A cable robot for a cable-stayed bridge

A cable-stayed bridge cable and robot technology, applied in the field of robots, can solve the problems of secondary damage, high difficulty and high risk, and achieve the effects of prolonging the working life, reducing the frequency of switching on and off, and preventing sliding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

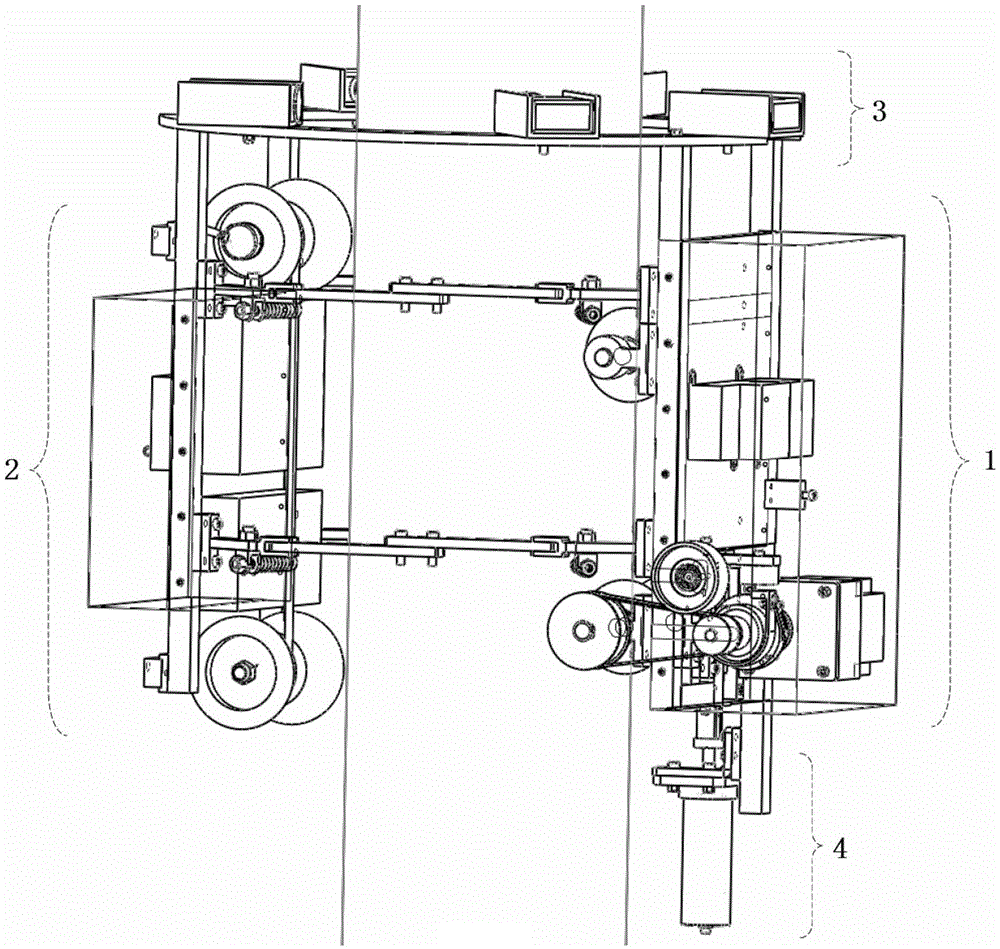

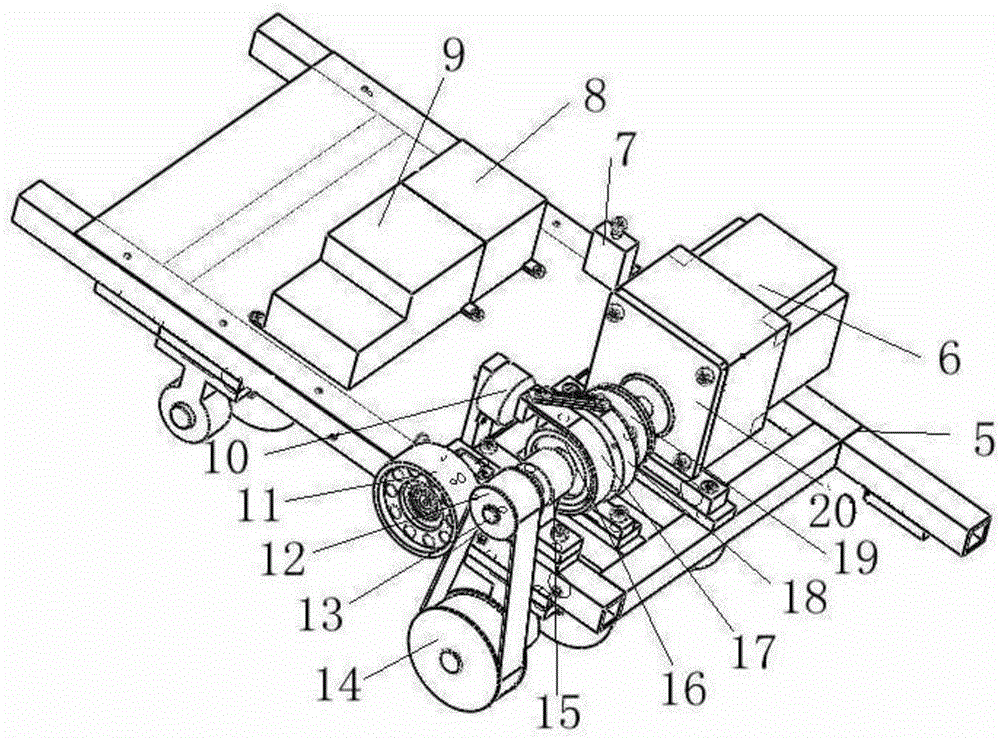

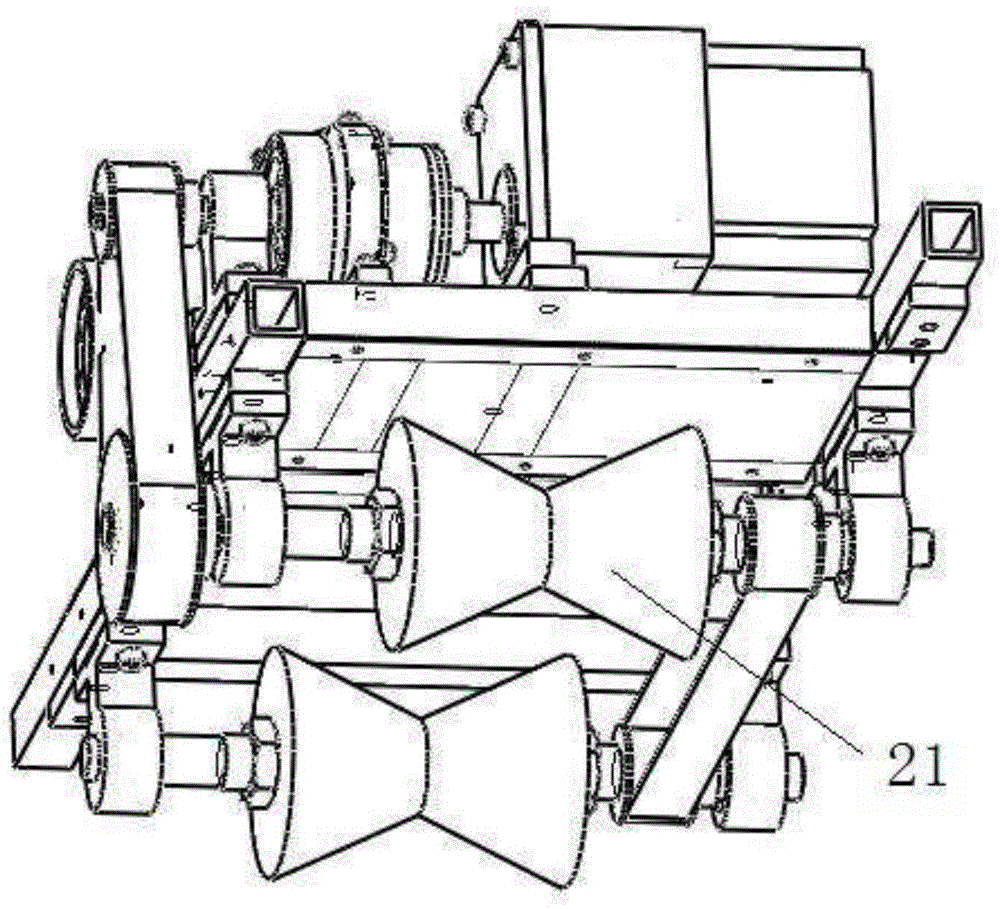

[0076] figure 1 A general assembly drawing of a cable-stayed bridge cable robot according to the first embodiment of the present invention is shown. Specifically, those skilled in the art understand that in this embodiment, the cable-stayed bridge cable robot includes at least: an active module 1, which provides power for the cable-stayed bridge cable robot to realize the Move along the cable-stayed bridge; the driven module 2 at least provides power for the decelerating stepper motor 6 in the active module 1 of the cable-stayed bridge robot; the detection module 3 is used to detect the cable-stayed bridge being detected Cable status; power-off protection module 4, so that the cable-stayed bridge cable robot will not slide down along the cable-stayed bridge cable when the power is off, and realize the buffering effect on the cable-stayed bridge cable robot; The active module 1 uses the active frame 5 as the installation platform, the driven module 2 uses the driven frame 27 as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com