Welding tool for passenger car pivot rotating arms

A technology for welding tooling and passenger car doors, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. Improve assembly efficiency, improve accuracy, and ensure the effect of parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

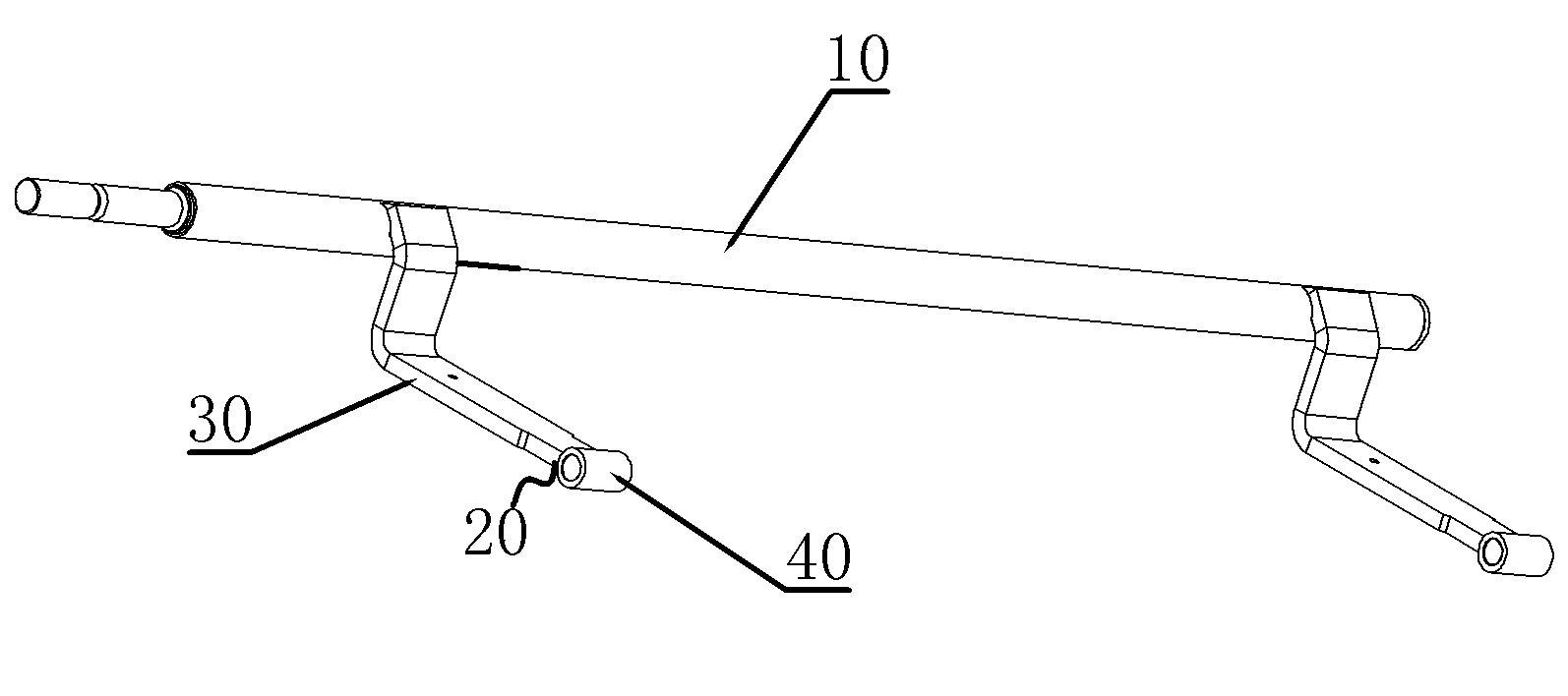

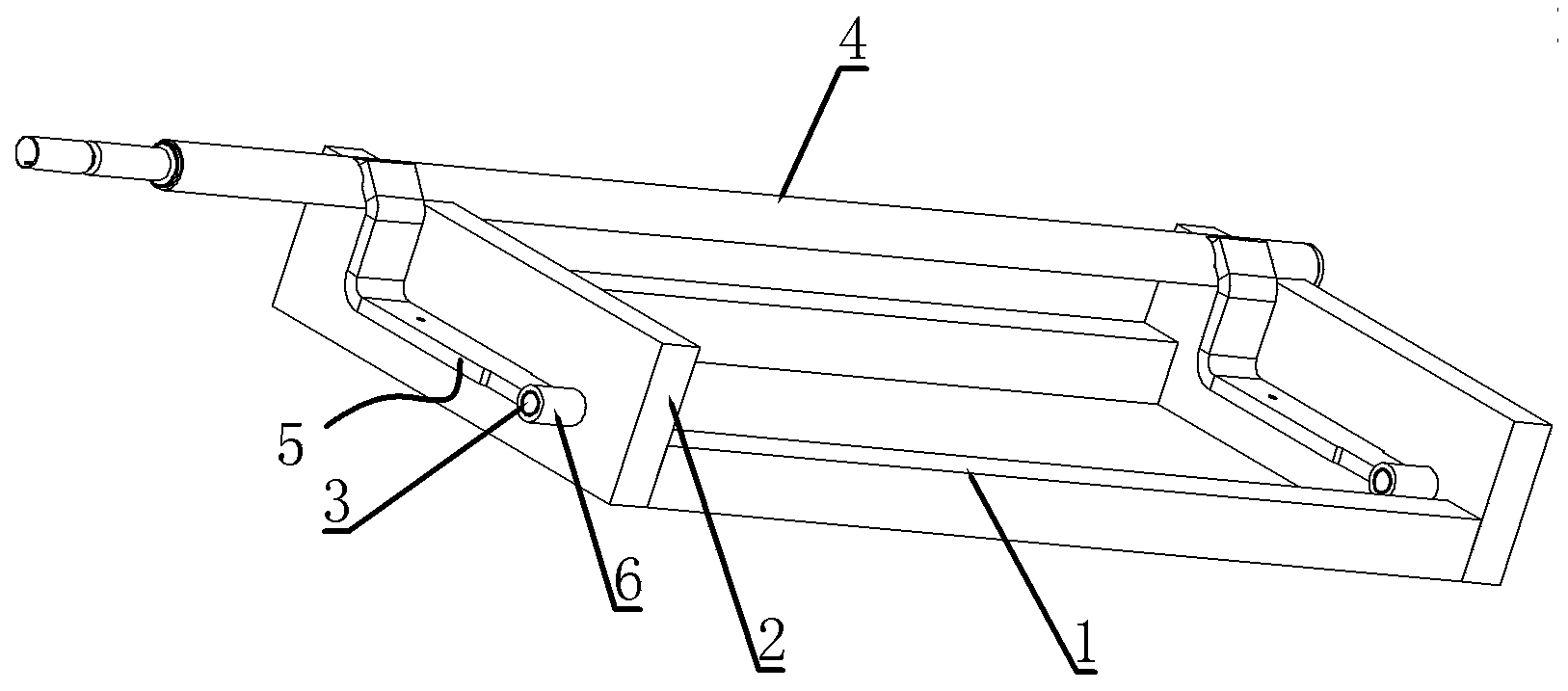

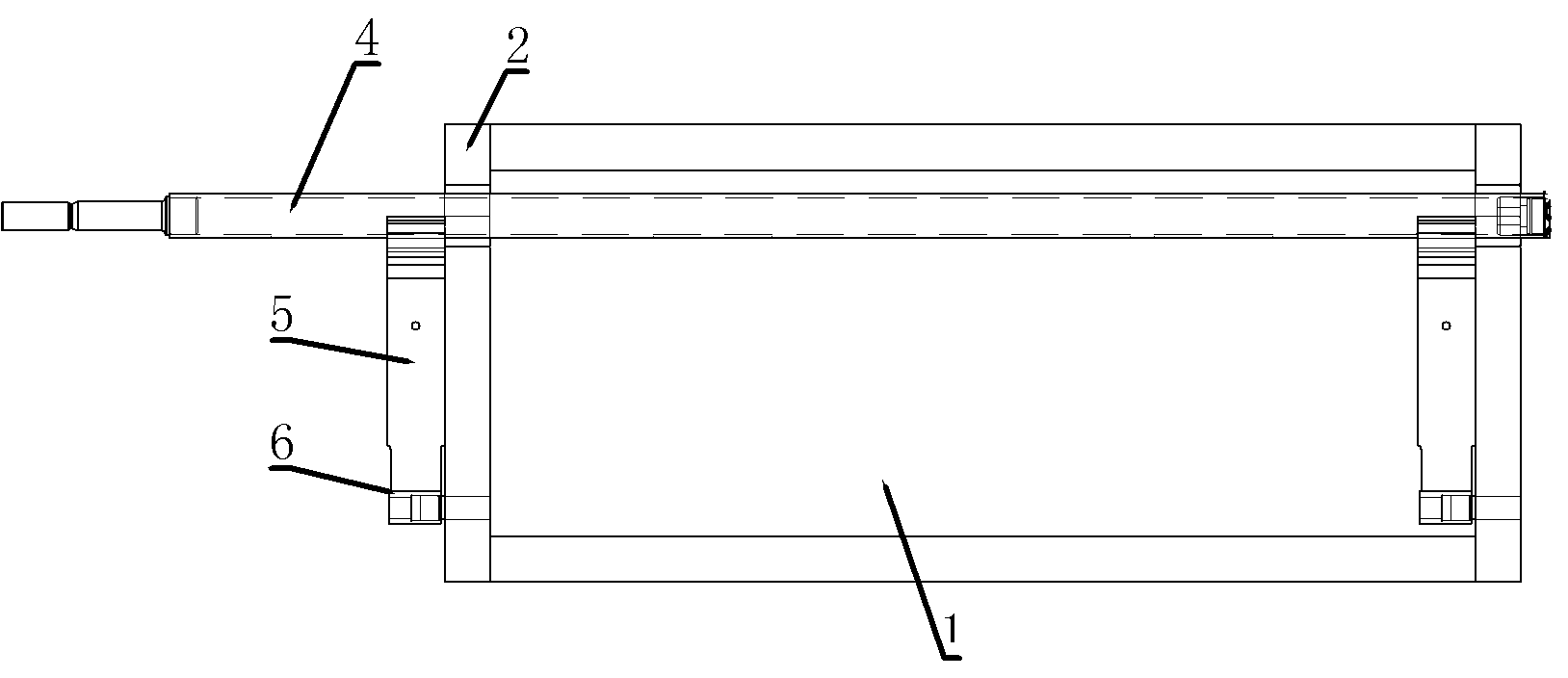

[0016] The embodiment of the passenger car door axle pivoting arm welding frock of the present invention: as Figure 2 to Figure 5 As shown, the tooling includes a base 1 and two positioning plates 2 fixed vertically and symmetrically on the left and right sides. The top surfaces of the two positioning plates 2 are respectively provided with door shaft locking grooves 21 extending along the same straight line extending left and right. The door shaft card slot 21 is a V-shaped slot with an opening facing upwards, and a positioning pin hole arranged parallel to the door shaft card slot 21 is opened on the left plate surface of the positioning plate 2, and a rotating sleeve is inserted in the positioning pin hole. Locating pin 3, the locating pin holes on the two locating plates 2 are coaxially arranged, so that the swivel locating pins 3 inserted in the two locating pin holes are coaxially arranged, and the axes of the two swivel locating pins 3 are aligned with the The extendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com