Soil turning machine

The technology of a tiller and frame, which is applied in the field of tiller, can solve the problems of shallow plowing of water chestnuts and arrowheads, high labor intensity requirements, and slow labor speed, etc., and achieves a high degree of mechanization and labor-intensive efficiency The effect of low and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

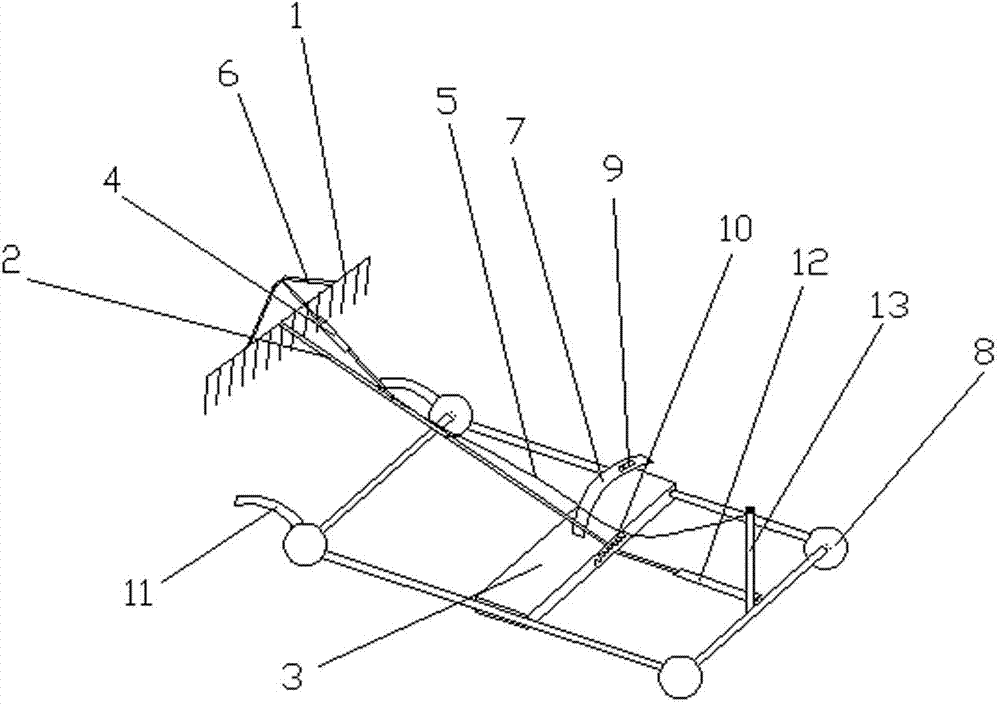

[0022] Embodiment 1: A kind of tiller, the reciprocating mechanism B12 first pushes the sliding frame 3 to move forward, and after moving to a certain distance, the chain cable 5 pulls the rake handle 2 which has been in a horizontal position to set up backward. The coil spring 10 located between the rake handle 2 and the sliding frame 3 produces a certain elastic potential energy. When the reciprocating mechanism B12 drags the sliding frame 3 to move backward, the rake handle 2 will be blocked by the latch 9 at first, Keep the standing state, when the reciprocating mechanism B12 drives the sliding frame 3 to move to a certain position, open the latch 9, and the rake handle 2 will move downward under the action of elastic potential energy and gravity, so that the rake 1 is directly inserted into the soil, and then reciprocates The mechanism continues to move backward, so that the rake handle 2 moves backward. Since the reciprocating mechanism A4 is stretched at this time, the r...

Embodiment 2

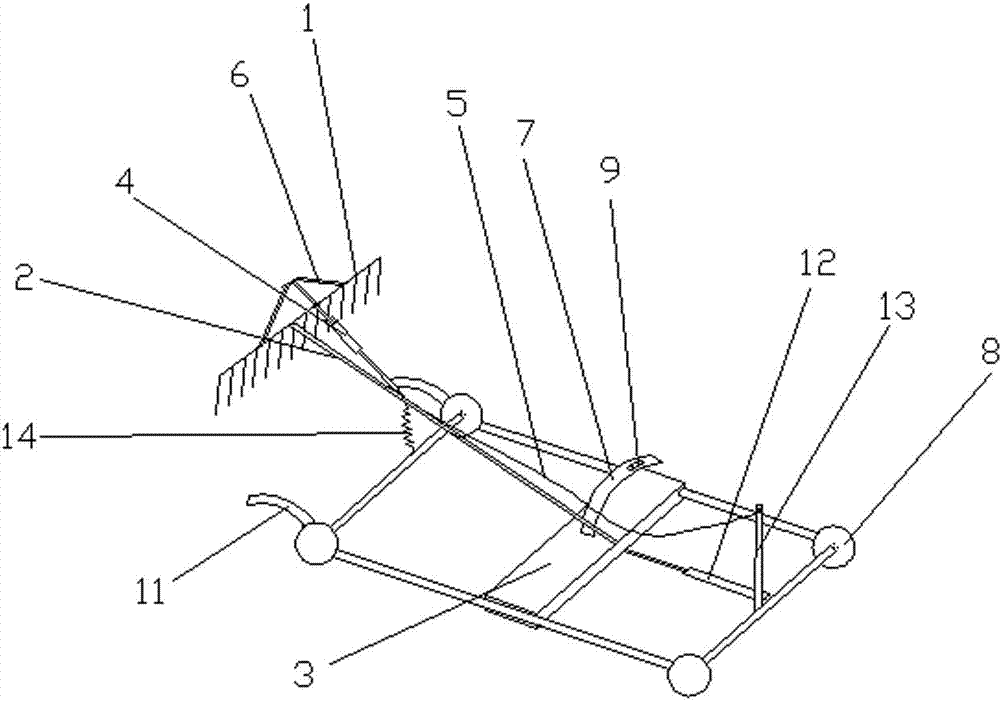

[0023] Embodiment 2: A kind of tiller, the reciprocating mechanism B12 first pushes the sliding frame 3 to move forward, after moving to a certain distance, the chain cable 5 pulls the rake handle 2 which has been in the horizontal position to erect backward, and during the erection process The telescopic spring 14 between the rake handle 2 and the front end of the frame produces a certain elastic potential energy. When the reciprocating mechanism B12 drags the sliding frame 3 to move backward, the rake handle 2 will first be held by the latch 9 to keep In the established state, when the reciprocating mechanism B12 drives the sliding frame 3 to move to a certain position, the latch 9 is opened, and the rake handle 2 will move downward under the action of elastic potential energy and gravity, so that the rake 1 is directly inserted into the soil, and then the reciprocating mechanism Continue to move backward, so that the rake handle 2 moves backward. Since the reciprocating mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com