Engine complicated structure ring pipe positioning repairing method

A complex structure and engine technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high positioning accuracy, poor consistency, poor consistency of ring pipe production, etc., to improve assembly positioning accuracy, The effect of improving production efficiency and shortening the assembly cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

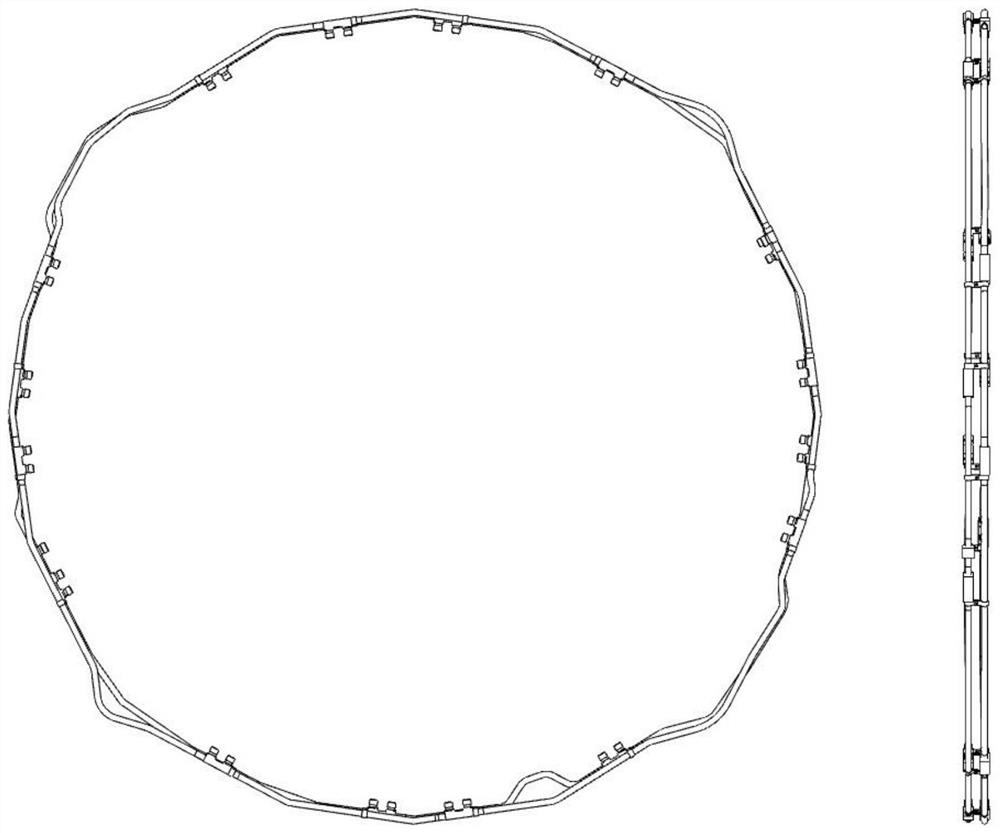

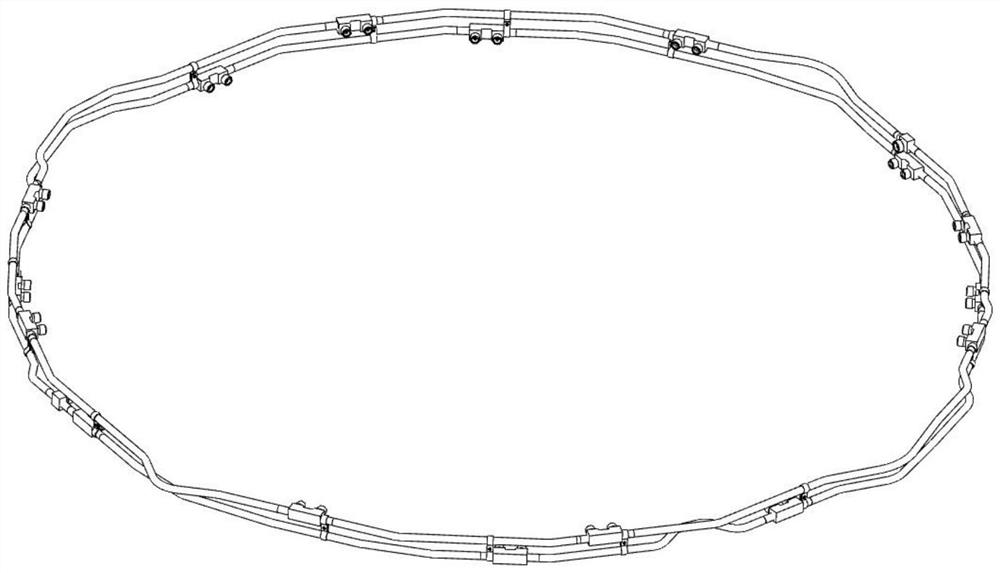

[0022] Examples of the present invention are figure 1 , figure 2 As shown, it is an engine ring pipe assembly, which is composed of two ring pipes arranged side by side, namely the oxidizer ring pipe and the fuel ring pipe, and the diameter of the pipe fittings is about 1.6m. The oxidant ring pipe is welded by 8 crosses, 1 tee and 8 titanium tubes, with a total of 17 welds. The fuel ring is welded by 8 crosses, 1 tee and 9 titanium tubes, with a total of 18 welds.

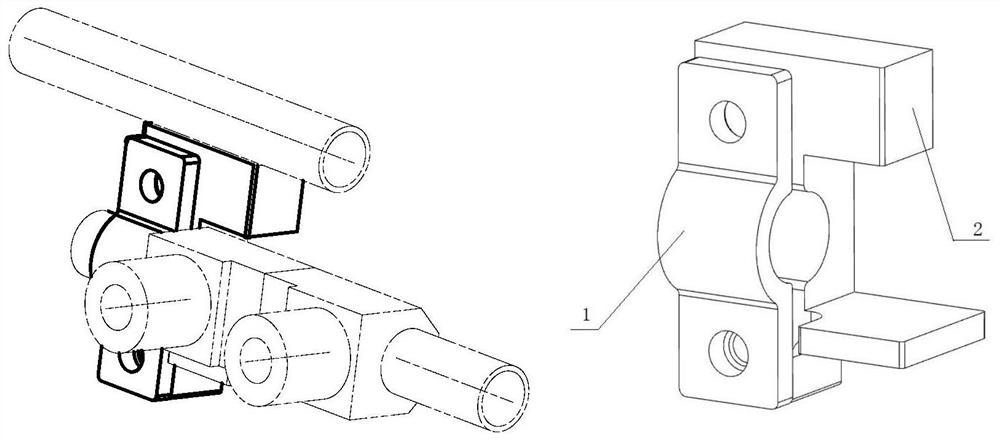

[0023] The present invention uses positioning clips to fix the tee and cross on the ring pipe; the positioning clips are two pieces that are fastened to each other, and the fastening places form a cylindrical through hole parallel to the plane where the ring pipe is located, and the inner diameter of the thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com