Heat exchanger plate set positioning device

A technology for positioning devices and heat exchangers, applied in heat exchange equipment, auxiliary devices, lighting and heating equipment, etc., can solve problems such as plate movement dislocation, plate group leakage, etc., to overcome plate deformation and dislocation, pressure bearing capacity High, easy-to-promote effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

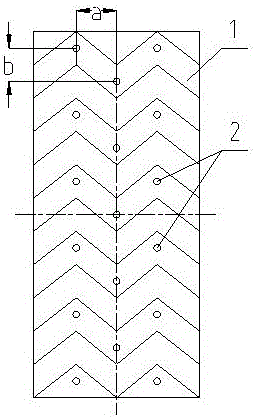

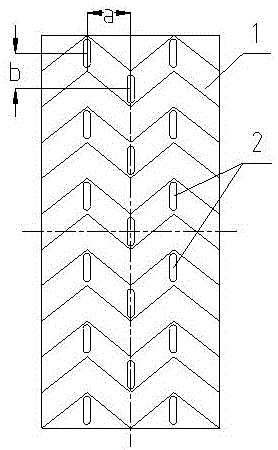

[0023] Embodiment 1, a herringbone corrugated plate with anchor points and the plate group composed of it.

[0024] refer to figure 1 , 2 According to the present invention, corrugated grooves for positioning points are arranged on the surface of the heat exchange area of the herringbone corrugated plate 1. The positioning point 2 is a convex or concave corrugation relative to one side of the plate, and a concave or convex corrugation relative to the other side of the plate. The position of the positioning point can be set not only on the convex corrugation of the plate, but also on the concave corrugation. Since there can be both convex and concave positioning point corrugated grooves on one side of the plate, the positioning points are symmetrically distributed on both sides of the plate heat exchange area. This arrangement makes the herringbone corrugated plates aligned. A plate can be combined with the previous plate only by horizontally rotating 180°, so that the conv...

Embodiment 2

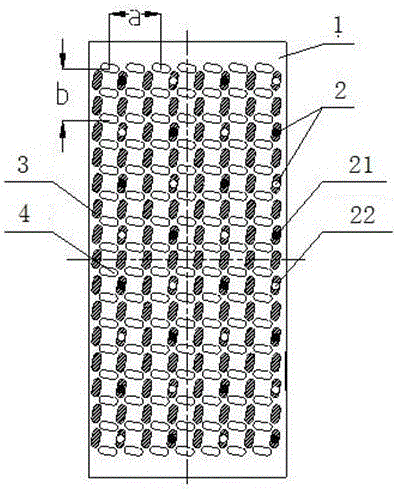

[0025] Embodiment 2, foam-shaped corrugated sheet with positioning points and the sheet group composed of it.

[0026] refer to Figure 3a , 3b , the number 3 in the figure is a raised corrugation, the number 4 is a concave corrugation, the number 21 is a raised positioning point, and the number 22 is a concave positioning point. The positioning point 2 can be set on the bubble corrugation, or it can be set on the flat plate between the bubble corrugations; similar to this kind of convex and concave bubble corrugated plates, when assembling, the latter plate needs to be vertical Or turn it horizontally 180° to pair with the previous plate, so that the raised corrugations of one plate are opposite to the raised corrugations of the adjacent plate, so when setting the positioning point, the side of the heat exchange area of the plate If the positioning point is a convex (concave) corrugation, then the positioning point on the other side that is vertically or horizontally symm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com