A double-sided laser-tig arc hybrid welding method

A hybrid welding and arc technology, used in laser welding equipment, welding equipment, metal processing and other directions, can solve problems such as increased welding cost, large welding seam deformation, laser or arc offset, etc., to ensure positioning accuracy and stability, The effect of reducing the number of thermal cycles and reducing the grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

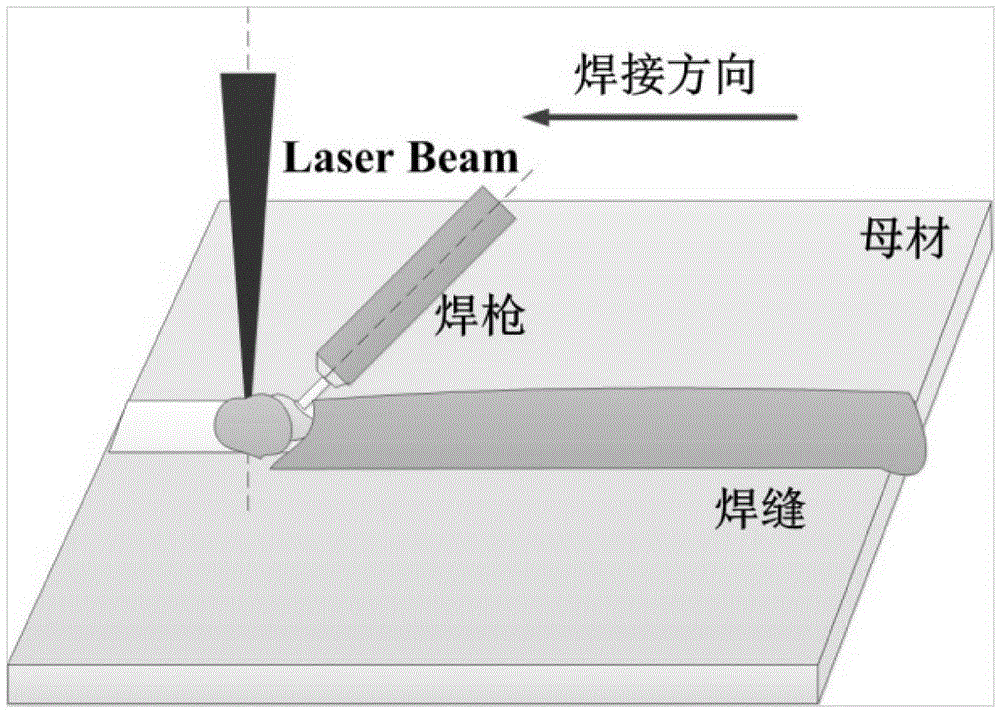

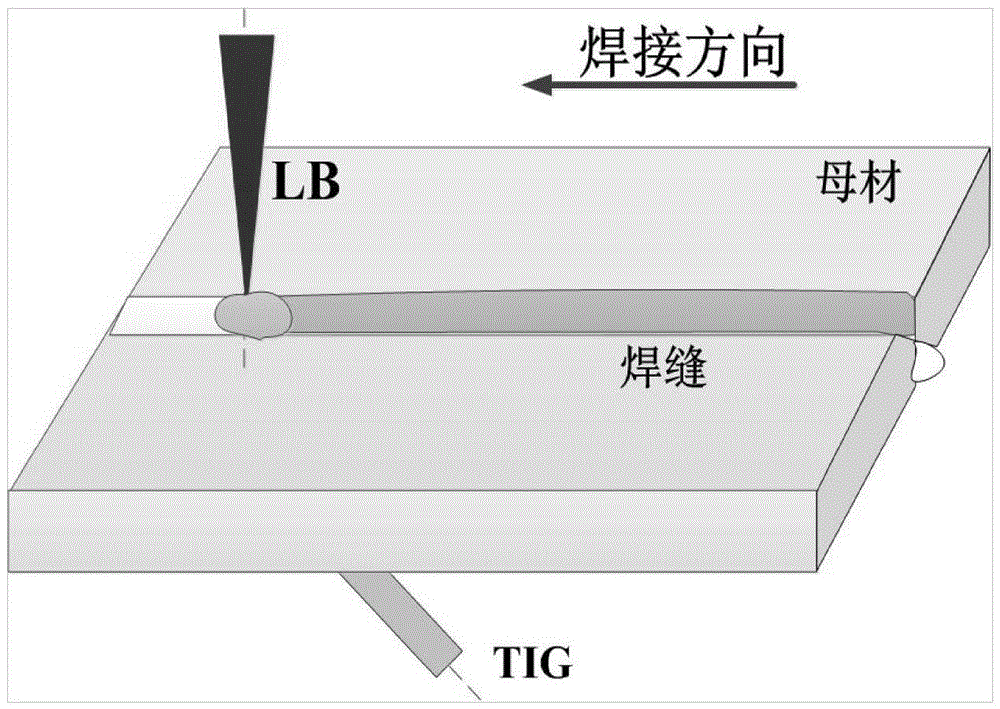

[0035] Specific embodiment one: a kind of double-sided laser-TIG electric arc hybrid welding method of this embodiment, concrete operation is as follows:

