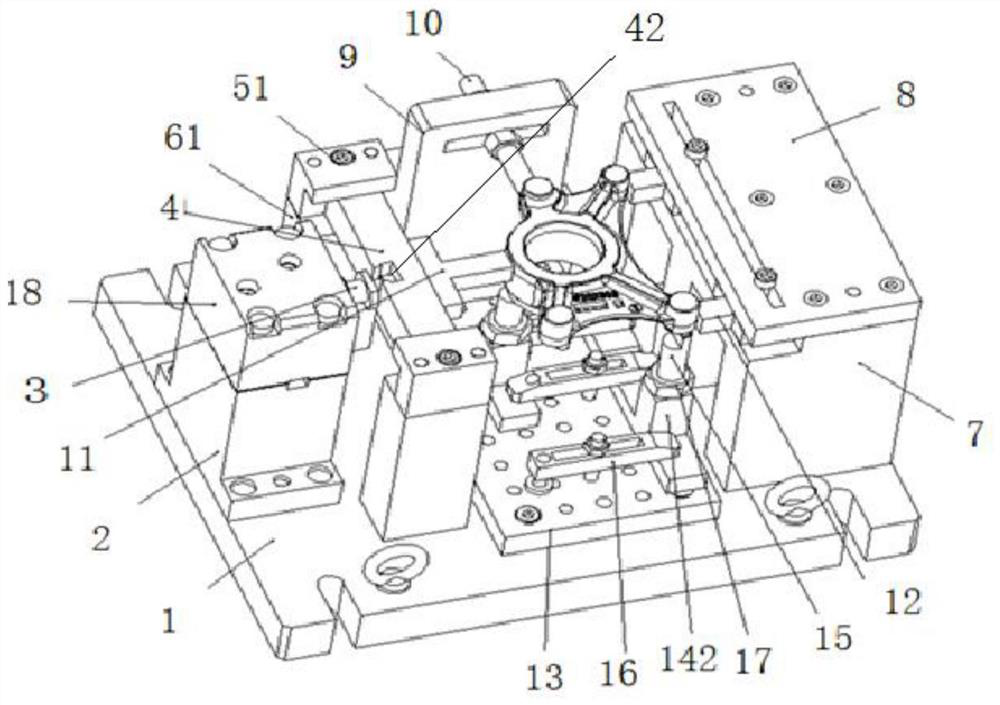

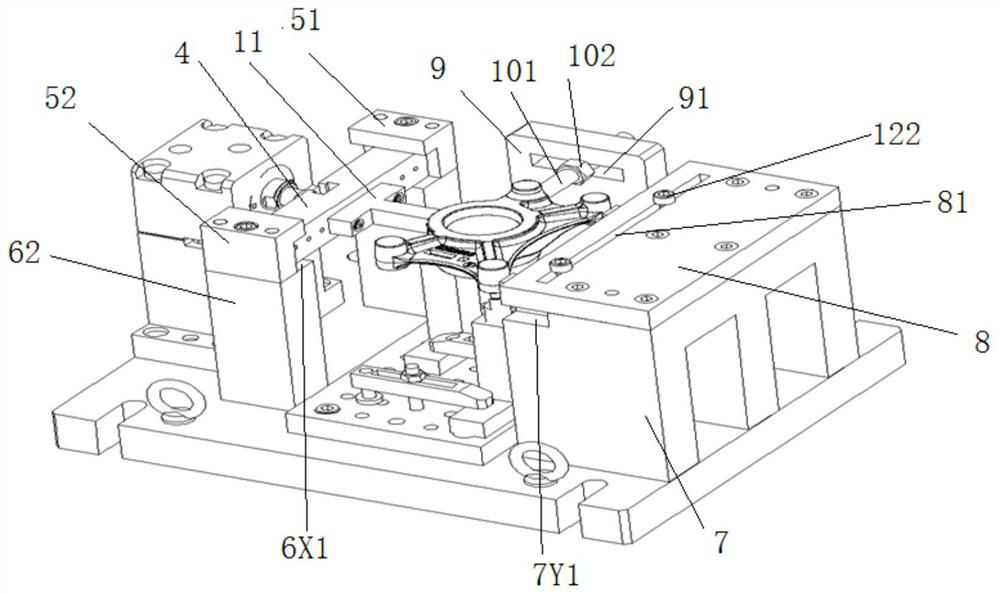

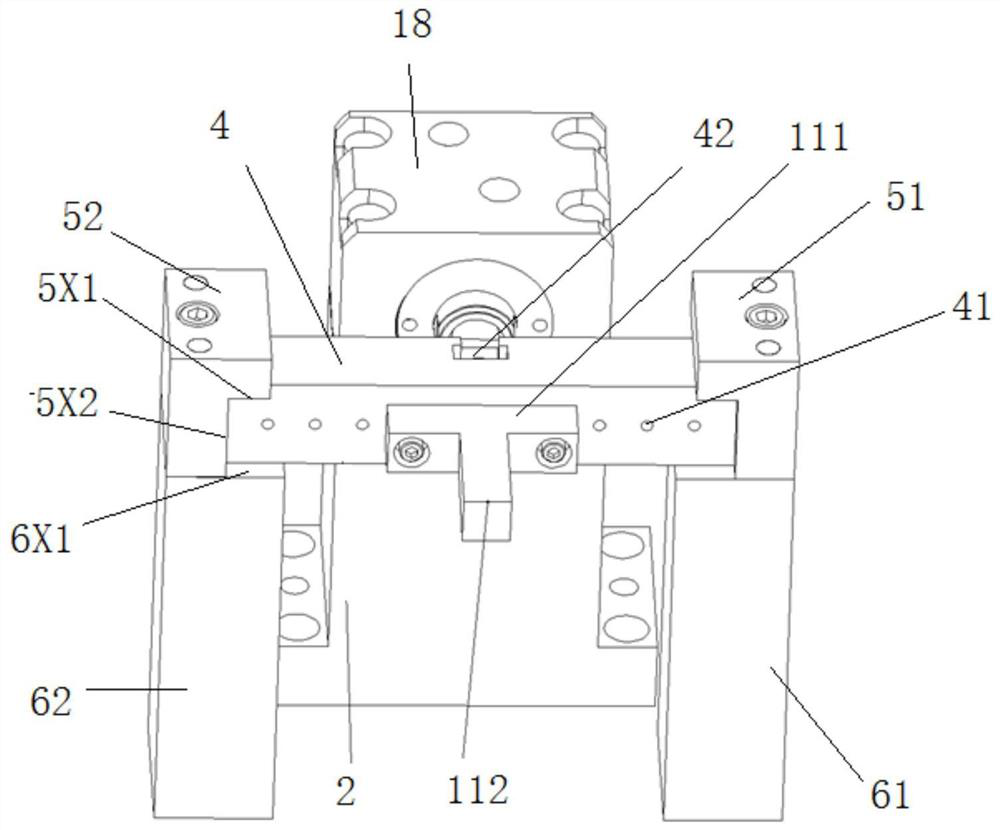

Flexible fixture for surface milling and drilling of fan bracket and clamping and positioning method

A flexible clamp, support and positioning technology, applied in the field of vehicle parts processing, clamping and positioning, can solve problems such as being unsuitable for fan bracket clamping, and achieve the effect of simple and easy-to-operate clamping methods, reducing development costs, and shortening development cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following specific implementation methods are used to explain the technical solutions of the claims of the present invention, so that those skilled in the art can understand the claims. The protection scope of the present invention is not limited to the following specific implementation structures. The protection scope of the present invention includes the technical solution of the claims of the present invention made by those skilled in the art and is different from the following specific embodiments. "Up", "Down", "Left", "Right" and so on in the following embodiments are only used to indicate the relative positional relationship in the illustration. When the absolute position of the described object changes, the relative positional relationship may also be Change accordingly. The X direction is the left and right direction of the view, the Y direction is the front and rear direction of the view, the left and right are ends, and the front and rear are sides.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com