Pull-wire angle measuring system

A wire-drawing and wire-drawing encoder technology, which is applied in the field of devices for measuring the rotation angle of indirect artillery barrels, can solve the problems that the measuring equipment cannot be used easily, is not suitable, and is expensive, and achieves simple and convenient clamping methods and increased Effects of measurement accuracy and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

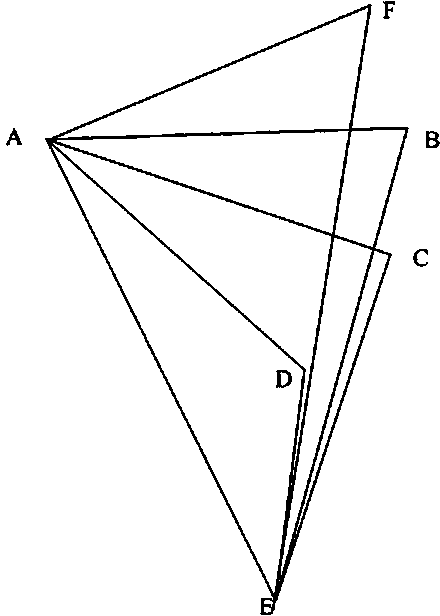

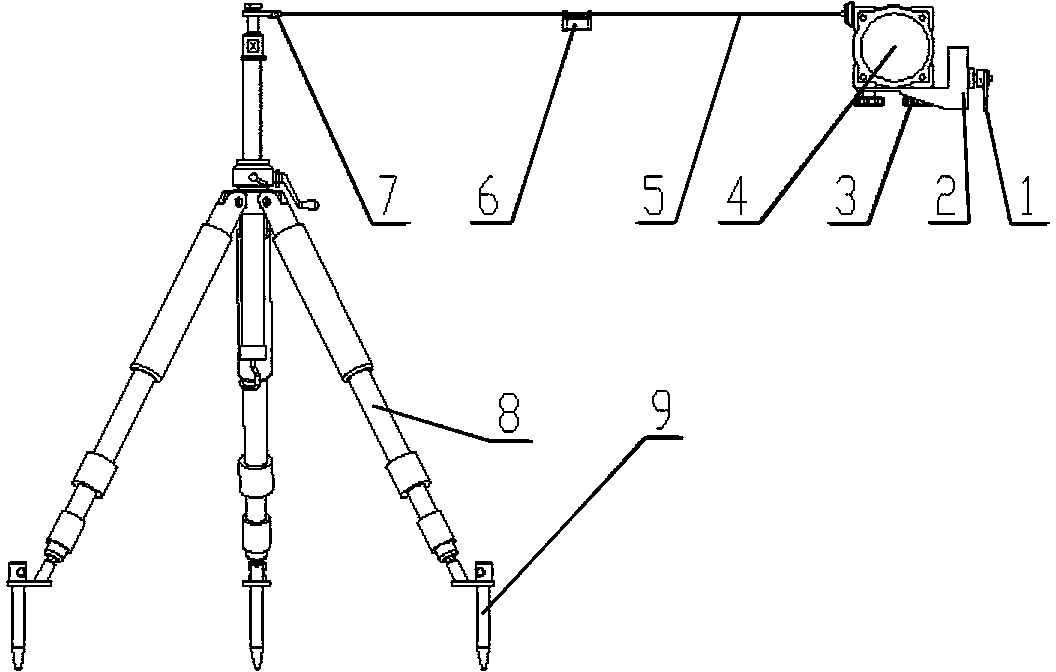

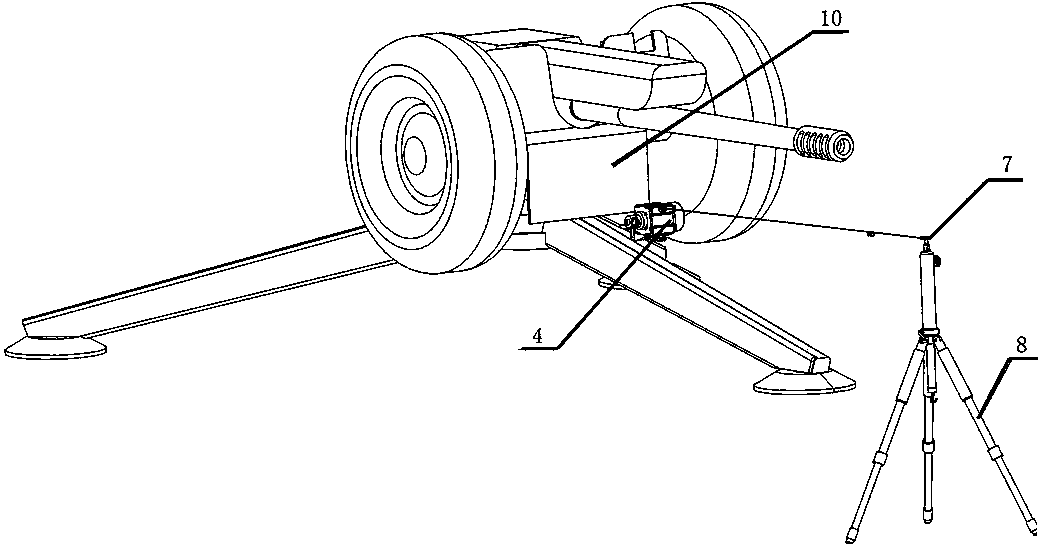

[0017] Refer to attached Figure 1~3 , The cable type angle measurement system of the present invention is composed of a cable length measuring mechanism, a solution circuit and a calibration circuit. The stay wire length measuring mechanism includes a stay wire encoder 4 , a tripod 8 , a stay wire fixing ring 7 , and a level measuring device 6 . The wire-guide encoder is a wire-guide encoder made in Germany, which is a high-resolution test device. The wire-guy encoder can measure the amount of change in the wire that comes with the device. The maximum measurement value is 10 meters, and the resolution is 0.05 The system calculates the change value of the corresponding angle by measuring the change in the length of the cable of the cable encoder. The shell side of the pull-wire encoder is equipped with threaded mounting holes, and the mounting parts are connected to the encoder through the threaded holes, and are connected and fixed with the artillery shield through the fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com