A piston type nut locking device

A nut locking and piston-type technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of long time-consuming installation of nuts, narrow space of the main board, and suffering of operators, so as to shorten the assembly time and be universal. Good performance and reduce the difficulty of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

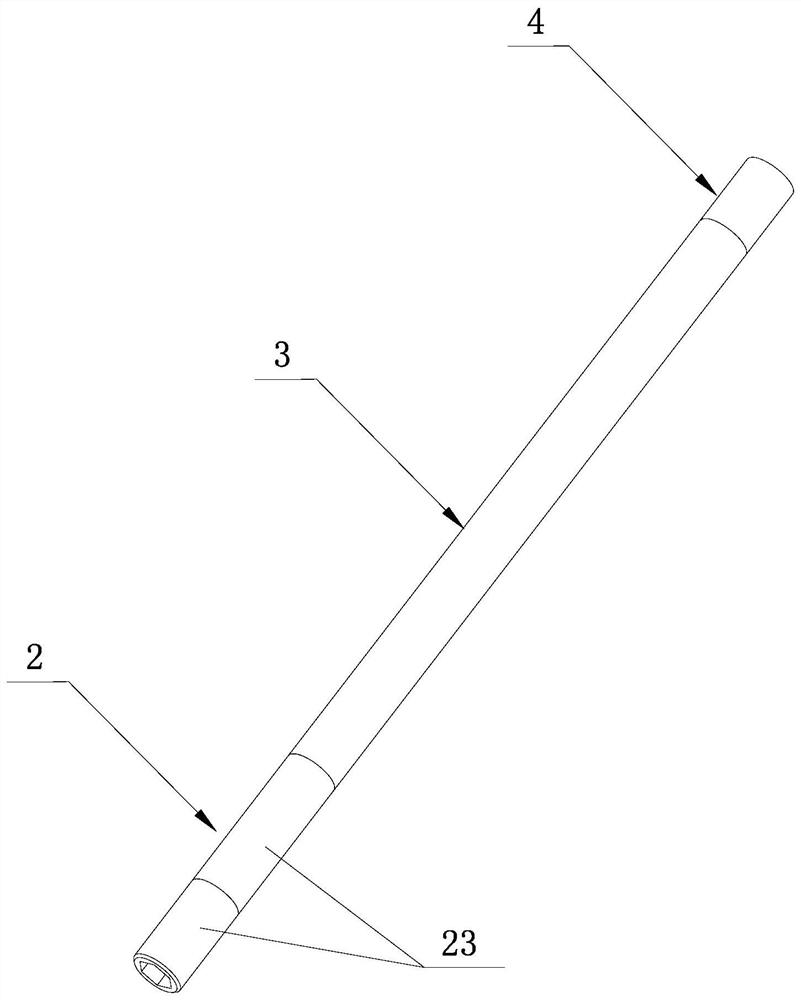

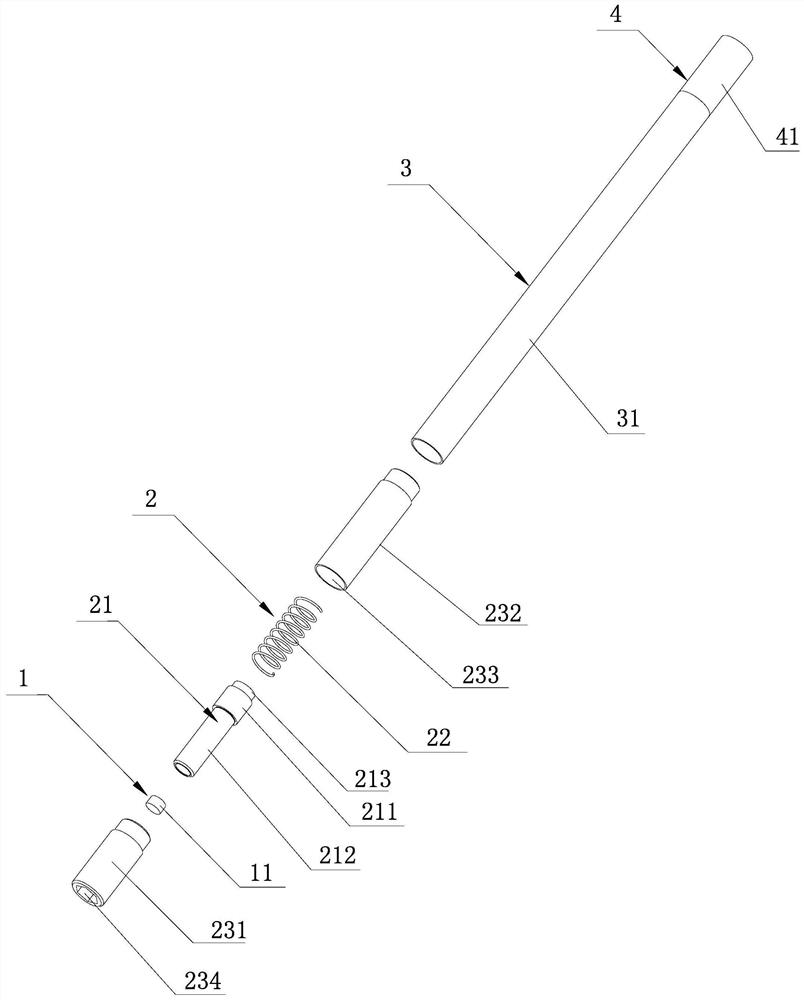

[0021] A piston type nut locking device proposed in this embodiment, as shown in the figure, includes a nut absorbing part 1 for absorbing a hex nut to prevent it from falling, The piston part 2 which is in a compressed state under the action of upward push, the extension rod part 3 used to lengthen the overall length according to the installation environment of the hex nut, the joint part 4 used to connect external electric tools or external pneumatic tools, and the piston part 2 drives when it moves The nut adsorption part 1 moves together; when installing the hexagonal nut, align the hexagonal nut absorbed by the nut adsorption part 1 with the screw and put it down. , start the external electric tool or external pneumatic tool, the power output by the external electric tool or external pneumatic tool drives the piston nut locking device to rotate through the joint part 4, the hexagonal nut absorbed by the nut adsorption part 1 is screwed into the screw rod, and the The pist...

Embodiment 2

[0025] A kind of piston type nut locking device proposed in this embodiment, its structure is basically the same as that of the piston type nut locking device in Embodiment 1, the only difference is: figure 1 and figure 2 The extension rod part 3 in the middle is made up of a group of connecting rods of different lengths, and each connecting rod is used separately, the front end of the connecting rod is fixedly connected with the rear end of the rear sleeve 232, and the rear end of the connecting rod is connected with the front end of the joint sleeve 41 Fixed connection; since the length of each connection in a set of connecting rods varies, several different lengths of connecting rods can be designed according to different nut installation environments.

Embodiment 3

[0027] The structure of the piston-type nut locking device proposed in this embodiment is basically the same as that of the piston-type nut locking device in Embodiment 2, the only difference being: figure 1 and figure 2 The extension rod part 3 in the middle is made up of a group of connecting rods of different lengths, and a plurality of connecting rods are connected end to end to be used as a whole. The end is fixedly connected with the joint part 4; because the lengths of a group of connecting rods are different, and the end-to-end connection of multiple connecting rods has a variety of combinations of different lengths, the piston nut locking device can be adapted to all occasions with different depths nut installation.

[0028] As mentioned above, in the piston-type nut locking devices given in Embodiment 2 and Embodiment 3, all connecting rods are connected in the same way, so that they can be combined at will, and the front end of any connecting rod can be connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com