Tool for improving assembling efficiency of screws in deep cavity and narrow space

A technology with narrow space and assembly efficiency, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as difficulty in assembling screws, and achieve significant use effects and solve screw assembly problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] Introduce the technical problems to be solved, the technical solutions adopted and other aspects involved in this patent.

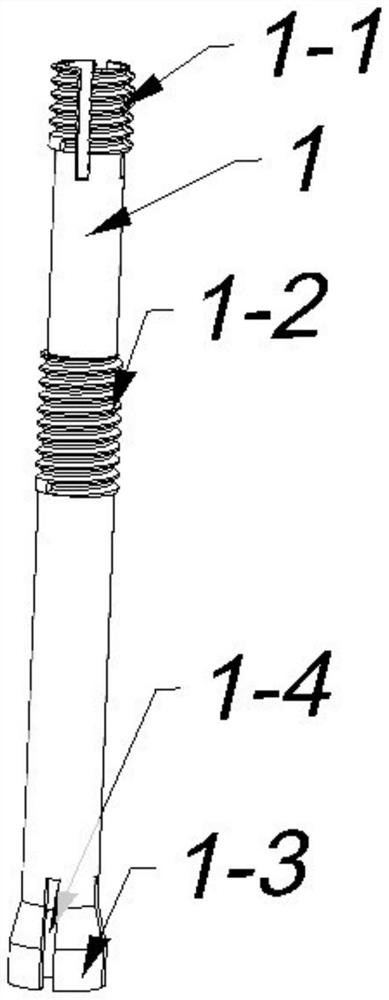

[0034] Aiming at the low efficiency and difficulty of screw assembly in deep cavity and small space, the corresponding assembly tooling is designed, which can control the radial direction of the screw end, and can meet the screw assembly requirements with one-handed operation, and can ensure that the screw is in the assembly process The drop phenomenon does not occur any more, and the assembly efficiency of the screw is effectively improved.

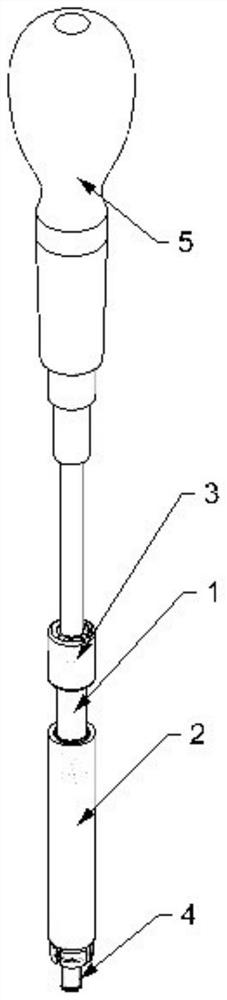

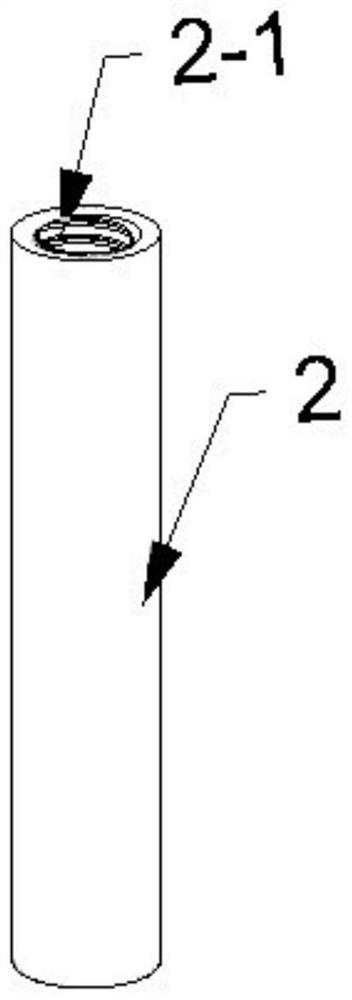

[0035] The designed tooling includes four structural parts: screw clamping tube 1, lock column 2, lock nut 3 and screw driver 5. Among them, the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com