Intelligent helmet production and assembly device

A technology for smart helmets and assembly devices, applied in assembly machines, metal processing equipment, metal processing, etc., can solve the problems of low efficiency, inconvenient clamping, and affecting the efficiency of assembly, and achieve simple clamping methods and ensure reliability , The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

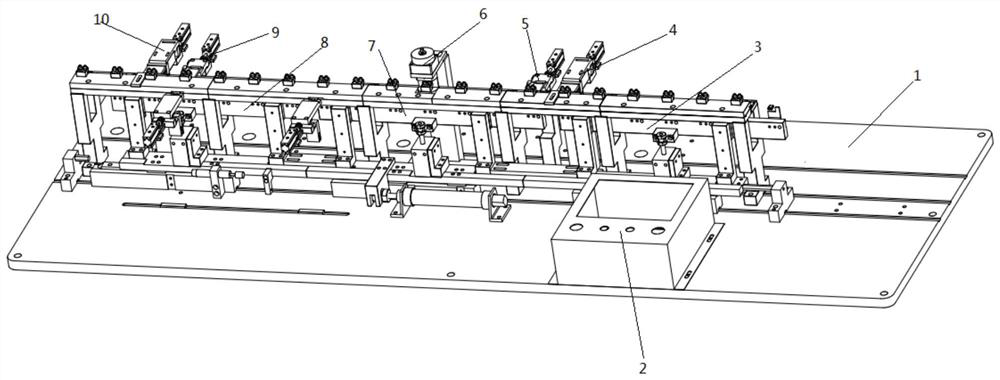

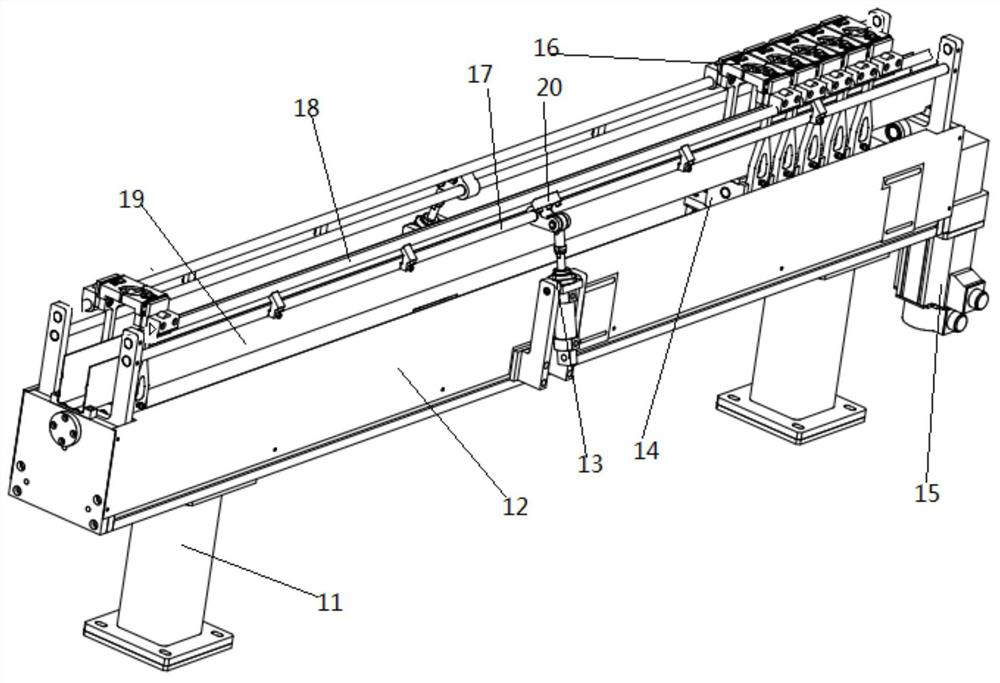

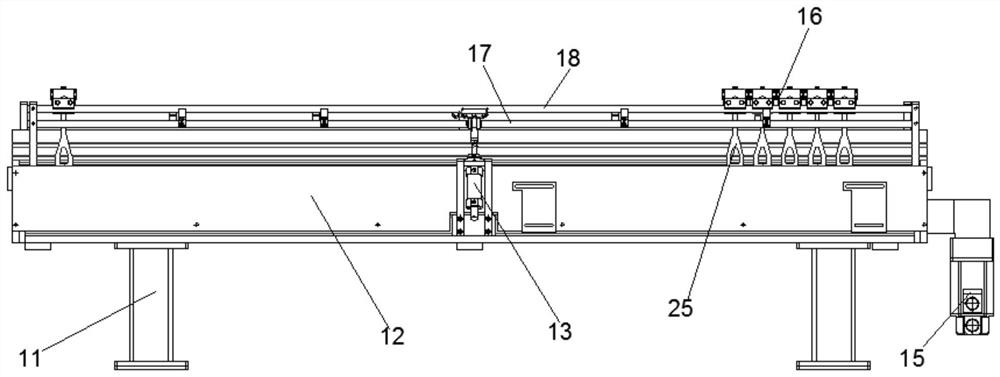

[0023] see Figure 1~6 , in the embodiment of the present invention, the intelligent helmet production and assembly device is used to assemble the helmet protective cover on the helmet, which includes a support base plate 1, a left assembly line conveying mechanism 3, a right assembly line conveying mechanism 8, a pressing assembly conveying Mechanism 7, protective cover feeding manipulator, pin shaft feeding manipulator and pin pressing mechanism 6, wherein, the left assembly line conveying mechanism 3, the pressing assembly conveying mechanism 7, and the right assembly line conveying mechanism 8 are arranged in a straight line Fixed on the support base plate, it is characterized in that the left assembly line conveying mechanism and the right assembly line conveying mechanism are docked in a symmetrical manner and located on both sides of the pressing assembly conveying mechanism 7, and the pressing pin mechanism 6 Located above the middle of the press-fit assembly delivery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com