[0036] Step 1: Before welding, process the to-be-welded part of the workpiece to be welded into a double V-shaped groove, and grind or clean the processed double-sided groove and the surfaces on both sides, and fix the polished or cleaned workpiece to be welded On the welding fixture;

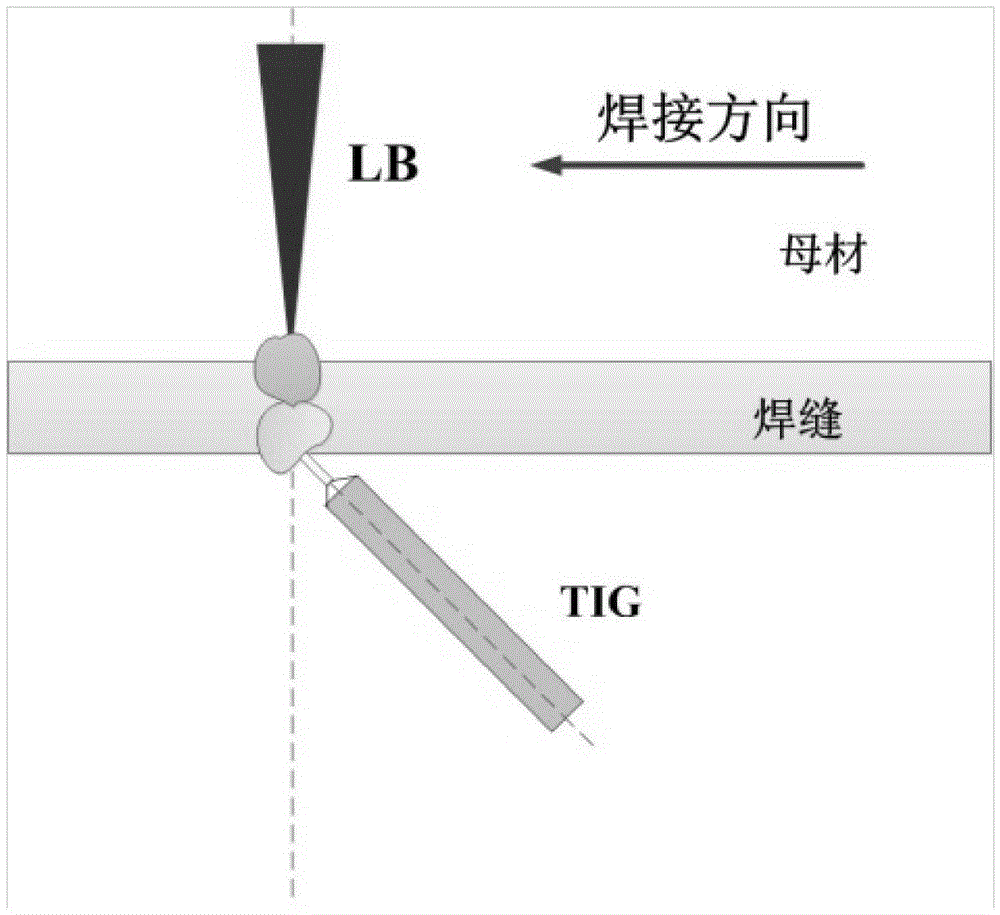

[0037] Step 2: Place two relatively independent laser-TIG arc systems on both sides of the workpiece to be welded, keep the two sets of lasers on the same axis, and the angle between the axis and the workpiece is 60°~90°, and adjust the two sets of TIG arc The included angle between the welding torch and the laser beam is 25°~55°;

[0038] Step 3: Set welding process parameters: laser power is 500~10000W, spot diameter is -4~+4mm; arc current is 50~500A, welding speed is 50~500mm / min;

[0039] Step 4: After setting the welding process para...

specific Embodiment approach 2

[0041] Embodiment 2: This embodiment is different from Embodiment 1 in that: the arc welding is carried out by argon tungsten arc welding machine. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0042] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the arc welding method is DC welding or AC welding. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com