Assembling mechanism applied to heat exchangers and assembling method thereof

An assembly mechanism and assembly method technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of long time consumption and low heat exchanger assembly efficiency, so as to reduce assembly or assembly costs and reduce the number of workers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

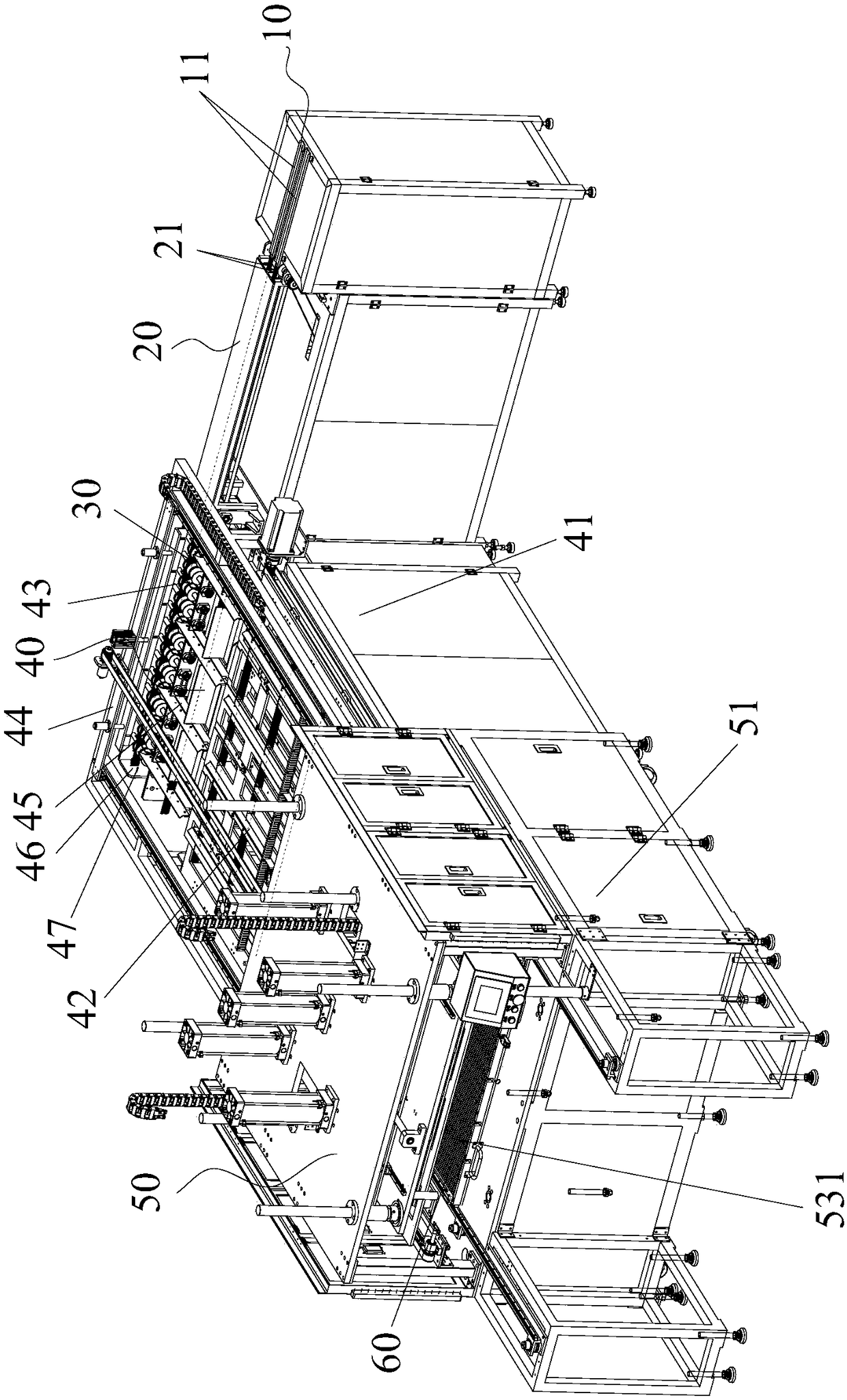

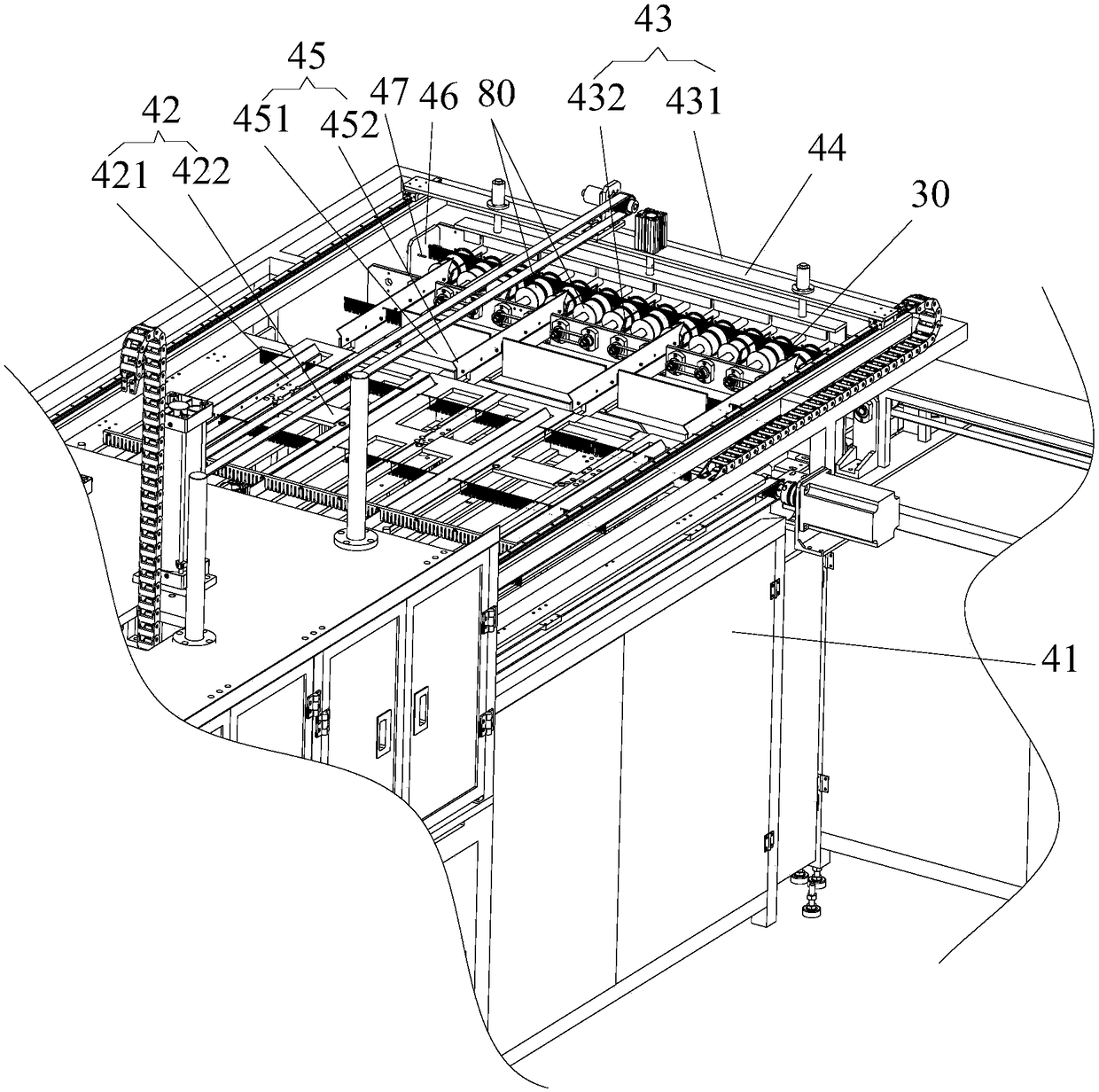

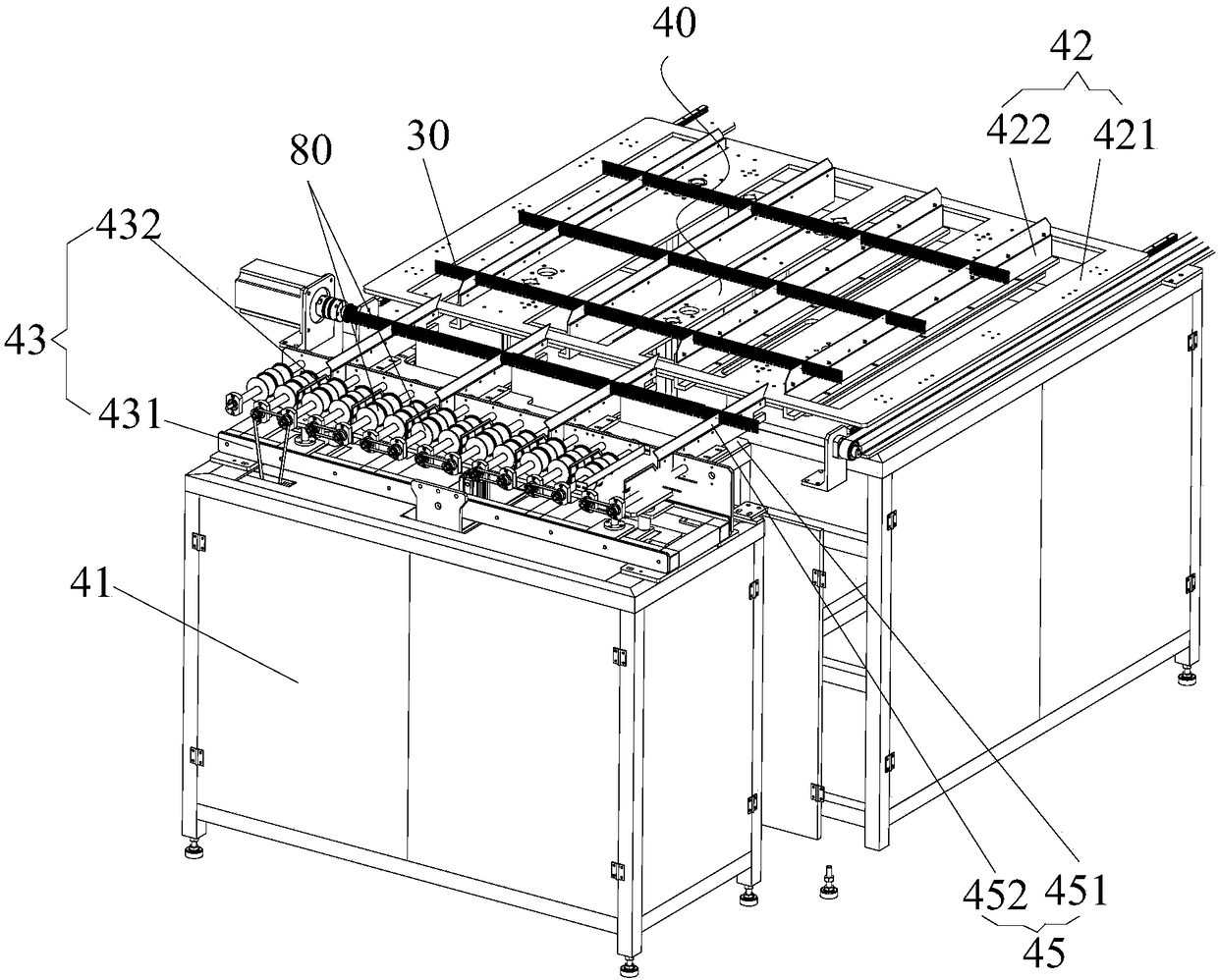

[0050] Such as figure 1 As shown, the assembly mechanism for the heat exchanger includes a material receiving device 10 , a conveying device 20 , a summarizing device 40 and an assembling device 50 . Wherein, the conveying device 20 is connected with the material receiving device 10 , and the conveying device 20 conveys the heat exchange fins 30 on the material receiving device 10 . The summarizing device 40 can be docked with the conveying device 20 , and the summarizing device 40 turns over the heat exchange fins 30 transported to the summarizing device 40 , and transports the turned heat exchange fins 30 . The assembly device 50 is located downstream of the induction device 40 , and the heat exchange fins 30 delivered to the assembly device 50 are assembled with the flat tubes 60 to be crimped to form a heat exchanger.

