High-low-cycle complex fatigue test clamp of turbine joggle joint structure

A fatigue test and fixture technology, which is applied in the testing of machine/structural parts, testing of mechanical parts, measuring devices, etc., can solve the problems of easy slippage of blades and uneven stress distribution, and achieve rich high-low cycle composite fatigue tests and tests. Wide range, the effect of improving the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

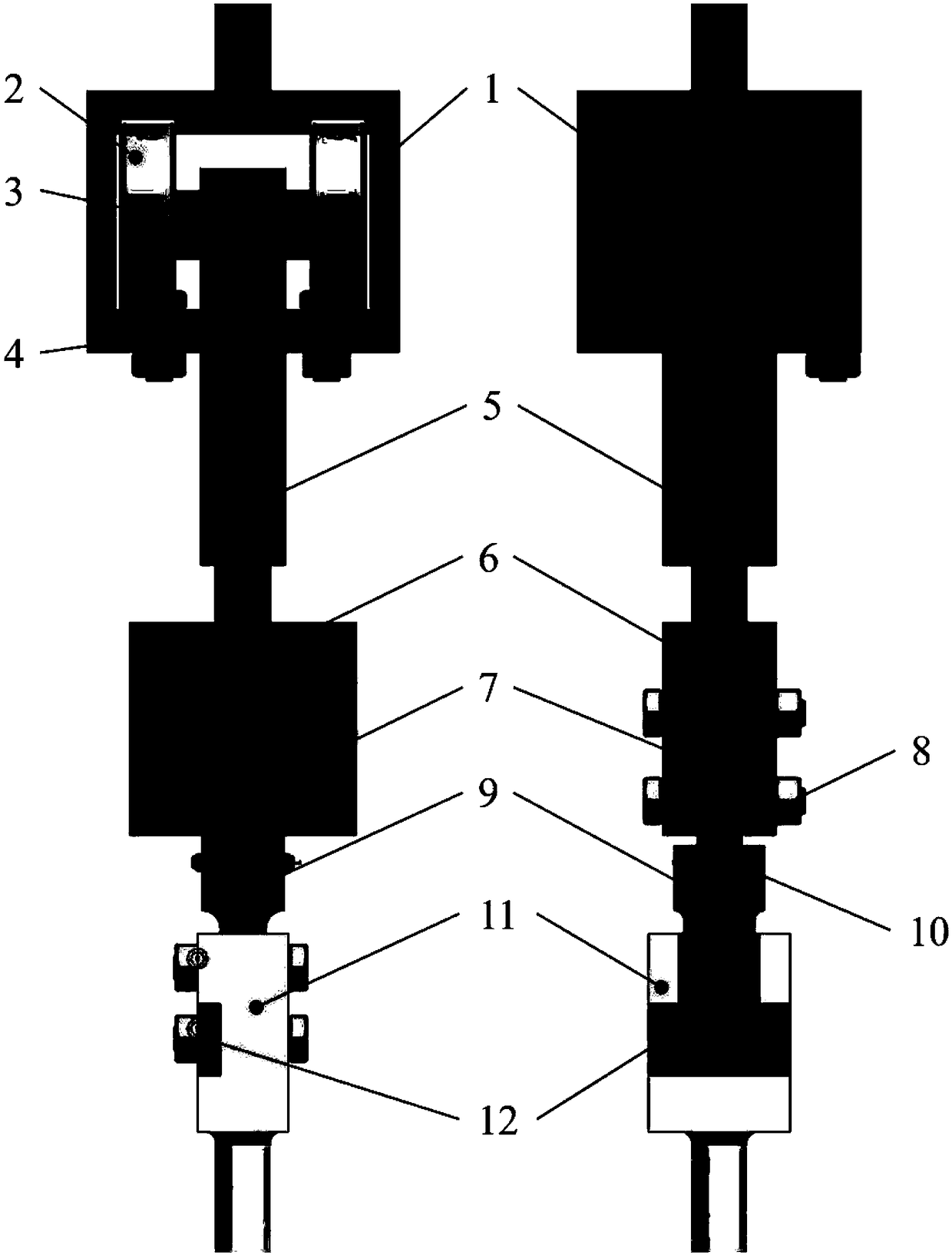

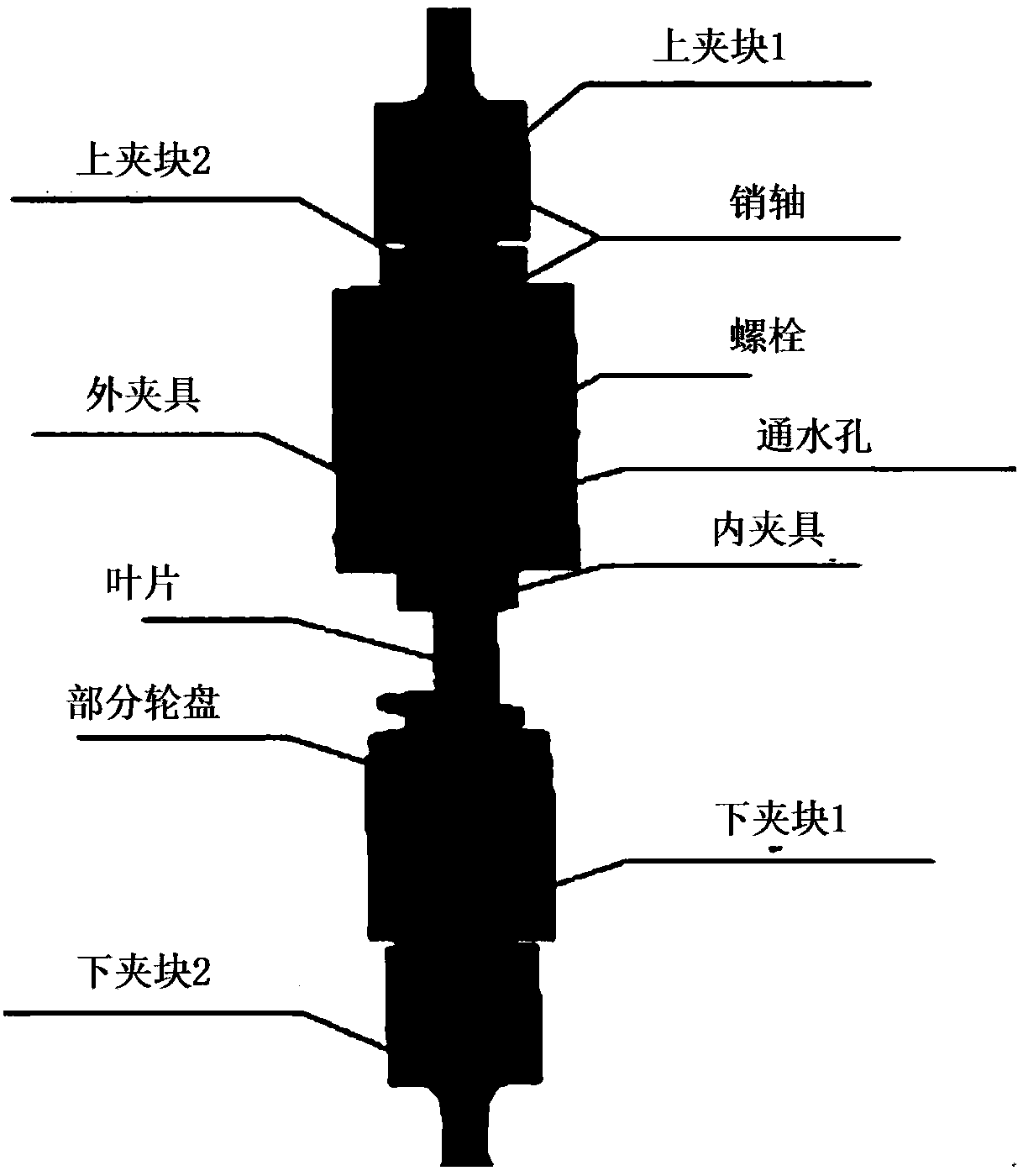

[0022] Such as figure 1 As shown, the present invention is mainly designed for the high-low cycle composite fatigue test fixture suitable for the turbine tenon joint structure, so as to realize the