Roller friction type one-way belt wheel

A pulley, friction technology, applied in the direction of belt/chain/gear, one-way clutch, components with teeth, etc., can solve the problems of easy heat generation, easy displacement and breakage of support springs, etc. The effect of high assembly position accuracy and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

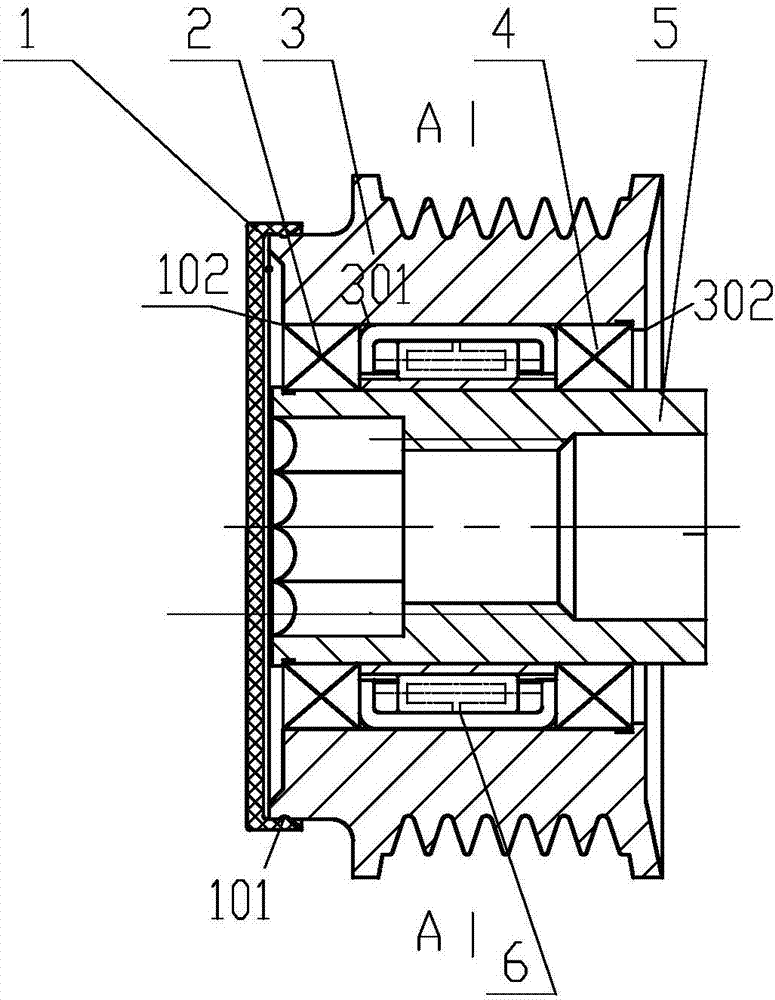

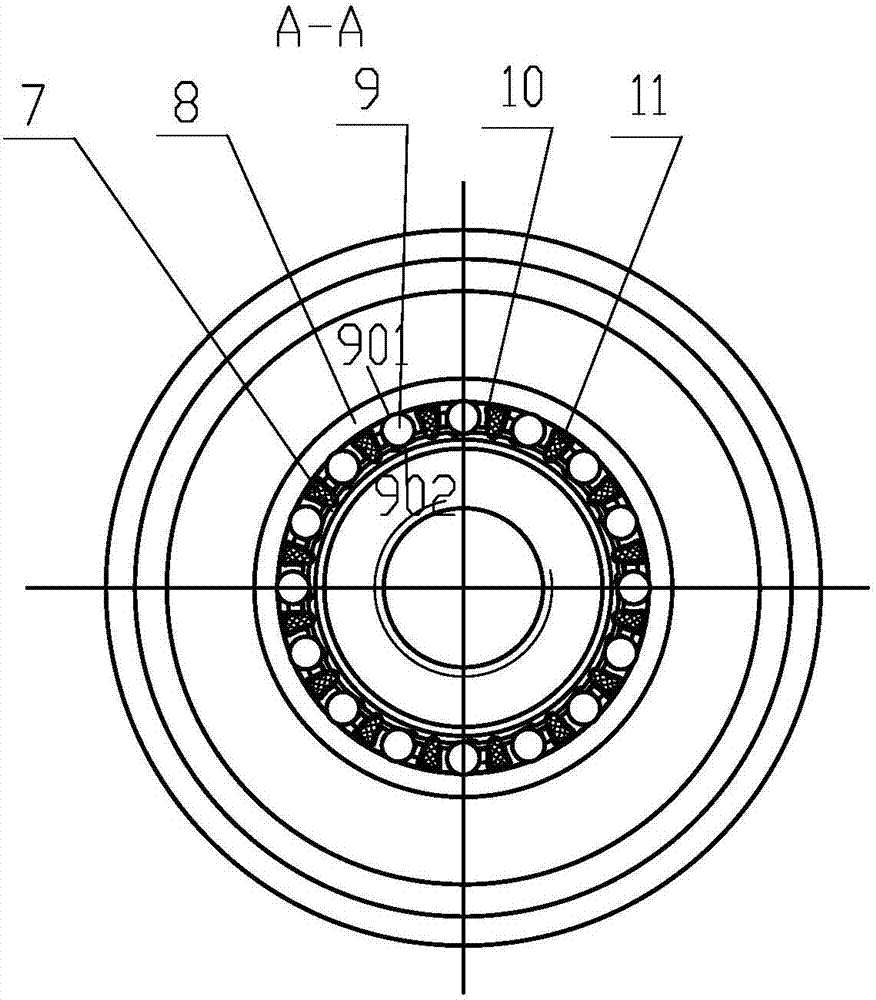

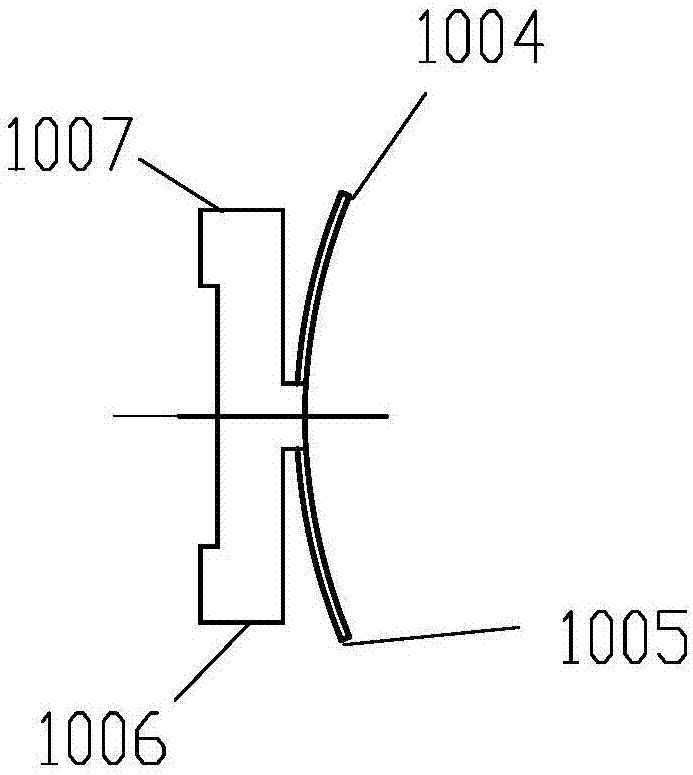

[0024] figure 1 Among them, it includes dust cover 1, first arc-shaped boss 101, first positioning bearing 2, pulley 3, second inner hole 301, inner boss 302, second positioning bearing 4, sleeve 5, one-way clutch Component 6, inner ring 7, working surface proximal end 701, working surface distal end 702, arc-shaped groove 703, outer ring 8, first rib 801, second rib 802, roller 9, upper ridge line 901, Lower ridge line 902, supporting spring 10, first side 1001, arc-shaped bottom 1002, second side 1003, first supporting free end 1004, second supporting free end 1005, first end face 1006, second end face 1007, cage 11. The second arc-shaped boss 110, the third side 111, the outer circular arc 112, the fourth side 113, the first outer circular step end face 115, the second outer circular step end face 116, the first disc body 117, The secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com