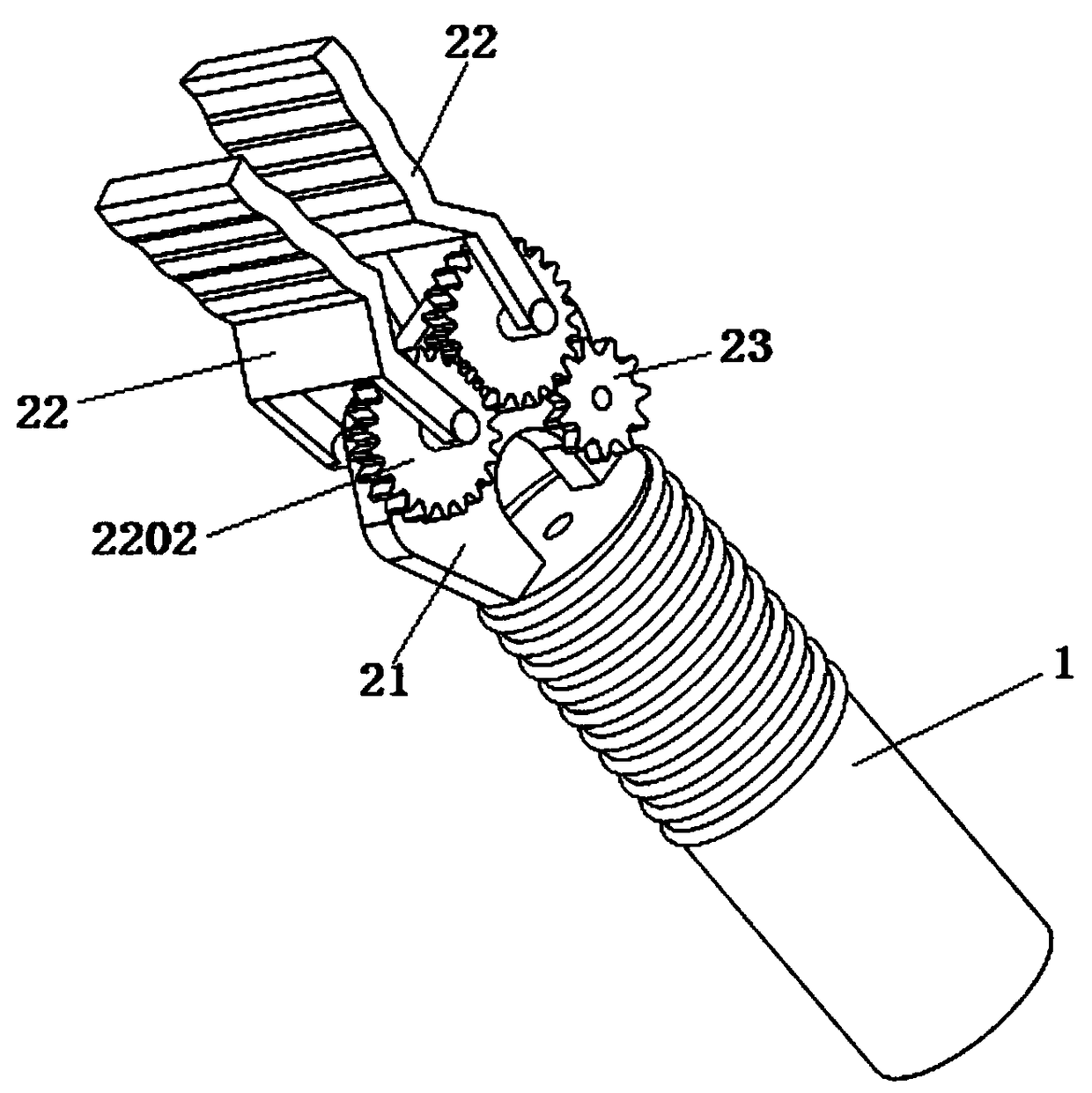

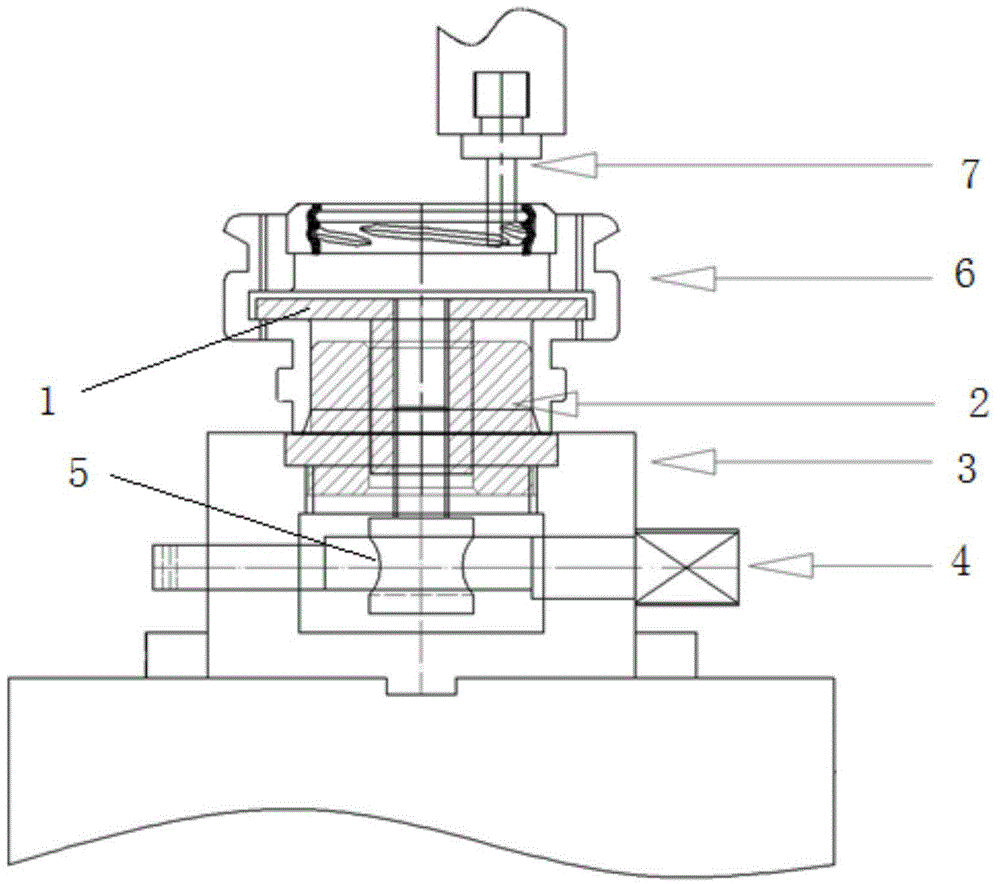

The invention provides a cable-stayed bridge cable, which comprises a driving module 1, a driven module 2, a detection module 3 and a power-off protection module 4, wherein the driving module 1 takes a driving frame 5 as a mounting platform; the driven module 2 takes a driven frame 27 as a mounting platform; the detection module 3 takes a camera support frame 53 as a mounting platform; the power-off protection module 4 takes a mounting frame 56 as a mounting carrier; the driving frame 5 is connected with the driven frame 27 through connecting yokes 44 and connecting bars 45; the detection module 3 is connected with the driving frame 5 and the driven frame 27 respectively through the camera support frame 53; the power-off protection module 4 is connected with the driving frame 5 through the mounting frame 56. When an electromagnetic clutch is cut off, an electromagnet works to drive a brake band to enclasp a brake wheel, so that the robot is prevented from slipping off; and a clamping way is simple and practicable.

Owner:SHANGHAI TONGJI CONSTR QUALITY INSPECTION STATION

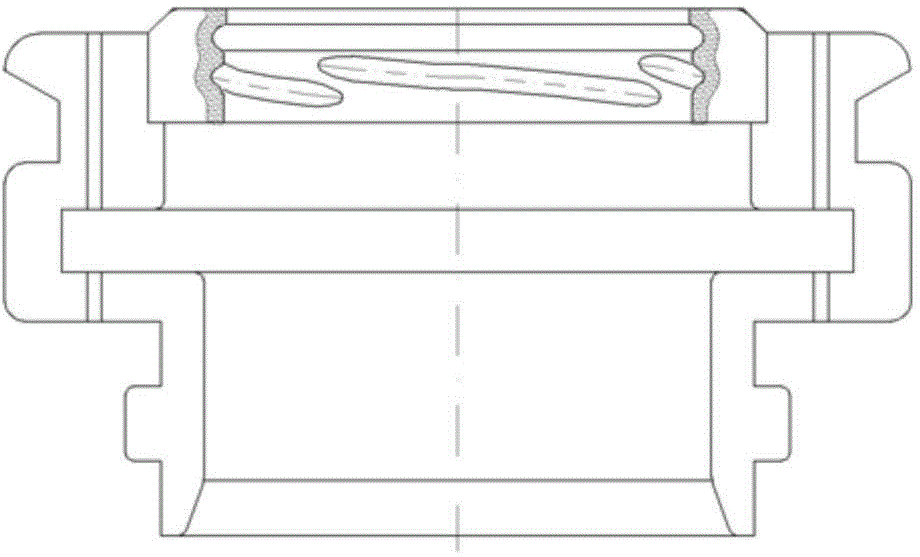

Lathe work method for thin-walled parts of middle-small diameter

ActiveCN101015863AImprove stabilityReduce distortionAutomatic control devicesTurning toolsEngineeringMechanical engineering

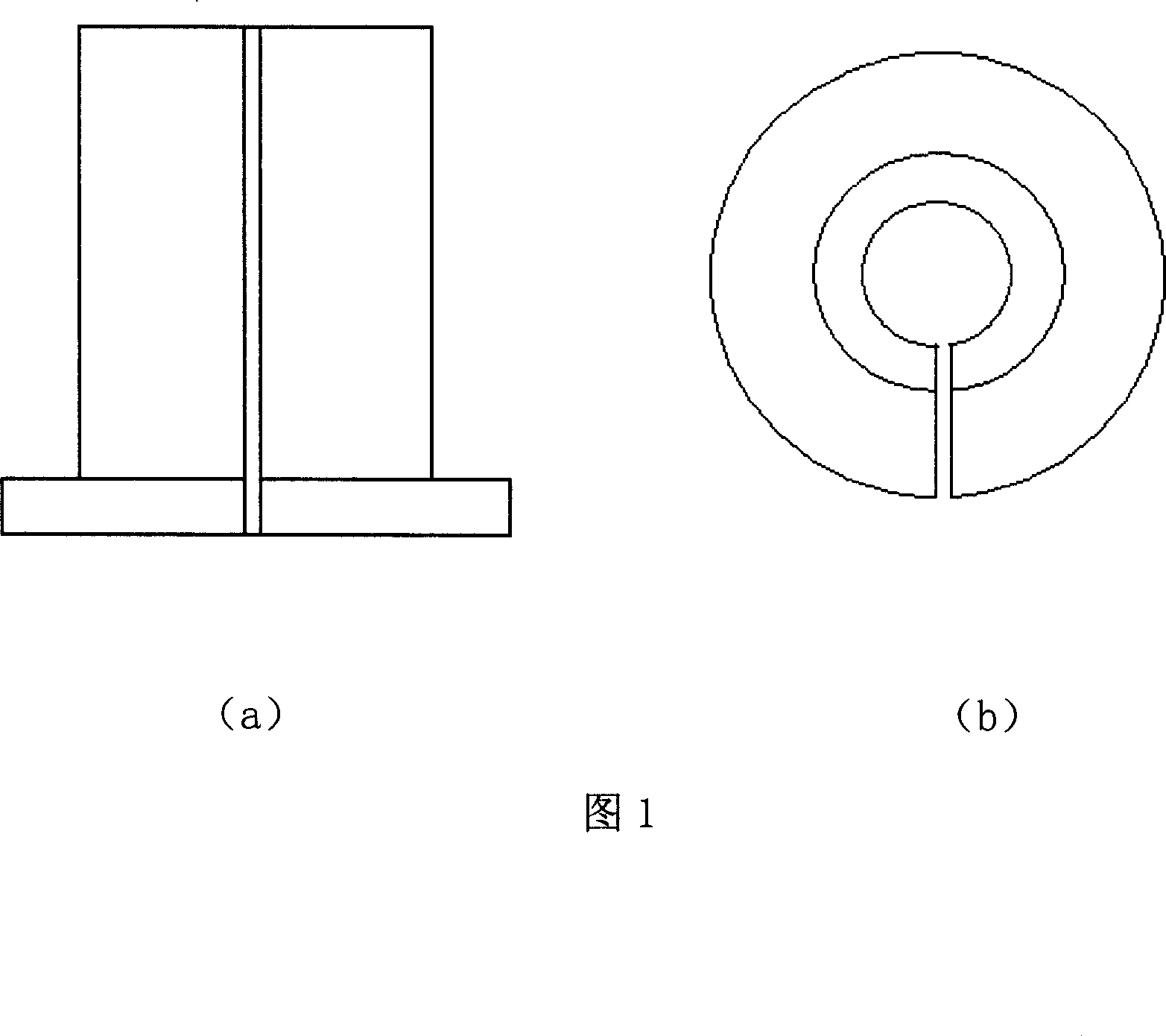

The invention discloses a method for turning middle and small thin-wall element, wherein the invention uses auxiliary clamper on general turning machine, first based on the outer diameter of element, produces a slim sheath with same diameter and middle slim as auxiliary clamper, machines the blank of object element, then puts the draw-in gear into the inner hole of slim sheath, puts them together into three-claw positioning clamping disc of turning machine, clamping and machining roughly and finely, and since the invention uses slim sheath as auxiliary clamper, the long-disc claw can obtain uniform dispersed clamping force on the surface of object element, to reduce unit clamping force, reduce vibration and deformation or the like. And the invention improves efficiency via transferring thin-wall element on three-claw automatic positioning clamping disc.

