Turning method for eccentric circle of crank shaft of RV (Rotary Vector) speed reducer and special eccentric tool

A crankshaft and reducer technology, which is applied to turning equipment, turning equipment, manufacturing tools, etc., can solve the problems of high cost, low efficiency of CNC milling, long processing time, etc., and achieve low production cost, high processing efficiency, and parts high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

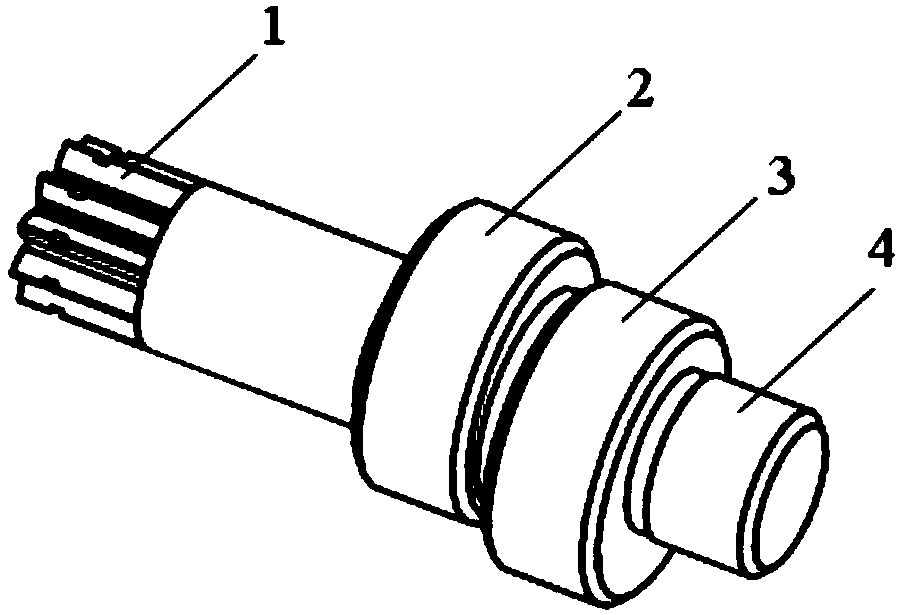

[0020] In order to facilitate the understanding of the method of the present invention, the structure of the special eccentric tooling used in the method is first introduced in detail:

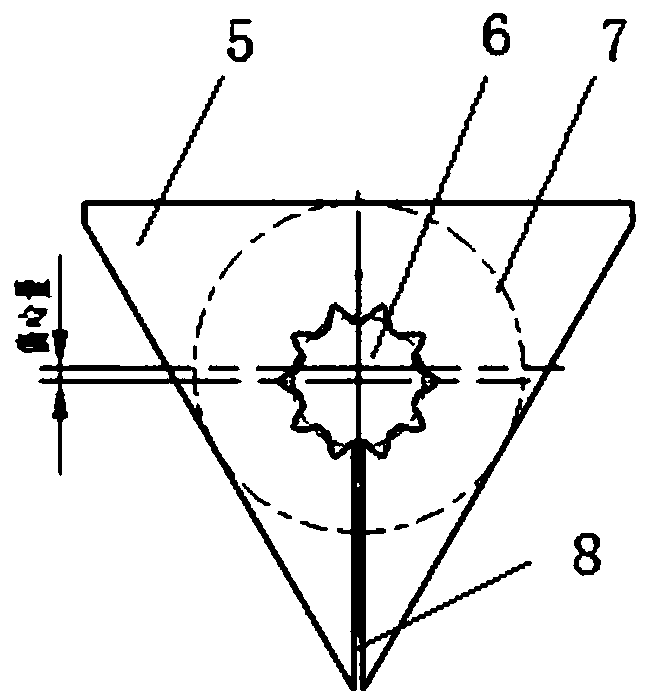

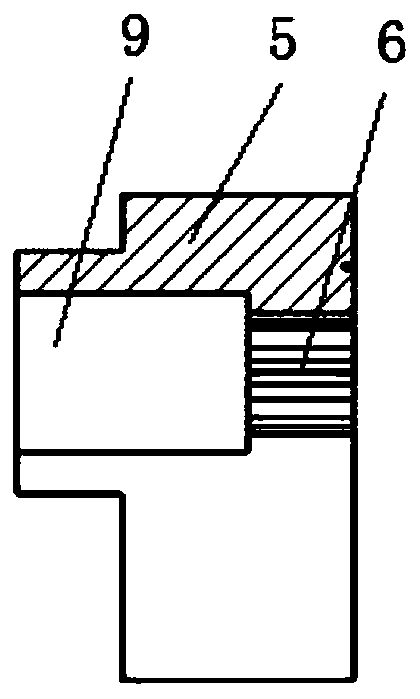

[0021] Such as figure 2 and image 3 As shown, the inside of the eccentric tooling 5 is provided with an inner spline 6 and a stepped inner hole 9, the inner spline and the stepped inner hole are coaxially arranged and communicated with each other to ensure that the inner spline and the stepped inner hole are concentric. The external shape of the eccentric tooling is a triangle, and the axis of the triangular inscribed circle 7 is not coaxial with the axis of the step inner hole, ensuring that the distance between the axis of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com