Mold mechanism with popup after ejection in automatic demoulding

A technology of automatic demoulding and mold mechanism, which is applied in the field of automotive supplies to achieve the effects of ensuring bonding strength, improving production efficiency, and reducing assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

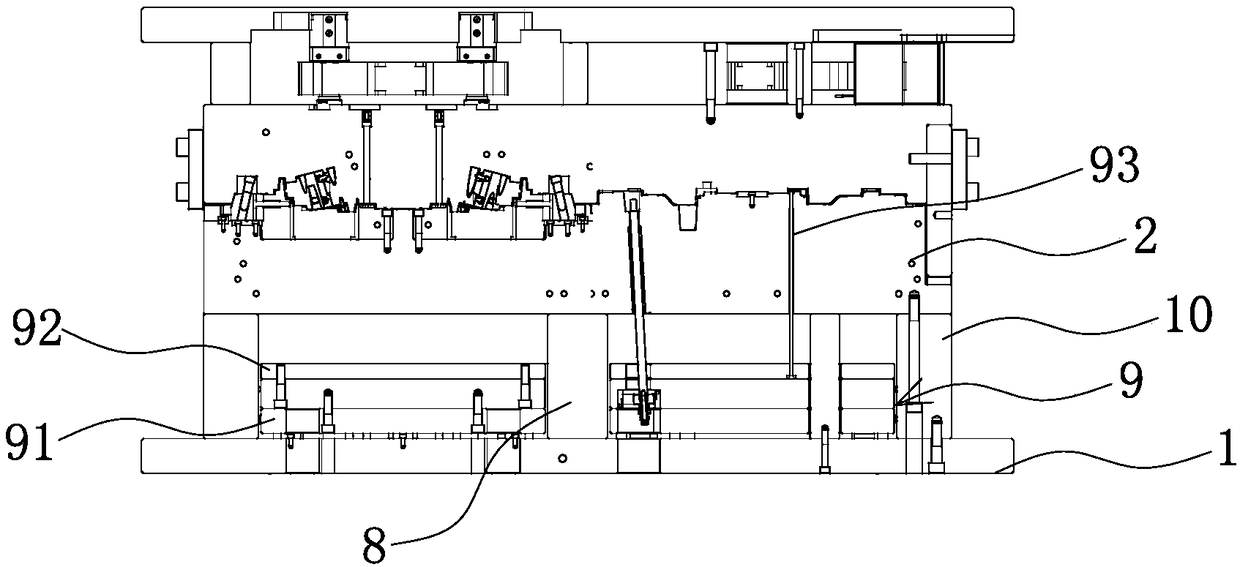

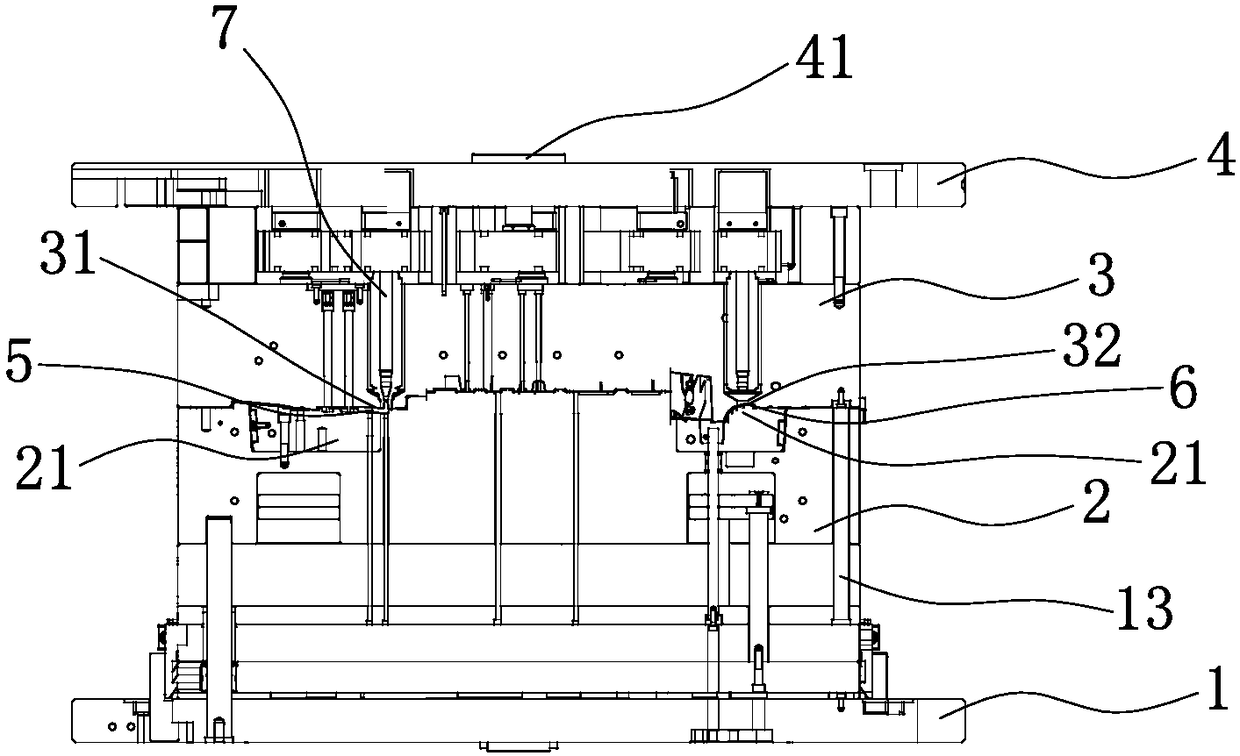

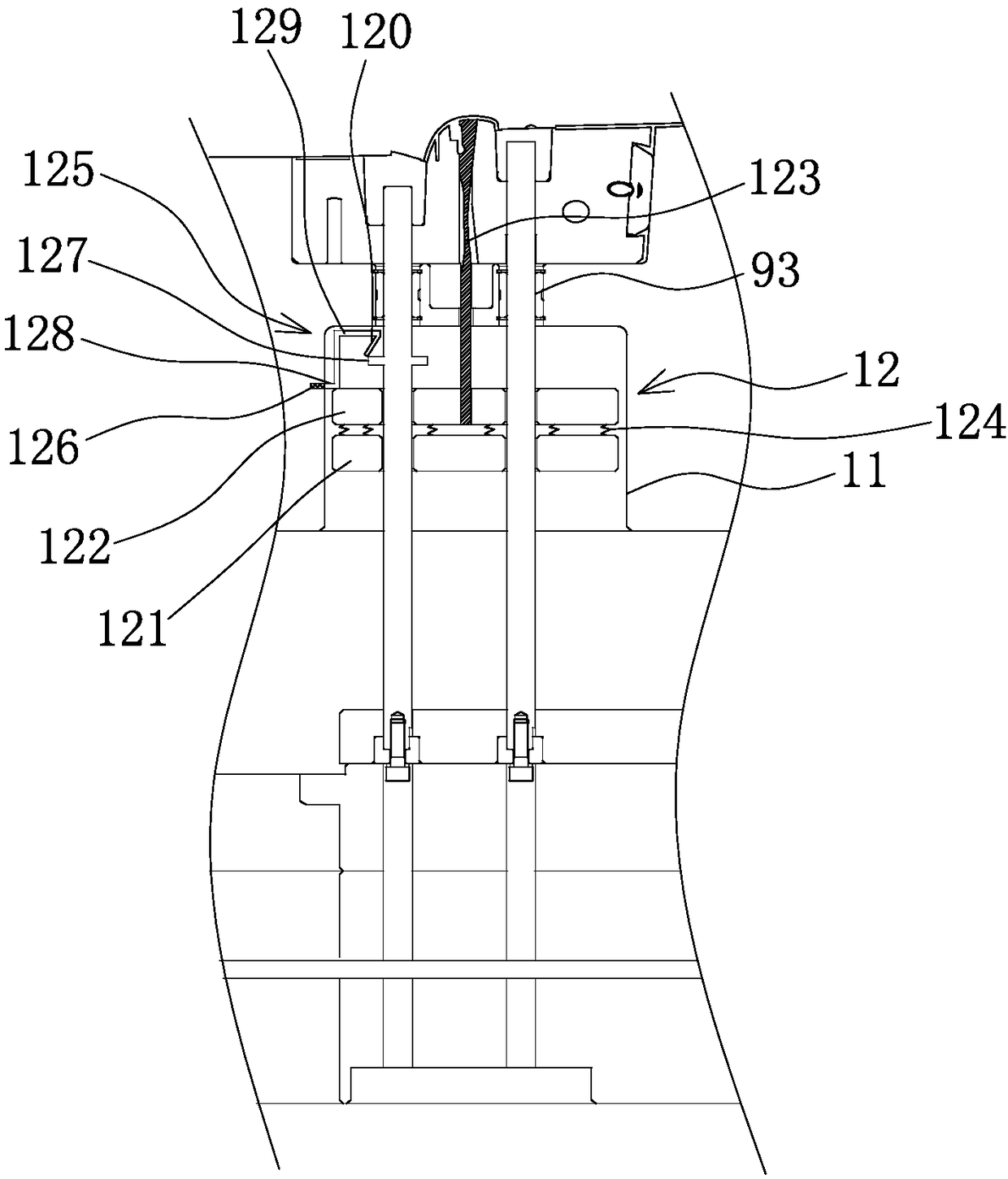

[0025] Such as figure 2 As shown, a mold mechanism for automatic demoulding after ejection includes a bottom plate 1, a movable template 2, a fixed template 3 and an injection molding plate 4 in turn. The injection molding plate 4 has an injection port 41, and the movable template 2 has two A core 21 that protrudes from the surface of the movable template 2, the fixed template 3 has a first cavity 31 and a second cavity 32 that are sunken inside the fixed template 3, and the size of the first cavity 31 is smaller than that of the second cavity 32, the first cavity 31 and the second cavity 32 cooperate with a core 21 to form the first forming cavity 5 and the second forming cavity 6, preferably, the first cavity 31 and the second cavity The cavity 32 is arranged symmetrically along the axis line of the movable template 2, and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com