Rolling vacuum body-fitted shaping packaging machine

A packaging machine and body-fitting technology, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of unable to adhere to the surface of the product, the packaging bag is easy to break, and the appearance is not beautiful enough, so as to achieve beautiful packaging effect and short assembly time , beautiful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

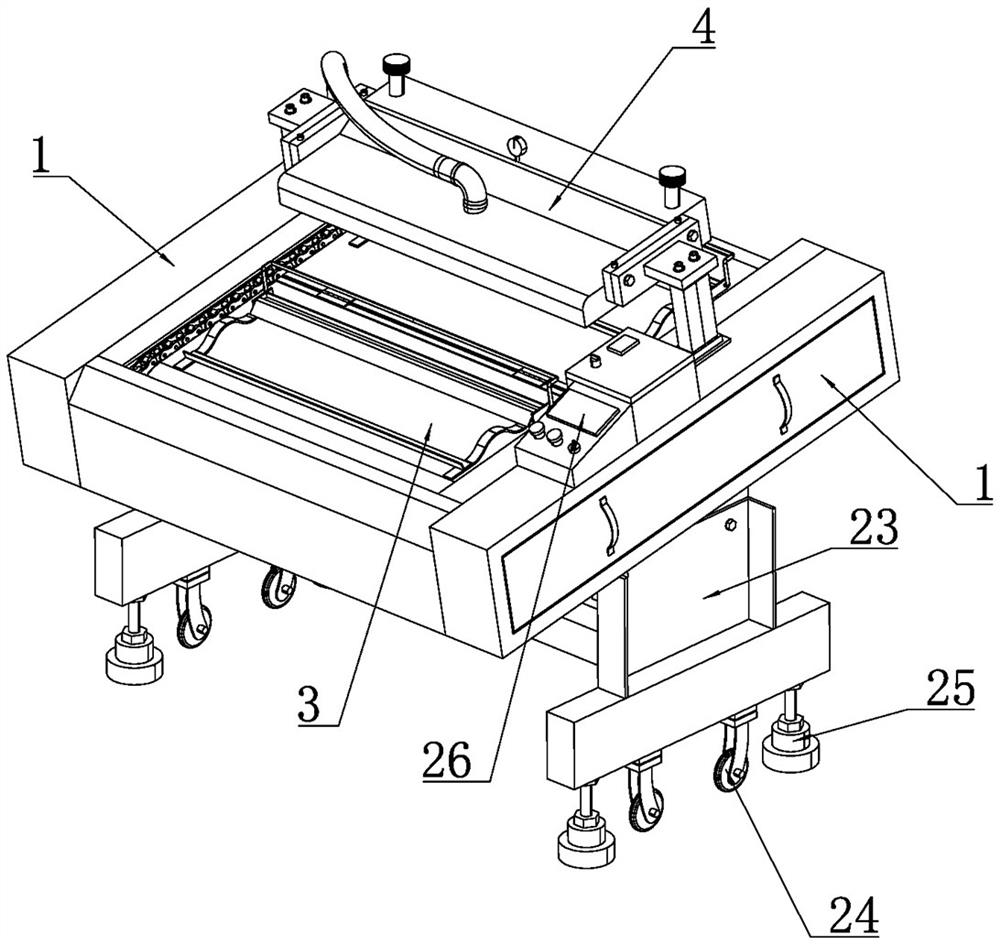

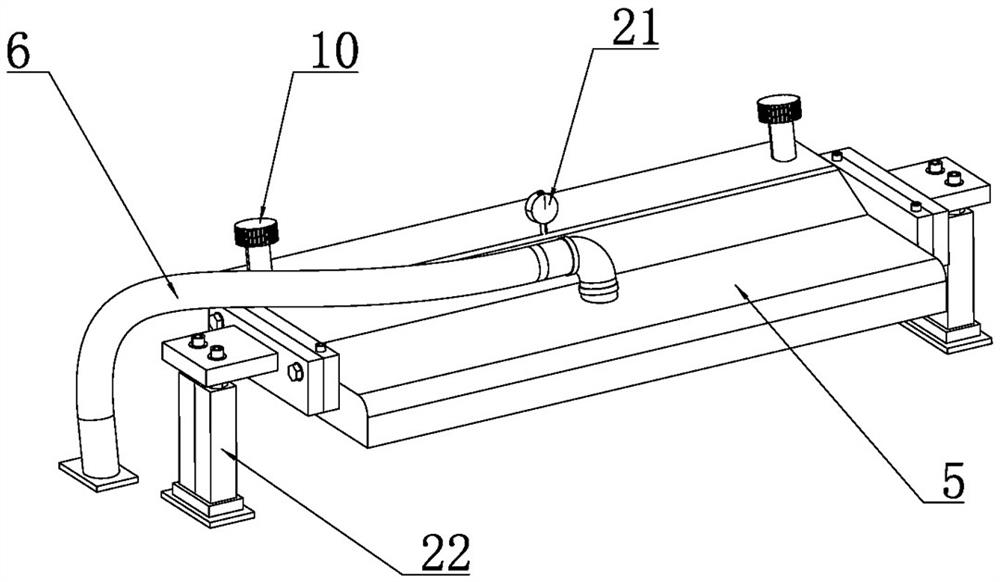

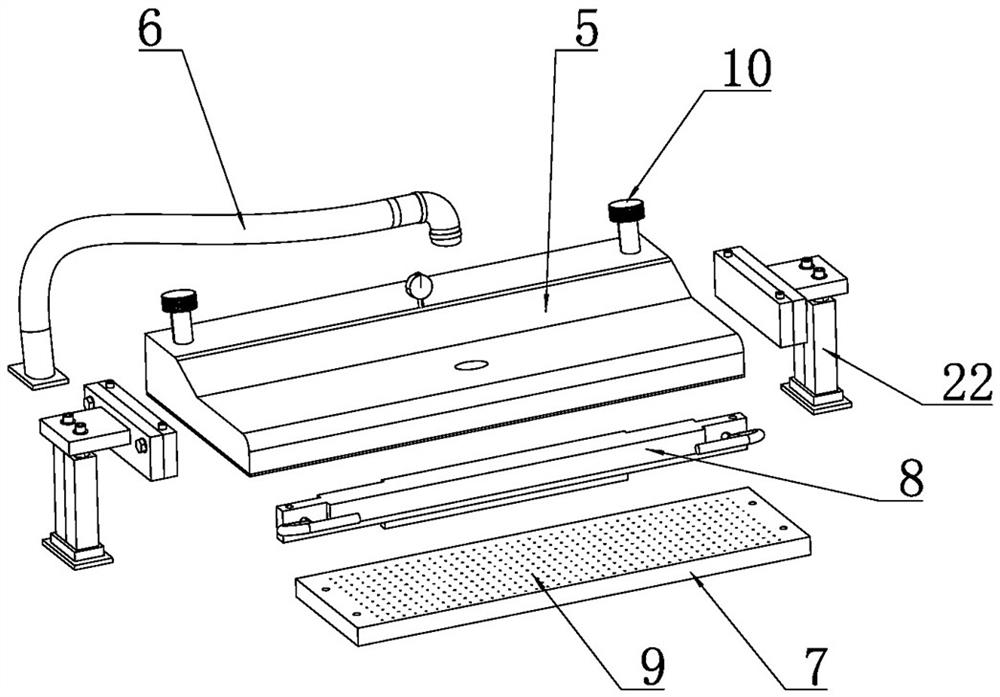

[0034] Such as Figure 1 to Figure 6 As shown, the rolling vacuum skin-fitting shaping packaging machine includes a box body 1, a mounting plate 2, a transmission device 3 and a heat-sealing device 4. The number of box bodies 1 is two and fixed on both sides of the mounting plate 2 respectively. 1 has a door panel that can be opened and closed, and the necessary parts of the equipment can be installed in the box body 1, which plays a certain role in protection and is not easy to collide. According to the actual situation, the box body 1 can also be reduced to one. The space is designed enough to accommodate the installation of the components. The conveying device 3 is set in the mounting plate 2. The heat sealing device 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com