Infrared oven adopting integrated oven plate assembly

An integrated, infrared furnace technology, applied in the field of infrared furnaces, can solve the problems of poor quality consistency of assembled finished products, low assembly production efficiency, long assembly time, etc., to achieve good heat insulation effect, high assembly production efficiency, and time-consuming assembly short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention.

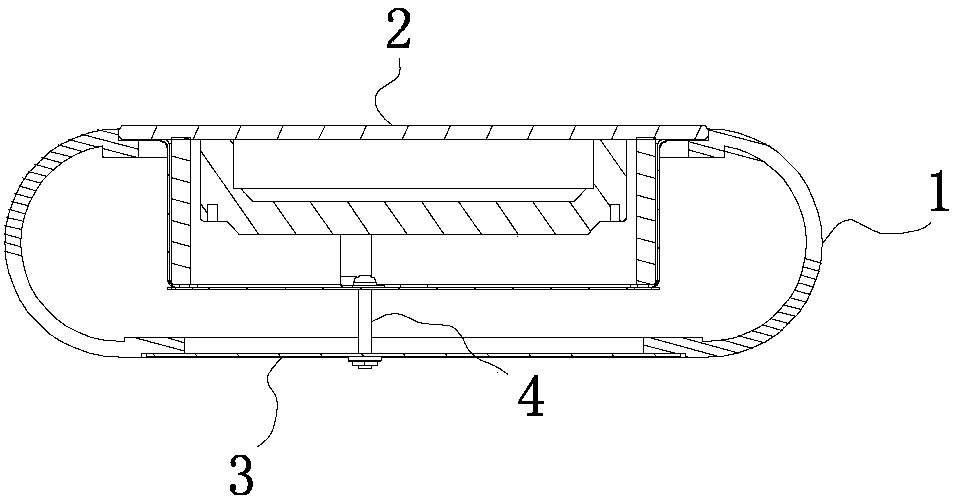

[0019] like figure 1 The present invention shows an infrared furnace adopting an integrated hob assembly, including a furnace shell 1, an integrated hob assembly 2 and a fixed bottom plate 3, and the furnace shell 1 is made of ceramics, cast iron, cast copper, stone or bamboo wood. , the integrated hob assembly 2 is installed on the furnace shell 1, the furnace shell 1 is fixed between the integrated hob assembly 2 and the fixed bottom plate 3, the fixed bottom plate 3 is installed at the bottom of the furnace shell 1, the integrated hob assembly 2 and the fixed The bottom plate 3 is fixedly connected.

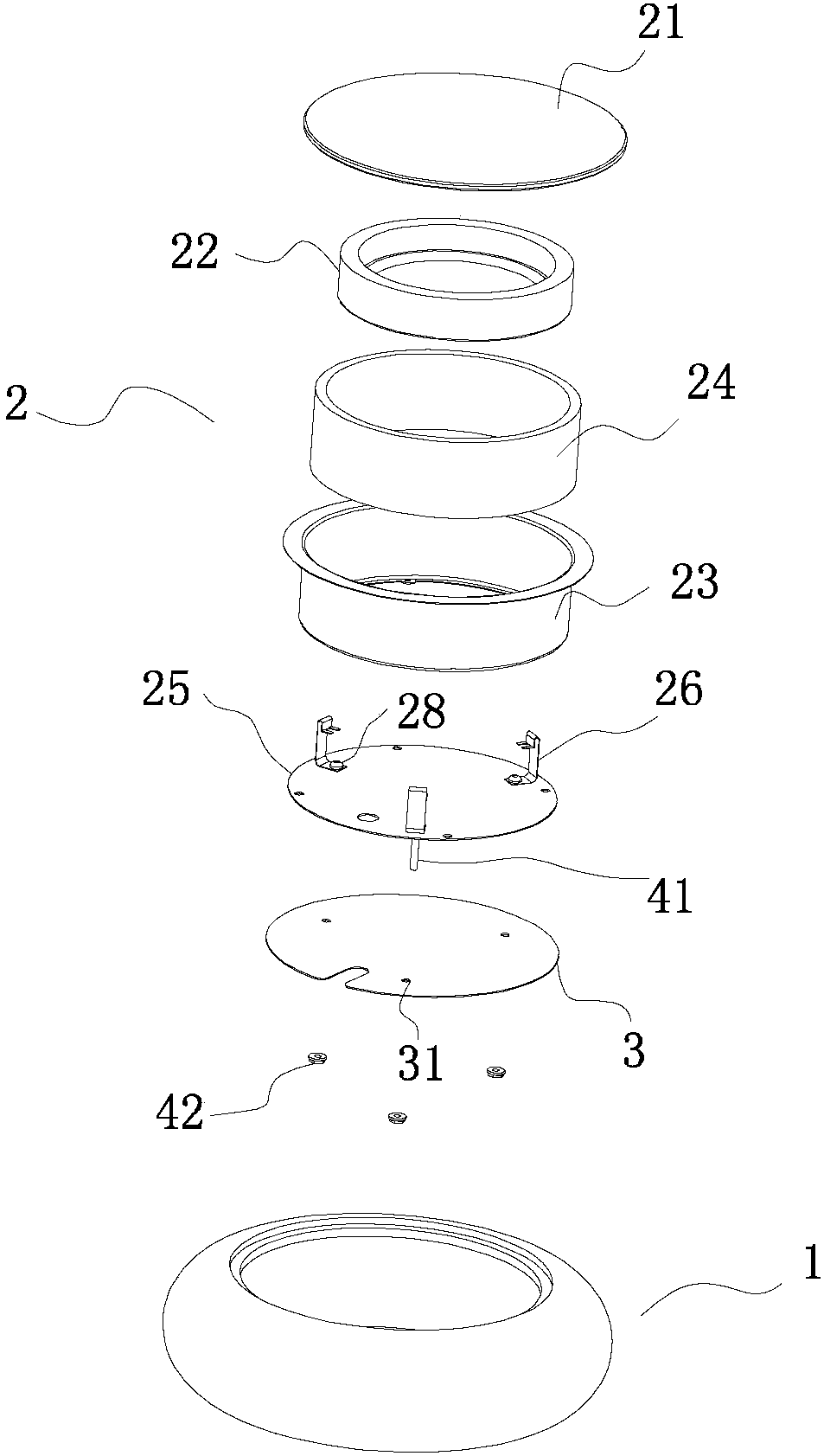

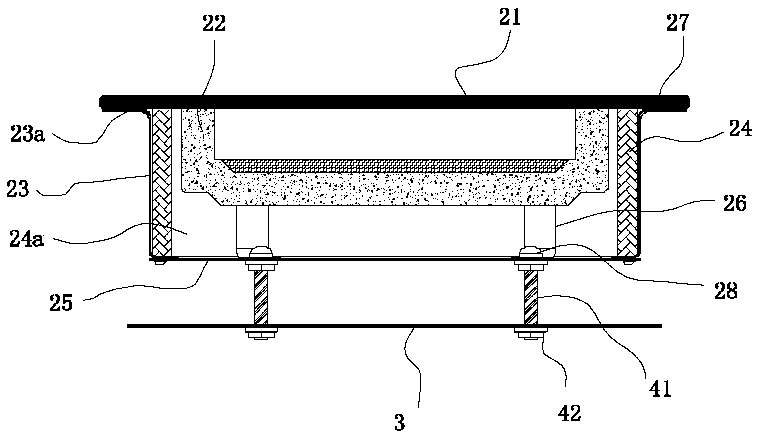

[0020] like Figure 2-3 As shown, specifically, the above-mentioned integrated hob assembly 2 is fixedly connected to the fixed bottom plate 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com