Owner:XIAN SHAANGU POWER

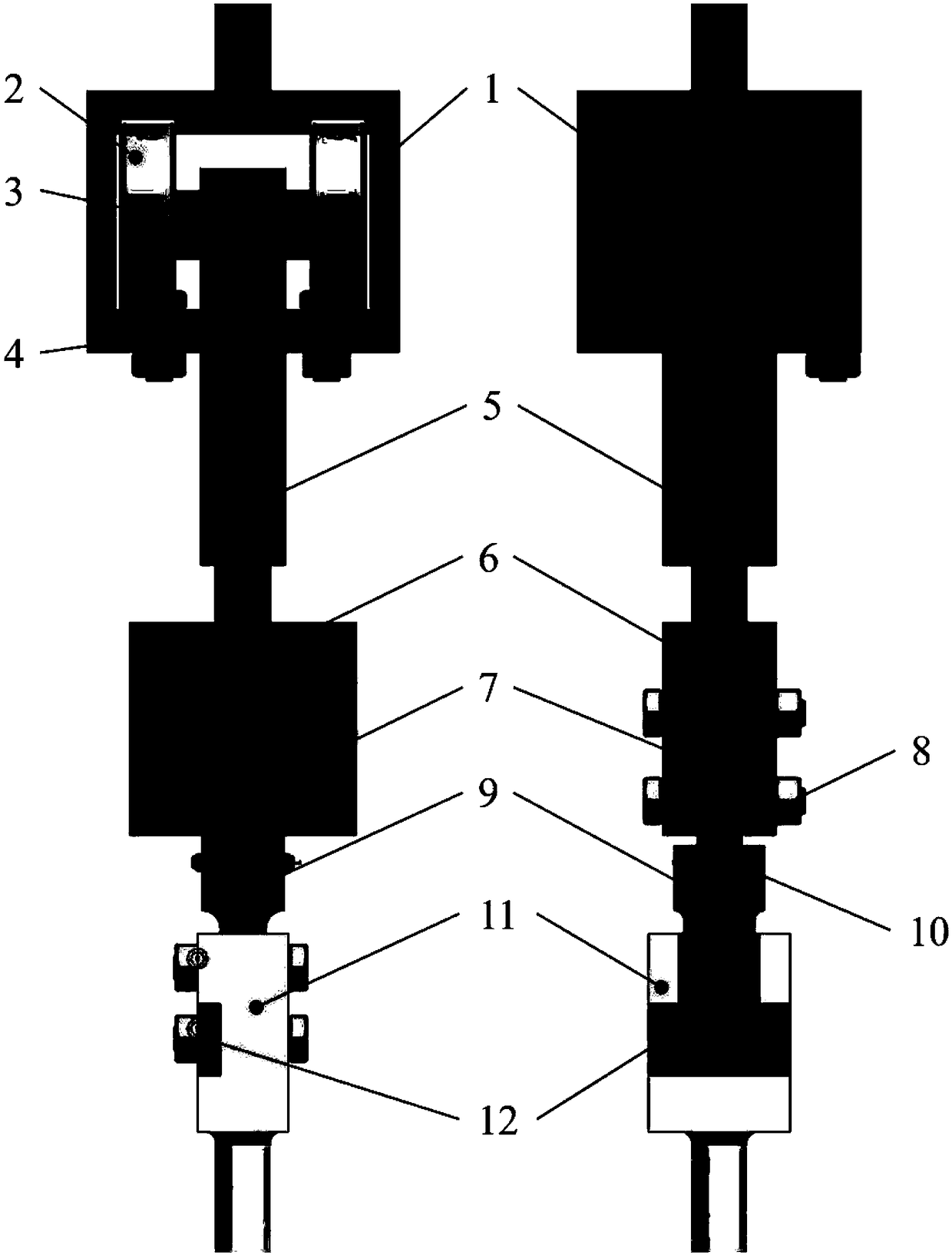

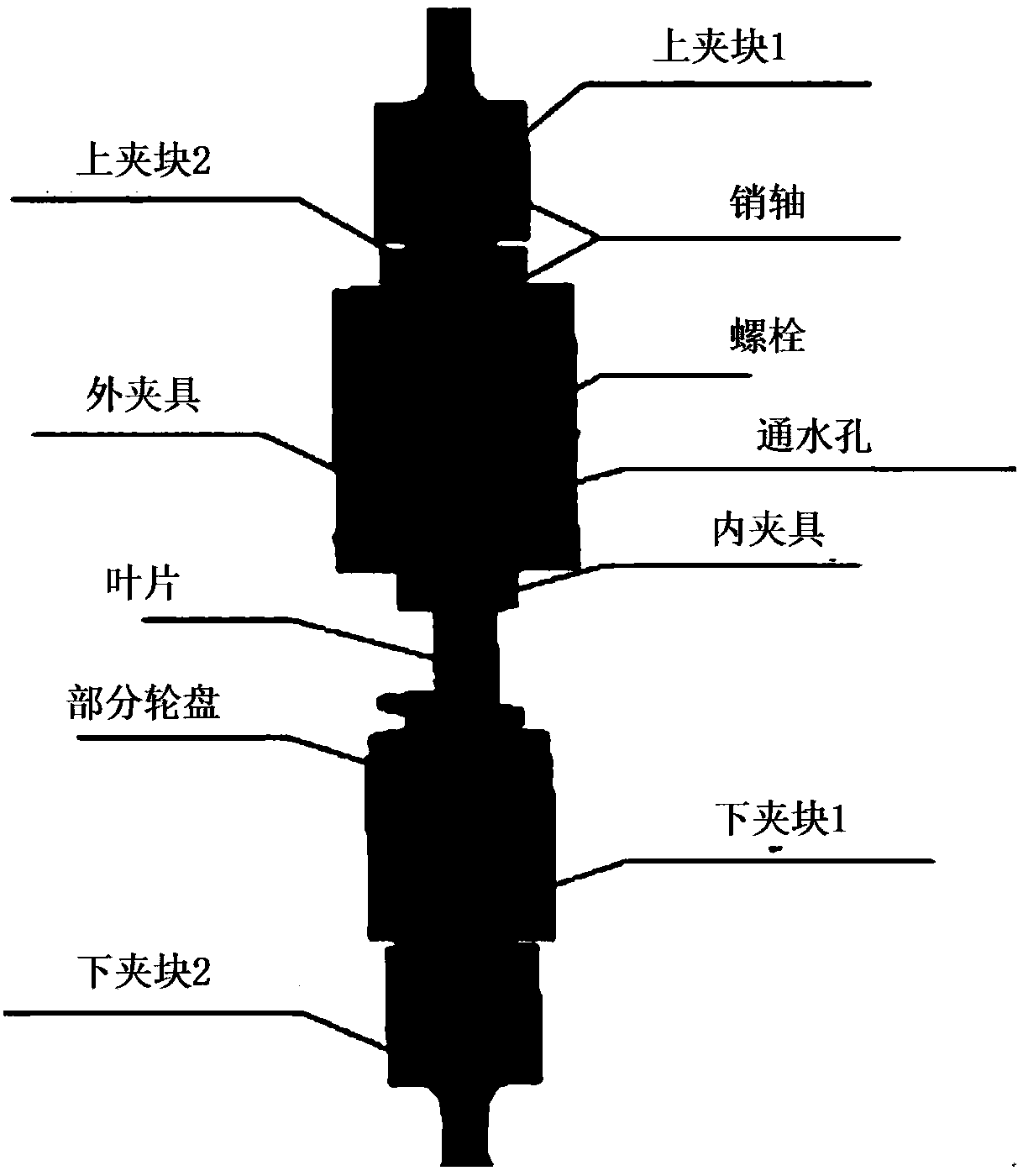

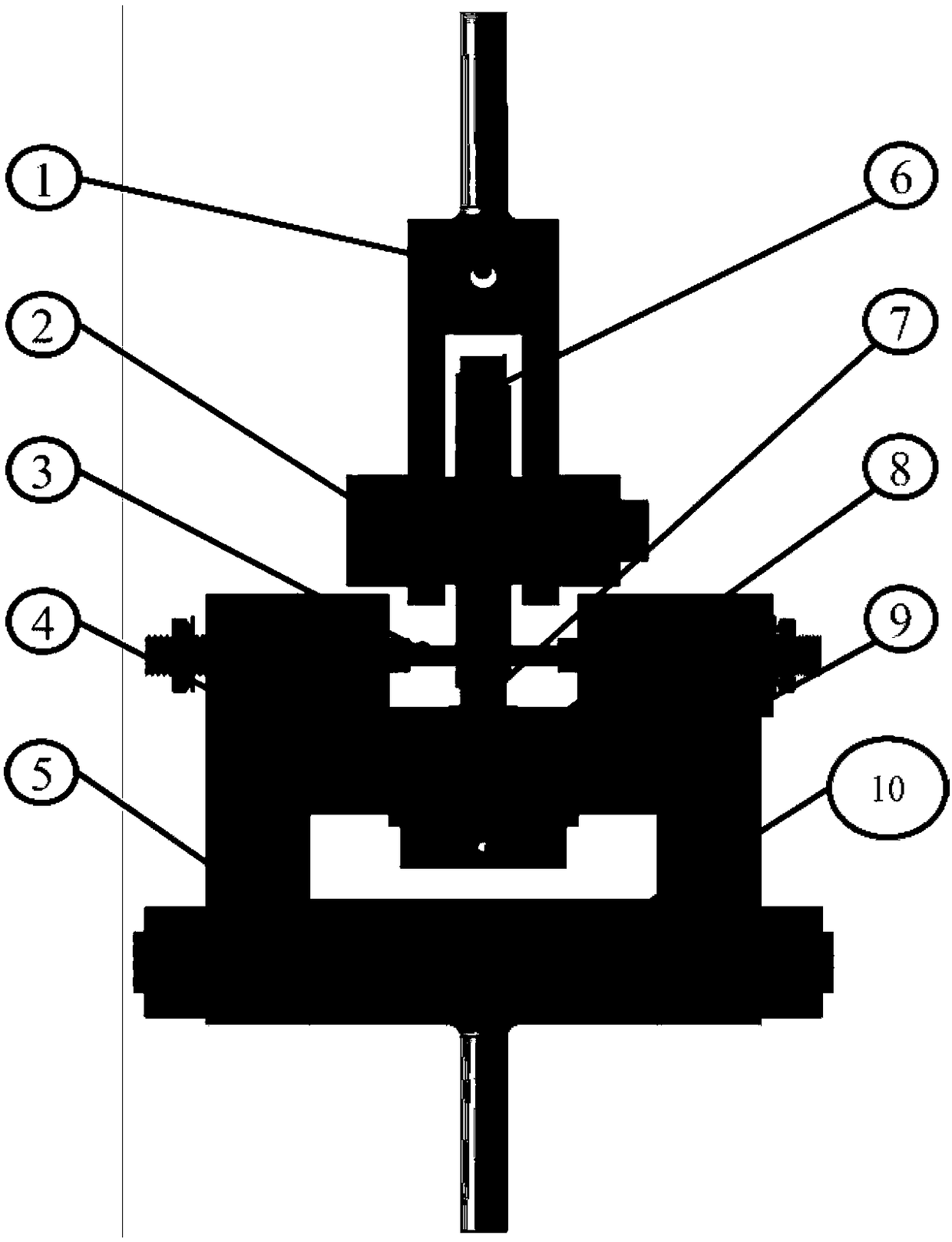

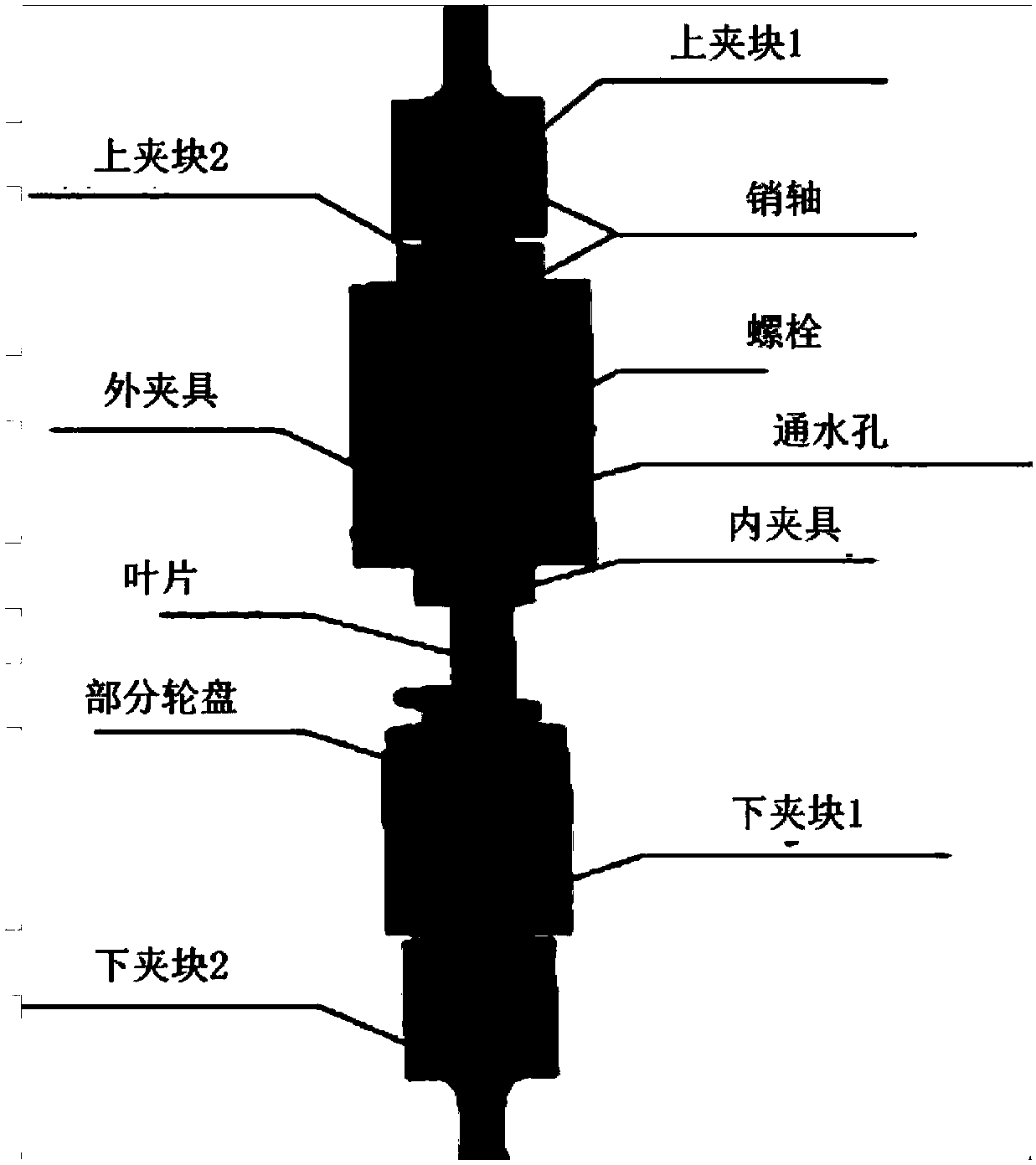

High-low-cycle complex fatigue test clamp of turbine joggle joint structure

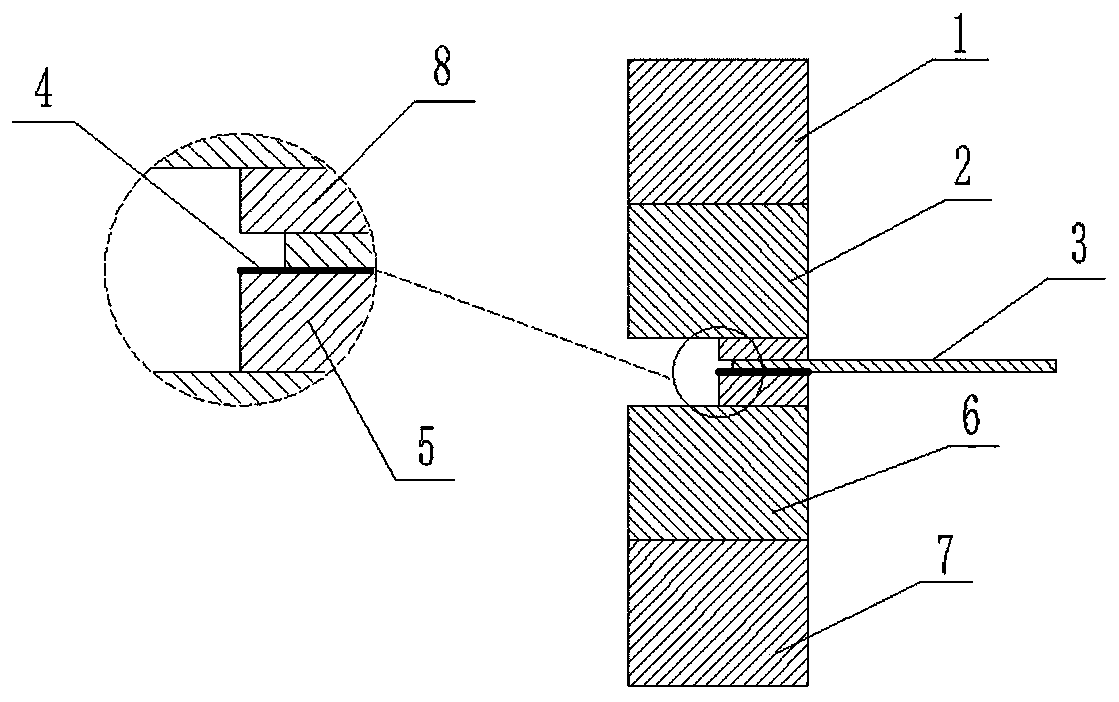

The invention relates to a high-low-cycle complex fatigue test clamp of an aero-engine turbine joggle joint structure. A fatigue machine clamps the lower end of a mortise clamp and fixes a mortise test piece through bolts; the mortise test piece is connected with a tenon test piece through tenon teeth and limited to slide in the mortise direction of the mortise through a limiting baffle; a tenon clamp clamps a tenon test piece clamping part through a double-wedged surface; the upper portion of the tenon clamp is connected with a force transmission pull rod through threads; three threaded holesare formed in the force transmission pull rod, high-cycle vibration excitation rods are screwed in the threaded holes, and the upper portion of the force transmission pull rod is in clearance fit with a roller transmission shaft through a shaft hole structure; the two ends of the roller transmission shaft are symmetrically provided with a pair of ball bearings to form a roller structure, the rollers move along two guide grooves in an installation box, and the constraint of the high-cycle load application direction is released; the top end of the installation box is clamped by the fatigue machine; a low-cycle load is applied by the fatigue machine, the excitation rods are externally connected with a vibration exciter to apply a high-cycle load, and the joggle joint position is externally connected with an electric induction heating copper coil to apply a heat load.

Owner:BEIHANG UNIV

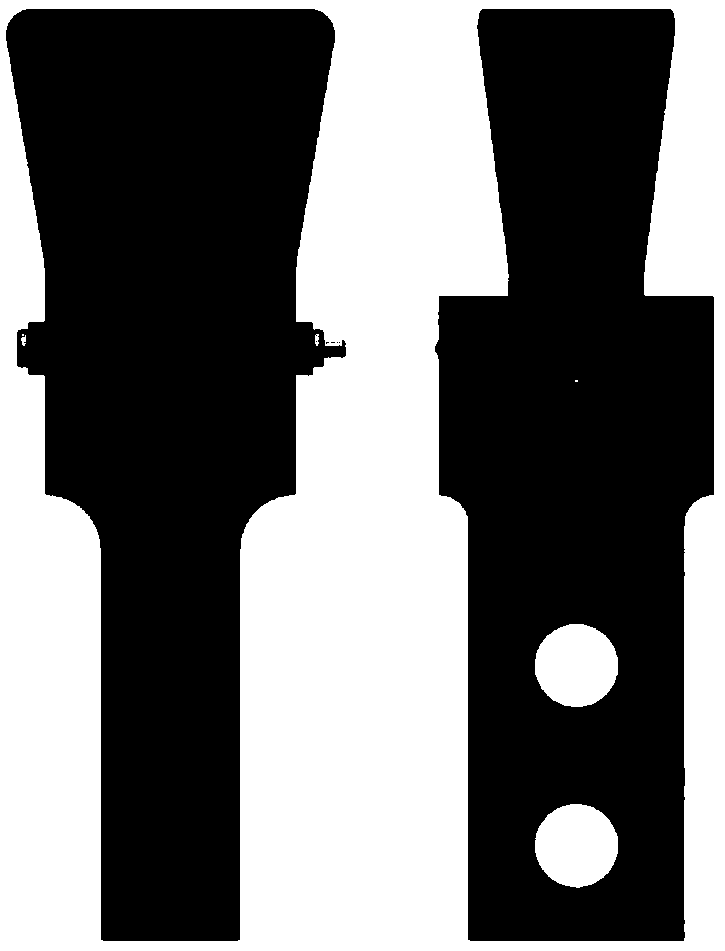

High-low cycle complex fatigue test clamp for mortise-joint structure of small blade of turbine

ActiveCN108444720ANo risk of being crushedNo risk of crushingEngine testingStrength propertiesTurbine bladeCopper coil

The invention relates to a high-low cycle complex fatigue test clamp for a mortise-joint structure of a small blade of a turbine on an aeroengine. By adoption of the high-low cycle complex fatigue test clamp, synchronous loading of longitudinal low-cycle large load, horizontal high-cycle vibration load and heat load in test of the mortise-joint structure of the small blade of the turbine is realized. The high-low cycle complex fatigue test clamp is characterized in that a top holding structure is clamped on a fatigue machine, and a turbine disc is fixed by a clamping bolt; the turbine disc isconnected with the turbine blade in a mortise-joint manner; a small blade clamp clamps a blade body of the turbine blade by means of frictional force; the bottom part of the small blade clamp is tightly screwed with a high-cycle excitation rod by a bolt, and the top part of the small blade clamp is in clearance fit with a force-transmission top plate by a shaft-hole structure; the force-transmission top plate is in clearance fit with force-transmission pulling plates by shaft-hole structures, the stability of the structure is maintained by fixed long bolts; the force-transmission pulling plates are tightly screwed with a low-cycle force applying structure by nuts; the lower part of the low-cycle force applying structure is clamped by the fatigue machine; the fatigue machine applies the low-cycle load, the excitation rod is externally connected with an exciter to apply the high-cycle load, and the mortise-joint position is externally connected with an induction heating copper coil to apply the heat load. The high-low cycle complex fatigue test clamp has the beneficial effects that stable clamping of the mortise-joint structure of the small blade of the turbine can be met, and the high-low cycle compounding fatigue under the high-temperature condition can be realized.

Owner:BEIHANG UNIV

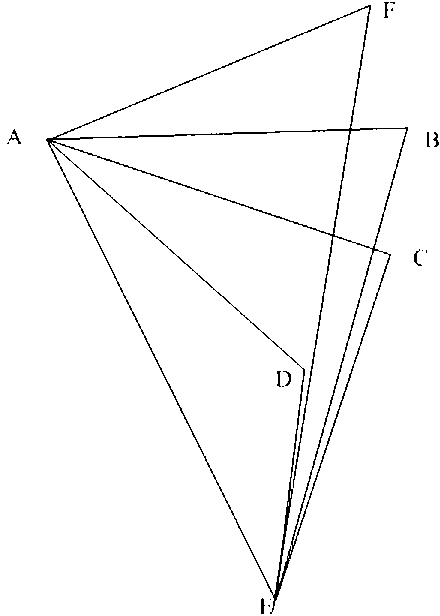

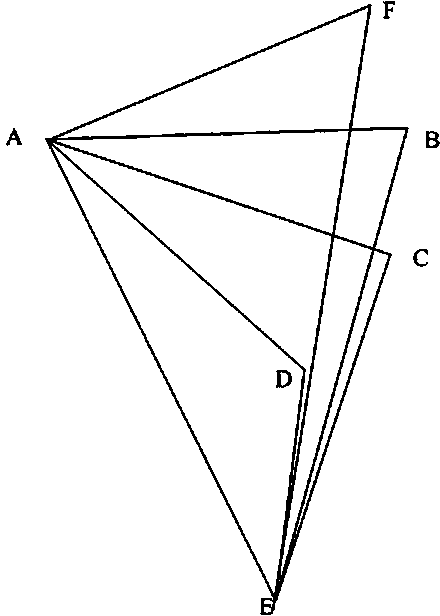

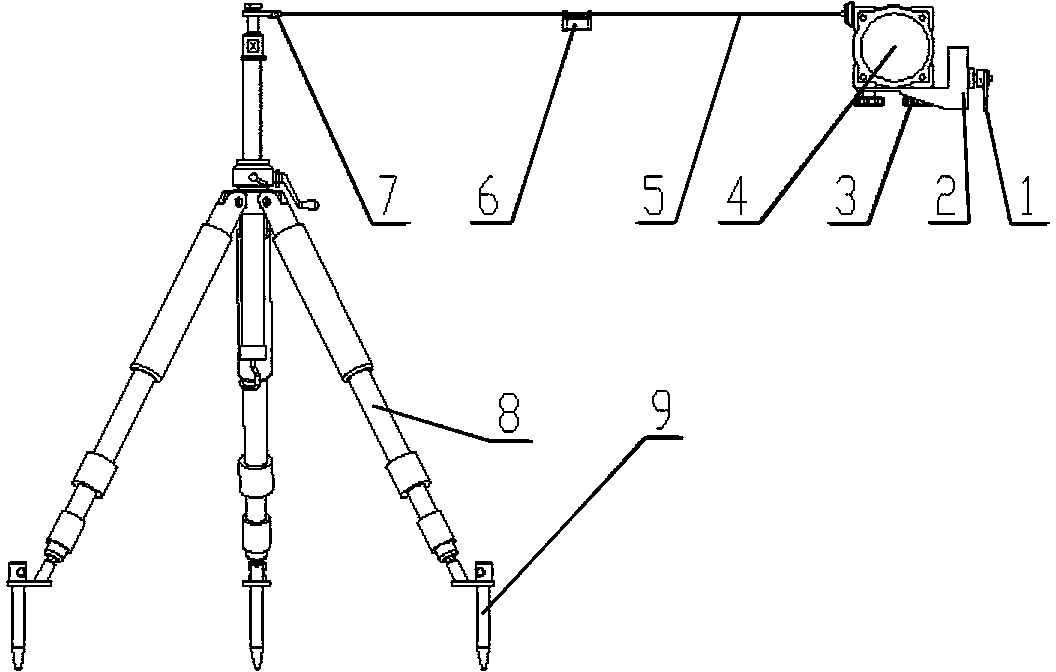

Pull-wire type angle measurement system

InactiveCN102721392AHigh measurement accuracyLow costMeasurement devicesControl theoryMechanical engineering

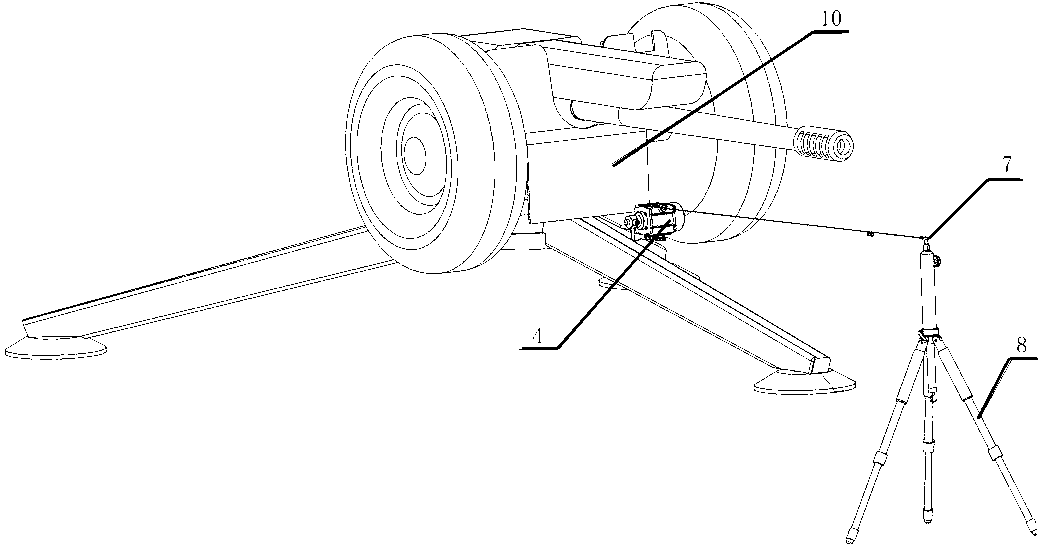

A pull-wire type angle measurement system of the invention relates to the angle measurement system based on a high-precision pull-wire type encoded sensor and especially relates to an apparatus applying for indirect aim gun tube rotation angle measurement. A function of the system is that a rotation angle of a gun tube which projects on a horizontal plane is measured precisely and a backlash influence of a structure of the gun itself is eliminated under the condition that structure reconstruction is not performed on indirect aim gun equipment. The system is formed by a pull-wire length measurement mechanism, a resolving circuit and a calibration circuit. The pull-wire length measurement mechanism comprises a pull-wire type encoder, a fixing and guiding device and a horizontal measurement apparatus. The resolving circuit and the pull-wire type encoder carry out data communication through a RS422 interface. A core control chip of the resolving circuit is a microprocessor based on an ARM-Cortex3 core. The calibration circuit adopts an ARM-Cortex3 series microprocessor, is connected with the resolving circuit through an RS232 interface and comprises a group of operation keyboards and a display nixie tube.

