Propeller with combined continuous fiber reinforced composite blades for ship

A reinforced composite material and continuous fiber technology, which is applied in the direction of rotating propellers, rotating propellers, ships, etc., can solve the problems of affecting load bearing, high manufacturing or processing accuracy, and difficulty, and achieve high assembly positioning accuracy and forming The effect of low processing difficulty and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in detail below in conjunction with accompanying drawing. The technical solution of the present invention is not limited to the embodiments described above, and all equivalent or simple changes based on the structure, features and principles of the technical solution of the present invention are included in the technical solution of the present invention.

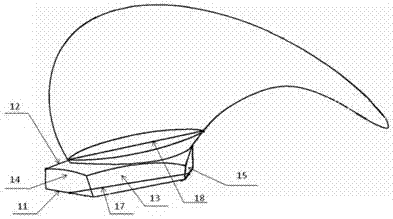

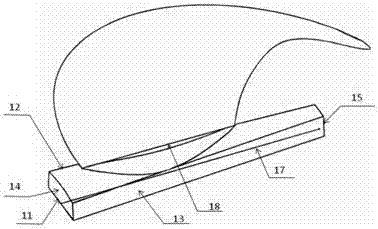

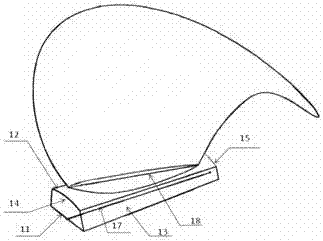

[0030] figure 1 The shown marine composite propeller consists of a hub 1 , an end cover 2 and five blades 3 , the diameter D of the propeller is 2500mm, and the hub 1 has a dovetail groove 4 for assembling with the blades 3 . figure 1 The material of the paddle hub 1 shown is a composite material, the shape is cylindrical, and the diameter of the paddle hub 1 is 550mm, such as figure 2 shown. The blade 3 is a continuous fiber reinforced composite material, such as image 3As shown; the fiber type is glass fiber, and the blade is connected with the dovetail groove 4 on the propel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com