simultaneous testing of the turbine tenon joint structure with the longitudinal large strain low cycle vibration load, the transverse high cycle vibration load and the thermal load. load.

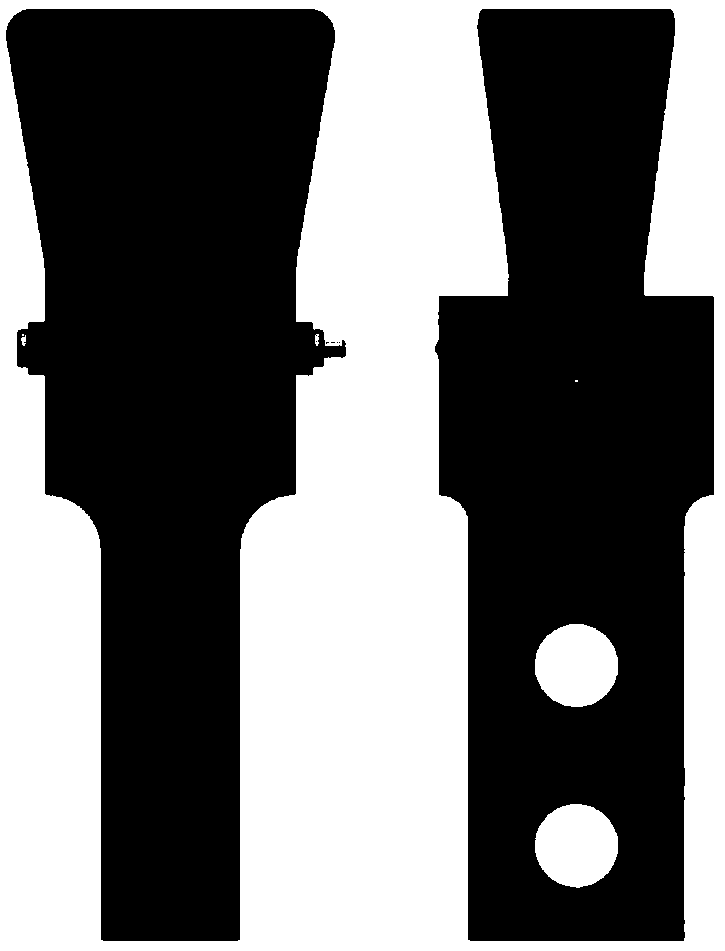

[0023] In the actual test, the structure of the whole set of fixtures is as follows: figure 1 As shown, it is divided into three parts: tenon clamping system composed of tenon fixture 6, compression block 7, tenon test piece 8; tenon and groove fixture 11, small compression block 12, tenon and groove test piece 9 Groove clamping system; a loading system composed of bearing installation box 1, ball bearing 2, transmission shaft 3, limit connection block 4, and force t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com