Owner:NO 60 RES INST OF GENERAL STAFF DEPT PLA

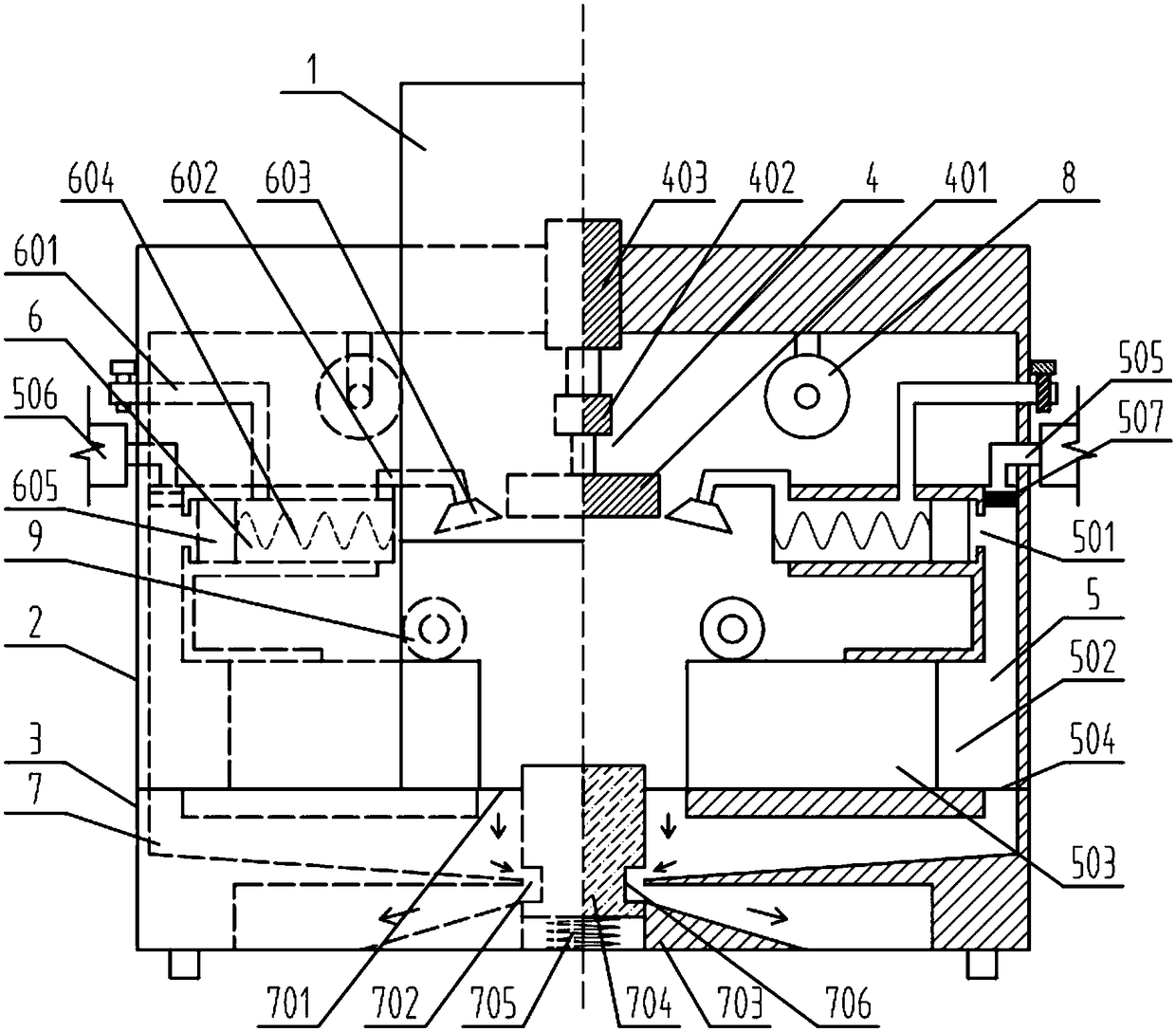

Car accessory grinding tool

InactiveCN108500847ASimple clamping methodAccelerateEdge grinding machinesGrinding carriagesMachiningVacuum pump

The invention belongs to the technical field of car accessory machining, and particularly discloses a car accessory grinding tool. The car accessory grinding tool comprises a box body vertically connected with a lifting door in a sliding manner and a base, a grinding mechanism is arranged on the center of the top of the box body, the left side wall and the right side wall of the box body are provided with an air flow guide pipe and a cleaning pipe, a sweeps pipe is arranged on the base, a dust suction opening and a dust outlet are formed in the sweeps pipe, an air outlet pipeline is arranged on the air flow guide pipe, the air outlet pipe is connected with a vacuum pump, a water inlet pipe and a water outlet pipe are arranged on the cleaning pipe, a first sliding block and a first spring are arranged in the cleaning pipe, a second communication opening is provided with a clamping block, a first sliding base is arranged on the center of the bottom of the base, a floating block is in sliding connection into the first sliding base vertically, and the bottom of the floating block is connected with a first sliding base through a second spring; and a power mechanism and a driven gear arearranged in the box body. The car accessory grinding tool is low in noise during work.

