Automatic gasket ordering system

An automatic sorting and shim technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as difficulty in ensuring installation in place, time-consuming and labor-intensive problems, and achieve the effect of saving time-consuming assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

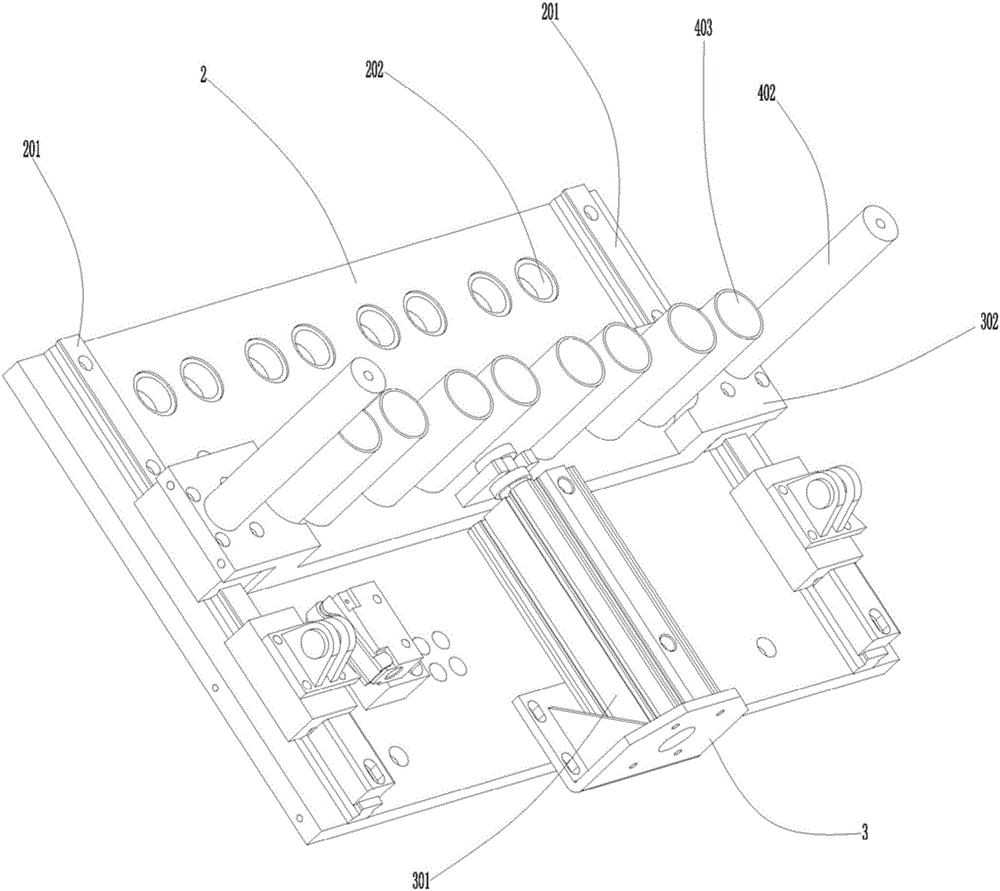

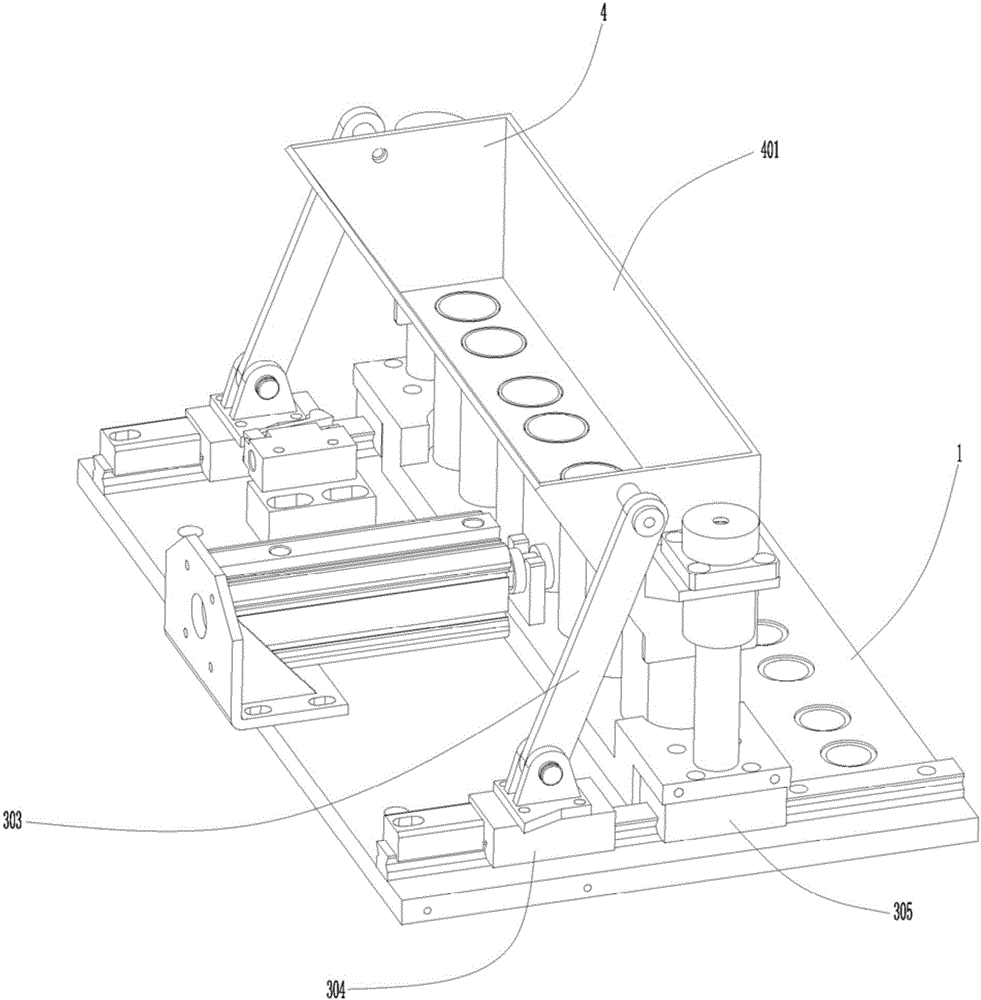

[0055] This embodiment provides a gasket automatic sorting system, such as Figure 1-4 As shown, the gasket automatic sorting system includes an automatic sorting device 1 and a jig 5 .

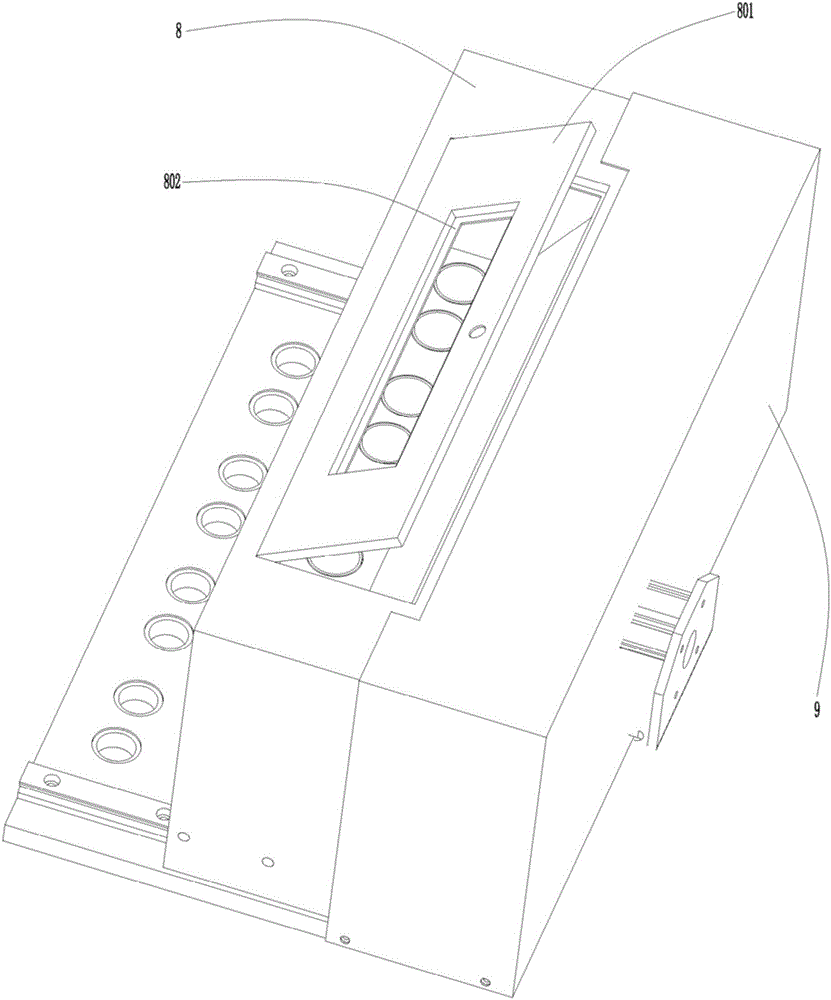

[0056]The automatic sorting device 1 includes a bottom plate 2 , a propulsion mechanism 3 , a feeding mechanism 4 , a front cover 8 and a rear cover 9 .

[0057] Wherein, the bottom plate 2 is provided with a slide rail 201 and a material hole 202; the bottom plate 2 is square; the number of the slide rail 201 is two, and the two slide rails 201 are parallel to each other; the position of the material hole 202 is the front end of the bottom plate 2; 202 is provided with annular steps (not shown in the figure), and when the gasket is placed on the steps, its upper surface is flush with the upper surface of the bottom plate 2; the material holes 202 are arranged in a straight line, and the number is eight, and they are located between rail 201.

[0058] The propulsion mechanism 3 includes a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com