Air cylinder cover water draining sleeve water feeding hole sand core tenon and mounting technique thereof

A cylinder head and tenon technology, which is applied in the field of tenon technology design of the water jacket sand core under the cylinder head, can solve the problems such as the deformation of the water jacket core under the cylinder head, achieve the effect of preventing the deformation of the sand core and improving the assembly positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

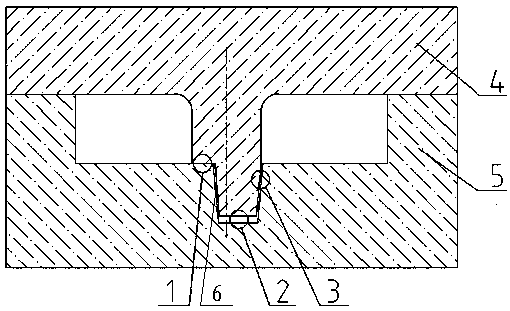

[0017] Example 1, the lower water jacket sand core (4) is installed on the chassis core (5), the non-conforming tenon (9) under the tenon (8) is put into the concave tenon pit (7), and the non-conforming tenon (9) is placed outside The diameter is an inverted cone with a slope distance (6), the concave tenon pit (7) is an inverted cone circle, and the outer diameter of the tenon head (9) to the side wall of the concave tenon pit (7) is the third gap (3), which is non-conformal There is a second gap (2) between the bottom surface of the tenon (9) and the bottom surface of the concave tenon (7), and there is a second gap (2) between the tenon (8) and the non-conforming tenon (9). a gap (1).

Embodiment 2

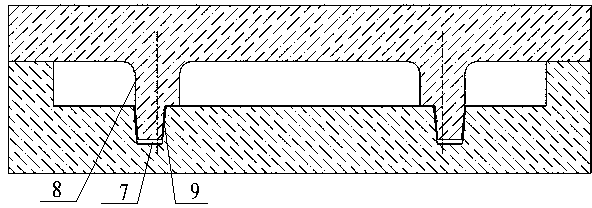

[0018] Example 2, a tenon for the sand core of the upper water hole of the lower water jacket of the cylinder head, including the first gap, the second gap, the third gap, the sand core of the lower water jacket, the chassis core, the slope distance, the concave tenon pit, the tenon head, and the non-conforming The tenon is characterized in that the lower water jacket sand core (4) is above the chassis core (5), the tenon head (8) of the lower water jacket sand core (4) is inserted into the concave tenon pit (7) of the chassis core (5), and the tenon head ( 8) The contact part of the tenon pit (7) is a non-conforming tenon (9), and the non-conforming tenon (9) is made in conjunction with the concave hole of the tenon pit (7), and the non-conforming tenon (9) of the tenon (8) ) into the tenon head pit (7), the gap between it and the pit wall is that the first gap (1) is 0mm, the second gap (2) is 0-5mm, and the third gap (3) is 0.1-1.0mm, The slope distance (6) is 5-30 mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com