Owner:宁波鑫神泽汽车零部件有限公司

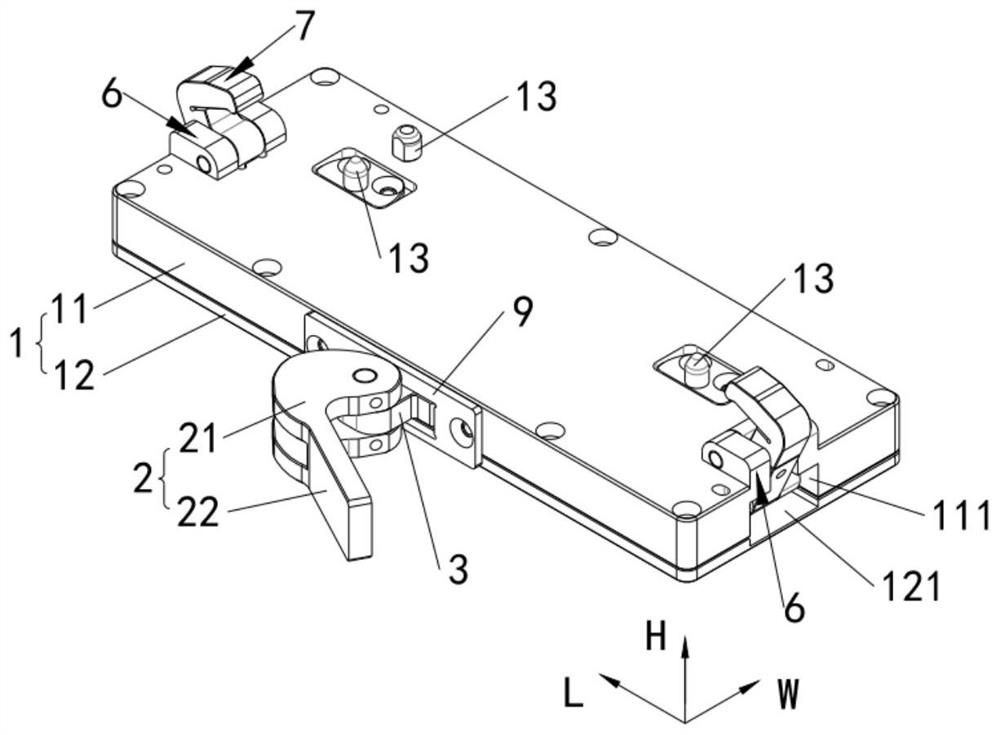

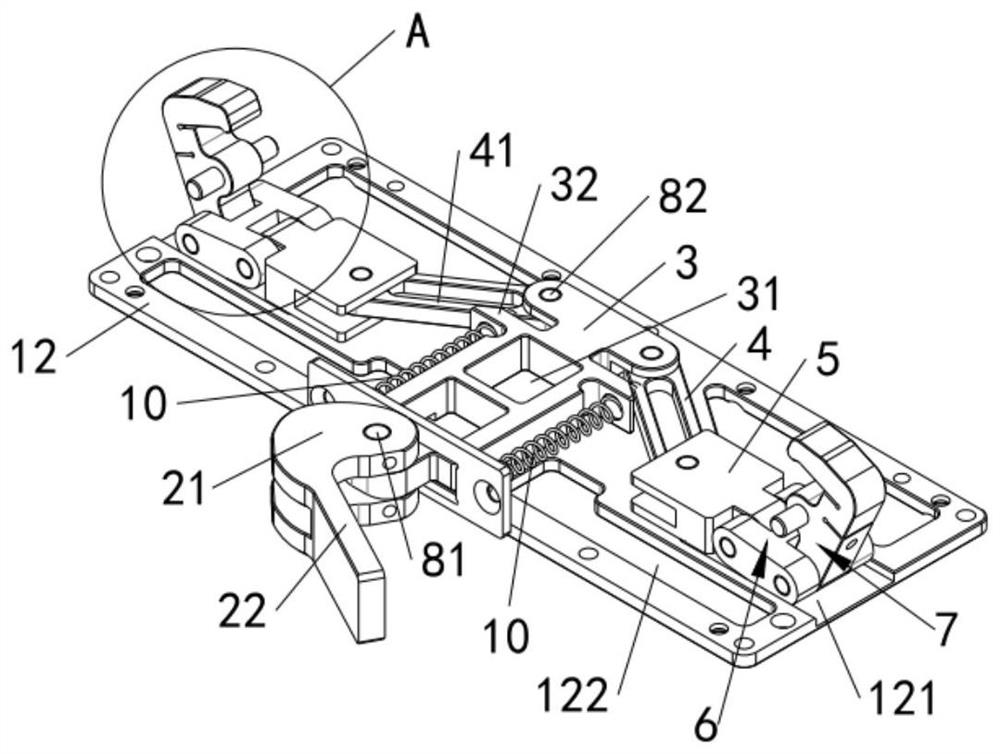

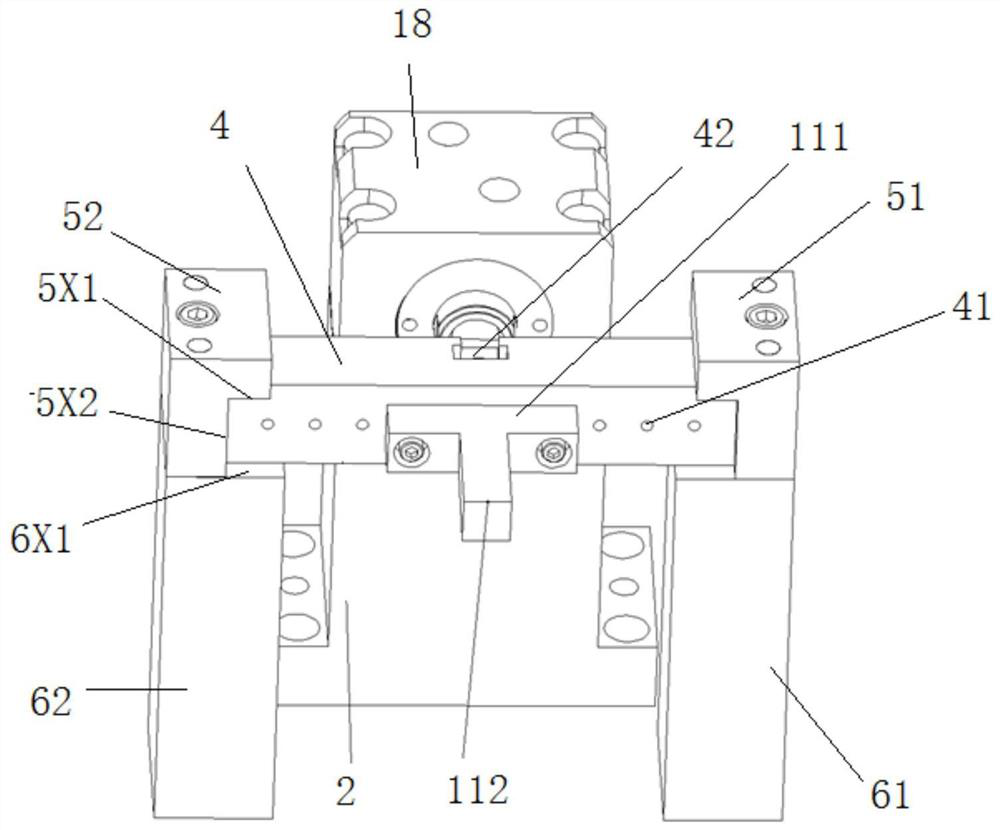

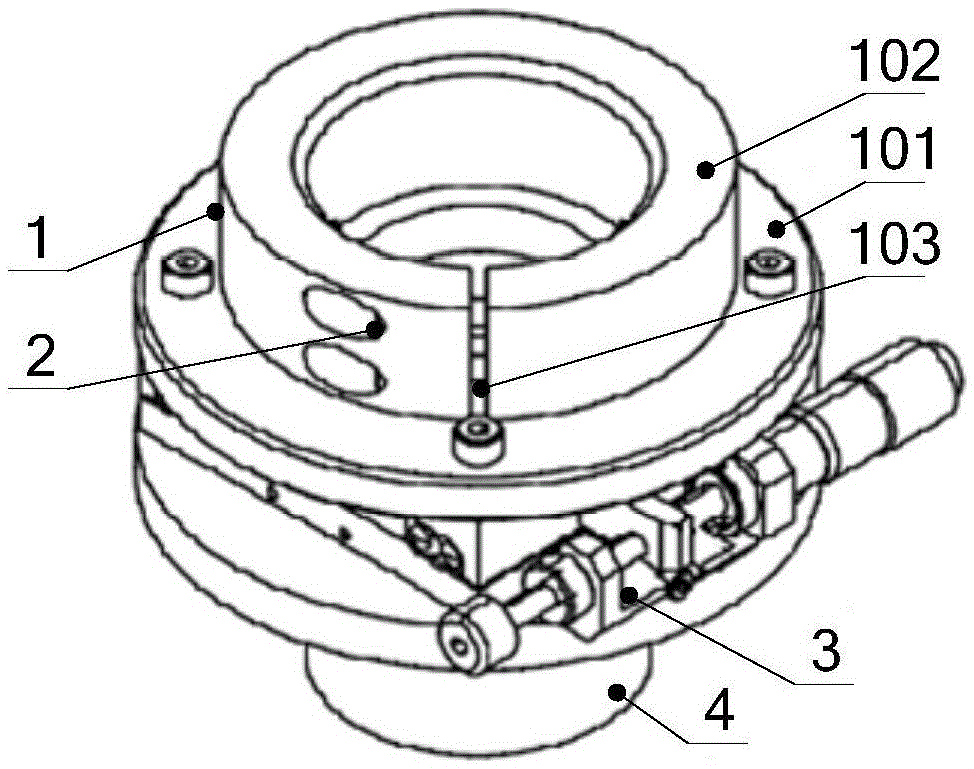

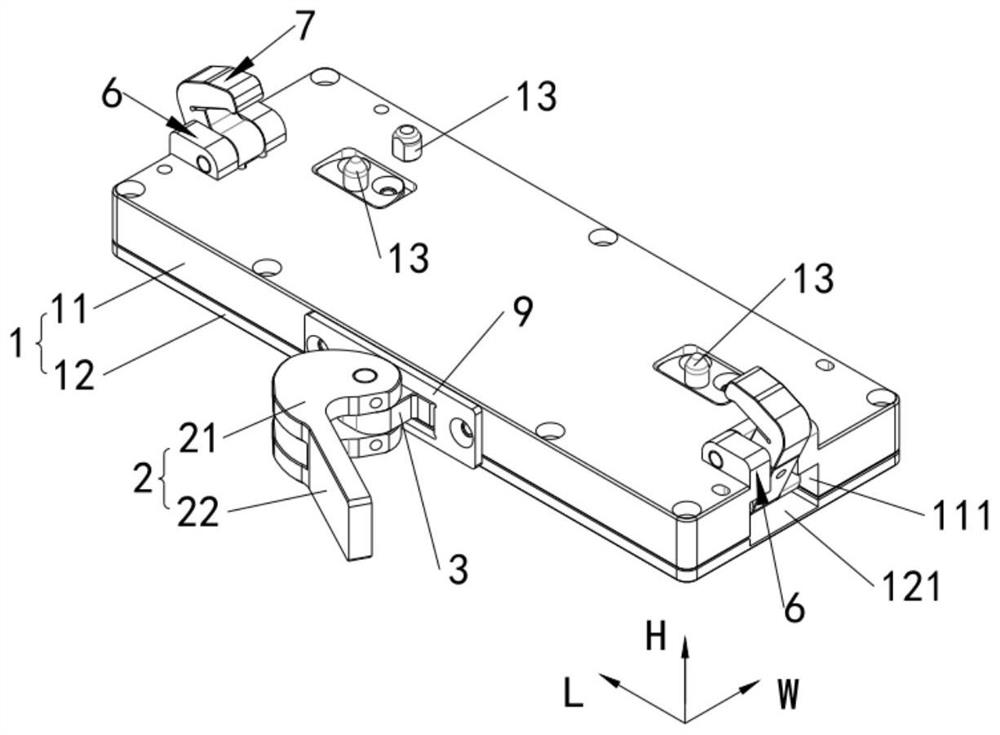

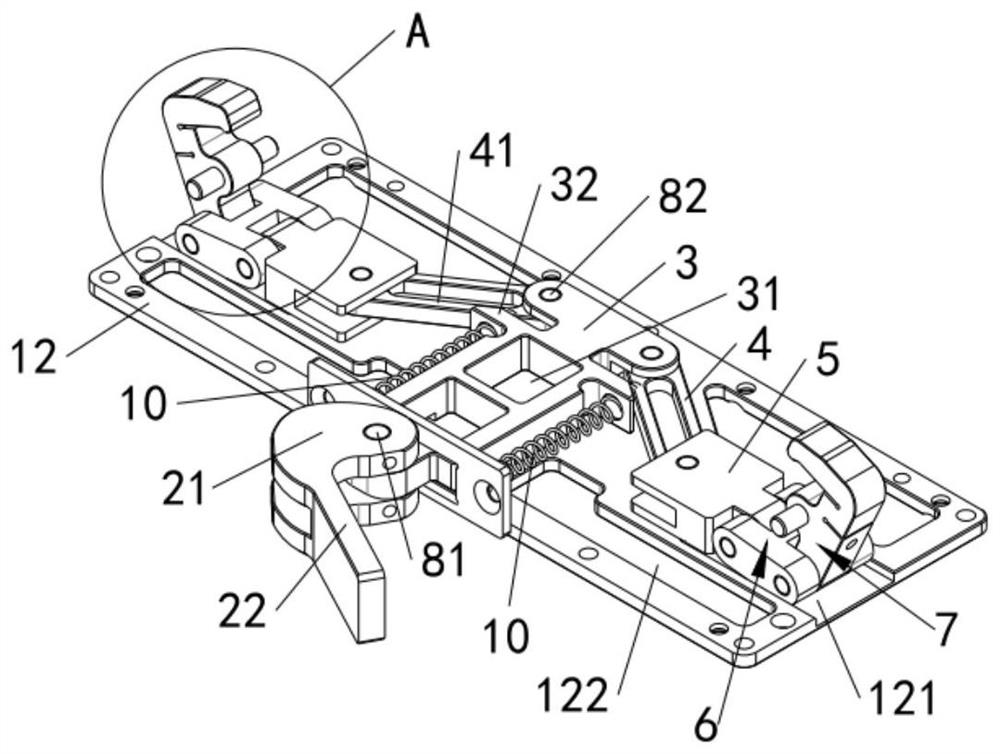

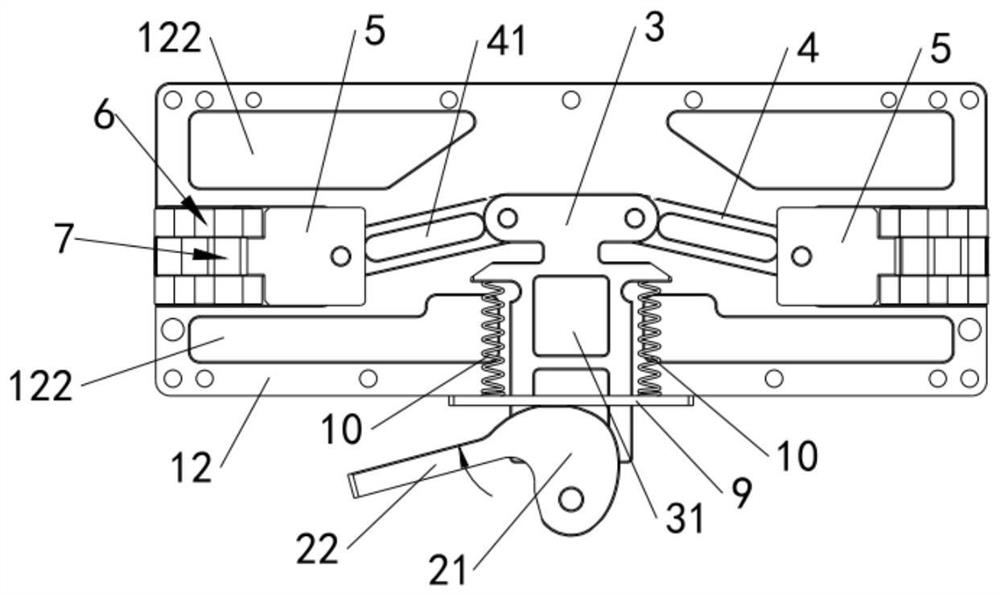

Manual positioning and clamping device

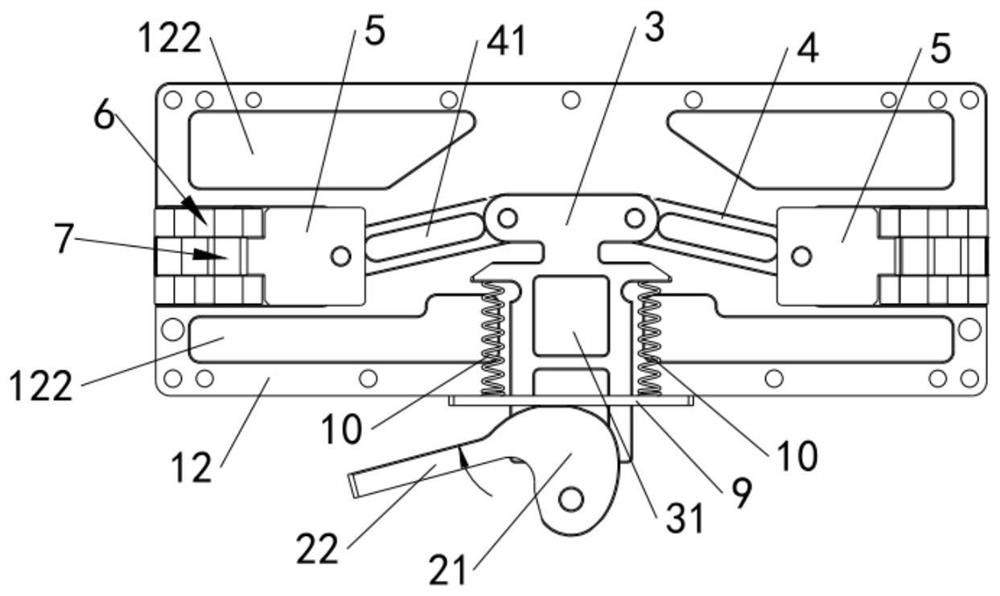

The invention relates to the field of clamping equipment, and particularly discloses a manual positioning and clamping device. The manual positioning and clamping device comprises a workbench, a cam handle, a first connecting rod, second connecting rods, sliding blocks, floating blocks and clamping jaws. The first connecting rod moves in the first horizontal direction by rotating the cam handle, the second connecting rods are driven to rotate relative to the first connecting rod and the corresponding sliding blocks, and then the second connecting rods are used for pushing the corresponding sliding blocks to move in the second horizontal direction. Then, the sliding blocks drive the corresponding floating blocks to rotate, the corresponding clamping jaws rotate around hinged shafts of the clamping jaws, and therefore the second ends of the two clamping jaws get close to each other or get away from each other so as to clamp or loosen a workpiece located on a cover plate. The manual positioning and clamping device is simple in structure, after the workpiece is placed on the workbench, the workpiece can be clamped and loosened through the clamping jaws only by rotating the cam handle to drive the first connecting rod, the second connecting rods, the sliding blocks and the floating blocks to act, the clamping mode is simple, operation is fast, and the clamping efficiency is improved.

Owner:苏州润弘安创自动化科技有限公司

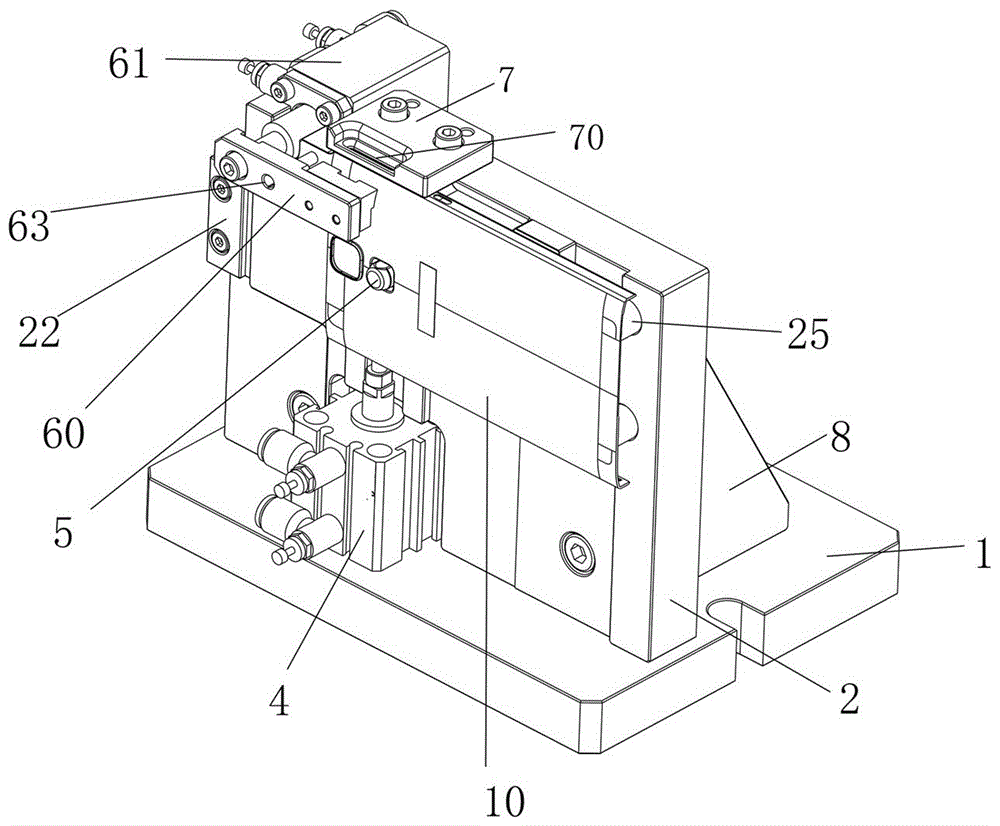

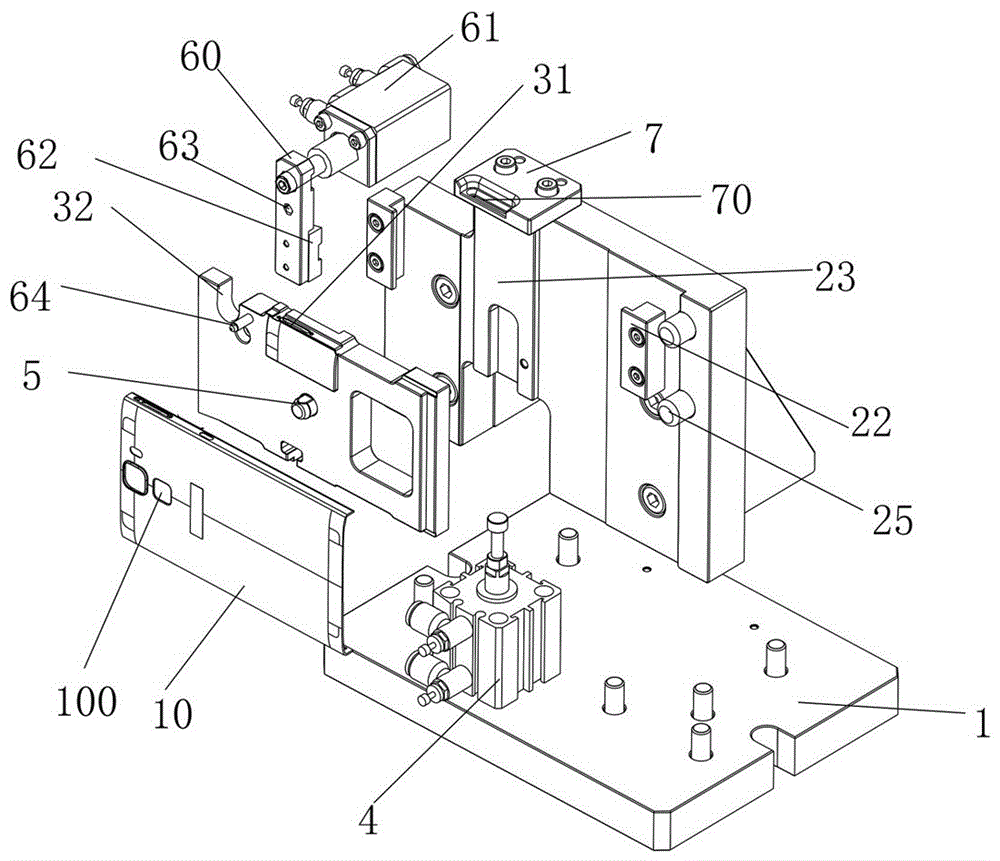

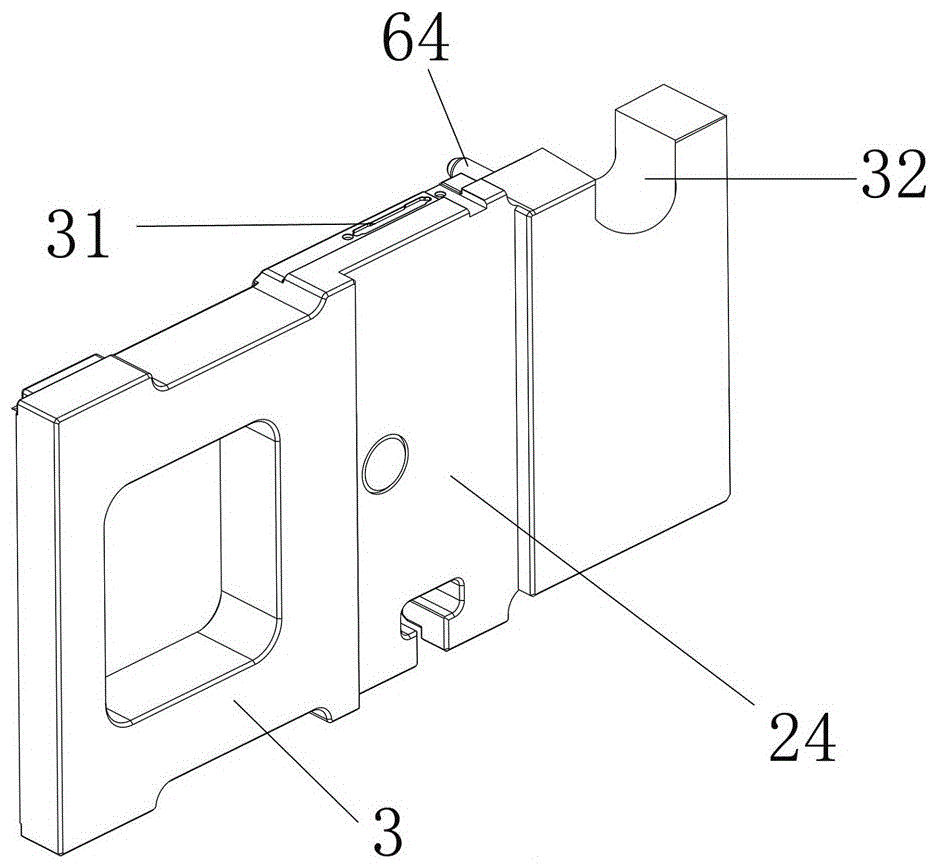

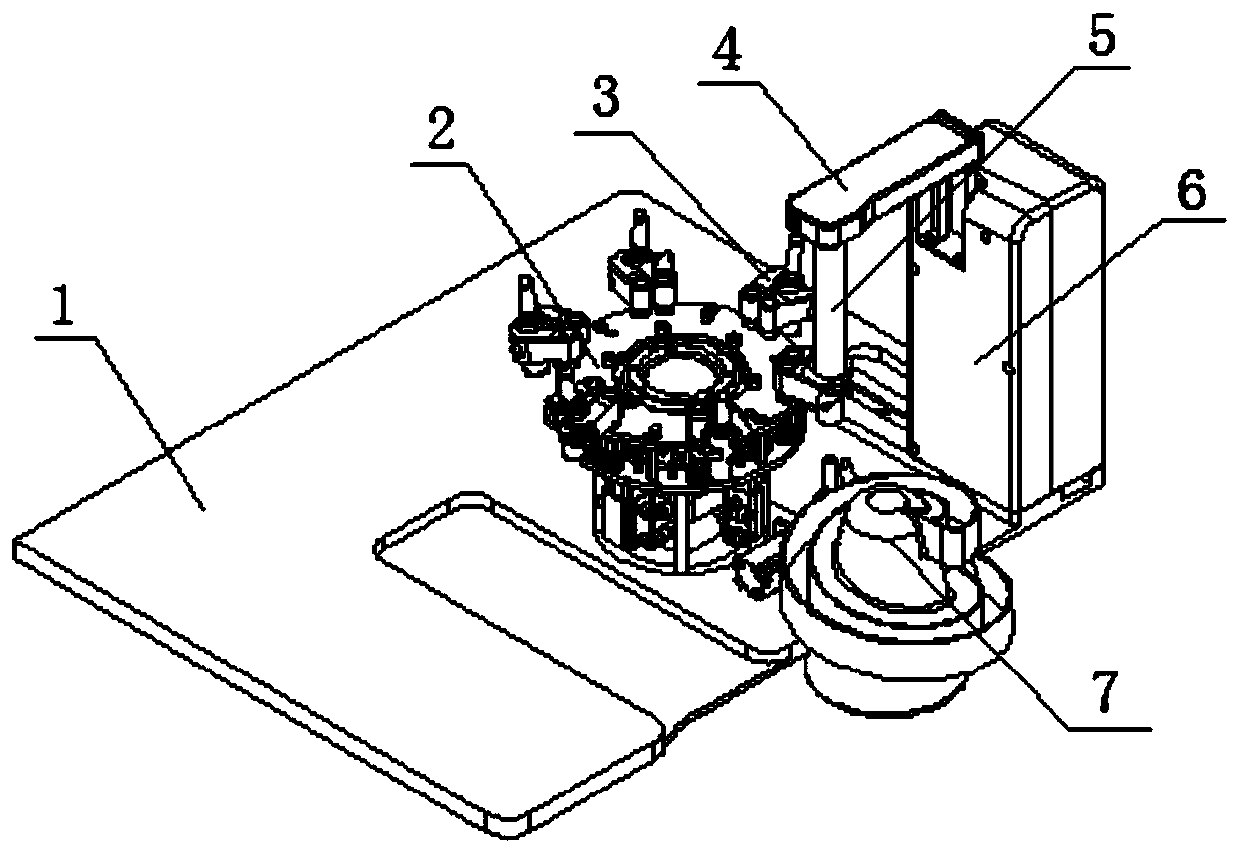

CNC jig for machining lateral holes of metal shell of mobile phone

ActiveCN105855964AImprove machining accuracyAvoid errorsPositioning apparatusMetal-working holdersReciprocating motionEngineering

The invention discloses a CNC jig for machining the lateral holes of a metal shell of a mobile phone. The CNC jig comprises a base, a vertical plate vertically arranged on the base, a drive device arranged on the base, a positioning plate for placing the metal shell of the mobile phone and a first clamping device which is arranged on the positioning plate and used for clamping the metal shell of the mobile phone, wherein the positioning plate is connected with the drive device and contacts with the vertical plate, the drive device drives the positioning plate to move between a feeding station and a machining station in a reciprocating manner along the vertical plate, the first clamping device clamps the metal shell of the mobile phone in a front-back manner from the length direction, and the drive device clamps the metal shell of the mobile phone in an up-down manner from the thickness direction when the positioning plate is located at the machining station. The CNC jig has the advantages that manual operation is avoided, and work efficiency is increased; the positioning plate and the metal shell of the mobile phone are positioned repeatedly, the machining station errors of the metal shell of the mobile phone are avoided, machining precision is increased, and only one cutter alignment is needed during batch production in the allowing range of the machining errors.

