Electronic product encapsulation device and method

An electronic product and potting technology, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve problems such as excess and damaged products, affect product performance, and unsafety, and reduce material consumption , Reduce the cost of raw materials, the effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

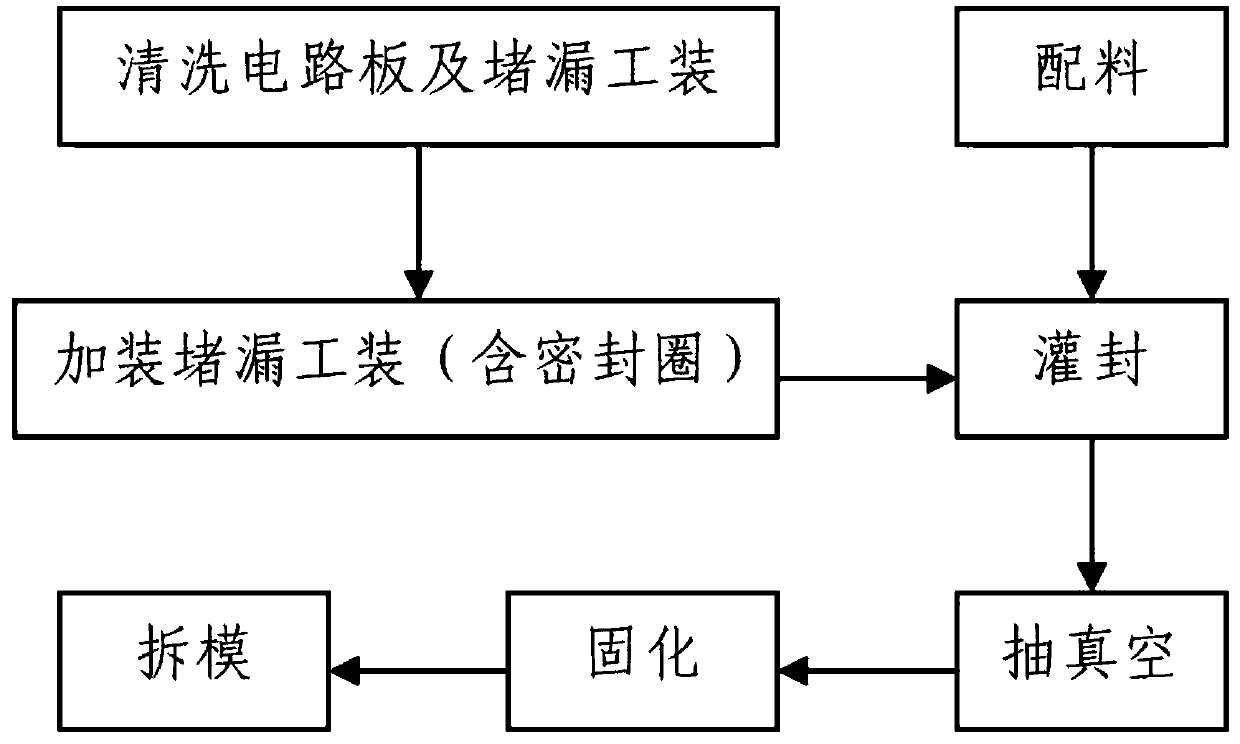

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention is further described below, but the scope of protection is not limited to the above.