[0051] Applying the technical solution of this embodiment, in the process of assembling the heat exchanger, the heat exchange fins 30 pass through the mat...

Embodiment 2

[0130] The difference between the assembly mechanism of the second embodiment and the first embodiment is that the internal structure of the assembly device 50 moves differently.

[0131] In this embodiment, step S3 includes:

[0132] Step S31: the second platform 421 of the induction device 40 moves into the assembly device 50;

[0133] Step S32: the claw driving part 522 of the clamping assembly of the assembly device 50 drives the claw 521 to move, and the claw 521 clamps the heat exchange fin 30 on the second platform 421;

[0134] Step S33: The flat tube tray 531 of the flat tube mounting assembly of the assembly device 50 moves toward the pressing plate 532 of the flat tube mounting assembly, so that the flat tube 60 to be crimped in the flat tube mounting assembly is pressed into the U-shape of the heat exchange fin 30 in the slot.

[0135] Such as Image 6 As shown, the second platform 421 drives the heat exchanging fins 30 into the assembly device 50 , and the claw...

Embodiment 3

[0137] The difference between the assembly mechanism of the third embodiment and the first embodiment lies in that the structure of the assembly device 50 is different.

[0138] Such as Figure 7 As shown, the assembly device 50 also includes a flat tube hanger 56 . Wherein, the flat tube hook 56 is fixed on the pressing plate 532 , and the flat tube hook 56 passes through the flat tube tray 531 , the assembly device 50 does not include the suspension structure 54 , and the flat tube hook 56 is used instead of the suspension structure 54 . Specifically, during the assembly process of the flat tube 60 to be crimped and the heat exchange fin 30 , the flat tube hook 56 is pressed down synchronously with the pressing plate 532 , and also achieves the function of hanging and positioning the heat exchange fin 30 .

[0139] Optionally, there are a plurality of flat tube hooks 56 , and the plurality of flat tube hooks 56 are arranged at intervals along the extending direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com