Owner:CHITWING DONGGUAN TECH

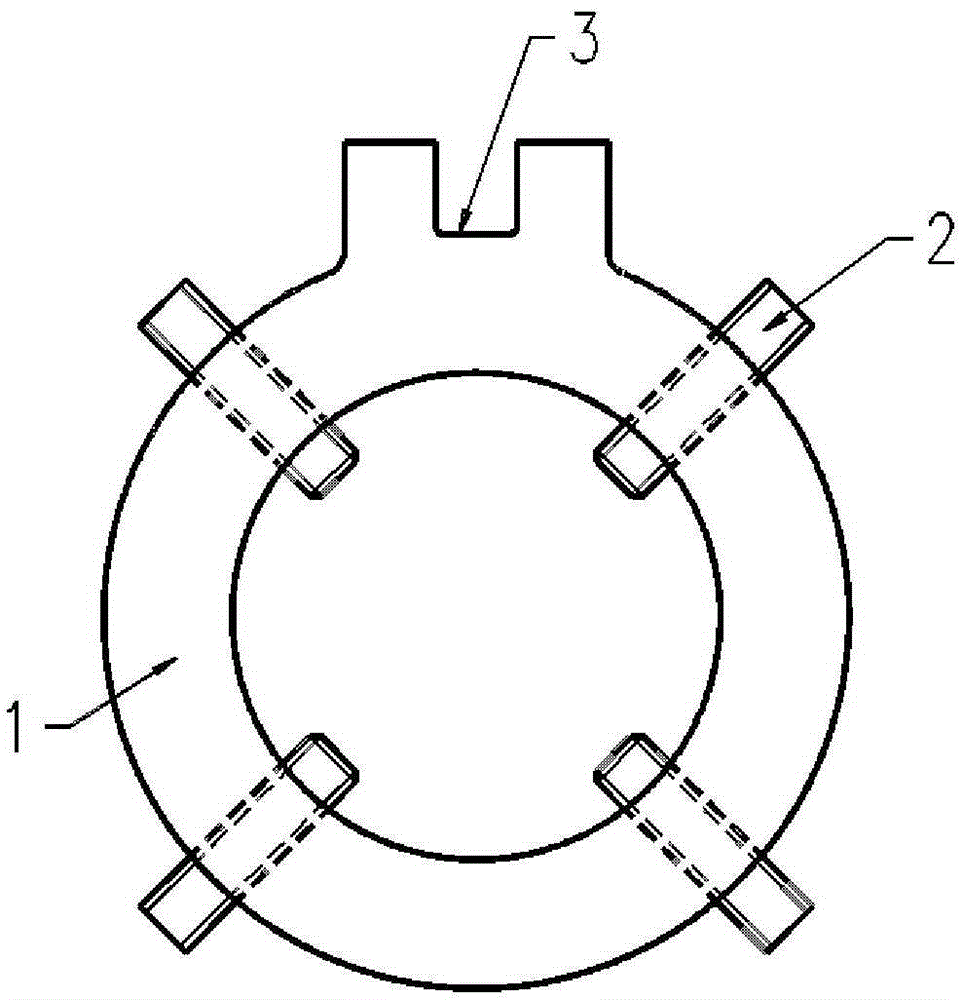

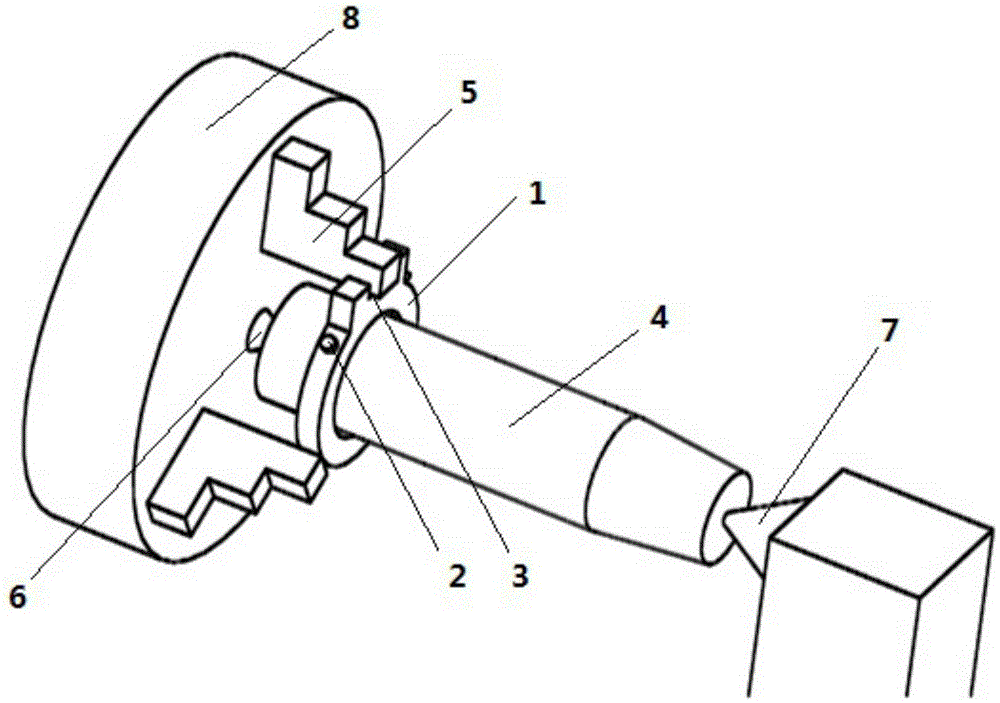

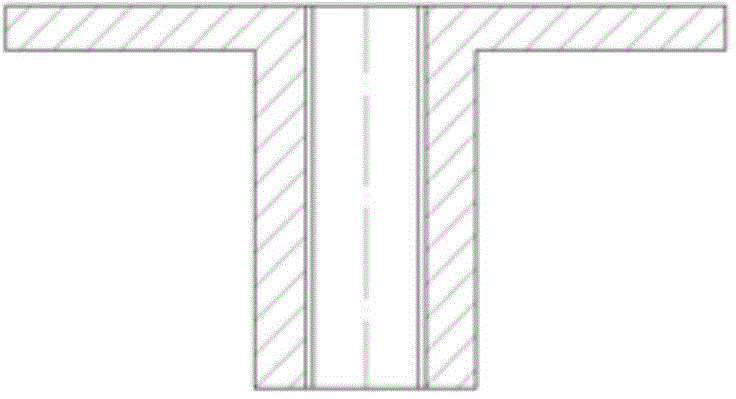

External thread secondary fitting fixture and clamping method

InactiveCN105397538APrecise clamping methodSimple clamping methodPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention provides a fixture for repeatedly turning and repairing an external thread by using a horizontal lathe simply, safely and precisely and a clamping method thereof. A poking disc fixture consists of four ejecting bolts and a U-shaped groove; a poking disc tool is fixed on a workpiece through the four ejecting bolts; the workpiece is supported by lathe head and lathe tail tips in the workpiece clamping; and the poking disc tool is connected to one clamping jaw of the lathe for transferring a torque through the U-shaped groove. After a thread of the workpiece is roughly machined, a horizontal turning chuck is locked to link with a tool post; and the workpiece and the poking disc fixture are dismounted from equipment for premounting. When the workpiece is horizontally turned again, the workpiece is also fixed by the horizontal turning lathe head and lathe tail tips; and the clamping jaw used in the first clamping process is adjusted to enter the U-shaped groove of the poking disc tool to finish the second clamping process; and the second fitting of the thread can be directly performed without alignment for a workpiece thread machining initial angle after clamping.

Owner:HARBIN ELECTRIC MASCH CO LTD

A cable robot for a cable-stayed bridge

ActiveCN103696365BReduce the frequency of on and offExtend working lifeBridge structural detailsVehicle frameElectromagnetic clutch

The invention provides a cable-stayed bridge cable, which comprises a driving module 1, a driven module 2, a detection module 3 and a power-off protection module 4, wherein the driving module 1 takes a driving frame 5 as a mounting platform; the driven module 2 takes a driven frame 27 as a mounting platform; the detection module 3 takes a camera support frame 53 as a mounting platform; the power-off protection module 4 takes a mounting frame 56 as a mounting carrier; the driving frame 5 is connected with the driven frame 27 through connecting yokes 44 and connecting bars 45; the detection module 3 is connected with the driving frame 5 and the driven frame 27 respectively through the camera support frame 53; the power-off protection module 4 is connected with the driving frame 5 through the mounting frame 56. When an electromagnetic clutch is cut off, an electromagnet works to drive a brake band to enclasp a brake wheel, so that the robot is prevented from slipping off; and a clamping way is simple and practicable.

Owner:SHANGHAI TONGJI CONSTR QUALITY INSPECTION STATION

Turning method for eccentric circle of crank shaft of RV (Rotary Vector) speed reducer and special eccentric tool

InactiveCN109604655AMeet the process requirementsGuaranteed Angle Correspondence RequirementsChucksTurning machinesEngineeringReducer

The invention relates to a turning method for an eccentric circle of a crank shaft of a RV (Rotary Vector) speed reducer and a special eccentric tool. The turning method adopts a three-claw clamping manner and has the advantages of simple method, concentrated procedures, low production cost, high part precision and the like. A part clamping method is simple, complicated adjustment is not needed and the processing efficiency is high. The same eccentric tool is adopted, so that an angular reference and an eccentric amount are fixed, and furthermore, the consistency of the eccentric amounts of two eccentric circles is good and the precision of eccentric indexing of 180 degrees is high; and the processing requirements of the crank shaft of the RV speed reducer are met.

Owner:天津旗领机电科技有限公司

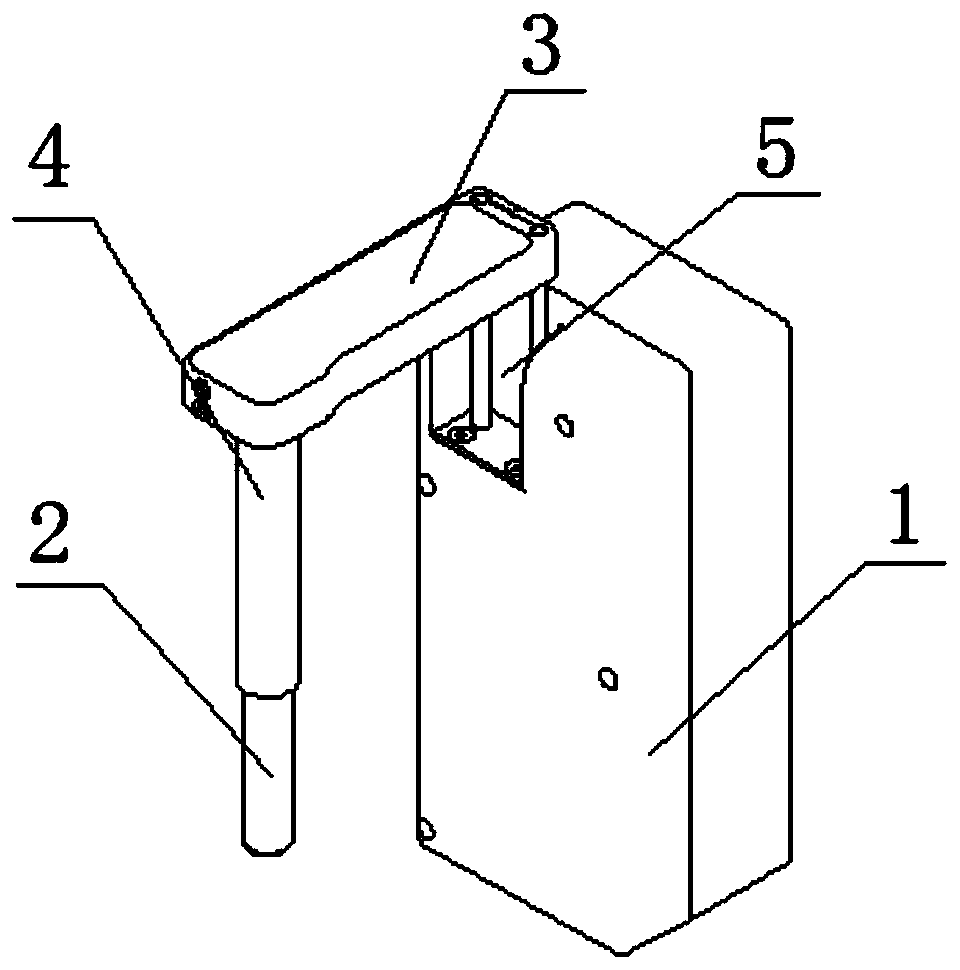

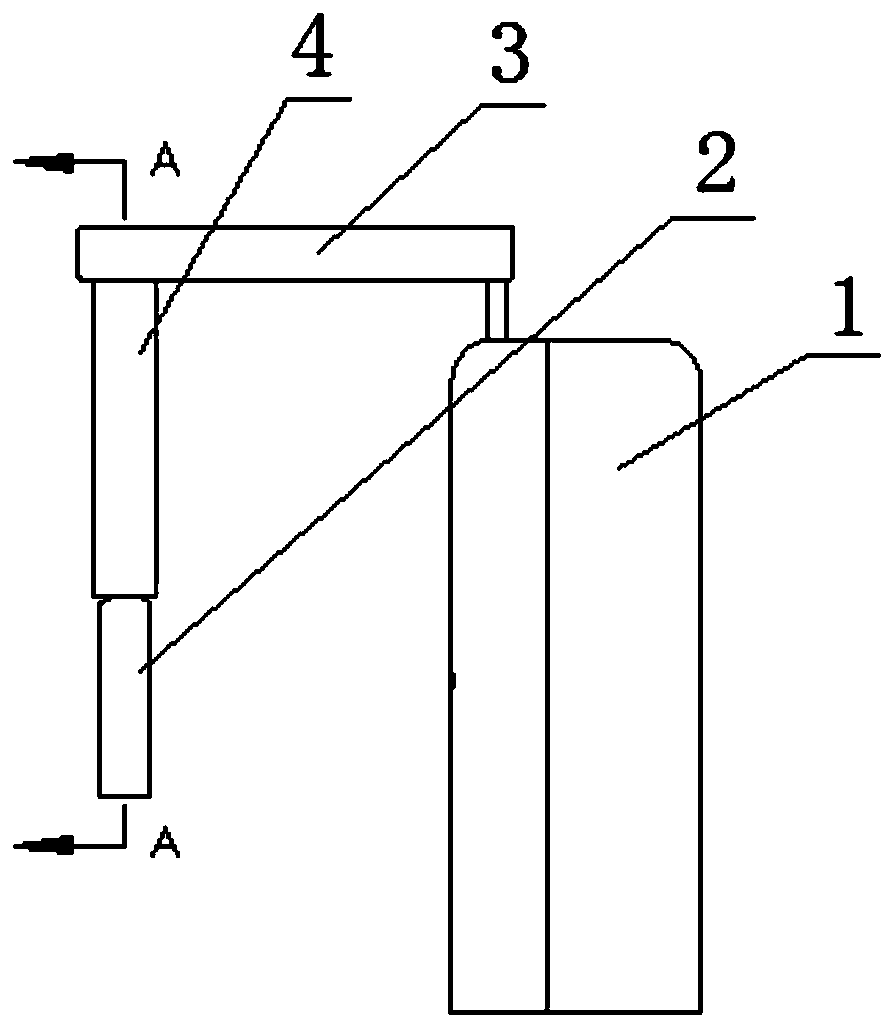

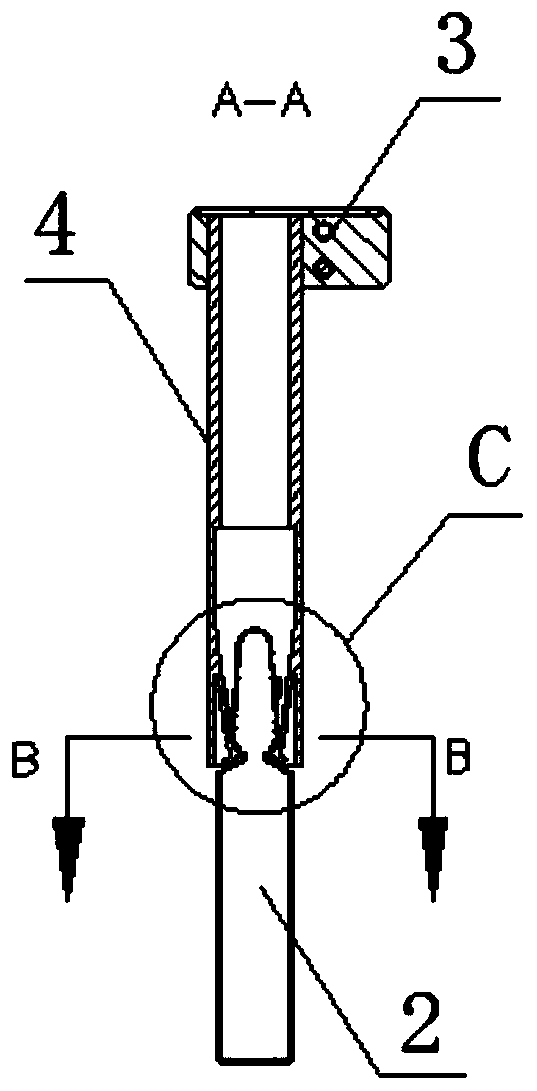

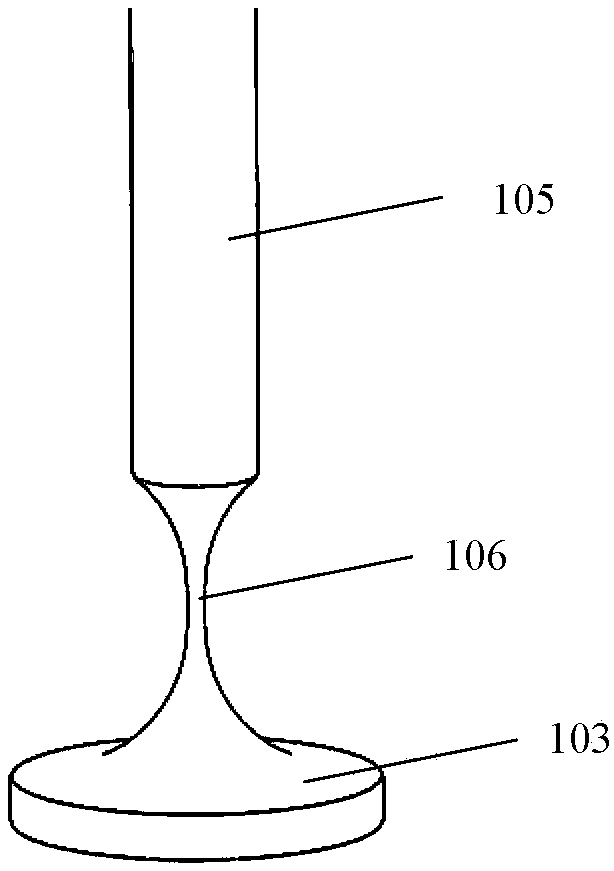

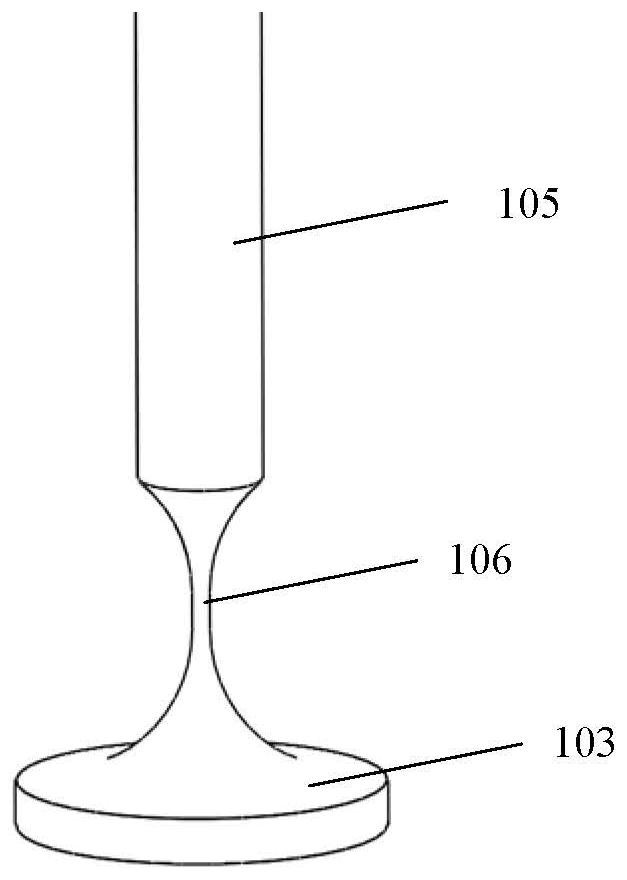

Ampoule bottle grabbing device for liquid medicine dispensing machine

The invention discloses an ampoule bottle grabbing device for a liquid medicine dispensing machine. The ampoule bottle grabbing device includes a ball screw linear driver, a connecting arm is arrangedat the output end of the ball screw linear driver, a clamp sleeve is fixed to the lower end surface of the side, away from the ball screw linear driver, of the connecting arm, the lower end of the clamp sleeve is elastically provided with an ampoule bottle in a clamped manner, and the minimum diameter of the clamp sleeve is smaller than the minimum diameter of the ampoule bottle. According to theampoule bottle grabbing device, the ball screw linear driver works by driving the clamp sleeve to move downwards through the connecting arm, the buckle end of the clamp sleeve is clamped in from a bottle cap end on the ampoule bottle, an elastic arm of the clamp sleeve stops when operating to the minimum bottleneck of the ampoule bottle, and the ampoule bottle is clamped by the elastic arm; and the clamping way is simple, the ampoule bottle cannot be damaged by mechanical clamping, the clamping safety is improved, the dispensing cost is lowered, the ampoule bottle grabbing device is suitablefor ampoule bottles with different diameters, and the application range is wide.

