Car accessory grinding tool

A technology for auto parts and tooling, used in grinding/polishing safety devices, grinding machines, manufacturing tools, etc., can solve problems such as high noise, achieve high efficiency, reduce noise, and improve the working environment of the workshop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

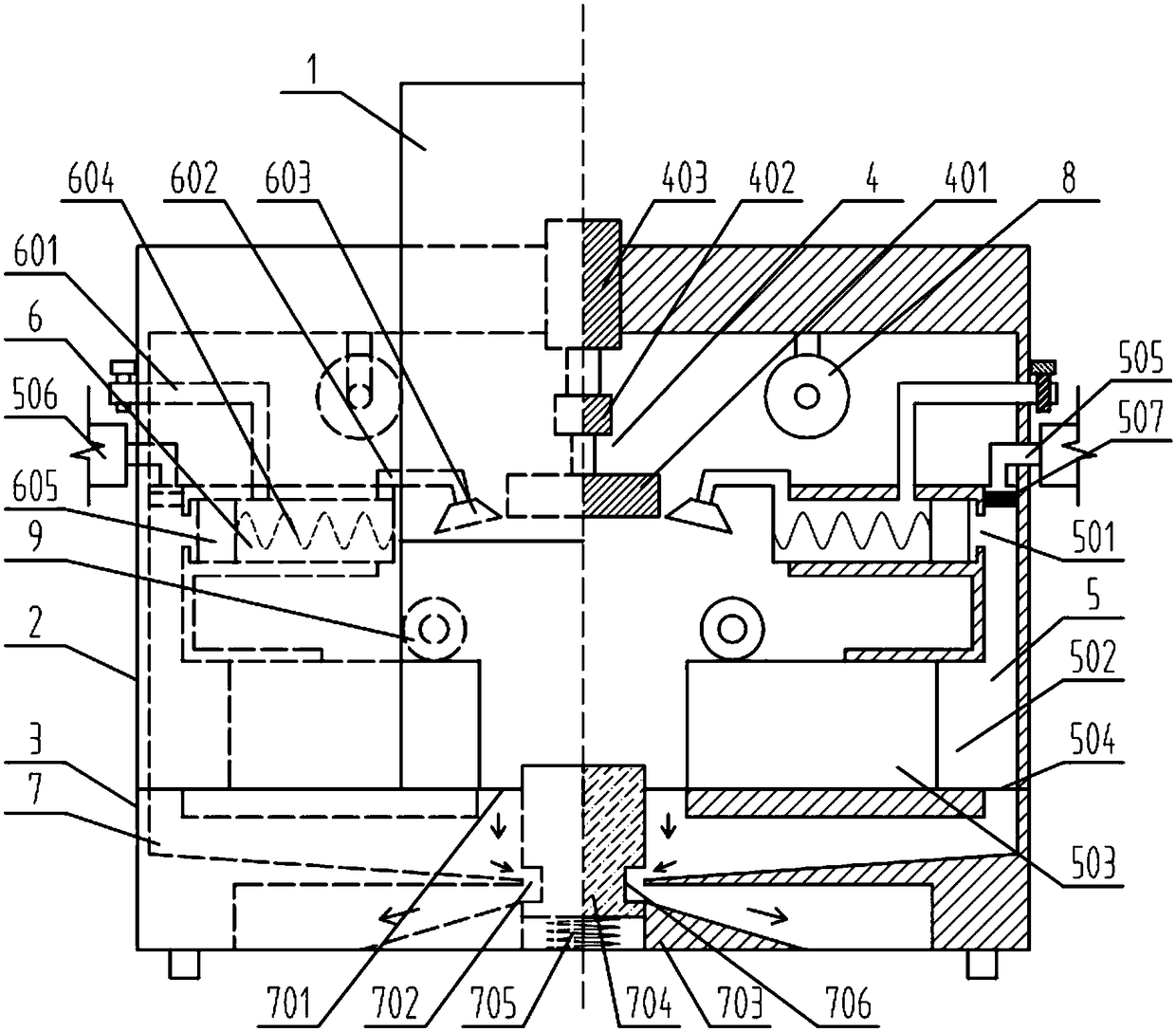

[0021] The reference signs in the accompanying drawings of the specification include: lifting door 1, box body 2, base 3, grinding mechanism 4, grinding wheel 401, grinding motor 402, telescopic motor 403, airflow guide pipe 5, first communication port 501, second Communication port 502, clamping block 503, third communication port 504, air outlet pipe 505, vacuum pump 506, dust filter 507, cleaning pipe 6, water inlet pipe 601, water outlet pipe 602, nozzle 603, first spring 604, first Slider 605, waste pipe 7, dust suction port 701, dust outlet 702, first slide seat 703, floating block 704, second spring 705, groove 706, power mechanism 8, driven gear 9.

[0022] Such as figure 1 As shown, the auto parts grinding tool includes a box body 2 and a base 3 , one side of the box body 2 is vertically slidably connected with a lifting door 1 , and the base 3 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com