Clamp controlling non-rotational symmetry errors for optical elements during polishing

A non-rotationally symmetric, optical element technology, used in manufacturing tools, optical surface grinders, grinding/polishing equipment, etc., can solve the problems of low processing convergence efficiency and difficult polishing, and achieve effective control, high resolution, The effect of ensuring positional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

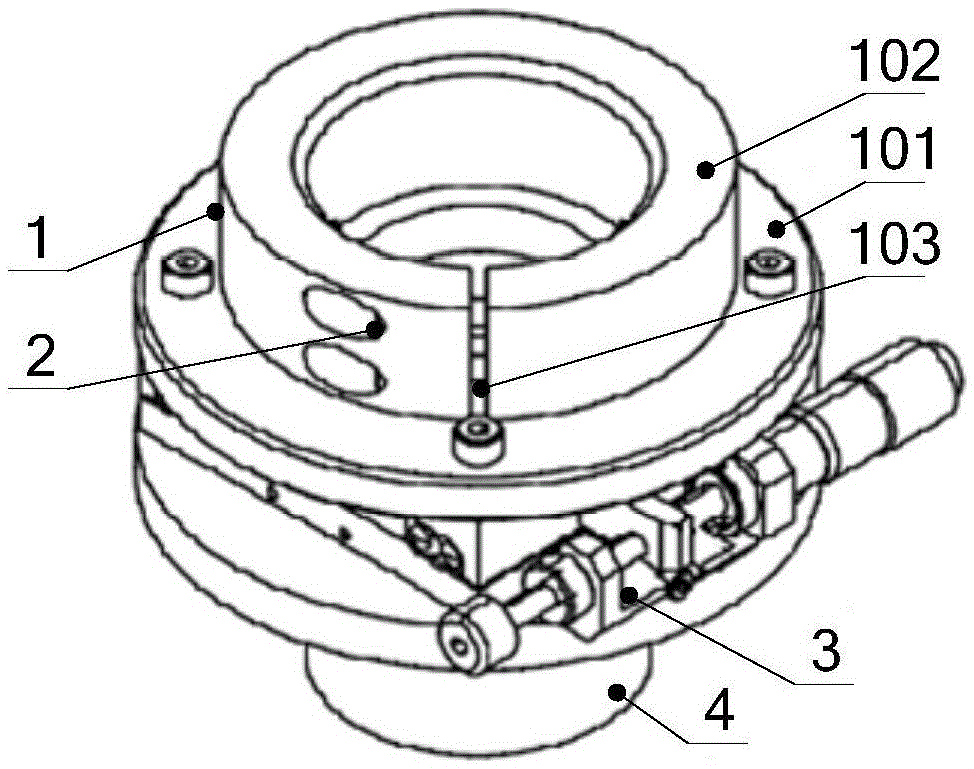

[0013] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0014] See attached figure 2 , a jig for controlling non-rotational symmetry error optical element polishing of the present invention includes a clamping sleeve 1, a locking screw A2, a one-dimensional translation stage 3 and a fixed base 4;

[0015] The clamping bushing 1 is fixed on the upper installation surface of the one-dimensional translation platform 3, and the lower installation surface of the one-dimensional translation platform 3 is fixedly connected with the fixed base 4;

[0016] When the adjustment knob of the one-dimensional translation table 3 is at the zero scale, the clamping sleeve 1 is coaxial with the fixed base 4, and the clamping sleeve 1 is a flexible structure, which is locked by the locking screw A2 .

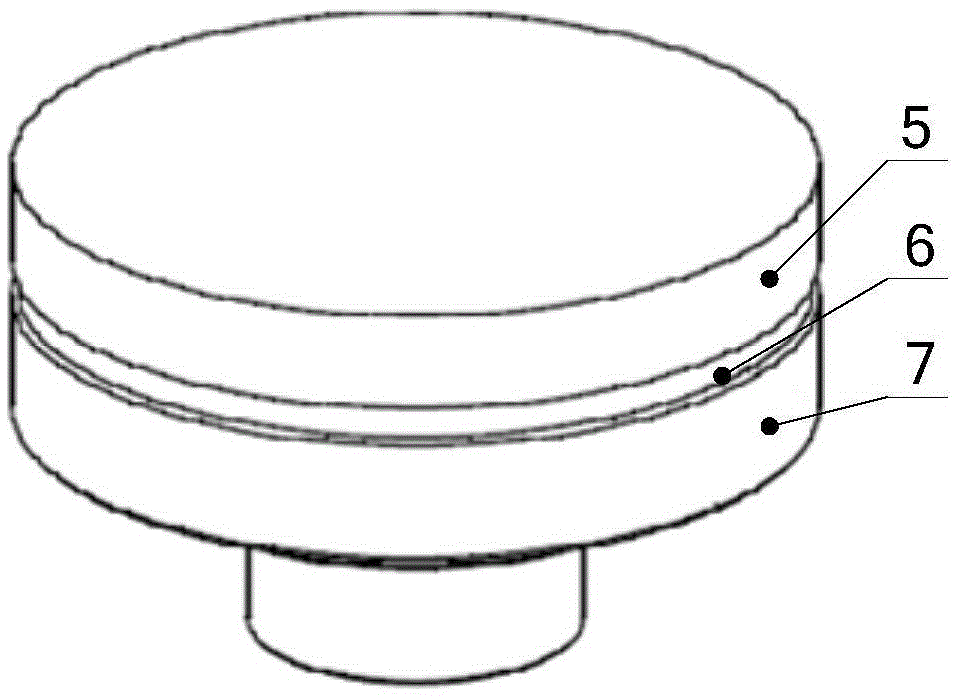

[0017] The clamping bushing 1 includes a circular ring structure 101 and a cylindrical structure 102. The side wall of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com