Owner:WUXI ANZHIZHUO MEDICAL ROBOT CO LTD

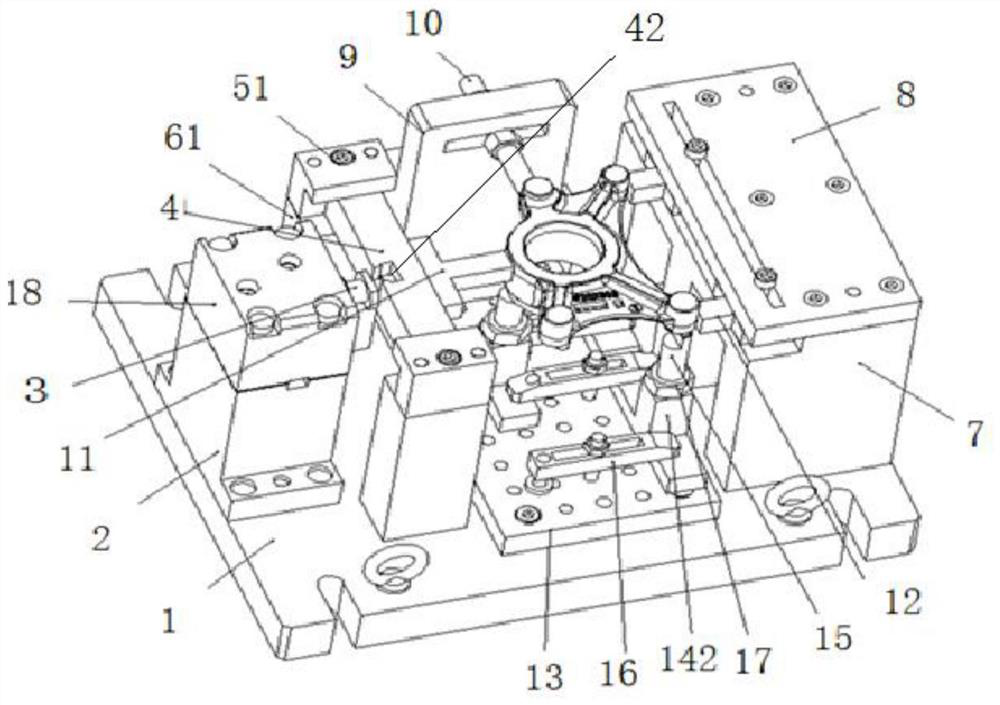

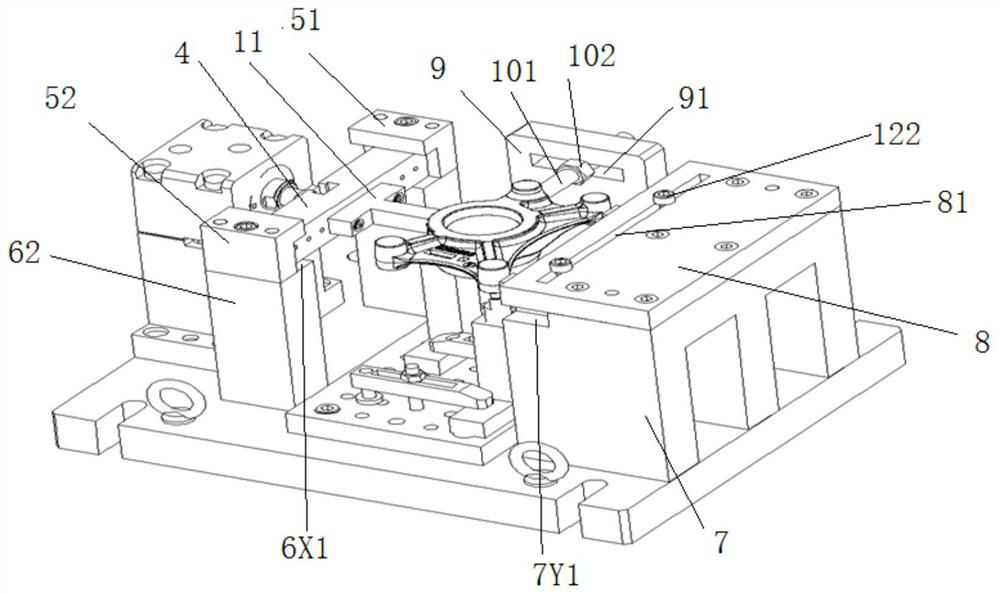

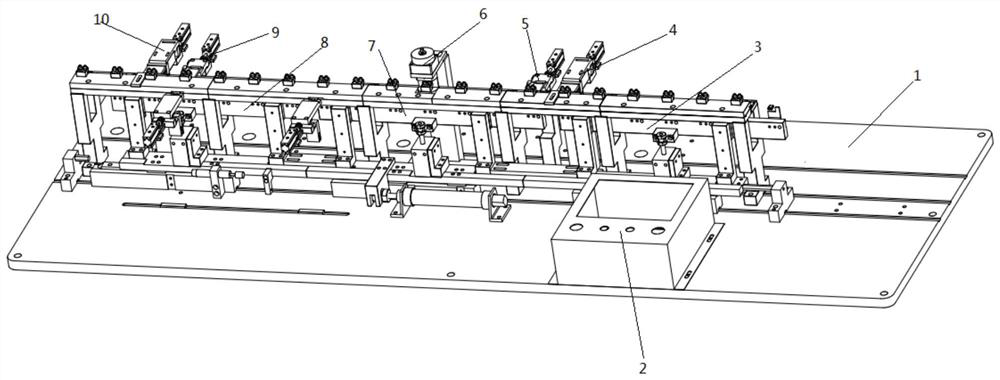

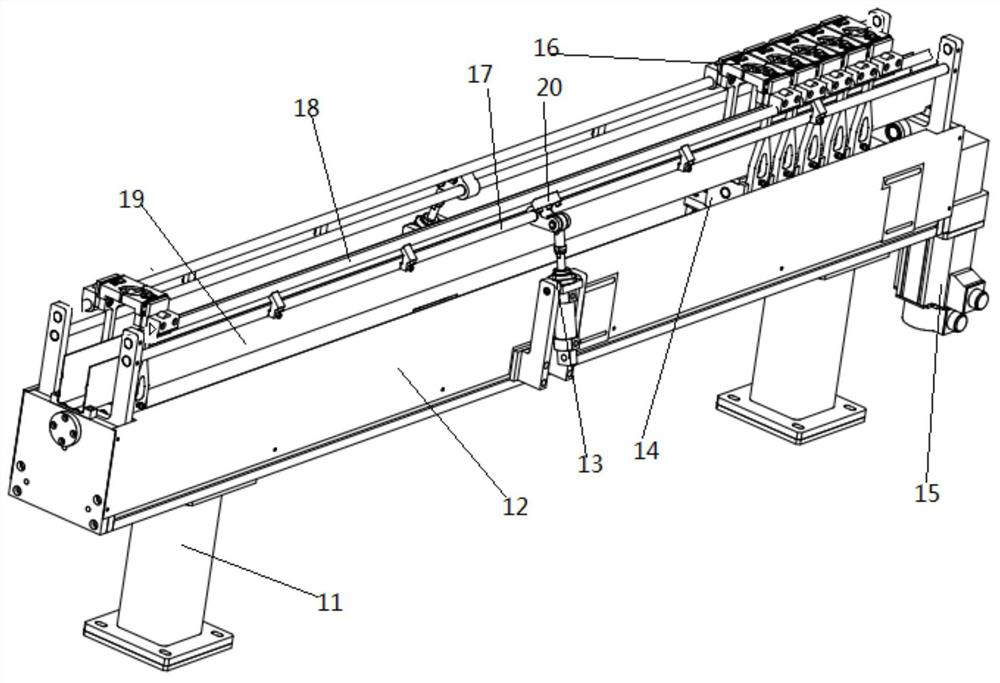

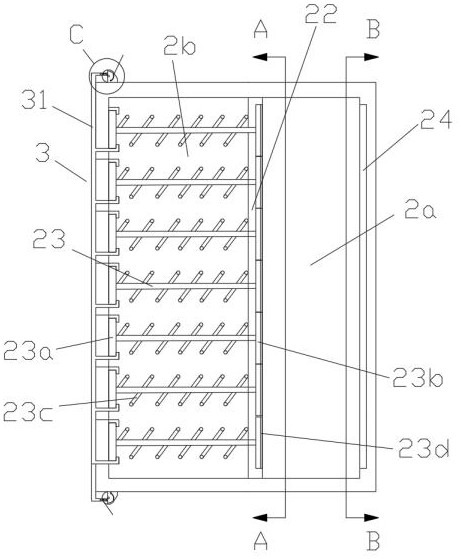

Flexible fixture for surface milling and drilling of fan bracket and clamping and positioning method

ActiveCN113199269ASimple clamping methodEasy to adjustWork clamping meansWind energy generationStructural engineeringMachining

The invention discloses a flexible fixture for surface milling and drilling of a fan bracket and a clamping and positioning method. The flexible fixture comprises a bottom plate, and the bottom plate is provided with a first positioning pressing block assembly capable of moving in the X direction, a second positioning pressing block assembly capable of being adjusted in the Y direction, a third positioning pressing block assembly capable of being adjusted in the X direction and the Y direction respectively, and at least three height-adjustable support positioning pin assemblies. The first positioning pressing block assembly is used for actively positioning and clamping a positioning point on the first side face of the fan bracket, the second positioning pressing block assembly is used for passively positioning and clamping two positioning points on the second side face of the fan bracket, and the third positioning pressing block assembly is used for pre-tightening, positioning and clamping a positioning point on the third side face of the fan bracket. When the flexible fixture is used for surface milling and datum hole drilling of fan bracket products, quick clamping switching of machining of different types of products can be achieved, the manufacturing number of fixtures in the product sample stage is reduced, the sample development period is shortened, and the development cost before product shaping and mass production is reduced.

Owner:东风汽车动力零部件有限公司

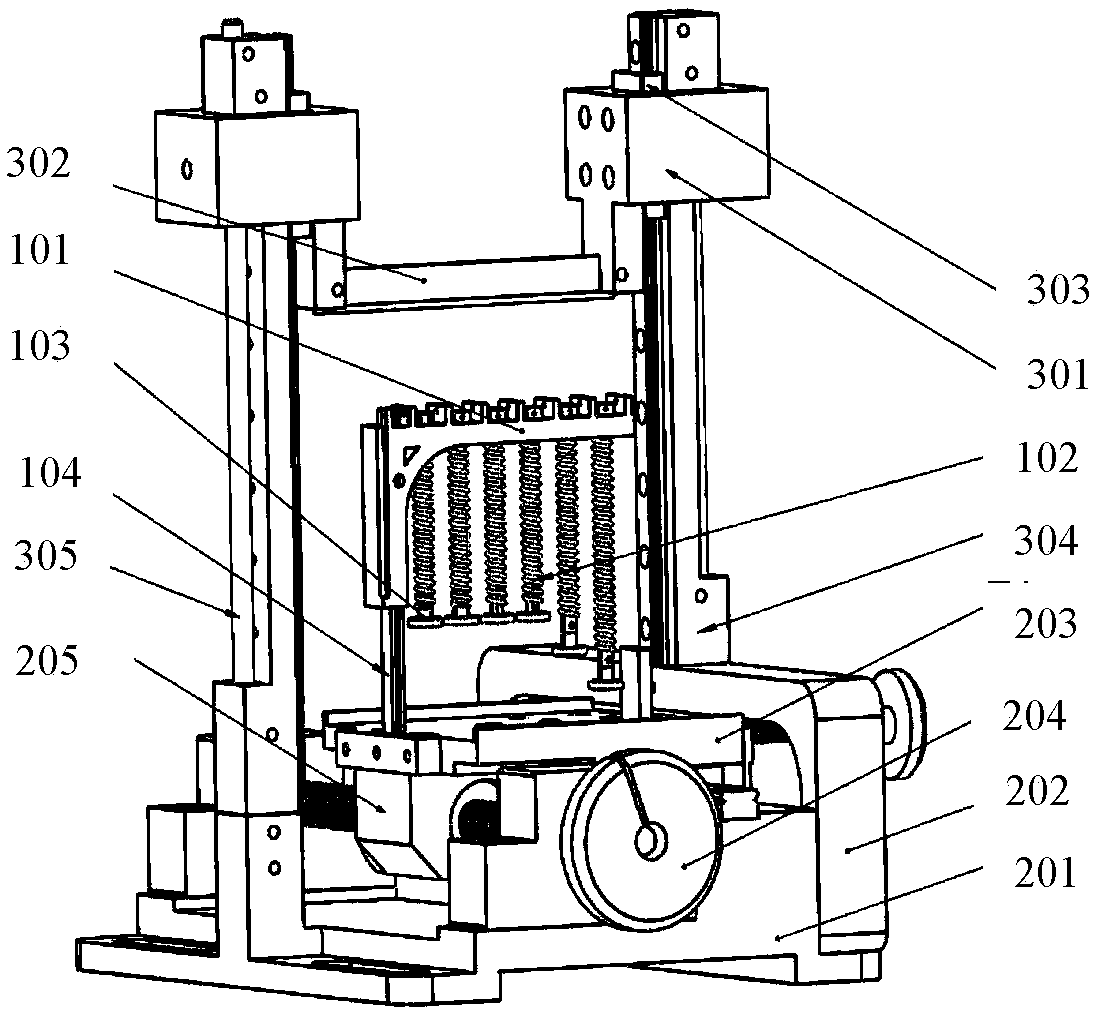

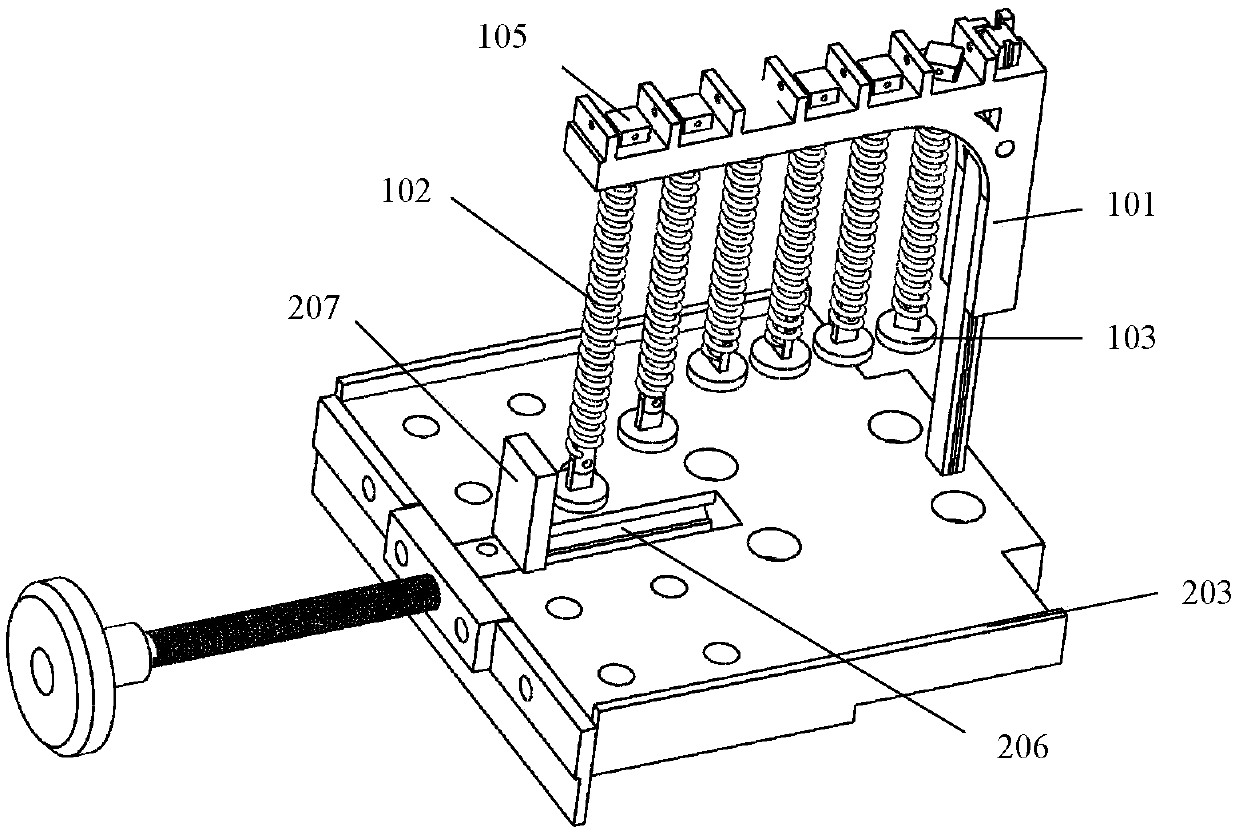

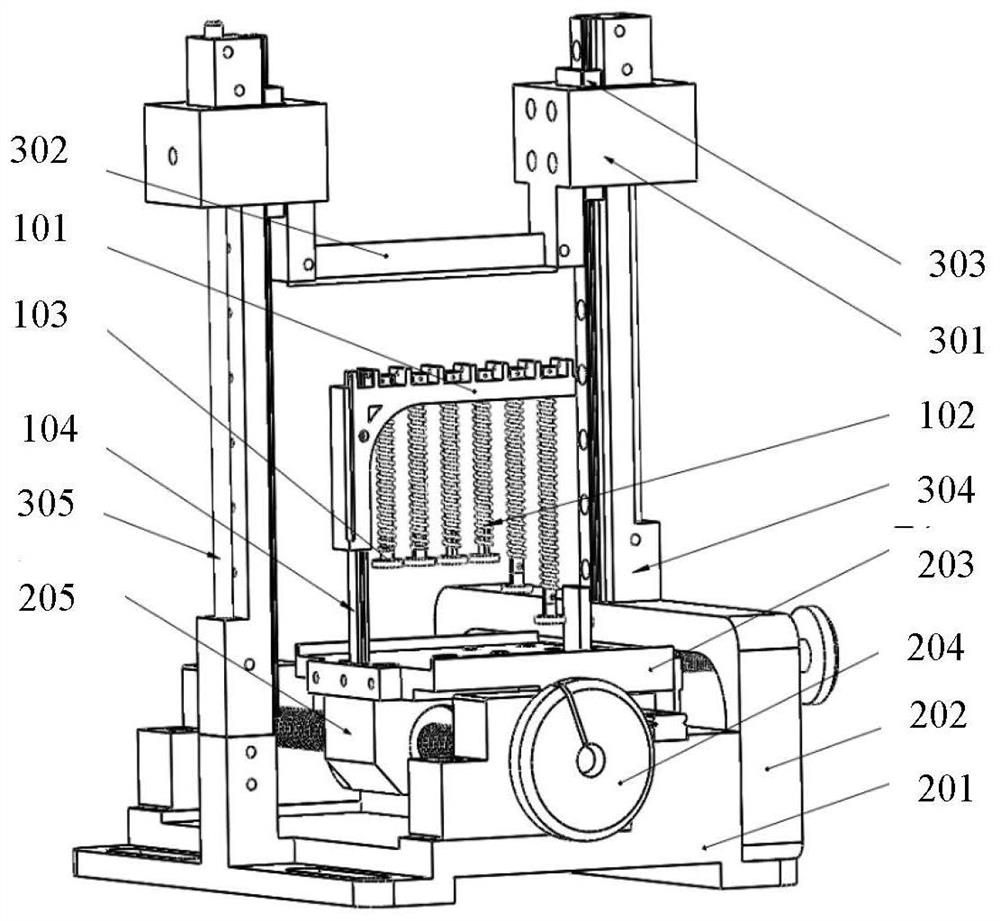

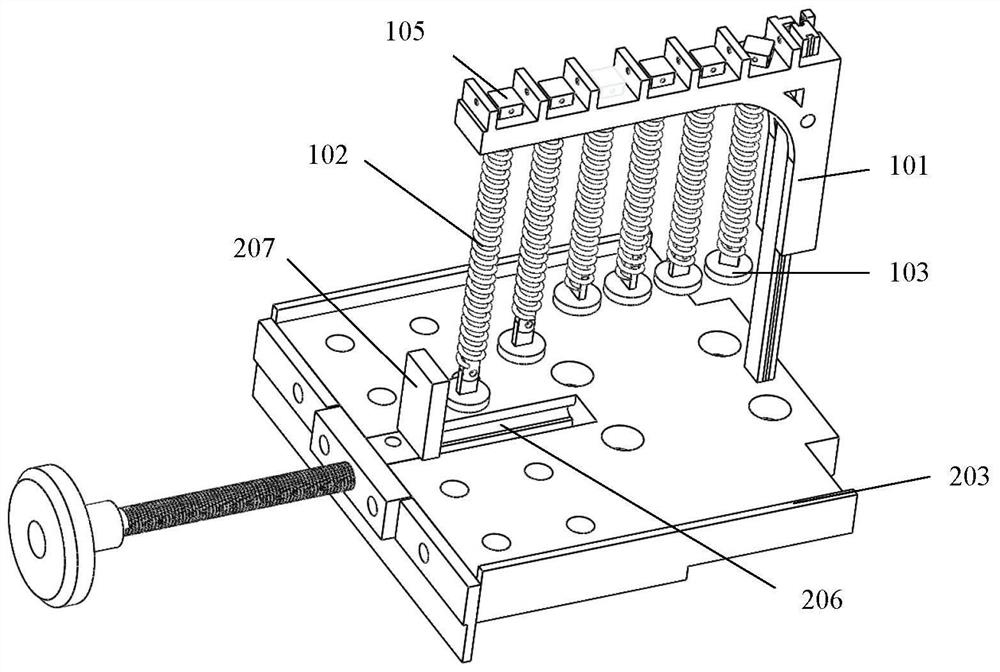

Self-adaptive clamping device and clamping method for irregular object

ActiveCN109623890AAchieve clampingSmall clamping deformationMetal working apparatusSelf adaptiveMechanical engineering