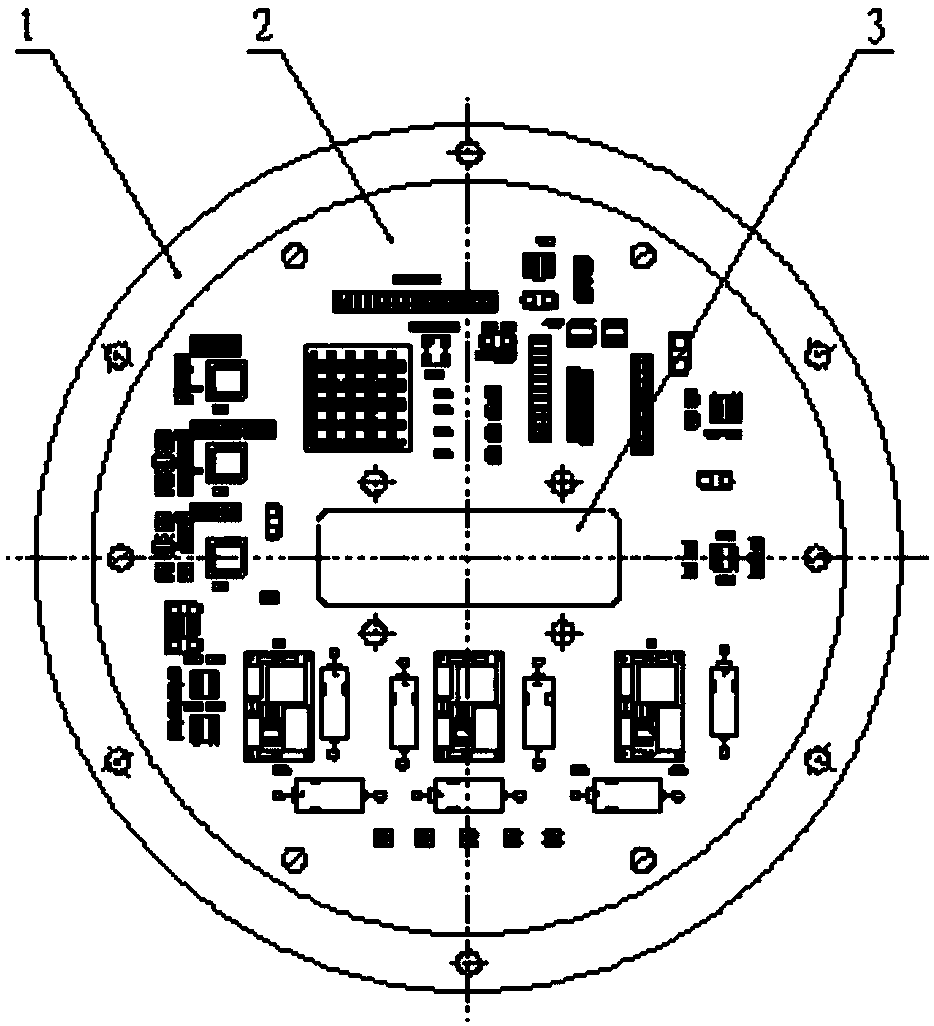

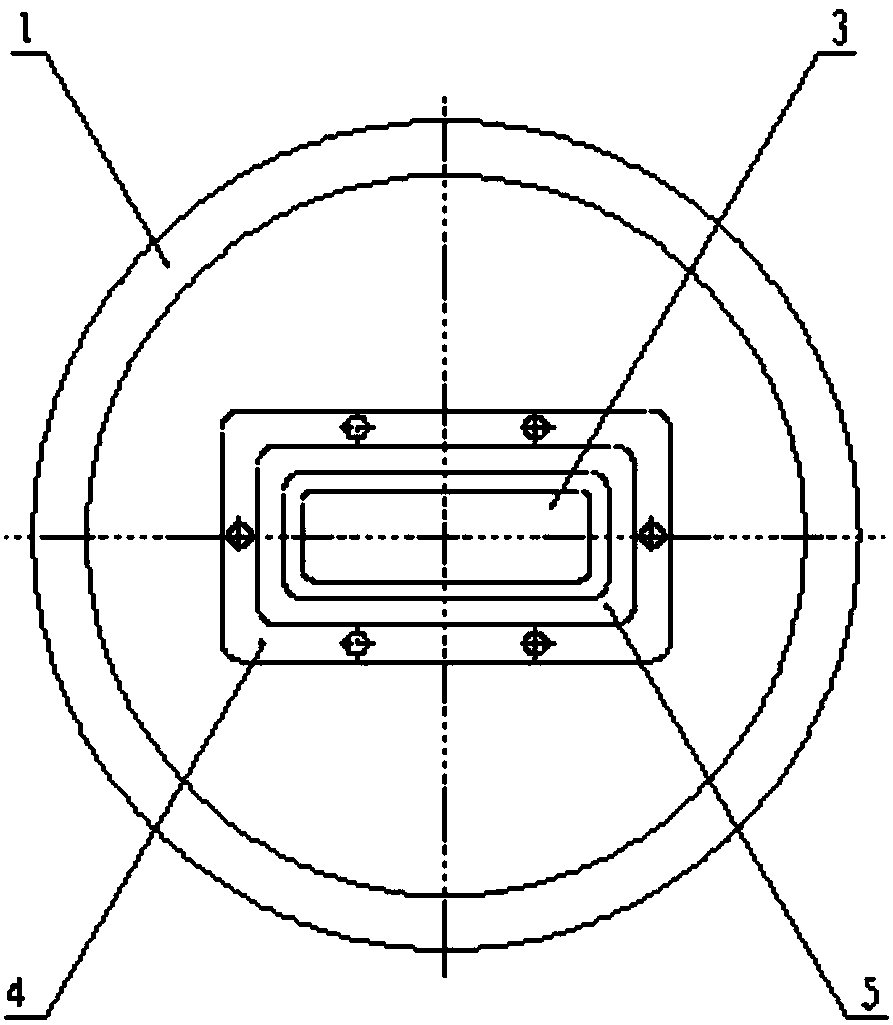

[0035] Such as Figure 2 to Figure 5 A potting device for electronic products includes a plugging tool 6; the plugging tool 6 is a flange structure, the circuit board 2 is placed and fixed in the box body 1, the circuit board 2 has a through cavity 3 in the middle position, and the box body 1 There is a recessed platform 4 on the back of the device. The main part of the plugging tool 6 is structurally matched with the through cavity 3, and the flange part is structurally matched with the recessed platform 4.

[0036] A sealing ring 7 is also included, and the sealing ring 7 is sleeved on the main body part of the leak plugging tool 6 to closely adhere to the flange part.

[0037] The inner edge size of the sealing ring 7 matches the external size of the main part of the leak plugging tool 6, and the outer edge size of the sealing ring 7 is sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com