The invention belongs to the field of medical apparatus, and discloses an self-adaptive clamping device for an irregular object. The self-adaptive clamping device includes a positioning platform, anda flexible clamping mechanism, the flexible clamping mechanism comprises a flexible fixture bracket and a plurality of flexible fixtures connected in parallel, each flexible fixture comprises a springmounting rod, a spring and a pressing disc, and one end of each spring mounting rod is movably mounted in the flexible fixture bracket; and the other end of each spring mounting rod is hinged to thecorresponding disc so that the corresponding pressing disc can swing around the hinge center, and the springs are externally arranged on the spring mounting rods in a sleeving mode and placed betweenthe flexible fixture bracket and the pressing discs so that the springs generate the self-adaptive pressure to the flexible fixture bracket and a hinging rotating shaft when the spring mounting rods move in the flexible fixture bracket. The self-adaptive clamping device further includes a position adjusting mechanism and a cutting mechanism except the flexible clamping mechanism and aims to solvethe technical problems that large elastic deformation or even yield deformation and invalid clamping are easily produced during clamping of the irregular object, especially, the elastic textures.

Owner:HUAZHONG UNIV OF SCI & TECH

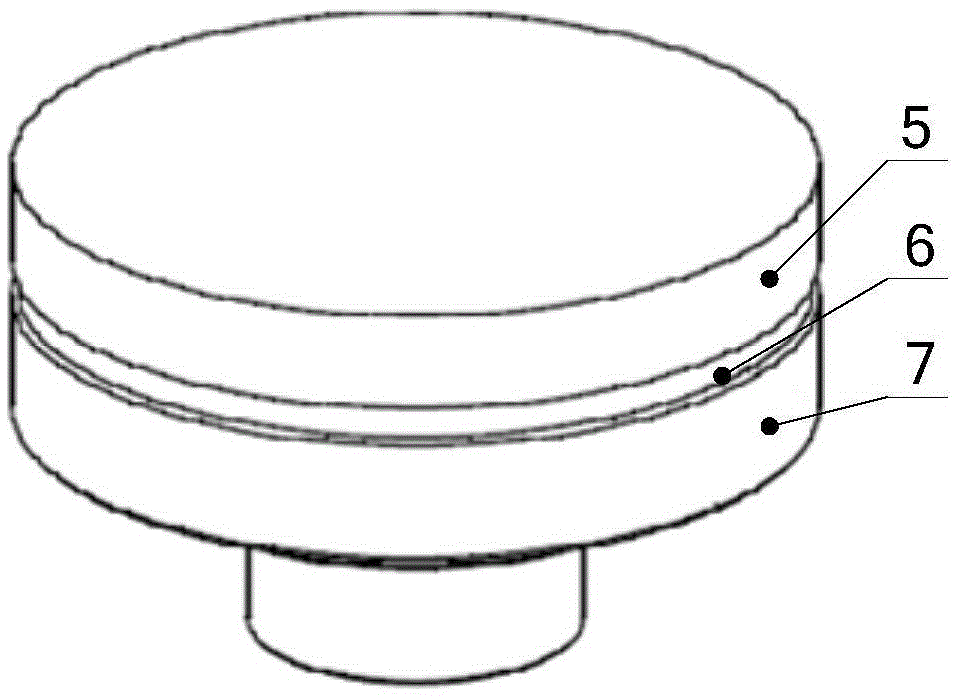

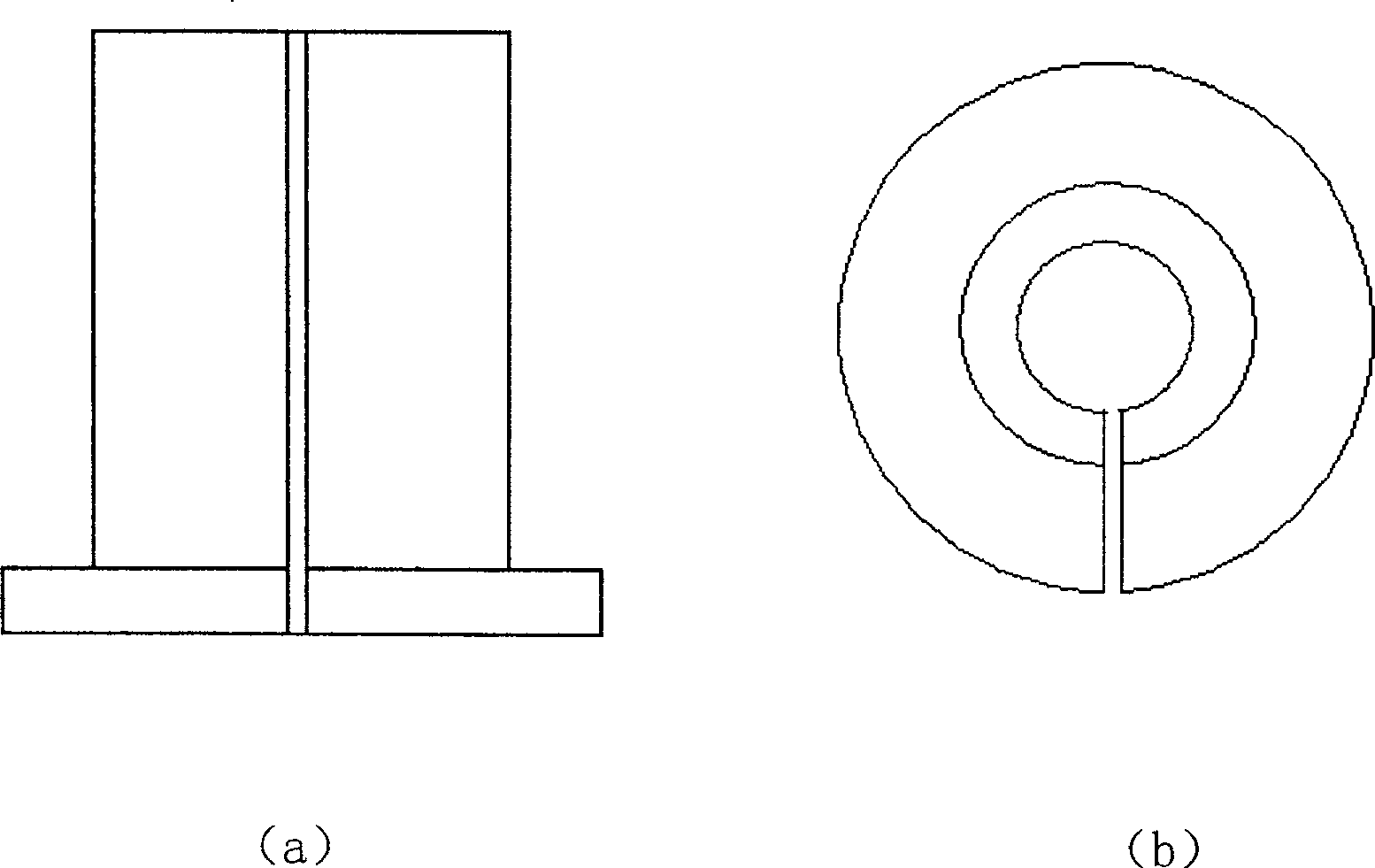

Clamp controlling non-rotational symmetry errors for optical elements during polishing

InactiveCN105458867AGuaranteed positional stabilityAccurate correctionOptical surface grinding machinesManufacturing technologyEngineering

The invention belongs to the technical field of optical fabrication and provides a clamp controlling non-rotational symmetry errors for optical elements during polishing. The clamp aims to solve the problems that the polishing difficulty is high and the machining convergence efficiency is low in the prior art and comprises a clamping shaft sleeve, locking screws A, a one-dimensional translation table and a fixed base; the clamping shaft sleeve is fixed to the upper installation surface of the one-dimensional translation table, and the lower installation surface of the one-dimensional translation table is fixedly connected to the fixed base; the clamping shaft sleeve is coaxial with the fixed base, is of a flexible structure and is locked by the locking screws A. According to the invention, through monitoring to the magnitude and the directions of the non-rotational symmetry errors in the machining process, the offset of the optical elements can be adjusted in the directions of the errors correspondingly, the non-rotational symmetry errors can be corrected, and the machining efficiency can be improved. Through the simple, accurate and reliable clamping mode, the non-rotational symmetry errors of the optical elements in the classical polishing process can be effectively controlled.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

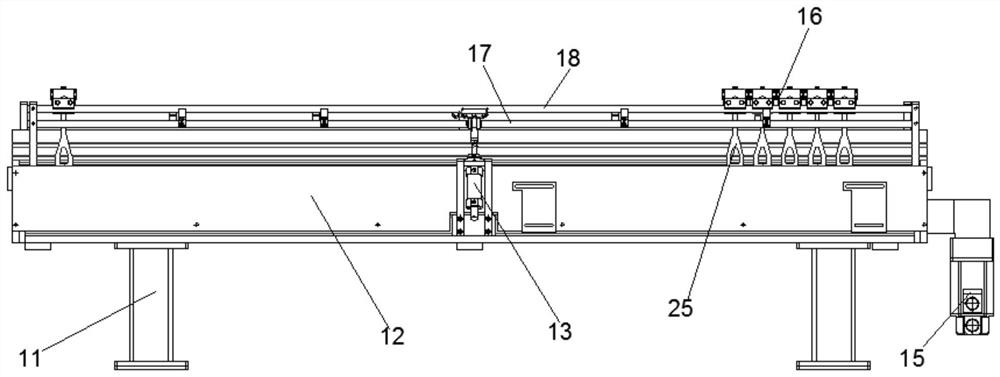

Bottle feeding device of aqueous solution dispensing machine

PendingCN111137480AConvenient rightingEasy to grab materialLiquid materialLiquid bottlingEngineeringBottle

The invention discloses a bottle feeding device of an aqueous solution dispensing machine. The bottle feeding device comprises an equipment base, wherein a rotary bottle feeding mechanism for conveying ampoule bottles, a grabbing mechanism for grabbing the ampoule bottles in the rotary bottle feeding mechanism and conveying the ampoule bottles, and a rotary disc for clamping the ampoule bottles onthe grabbing mechanism and rotatably conveying the ampoule bottles are arranged on the equipment base. The ampoule bottles are spirally sorted and intermittently shielded, so that more ampoule bottles are accommodated in a narrow space, and therefore, automatic sorting and low-cost feeding are realized; a baffle plate is convenient for righting the ampoule bottles, so that the ampoule bottles areconveniently grabbed and crushed; the ampoule bottles are elastically clamped by a connecting arm, so that the ampoule bottles are not damaged due to mechanical clamping, and therefore, the dispensing cost is reduced, and the bottle feeding device is suitable for ampoule bottles of different diameters; a ball screw linear driver can control any needed position of the ampoule bottles in a stroke,and follow-up station changes are not needed, so that the structure of a follow-up station can be simplified; and the rotary disc is adopted for feeding, so that feeding continuity is guaranteed, andintegral streamlined feeding is realized.

Owner:WUXI ANZHIZHUO MEDICAL ROBOT CO LTD

Pull-wire angle measuring system

The invention relates to an angle measurement system based on a high-precision wire-type coded sensor, in particular to a device for measuring the rotation angle of an indirect gun barrel. Its function is to accurately measure the rotation angle of the artillery barrel projected on the horizontal plane without structural modification of the indirect artillery equipment, and to eliminate the influence of the "empty back" of the artillery's own structure. It is composed of a wire length measuring mechanism, a calculation circuit and a calibration circuit; the wire length measurement mechanism includes a wire encoder, a fixing and guiding device, and a level measuring device; the data communication between the calculation circuit and the wire encoder is performed through the RS422 interface, and the calculation The core control chip of the circuit is a microprocessor based on the ARM-Cortex3 core; the calibration circuit also uses the ARM-Cortex3 series microprocessor, which is connected to the solving circuit through the RS232 interface, including a set of operation keyboards and display digital tubes.

Owner:NO 60 RES INST OF GENERAL STAFF DEPT PLA

A stranded wire rope production and packaging equipment

The invention discloses a twisted steel rope production and packaging equipment, which includes a winding box body, the twisting box body is fixedly installed on the top surface of the winding box body, and when the first motor is started, the first motor drives When the spline shaft rotates, the rotation of the spline shaft can drive the rotating sleeve and the twisting plate to rotate, and the rotation of the rotating disc can drive the rotation of the steel rope placed on the installation rod, so that the rotation sleeve and the twisting plate are opposite to the steel rope on the installation rod. Rotating together can ensure that when making steel strands, the steel ropes of each part will not be knotted with each other, which is convenient for strand production. After the production is completed, it can be quickly wound and packaged on the winding drum. The clamping of both ends of the coiled steel strand rope is very fast, and the clamping method is very simple, does not require a large amount of labor, and has high production efficiency.

Owner:江苏神猴钢绳开发有限公司

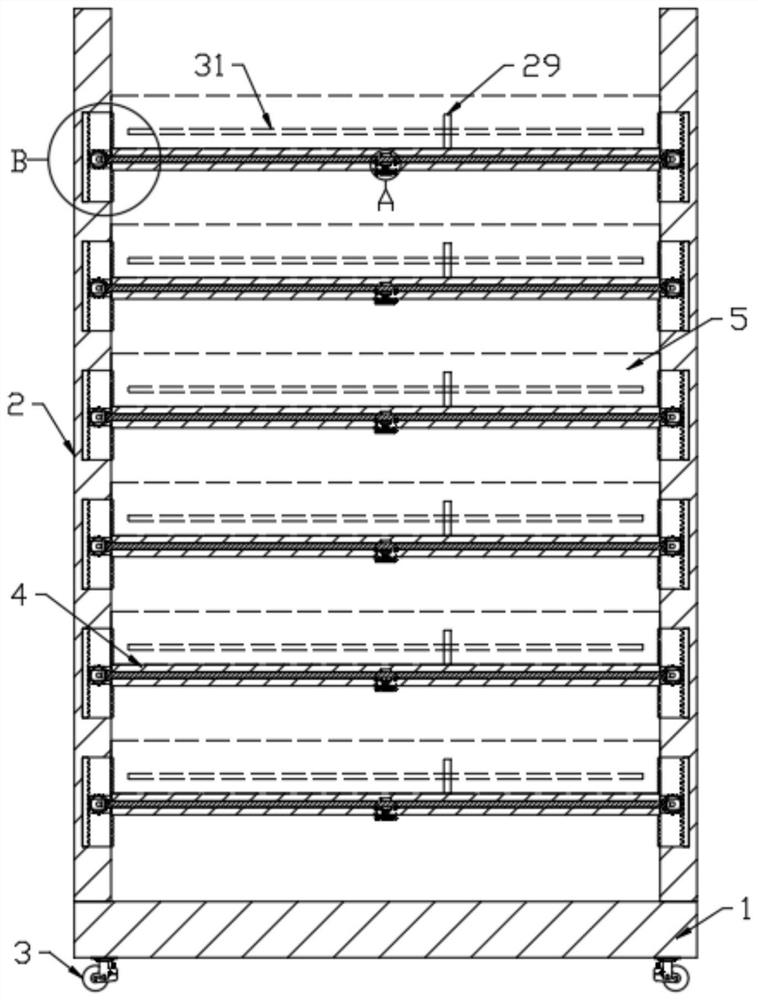

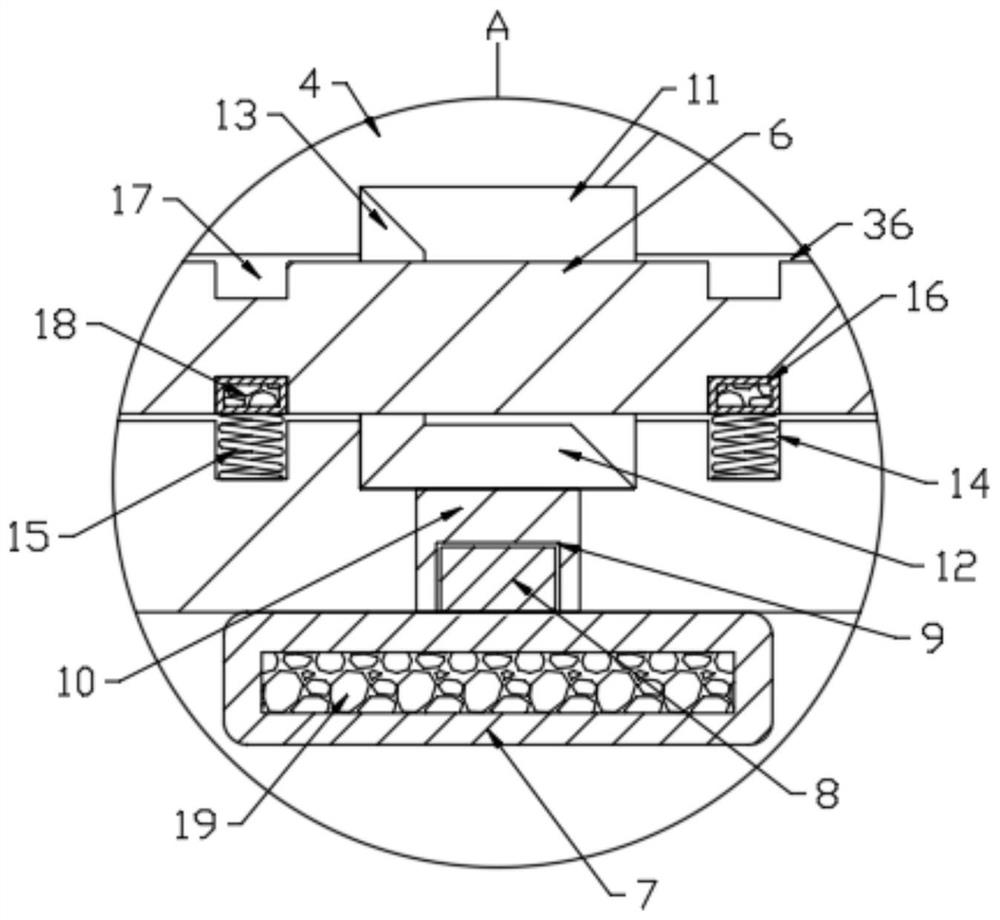

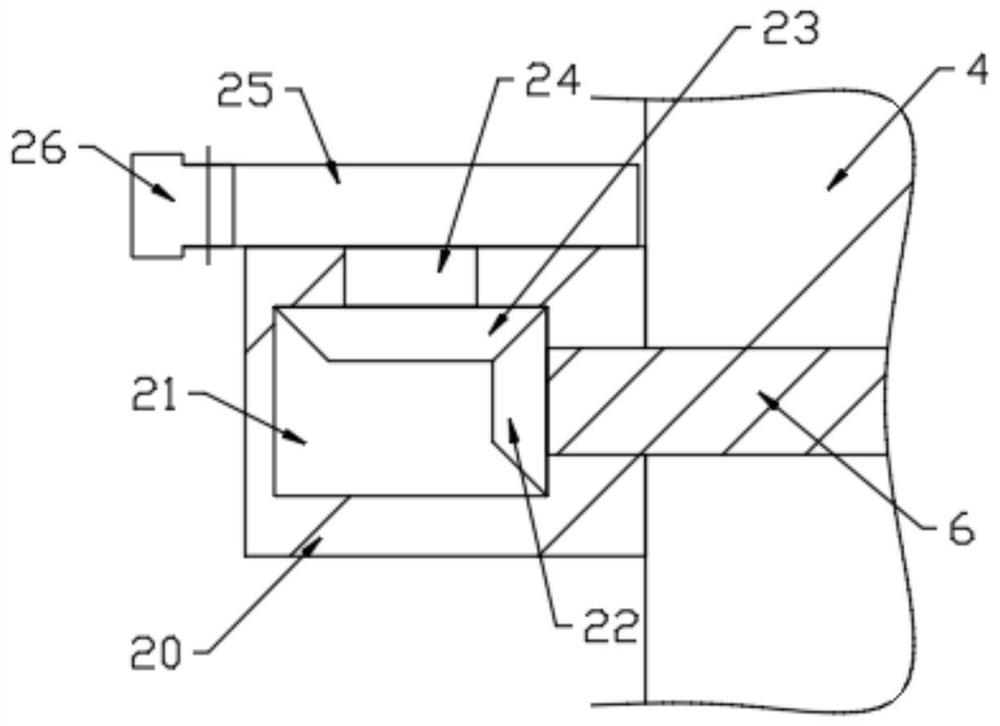

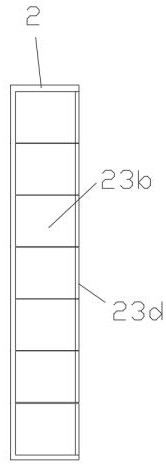

Book Fixing Mechanism for Library

ActiveCN112353130BEasy to fixImprove versatilityBook cabinetsBook-troughsClassical mechanicsStructural engineering

The invention discloses a book fixing mechanism for a library, which relates to the technical field of library appliances, including a base and a column, a plurality of placing plates and vertical plates are arranged between the two columns, and a rotating column and a turning groove are arranged in the placing plate. A rotating assembly and a fixed assembly are arranged on the placing plate, sliders are fixedly connected to both ends of the placing plate, a displacement assembly is arranged on the column, a partition is slidably connected to the vertical plate, and a fixed assembly for fixing the partition is arranged in the vertical plate. Through the cooperation of the clamping block and the card slot, the clamping connection between the running wheel and the vertical shaft is realized. Turning the running wheel makes the vertical shaft rotate, and then through the first bevel gear, the rotating column, the third bevel gear, the connecting shaft and other components, the displacement gear moves along the The gear rack that meshes with it moves up and down, thereby realizing the height adjustment of the placing plate and the slider between the two columns, and the relative height of the placing plate between the columns can be adjusted according to different book height requirements, with high versatility .

Owner:BINZHOU UNIV

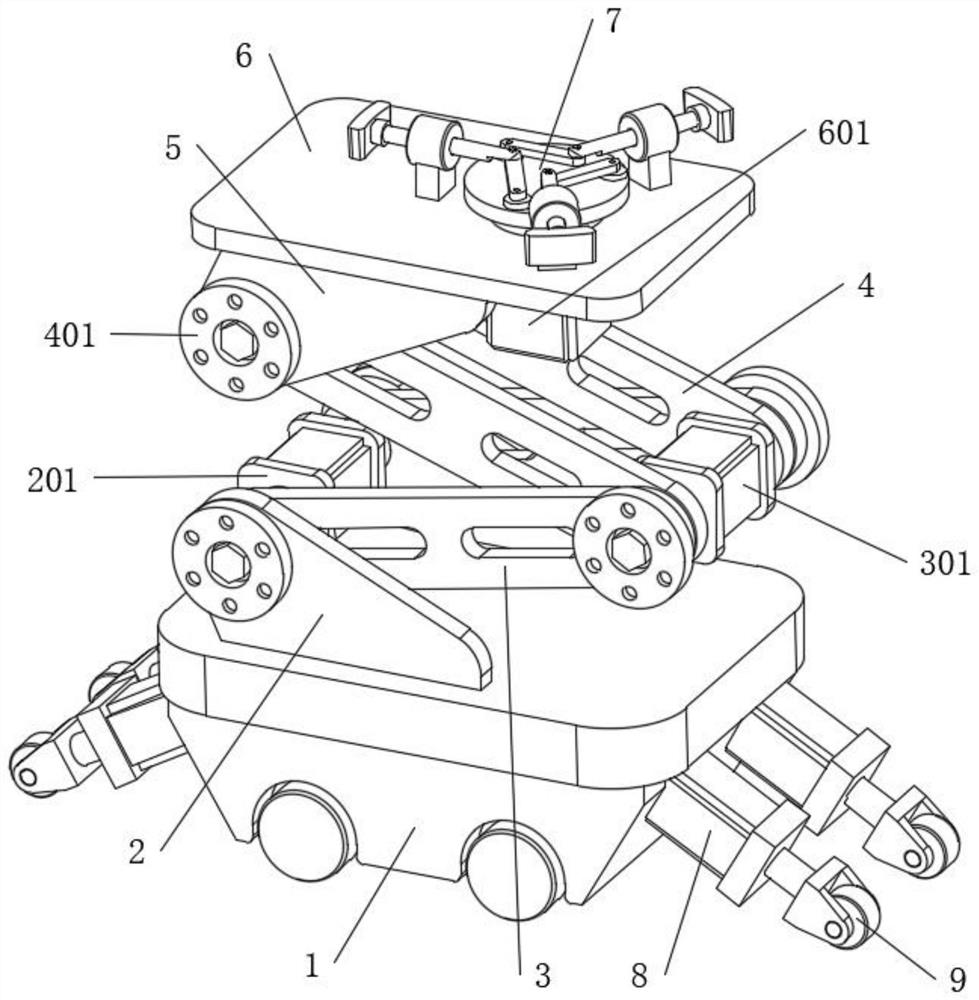

Tyre setting device and method for operating setting device

PendingCN114477009AAchieve fixed clampingPrecise positioningLifting framesAutomotive engineeringElectric motor

The invention discloses a tire placement device and a method for operating the same, and relates to the field of transfer placement equipment, the tire placement device comprises a transfer vehicle body, a lifting rod assembly and a clamping device, the top of the transfer vehicle body is connected with a bearing plate through the lifting rod assembly, and the clamping device is arranged on the bearing plate. The clamping device is arranged in the middle cavity of the tire, then the motor is controlled to work to drive the rotating disc to rotate, and when the rotating disc rotates, the three connecting rods are pulled to jack and press the three sliding rods at the same time, so that the three sliding rods are jacked outwards at the same time until the jacking heads arranged at the outer ends of the sliding rods abut against the inner wall of the tire, and the tire is fixedly clamped. And meanwhile, the tires are accurately positioned, and through adjustment of the lifting rod assembly, stacking feeding in the vertical direction of the tires and transverse arrangement feeding of the tires can be achieved.

Owner:胡靓

A cnc jig for processing the side hole of the metal shell of the mobile phone

ActiveCN105855964BImprove machining accuracyAvoid errorsPositioning apparatusMetal-working holdersReciprocating motionEngineering

The invention discloses a CNC jig for machining the lateral holes of a metal shell of a mobile phone. The CNC jig comprises a base, a vertical plate vertically arranged on the base, a drive device arranged on the base, a positioning plate for placing the metal shell of the mobile phone and a first clamping device which is arranged on the positioning plate and used for clamping the metal shell of the mobile phone, wherein the positioning plate is connected with the drive device and contacts with the vertical plate, the drive device drives the positioning plate to move between a feeding station and a machining station in a reciprocating manner along the vertical plate, the first clamping device clamps the metal shell of the mobile phone in a front-back manner from the length direction, and the drive device clamps the metal shell of the mobile phone in an up-down manner from the thickness direction when the positioning plate is located at the machining station. The CNC jig has the advantages that manual operation is avoided, and work efficiency is increased; the positioning plate and the metal shell of the mobile phone are positioned repeatedly, the machining station errors of the metal shell of the mobile phone are avoided, machining precision is increased, and only one cutter alignment is needed during batch production in the allowing range of the machining errors.

Owner:CHITWING DONGGUAN TECH

Intelligent helmet production and assembly device

ActiveCN111250990BRealize clamping and fixingSo as not to damageAssembly machinesMetal working apparatusAssembly lineManipulator

Owner:FOSHAN NANHAI JIUJIANG JIADESHI HELMET CO LTD

Adaptive clamping device and clamping method for irregular objects

ActiveCN109623890BAchieve clampingSmall clamping deformationMetal working apparatusEngineeringApparatus instruments

The invention belongs to the field of medical apparatus, and discloses an self-adaptive clamping device for an irregular object. The self-adaptive clamping device includes a positioning platform, anda flexible clamping mechanism, the flexible clamping mechanism comprises a flexible fixture bracket and a plurality of flexible fixtures connected in parallel, each flexible fixture comprises a springmounting rod, a spring and a pressing disc, and one end of each spring mounting rod is movably mounted in the flexible fixture bracket; and the other end of each spring mounting rod is hinged to thecorresponding disc so that the corresponding pressing disc can swing around the hinge center, and the springs are externally arranged on the spring mounting rods in a sleeving mode and placed betweenthe flexible fixture bracket and the pressing discs so that the springs generate the self-adaptive pressure to the flexible fixture bracket and a hinging rotating shaft when the spring mounting rods move in the flexible fixture bracket. The self-adaptive clamping device further includes a position adjusting mechanism and a cutting mechanism except the flexible clamping mechanism and aims to solvethe technical problems that large elastic deformation or even yield deformation and invalid clamping are easily produced during clamping of the irregular object, especially, the elastic textures.

Owner:HUAZHONG UNIV OF SCI & TECH

Heart valve positioning device

The invention discloses a heart valve positioning device which comprises anchoring units, and the number of the anchoring units is not smaller than the number of valves at a target installation position. The plurality of anchoring units are distributed along the circumference and are connected with one another through axially extending connecting parts to form a closed hollow thin-wall structure; each anchoring unit comprises an upper component and a lower component, the two ends of the upper component and the two ends of the lower component are fixedly connected with the connecting parts respectively, and two connecting points on the same side of each connecting part are distributed at intervals; the upper component and the lower component are arranged at intervals in the axis direction of the hollow thin-wall structure, at least one first interval is formed between the upper component and the lower component, and the first interval is used for clamping a heart native valve. The clamping force of the native valve between the upper component and the lower component can be adjusted by controlling the distance of the gap between the upper component and the lower component; the clamping mode of the original valve leaflet is simplified, and the design complexity and the machining difficulty are reduced.

Owner:SHANGHAI HUIHE HEALTHCARE TECH CO LTD +1

Lathing method for Semi-circle bush

ActiveCN100503095CImprove stabilityReduce distortionAutomatic control devicesTurning toolsSEMI-CIRCLEEngineering

The invention discloses a turning processing method of thin-walled parts with small and medium diameters. In the method, an auxiliary fixture is used for processing on an ordinary lathe. First, according to the outer diameter of the processed part, a piece with the same diameter as the part and a slit in the middle is made. The slotted sleeve is used as an auxiliary fixture to chuck the blank of the part to be processed; then put the chuck in the part into the inner hole of the slotted sleeve, and clamp it together with the slotted sleeve to the three-jaw automatic centering chuck of the lathe On the disk, after clamping, rough turning and finishing turning are performed; since the slotted sleeve is used as an auxiliary fixture to clamp thin-walled parts, the clamping force of the long disk jaws acting on the parts is more evenly distributed to the processed parts. On the surface of the part, the clamping force per unit area is reduced, the stability of the part clamping is increased, and the deformation and vibration of the part are reduced. The wall parts are transferred to the three-jaw self-centering chuck for processing, which improves the processing efficiency.

Owner:XIAN SHAANGU POWER

A method of intermediate frequency resistance diffusion welding of graphite electrodes with controllable deformation

ActiveCN108381017BAvoid deformationHigh melting pointResistance welding apparatusMetallic materialsCapillary Tubing

The invention discloses a graphite electrode intermediate frequency resistance diffusion welding method with controllable shape variables, and belongs to the technical field of metal material welding.The method comprises the following steps that an anti-deformation protection layer is formed on the periphery of a welding piece by utilizing an anti-deformation cushion block with high-temperature-resistant and high-conductivity, low-loss cushion blocks and flexible conductive paper, and prefabricated pressure clamping and welding assemblies are applied to the upper end and the lower end of a copper anode and a copper cathode correspondingly, and current pulses are applied to a graphite anode and a graphite cathode correspondingly; heat is uniformly diffused to a welding interface and risesto a peak value, and the welding interface and a high-temperature solder are dissolved; and the formed liquid phase achieves joint filling and spreading through capillary force and external extrusionforce to form an interface liquid phase, so that a thick welding piece and a thin welding piece are enabled to be in atomic contact. In conclusion, according to method, the technical problems that a welding material is large in deformation and low in welding quality can be effectively solved.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

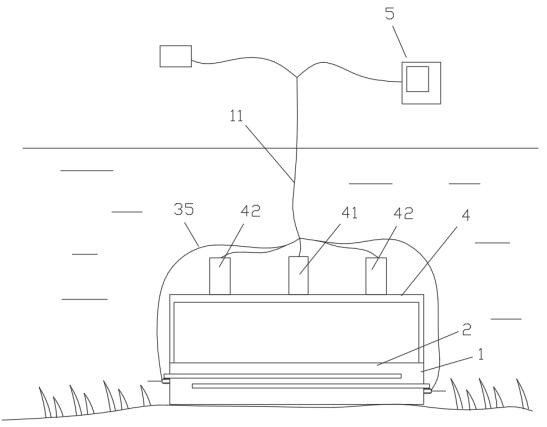

Underwater plant quadrat collecting device and sampling method thereof

PendingCN112816243AAccurate estimation of growth statusEasy to cutWithdrawing sample devicesFisheryStructural engineering

The invention discloses an underwater plant quadrat collecting device which comprises a submerged frame, the submerged frame is connected with a hanging wire, the submerged frame comprises a side wall frame body, a bottom plate, a partition plate and a push rod, the side wall frame body is a vertically-through surrounding frame, a vertically-through sampling groove is formed in the position, corresponding to a sampling and cutting area, of the bottom plate, a magnet is fixed to the right side face of the sampling and cutting area, the push rod horizontally penetrates through the partition plate, so that the left end of the push rod is located in the elastic pushing area and the right end of the push rod is located in the mining and cutting area, a head plate is installed at the left end of the push rod, a ferromagnetic plate is installed at the right end of the push rod, a spring is further installed on the push rod, and an operable buckle is arranged in the elastic pushing area and can clamp the head plate, a mounting rack is fixedly arranged over thesubmerged frame, and a waterproof camera and a water pump are mounted on the mounting rack. The underwater plant quadrat collecting device can directly sink into the water bottom, carries out underwater plant quadrat sampling at the water bottom, and is simple in structure and convenient to use.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA +1

A manual positioning and clamping device

The invention relates to the field of clamping equipment, and specifically discloses a manual positioning and clamping device, which includes a workbench, a cam handle, a first connecting rod, a second connecting rod, a slider, a floating block and claws. By rotating the cam handle, Make the first connecting rod move along the first horizontal direction, and drive the second connecting rod to rotate relative to the first connecting rod and the corresponding slider, and then use the second connecting rod to push the slider to move along the second horizontal direction, and the slider will Drive the corresponding floating block to rotate, so that the corresponding claws rotate around their own hinge shafts, so that the second ends of the two claws approach or move away from each other, so as to clamp or loosen the workpiece on the cover plate. The manual positioning and clamping device provided by the present invention has a simple structure. After the workpiece is placed on the workbench, it only needs to turn the cam handle to drive the first connecting rod, the second connecting rod, the slider and the floating block to move, and then the jaws can be used to realize The clamping and loosening of the workpiece, the clamping method is simple, the operation is quick, and the clamping efficiency is improved.

Owner:苏州润弘安创自动化科技有限公司

Ultrathin part machining method

ActiveCN108788185ASimple clamping methodEliminate machining vibrationsMachining vibrationsManufacturing engineering

The invention discloses an ultrathin part machining method. The ultrathin part machining method comprises the following steps: (S1) lower materials of parts are lengthened by 1-2 mm; and the outer diameters are increased by 0.5-1 mm; (S2) one end surfaces are turned; the depths of inner holes are increased according to the sizes of the parts; the diameters of the inner holes are upper limits of the tolerances; internal thread grooves are formed in the ends of the inner holes; and the sizes of the threads are designed according to the size requirements of the parts; (S3) auxiliary tools are assembled with parts to be machined; (S4) the parts are formed by turning; (S5) sharp cutters with sharp right single edges are selected for cutting step places of the threads according to the size requirements; (S6) finished parts are taken down from thread core rods; and (S7) both inspection and warehousing are performed; and the auxiliary tools used in the step (S3) comprise the thread core rods and clamping devices. The parts are machined through design of the auxiliary tools; the parts to be machined are assembled on the auxiliary tools in use; the whole auxiliary tools and the parts to be machined are fixedly clamped on a lathe, so that the clamping mode is simple; after clamping, the machining vibration, the destruction and the deformation are eliminated; the machining precision and the product pass percent are improved; and ultrathin parts with single edges less than 1 mm can be machined.

Owner:ANHUI DONGFENG MACHINERY & ELECTRONICS TECHNCO

Glass die mouth die thread milling clamp and machining method thereof

ActiveCN104924129AEasy to processPracticalThread cutting machinesWork clamping meansEngineeringUltimate tensile strength

The invention discloses a glass die mouth die thread milling clamp. The glass die mouth die thread milling clamp comprises a mouth die, a plug gauge, a pressing plate, a clamp body and an eccentric shaft. The plug gauge is in threaded connection with the mouth die. The pressing plate penetrates through the plug gauge and is placed in a mouth ring of an inner cavity of the mouth die. The lower end of the pressing plate is in threaded connection with a puller in the clamp body. The eccentric shaft penetrates through the clamp body and the puller. The clamp body is installed on a machine tool rotation indexing table, the eccentric shaft is installed and locked, the plug gauge is installed in the clamp body and screwed, a half-piece mouth die to be machined abuts against the plug gauge, the eccentric shaft is adjusted to be in a loosening state, the pressing plate is rotated and is pressed on the mouth die, the other half-piece mouth die abuts against the plug gauge, the whole mouth die is assembled into a whole, a machined thread cutter is installed on a cutter handle, the whole mouth die is arranged on the outer side of the plug gauge in a sleeving mode, a circular hoop locking mouth die is installed on the outer side of the mouth die, and the eccentric shaft is rotated to lock the mouth die. The accessories of the clamp are easy to machine, practicability is high, the high-low staggering phenomenon of threads is avoided, the machining time is shortened, and the working intensity of workers is relieved.

Owner:ORI MOLD TECH SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com